Gel-sol antibacterial agent and its preparation and application

A technology of antibacterial agent and sol, which is applied in the field of sol-gel antibacterial treatment agent for cotton fabrics and its preparation, can solve the problems of physical and chemical properties, textiles can not withstand high temperature roasting, and unrealistic problems, so as to promote health and longevity, improve The effect of human immunity and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

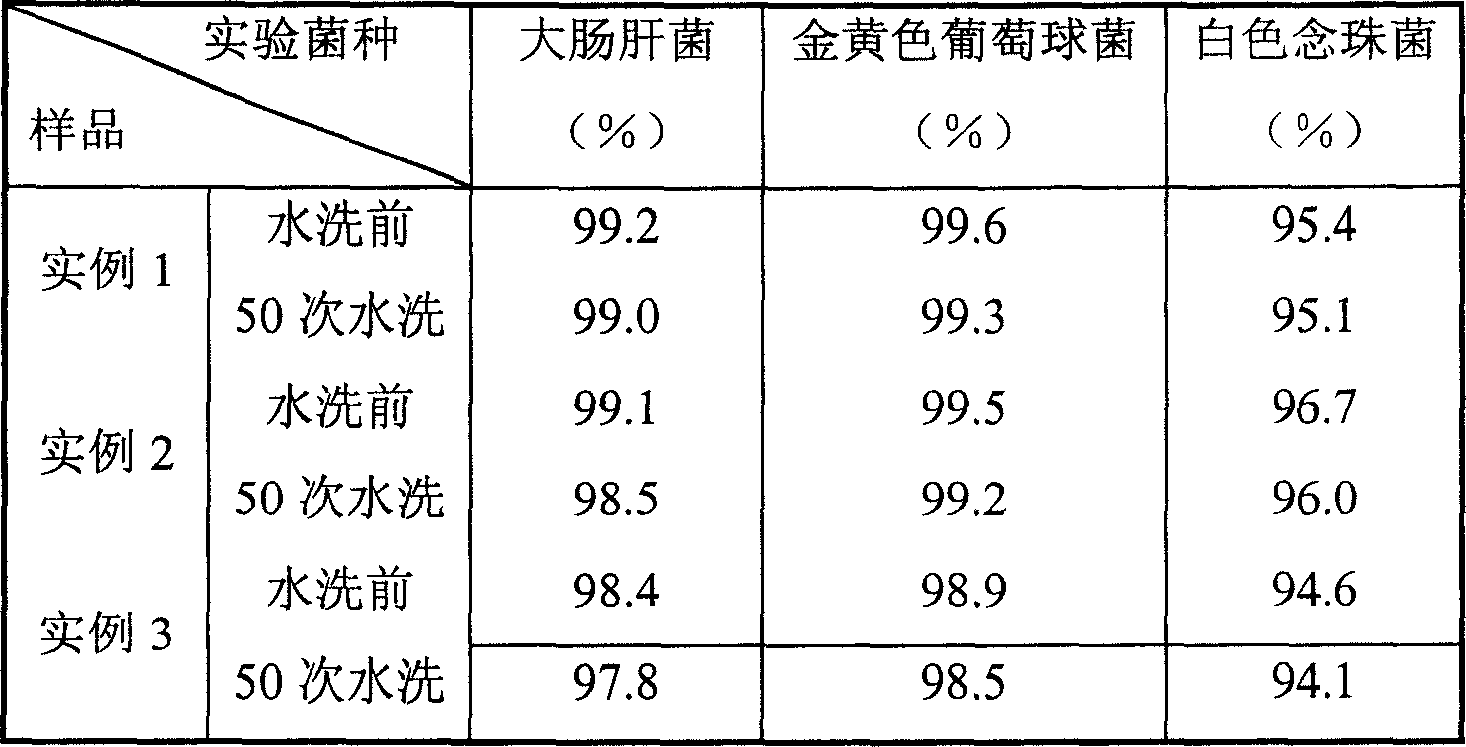

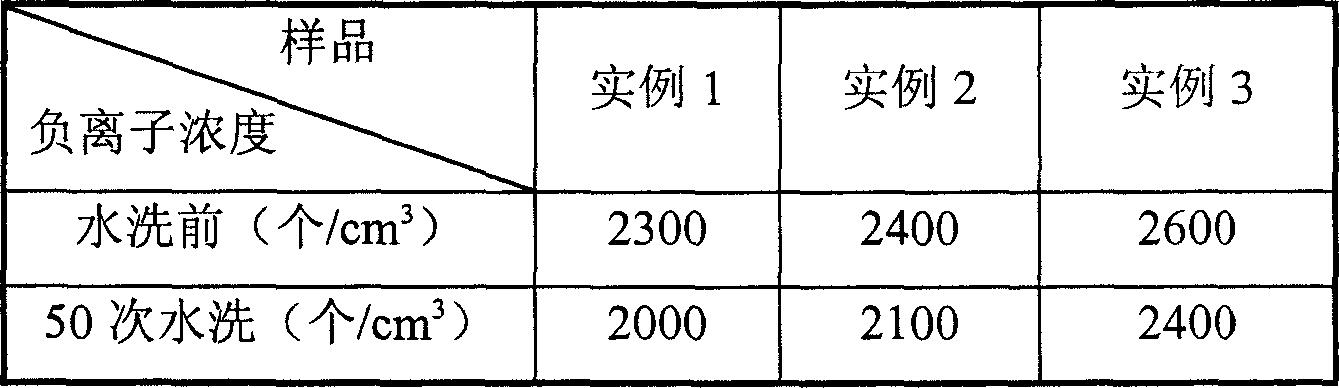

Examples

Embodiment 1

[0030] Dissolve 40 grams of tetrabutyl titanate in 13 grams of acetic acid, add the acetic acid solution of tetrabutyl titanate dropwise to 149 grams of aqueous solution containing 0.13 g of hydrochloric acid under mechanical stirring, mix them evenly, and stir at room temperature 2 hours, aging for 24 hours.

Embodiment 2

[0032] Dissolve 50 grams of tetrabutyl titanate in 8.5 grams of acetic acid, add the acetic acid solution of tetrabutyl titanate dropwise to 136 g of ethanol under mechanical stirring, mix them evenly, stir at room temperature for 2 hours, and age for 24 Hour.

Embodiment 3

[0034] Dissolve 40 grams of tetrabutyl titanate in 11 grams of acetic acid, add the acetic acid solution of tetrabutyl titanate dropwise to 0.06 gram of hydrochloric acid, 101 grams of water and 67 grams of ethanol under mechanical stirring, to make them Mix well, stir at room temperature for 2 hours, and age for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com