Chip carrier holed semiconductor package element and mfg. method thereof

A manufacturing method and a technology of chip holders, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as air holes that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

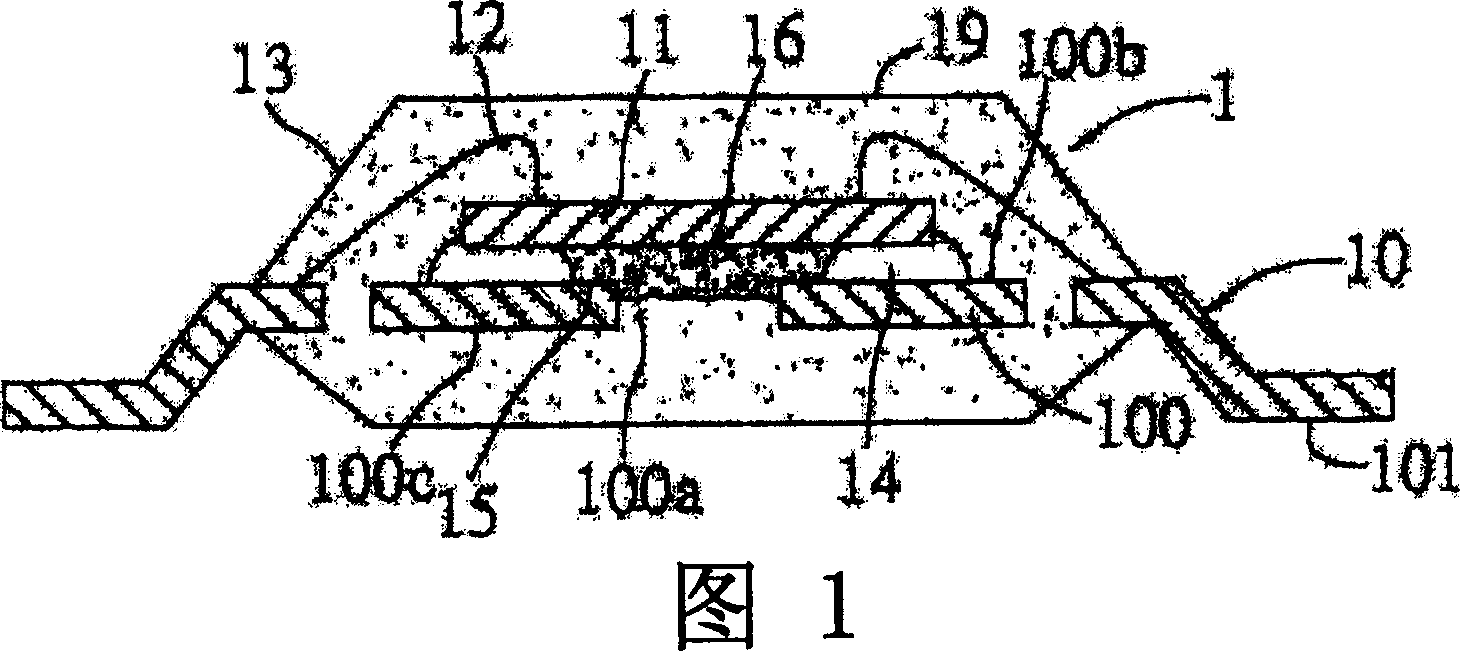

[0030] As shown in Figure 1, the semiconductor package 1 of the present invention is composed of a lead frame 10, a chip 11 bonded to the lead frame 10, and a plurality of bonding wires for conductively connecting the chip 11 and the lead frame 10. 12, and an encapsulant 13 for covering the chip 11, the bonding wire 12 and part of the lead frame 10.

