High-temp high-pressure condensation water corrosion simulated experiment device

A technology for simulating experimental devices, high temperature and high pressure, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of ineffective evaluation of corrosion inhibitor corrosion inhibition efficiency, limitation mechanism, law, and pipeline top corrosion simulation Sexual issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

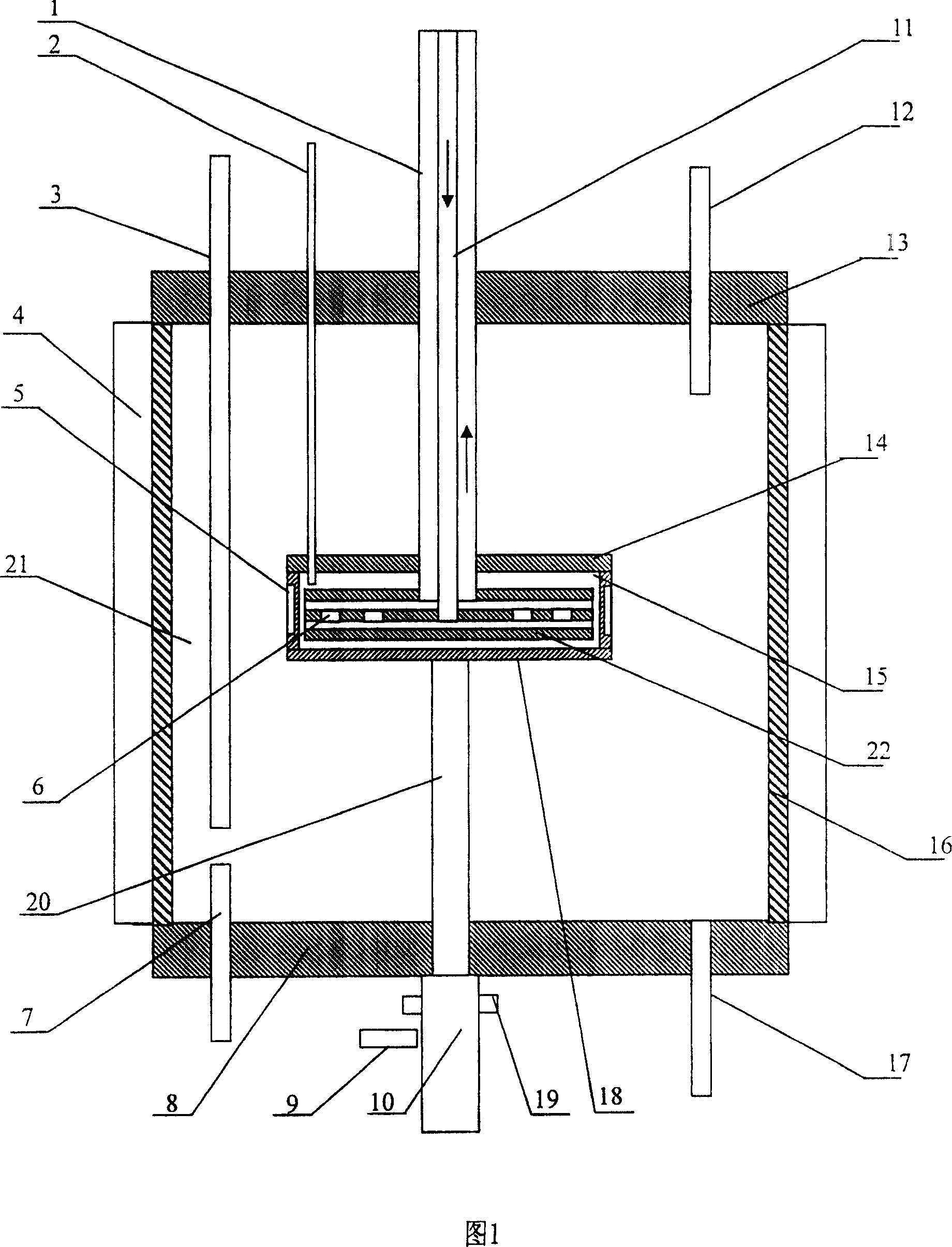

[0008] The magnetic drive device 10 of the present invention is connected with the lower cover 8 of the autoclave by bolts, and the middle is sealed with a gasket. The high-pressure gas cylinder air-conducting pipe and the autoclave air-inlet pipe 3 are screwed together. The condenser 18 and the cooling water outlet pipe 1 are welded and connected, the cooling water outlet pipe 1 passes through the autoclave upper cover 13, the water outlet pipe 1 and the autoclave upper cover 13 are fastened, and the water outlet pipe 1 and the autoclave upper cover 13 are connected by welding. Fasten with bolts and seal with sealing ring. Open the upper kettle cover 13 , pour the experimental solution into the kettle, and the liquid level of the solution should be lower than the lower surface of the condenser 18 . Place the sample 5 on the annular sample rack, pour the heat-conducting water medium into the condenser 18, cover the kettle cover 13, and seal the container upper cover plate 14 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap