Thin battery and method for manufacturing same

A battery, thin technology, applied in the direction of small flat battery/battery, small size battery/battery pack, large size battery/battery pack, etc., can solve problems such as expansion, and achieve the effect of preventing the increase of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

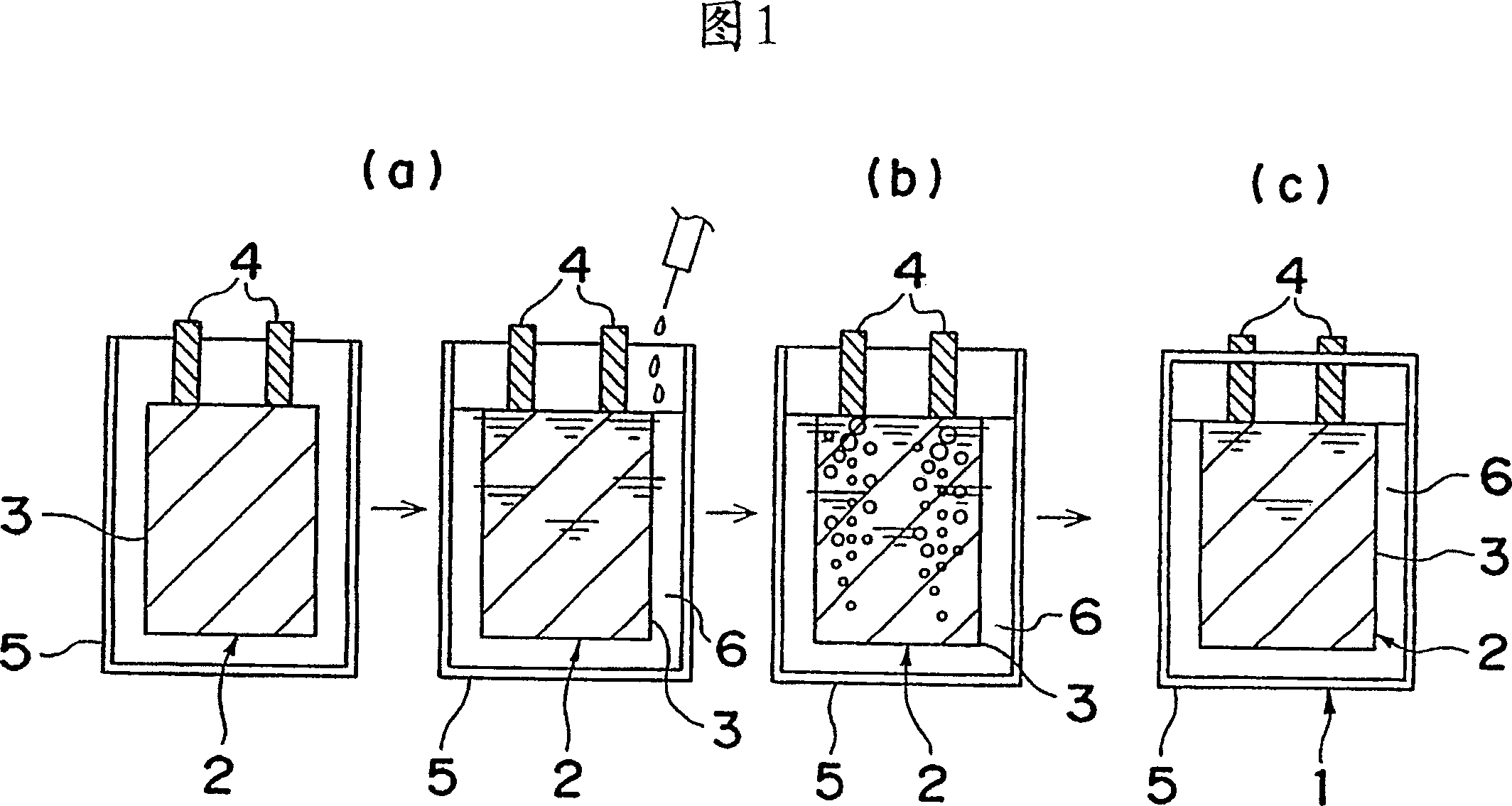

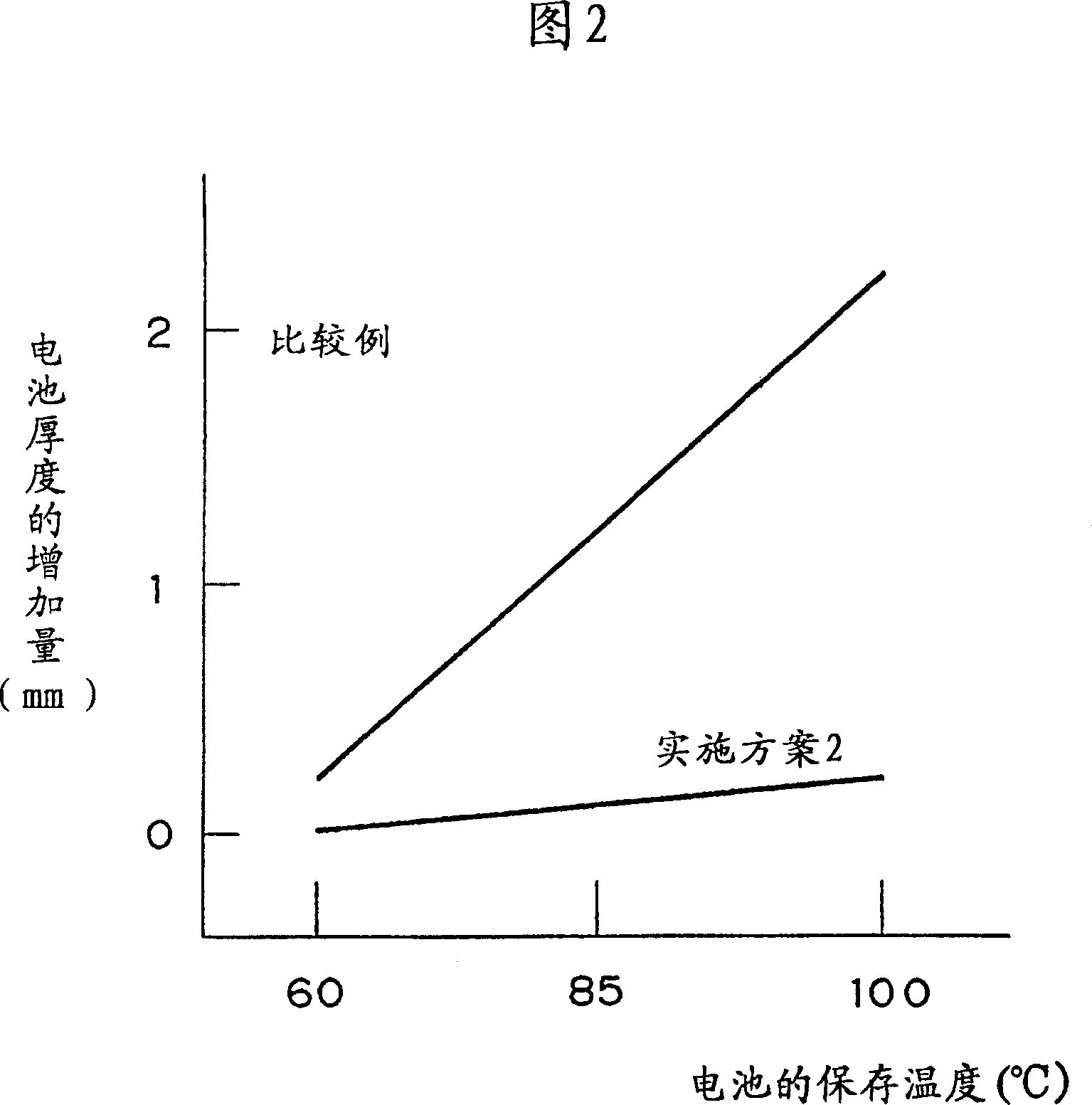

[0026] The electrolyte is a mixed electrolyte made by mixing ethylene carbonate (EC) and dimethyl carbonate (DMC) (volume ratio: EC:DMC=4:6), and then inject the mixed electrolyte through the separator and In negatively bonded battery bodies, the process takes place at low pressure. After precharging, the pressure in the vacuum chamber is reduced to 8.01 kPa at room temperature, which is just three times the vapor pressure of the mixed electrolyte solution of 2.67 kPa, and the casing 10 is sealed. The size of the lithium ion battery thus produced was 130 mm x 60 mm x 4 mm. After the pressure is restored to atmospheric pressure and placed for a specified time, put the entire battery into a flowing paraffin solution, and the casing is unsealed, then collect the gas released from the battery at this time, measure its volume, and use the measured volume as the remaining in the casing volume of gas. Then, it was stored at 85° C. for 24 hours, and the battery thickness increase du...

Embodiment approach 2

