Preparation technology of three section guiding wire for making electron gun

A preparation process and electron gun technology, applied in electrode system manufacturing, electrode assembly manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as kinescope tube needle falling off, uneven coating, and electron gun core column non-conduction, etc. Achieve the effects of reducing the incidence of non-failure, simple processing technology, and solving weak welding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

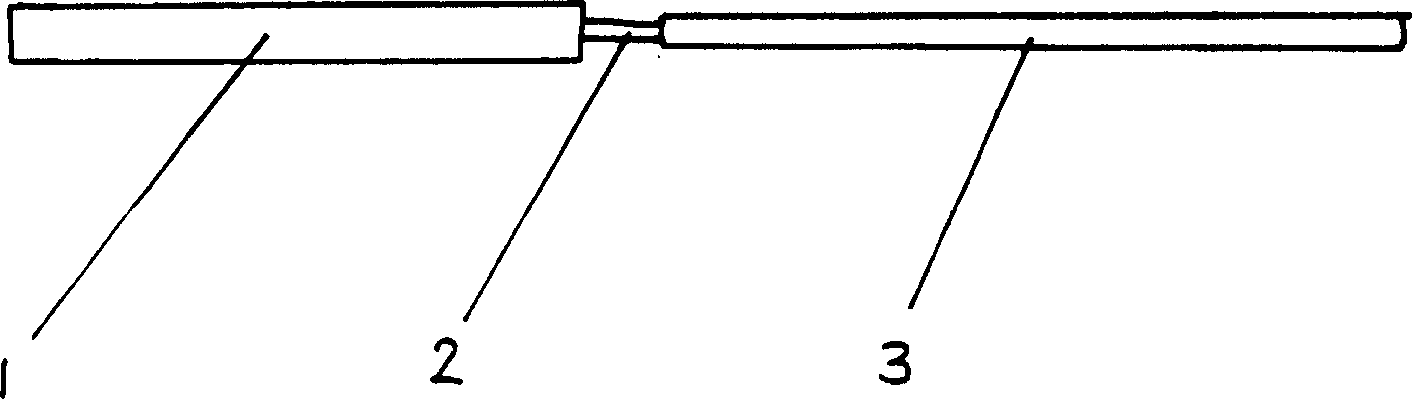

[0009] Embodiment 1, first according to the conventional process, the outer lead 1 of the three-section guide wire will be made of 0.05% carbon, 0.4% manganese and 99.55% nickel according to the conventional process; The inner lead 3 and one end of the Du magnesium wire 2 are welded as one, and the outer lead 1 and the other end of the Du magnesium wire 2 are welded together by resistance welding with a voltage of 5V and a current of 0.23KA, and the outer lead 1 and the Du magnesium wire 2 are welded together. The pressure applied during welding is 2.0Kg.

Embodiment 2

[0010] Embodiment 2, first according to the conventional process, the outer lead 1 of the three-section guide wire will be made of 0.1% carbon, 0.3% manganese and 99.6% nickel according to the conventional process; The inner lead 3 and one end of the Du magnesium wire 2 are welded as one, and the outer lead 1 and the other end of the Du magnesium wire 2 are welded together by resistance welding with a voltage of 5V and a current of 0.36KA, and the outer lead 1 and the Du magnesium wire 2 are welded together. The pressure applied during welding is 3.5Kg.

Embodiment 3

[0011] Embodiment 3, at first, according to the conventional process, the outer lead 1 of the three-section guide wire will be made of 0.08% carbon, 0.2% manganese and 99.72% nickel by mass percentage; the resistance welding with a voltage of 4V and a current of 0.23KA will The inner lead 3 and one end of the Du magnesium wire 2 are welded as one, and the outer lead 1 and the other end of the Du magnesium wire 2 are welded together by resistance welding with a voltage of 5V and a current of 0.28KA, and the outer lead 1 and the Du magnesium wire 2 are welded together. The pressure applied during welding is 2.8Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com