Hole punching device

A technology of punching device and hole position, which is applied in metal processing and other directions, and can solve problems such as deformation and shortening of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

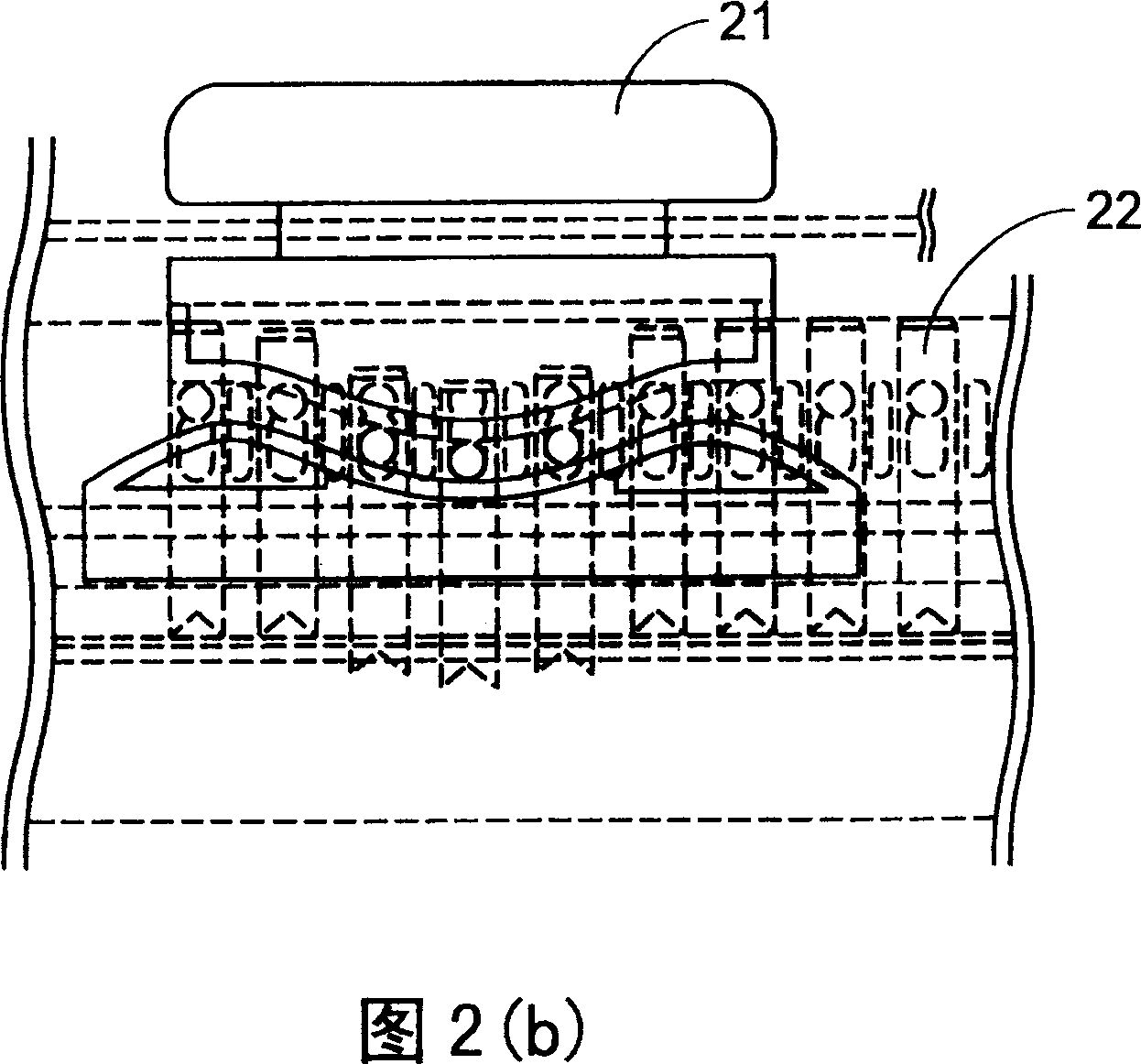

[0035] Please refer to Fig. 3(a) and Fig. 3(b), which are schematic diagrams of the structure of the first preferred embodiment developed by the present invention to improve the lack of commonly used punching devices. It is a punching device used in In the punching operation of a sheet (such as common paper), the punching device is mainly composed of a slide rail main body 30, a plurality of cutting knives 31 and a sliding assembly 32, wherein the slide rail main body 30 has two sides Wall 301, an accommodating space 302 is formed between the two side walls 301, the cutting tool 31 is placed in the accommodating space 302, and the top of the tool body 311 of each cutting tool 31 can abut against the sliding assembly 32, And each side of cutter main body 311 is fixedly connected with a guide cross column 310, and this guide cross column 310 passes through the corresponding guide groove 3010 on the side wall 301, makes this cutting tool 31 can carry out an initial position and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com