[0028]The electrolyte adopts the mixed electrolyte made by mixing ethylene carbonate (EC) and dimethyl carbonate (DMC) (volume ratio is EC:DMC=3:7), except at room temperature, the pressure of 4.02kPa (that is, mixing Electrolyte solution vapor pressure 1.34kPa 3 times) outside sealing, prepare lithium-ion secondary battery with the same method as embodiment 1, and battery is preserved at 85 ℃ for 24 hours, measure the increase of battery thickness at this moment, the result is as follows Table 1 shows. The residual gas volume is reduced to 0.03ml. Since the vapor pressure of the electrolyte in the battery is reduced, the pressure during sealing can be further reduced, thereby reducing the residual gas volume. Even if the battery is placed in a high-temperature environment, its thickness will not increase by more than 0.1 mm, that is, the thickness will remain basically unchanged.

Embodiment approach 3

[0030] A lithium-ion secondary battery was prepared in the same manner as in Embodiment 2, except that it was sealed at a low pressure in a vacuum chamber with a pressure of 53.3 kPa. The battery was also stored at 85° C. for 24 hours, at which time the thickness of the battery increased and changed as shown in Table 1. In this embodiment, the thickness of the battery does not increase by more than 0.1 mm. In this embodiment, the sum of the pressure increase caused by the gas generated by the self-discharging reaction of the battery and the increase in the vapor pressure of the electrolyte will not exceed 48 kPa in total. It is generally believed that this is because the pressure has not yet reached the atmospheric pressure of 101.3 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com