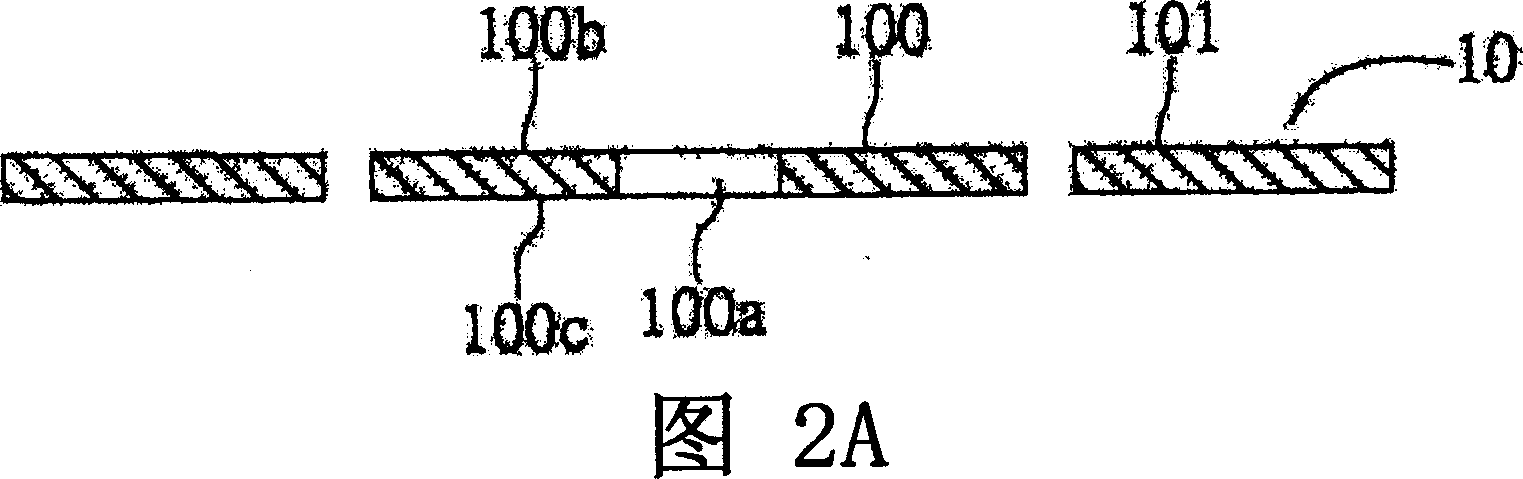

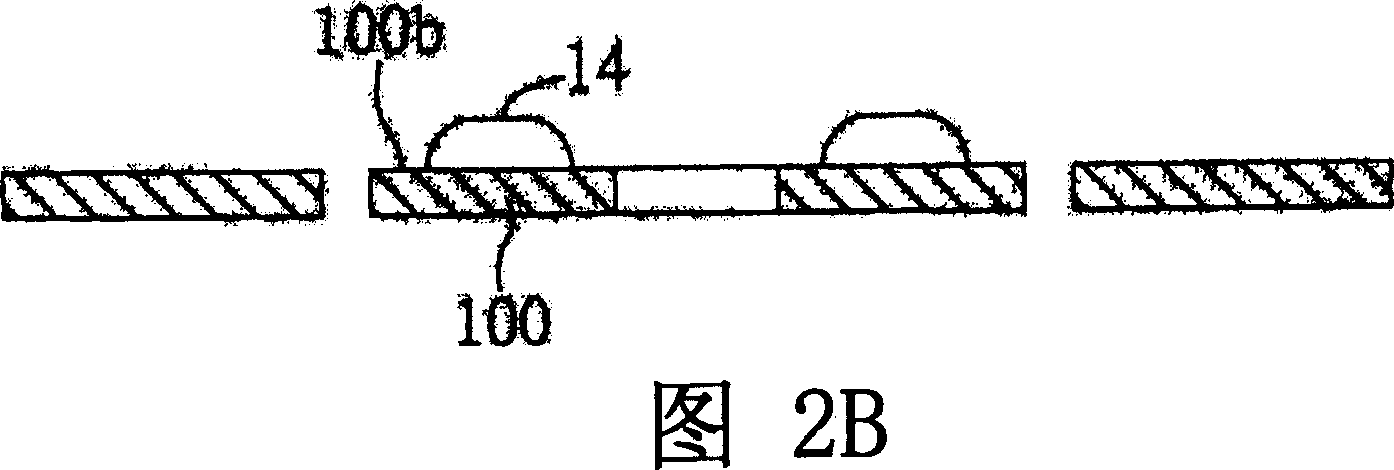

[0031] The lead frame 10 has a die holder 100 and a plurality of pins 101 disposed outside the die holder 100 . The chip holder 100 is also formed with an opening 100a, so that the opening 100a respectively penetrates the top surface 100b and the bottom surface 100c of the chip holder 100; meanwhile, the chip holder 100 can form a plurality of openings, and the shape is not limited, as long as The chip 11 can be bonded to the top surface 100b of the chip holder 100 using an existing adhesive 14 such as silver glue, and then the chip 11 must completely cover the opening 100a and be positioned on the top of the chip holder 100 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com