Luminous tube array display equipment

A technology for display equipment and light-emitting tubes, which is applied to alternating current plasma display panels, discharge tubes, cold cathode tubes, etc., can solve the problems of film cracking, poor ductility of transparent electroplating conductive films, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

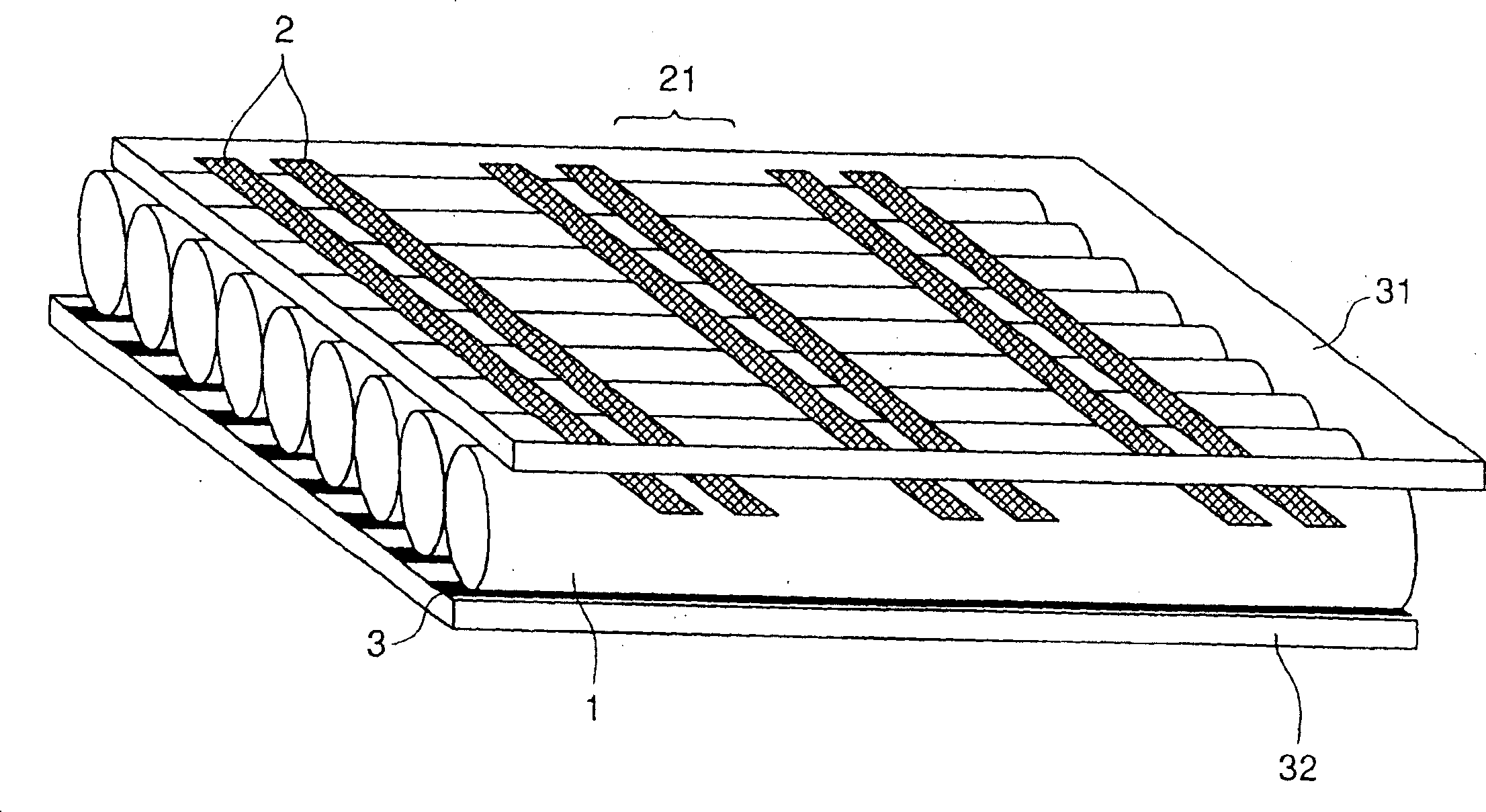

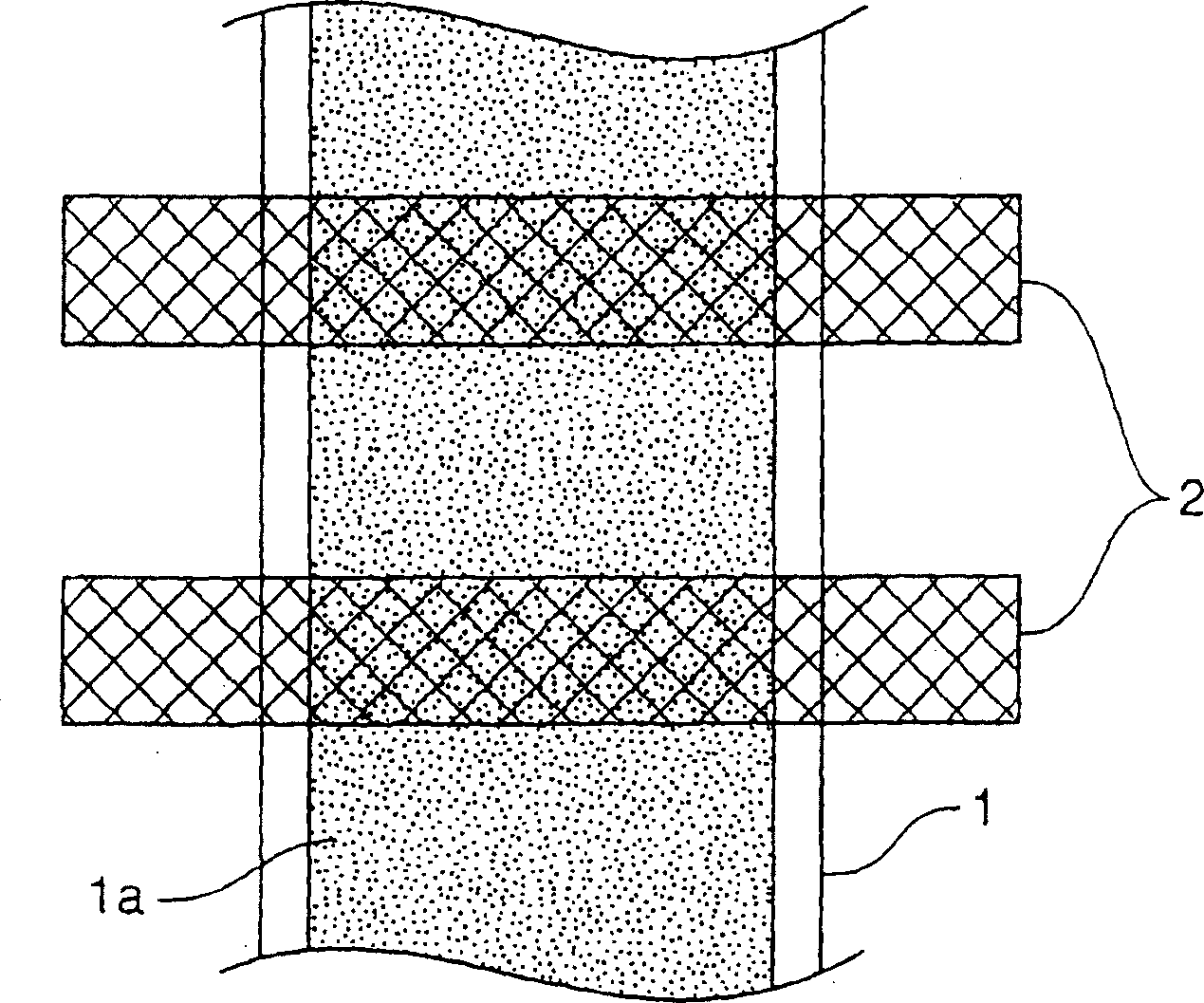

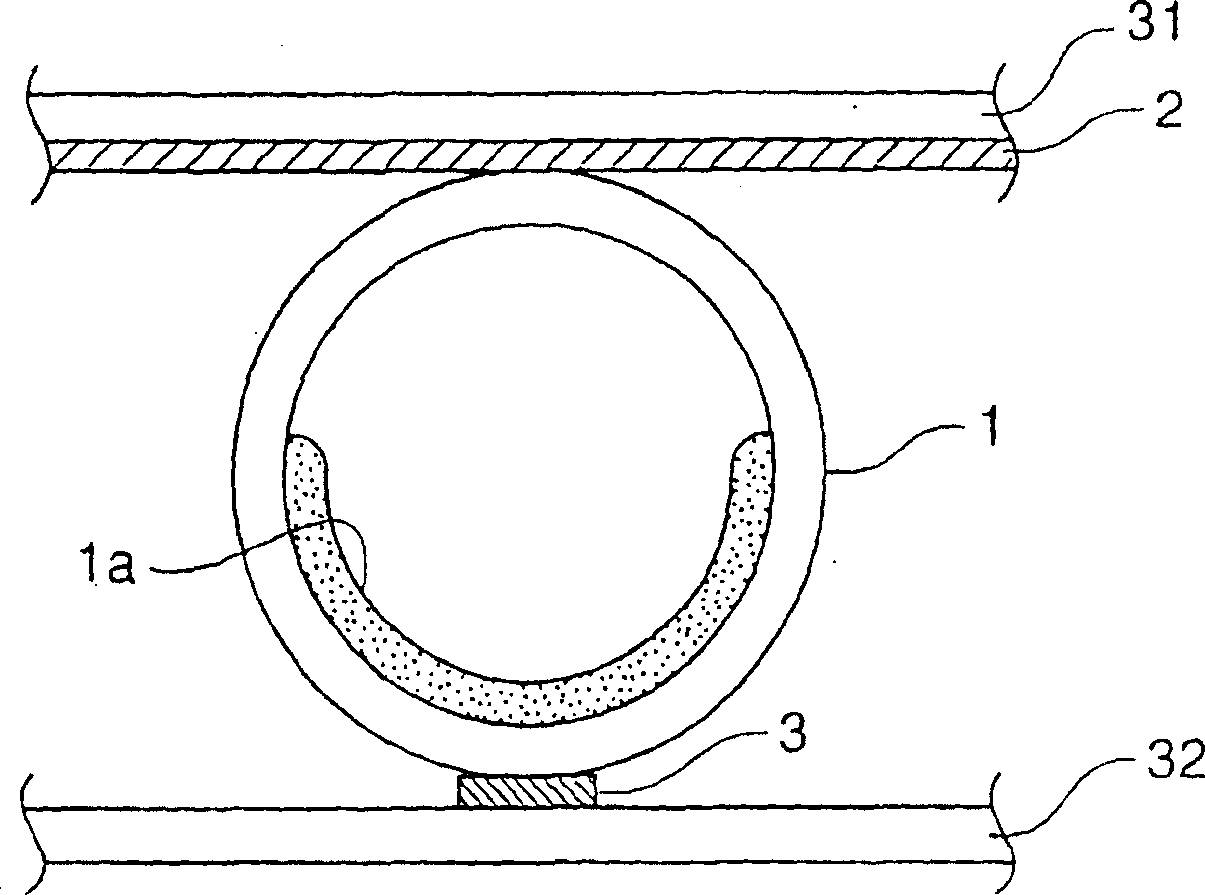

[0016] In the present invention, a luminous tube array can be used. The luminous tube array is composed of a plurality of luminous tubes arranged in parallel, and includes narrow tubes, each of which is equipped with a fluorescent layer and filled with discharge gas. Various light-emitting tubes known in the art can be used as the light-emitting tubes of the above-mentioned light-emitting tube array. A narrow tube of any diameter may be used to form the luminous tube, but a narrow glass tube having a diameter of about 0.5 to 5 mm is preferably used to form the luminous tube. The narrow tube preferably has a circular cross section, but may have a flat oval cross section.

[0017] A flexible sheet can be used which can properly support the array of light emitting tubes and deform it along a direction perpendicular to the longitudinal direction of the light emitting tubes. The flexible foil preferably consists of a light permeable membrane. As a film used for such a film, a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com