Direct downward optical background modular set and its supporting posts

A backlight module and support column technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as hindering the upward reflection of light, and achieve the effects of simplified assembly steps, stable support capacity, and average brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] By means of the accompanying drawings and the following detailed description, the above contents and many advantages of this invention can be easily understood, wherein:

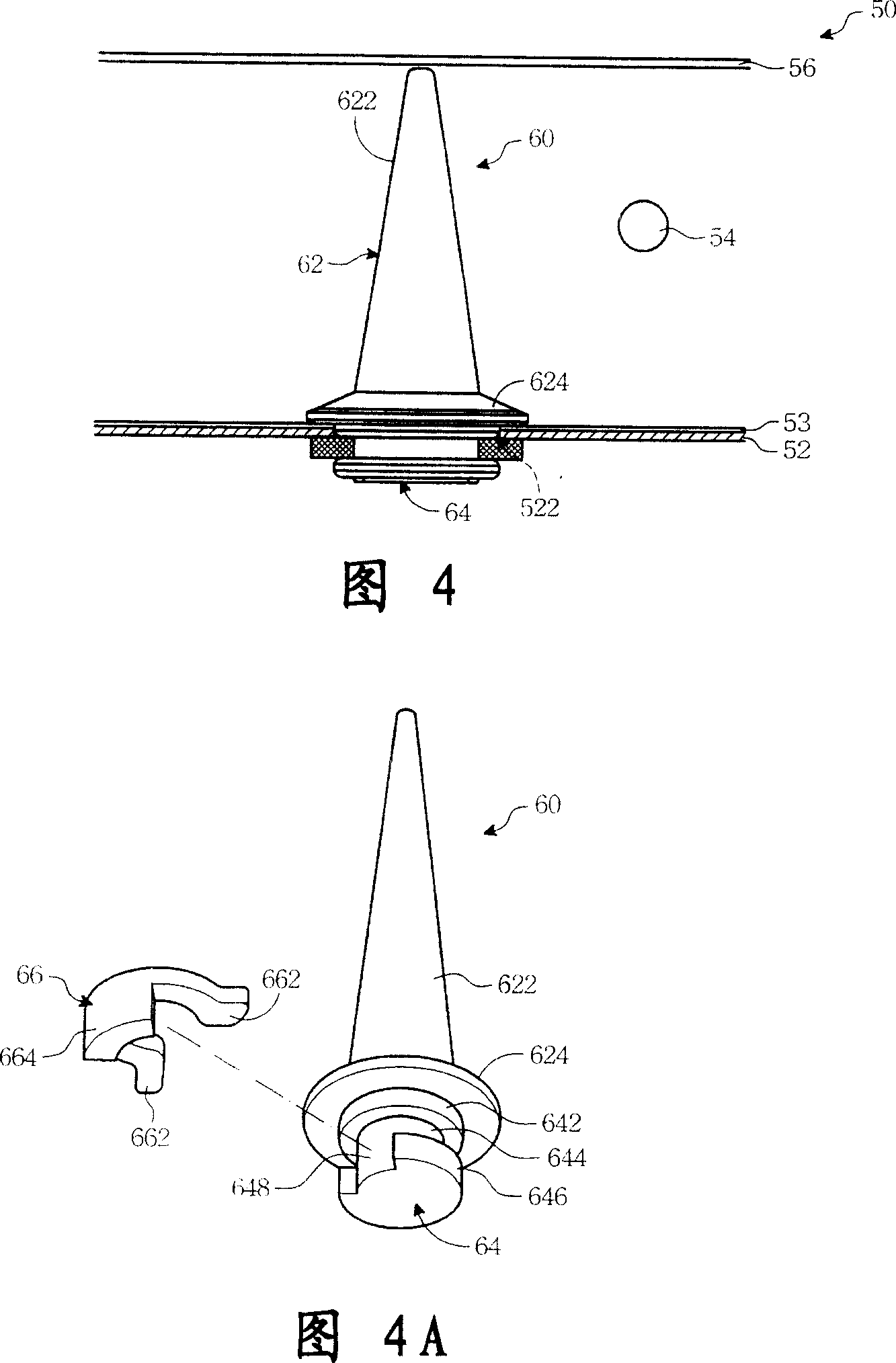

[0045] Please refer to FIG. 4 , which is a side sectional view of the backlight module of the present invention. The backlight module 50 includes a bottom plate 52 , a reflector 53 , a light tube 54 , a diffusion plate 56 and a supporting cone 60 of the present invention. Wherein the base plate 52 is located below the lamp tube 54, the diffuser plate 56 is located above the lamp tube 54, the reflector 53 spreads on the upper surface of the base plate 52, and the support column 60 is fixed in the base plate 52 to support the diffuser plate 56 upwards, in the base plate 52 And a fixing hole 522 is provided for fixing the support column 60 .

[0046] As shown in FIG. 4 , the support pole 60 includes a cone body 62 , a fixing bolt 64 and a snap ring 66 . The cylinder 62 is erected between the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com