Dynamic gradient pH three-stage countercurrent extraction process for tobacco waste raw materials of reconstituted tobacco

A three-stage countercurrent, reconstituted tobacco leaf technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of increased cost, low extraction efficiency of aroma components, etc., and achieves lower combustion temperature, promotes batch release of heat, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

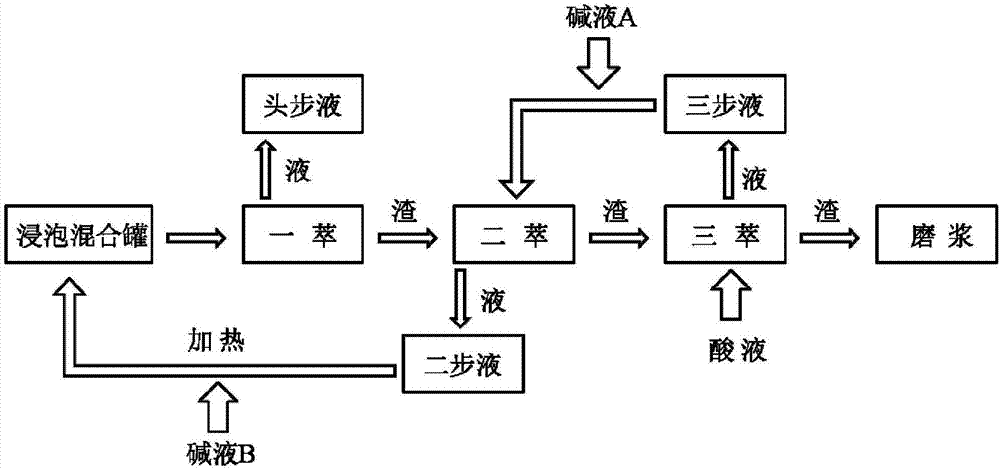

[0020] In this example, tobacco powder is used as raw material, and it is firstly extracted by a three-stage countercurrent extraction process. The extraction conditions of each stage are: the mass ratio of tobacco powder to extraction medium is 1:5, the extraction temperature is 50°C, and the extraction time is 40min. During the extraction process, the following operations are performed to realize the dynamic gradient change of the pH value of each extraction mixed system in the three-stage countercurrent extraction process:

[0021] (1) In the three-stage extraction section, pump continuously and uniformly the concentration of 1.13×10 -2 mol / L citric acid monohydrate solution is used as the extraction medium, and the pumping speed is 0.125m 3 / min, the total pumping volume of each batch is 5m 3 , so that the pH value of the three-stage extraction mixed system is about 3.1;

[0022] (2) In the secondary extraction section, the potassium hydroxide solution whose concentrati...

Embodiment 2

[0030] In this embodiment, the same tobacco dust raw material is subjected to three-stage countercurrent extraction in the same way, and the reconstituted tobacco leaf substrate is made in the same way, the only difference being:

[0031] The concentration of monohydrate citric acid solution is 3.39 * 10 in the step (1). -2 mol / L, the concentration of the potassium hydroxide solution in the step (2) is 3.39mol / L, and the concentration of the potassium hydroxide solution in the step (3) is 1.695mol / L, and the gained sample is marked as S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com