Mixed riprap sand foundation without cement for house and its producing method

A construction method and a cement-free technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of artificial repair of rubble, large amount of cement, and a lot of waste, so as to achieve overall cost saving, reduce project cost, and increase competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

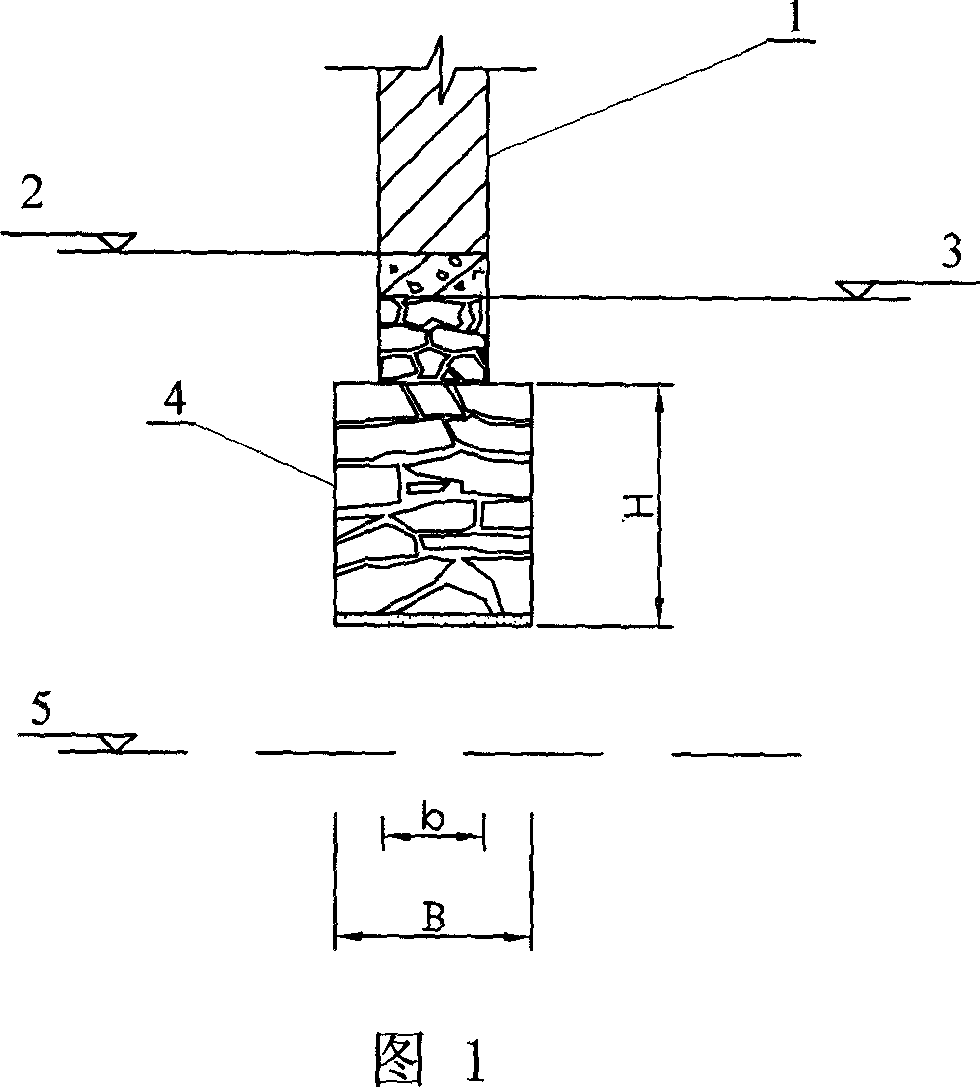

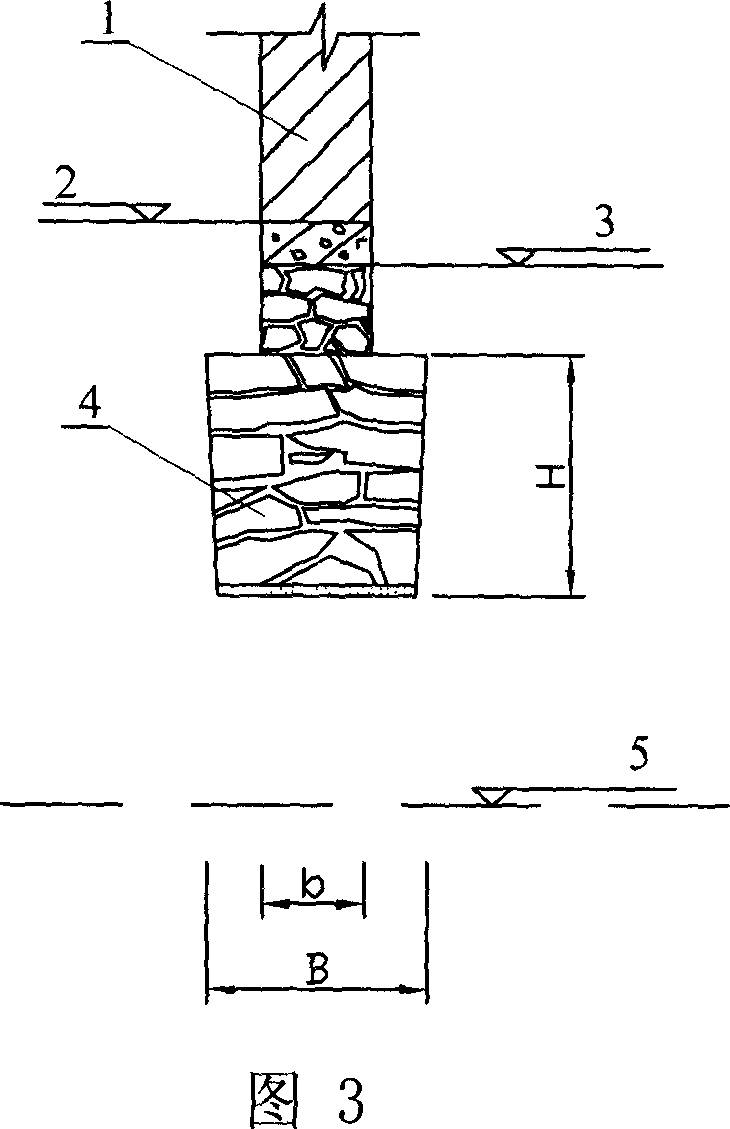

[0013] Specific implementation mode one: see Fig. 1, Fig. 3, the construction steps of the cement-free rough stone mixed sand foundation of the present embodiment are as follows:

[0014] 1. Excavate the foundation trench according to the size of the foundation entity, because there is no masonry operation surface, so it is not necessary to enlarge;

[0015] 2. Connect the water rubber hose on the construction site so that the water nozzle can reach all sides of the foundation groove;

[0016] 3. Level the bottom of the tank, spread mixed sand 5-8 cm thick, and place a layer of rubble one by one;

[0017] 4. Spread a layer of mixed sand, fill in the joints and make the sand surface cover the rough stone surface;

[0018] 5. Rinse the water, and vibrate with an iron drill or a vibrator at any time to make the sand sink with the water flow and fill the stone gap until the high part of the stone surface is exposed, the sand no longer sinks, and the water surface no longer bubble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com