Cement-base material gradient mixing mill

A cement-based material and mixing technology, applied in the direction of mixing operation control, chemical instruments and methods, mixing operation control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

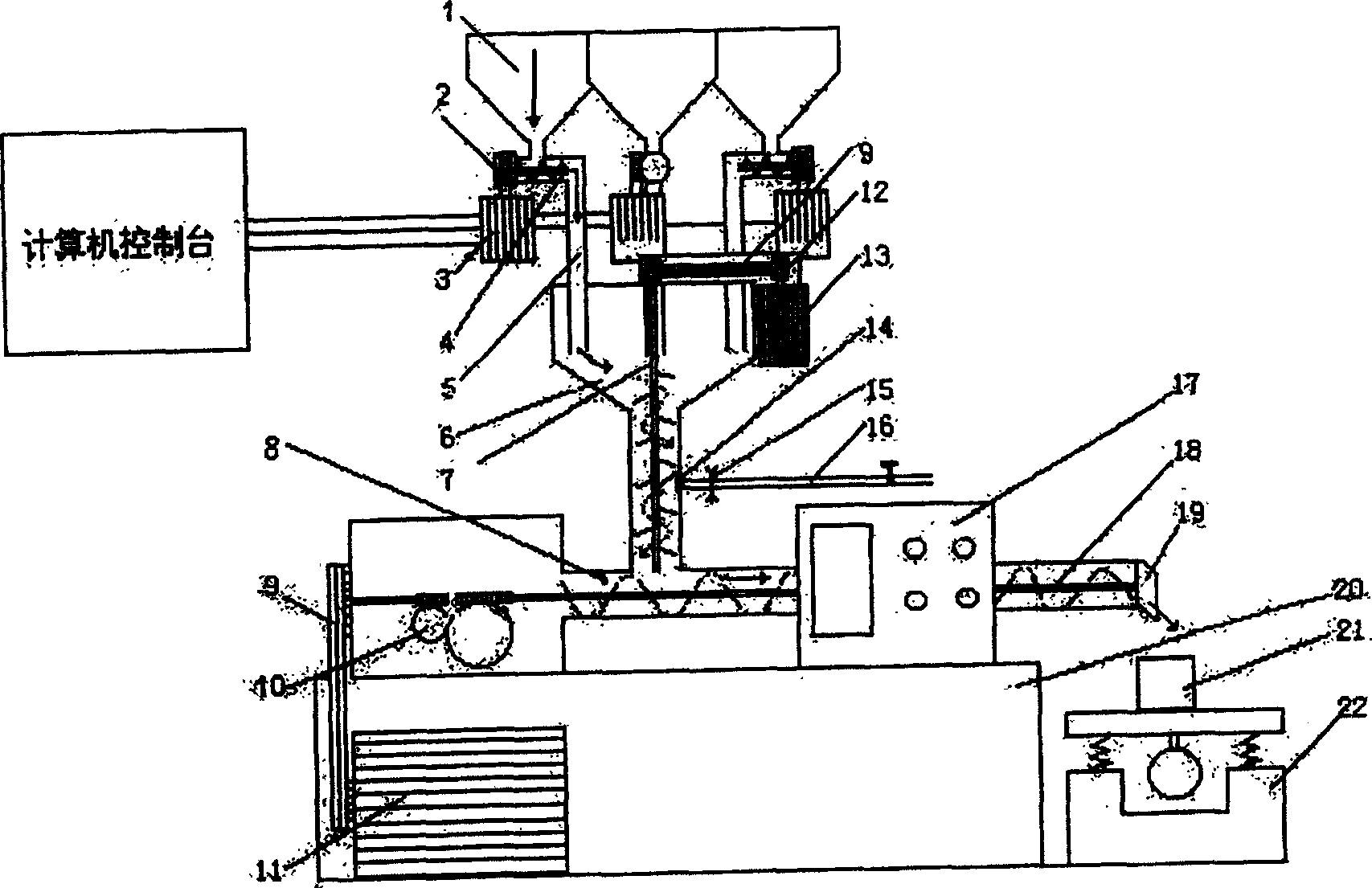

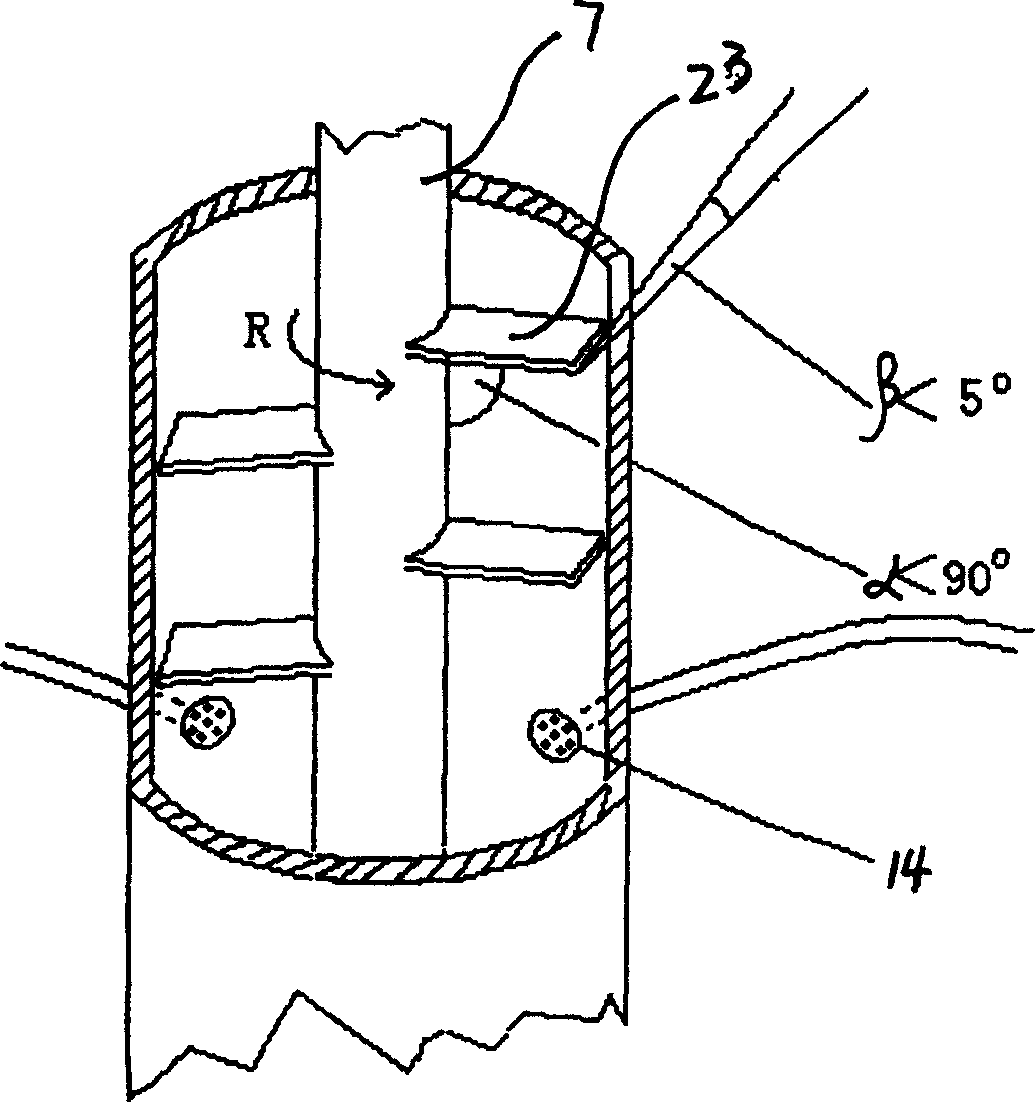

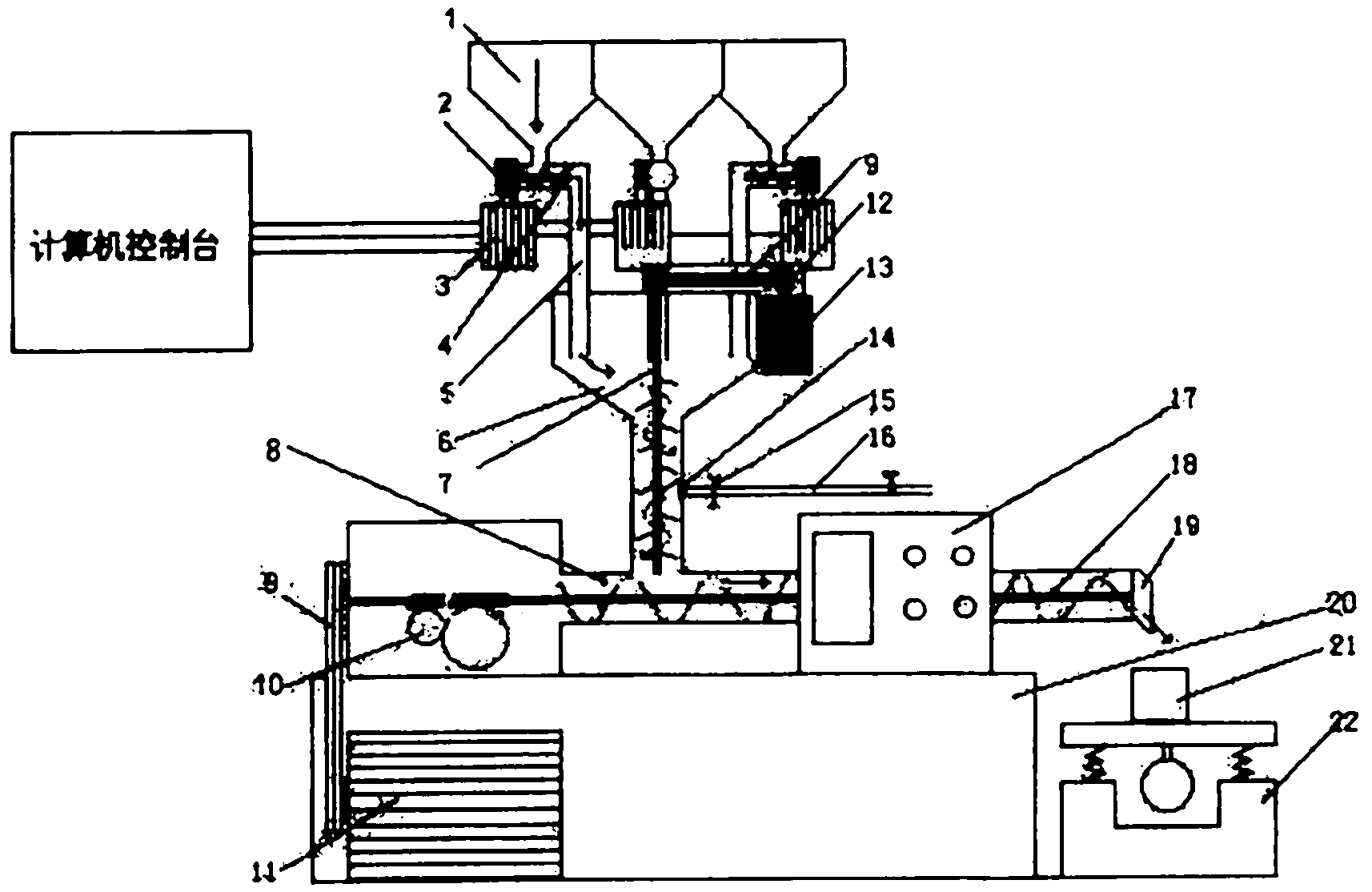

[0011] attached figure 1 . The structure schematic diagram of the present invention is given, and the arrows in the figure indicate the direction of material flow. attached figure 2 The structure of the vertical stirrer is given.

[0012] Working process of the present invention:

[0013] A certain amount of cement, aggregate (sand) and chopped fiber (surface-treated carbon fiber) are put into three storage hoppers 1 respectively, and under the action of gravity, they fall into the frequency conversion induction motor 3 whose instantaneous speed is controlled by a computer. The screw feeder 4 driven by the gear 2 is fed into the vertical agitator 6 through the feeding pipe 5, and the material entering the vertical agitator 6 is stirred by gravity and the stirring rod 7 and the stirring blade 23 (stirring rod) rotating at a high speed (1400r / min). 7 is driven by the three-phase AC asynchronous motor 13 controlled by main controller 17 through belt 9, and 12 is under the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com