Detecting assemble for film products

A technology for detecting components and products, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of square flat membrane detection components being bulky, unfavorable for promotion and use, and insufficient sealing, and achieves easy on-site online detection , easy to observe and monitor, easy to carry and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

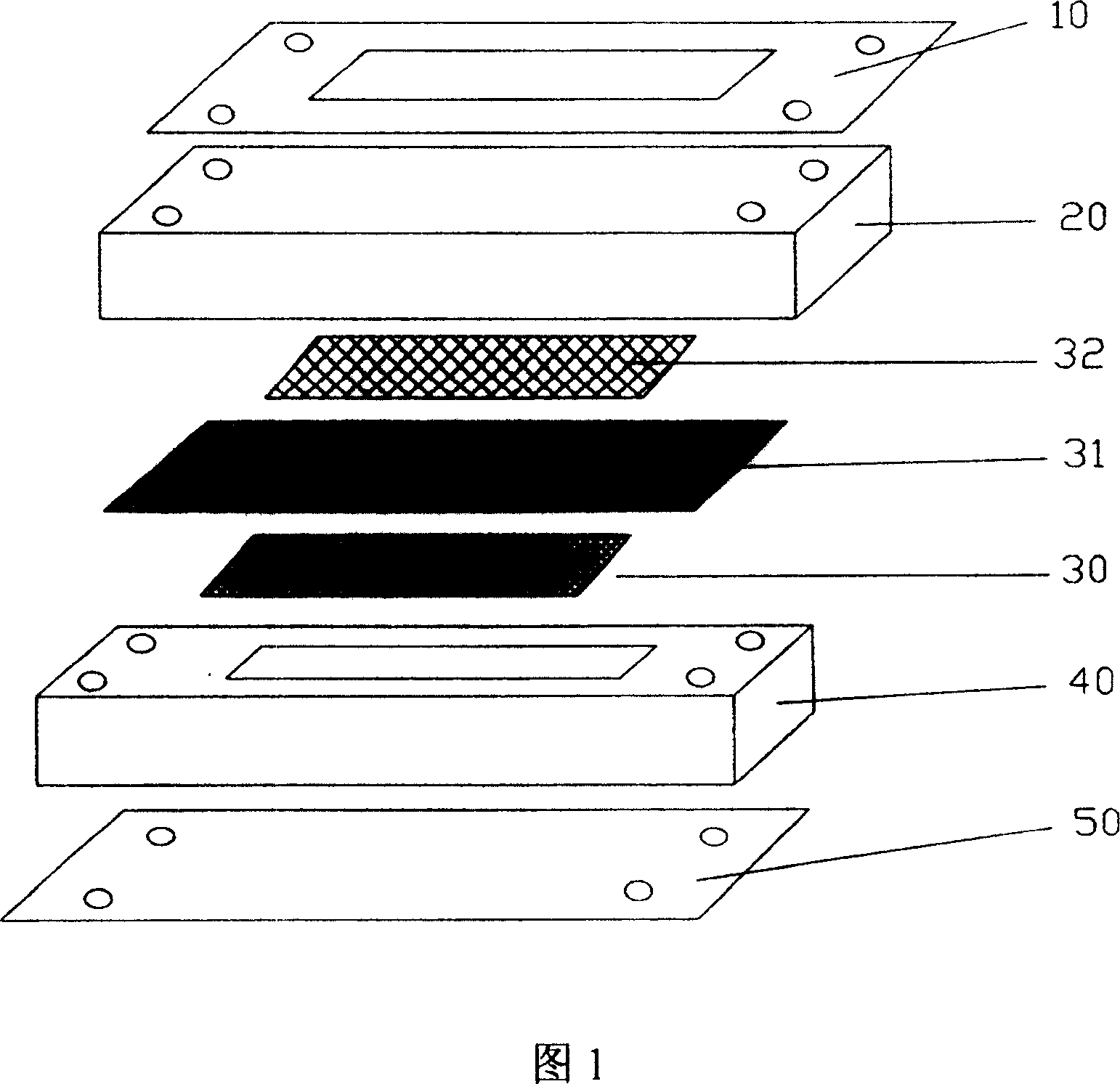

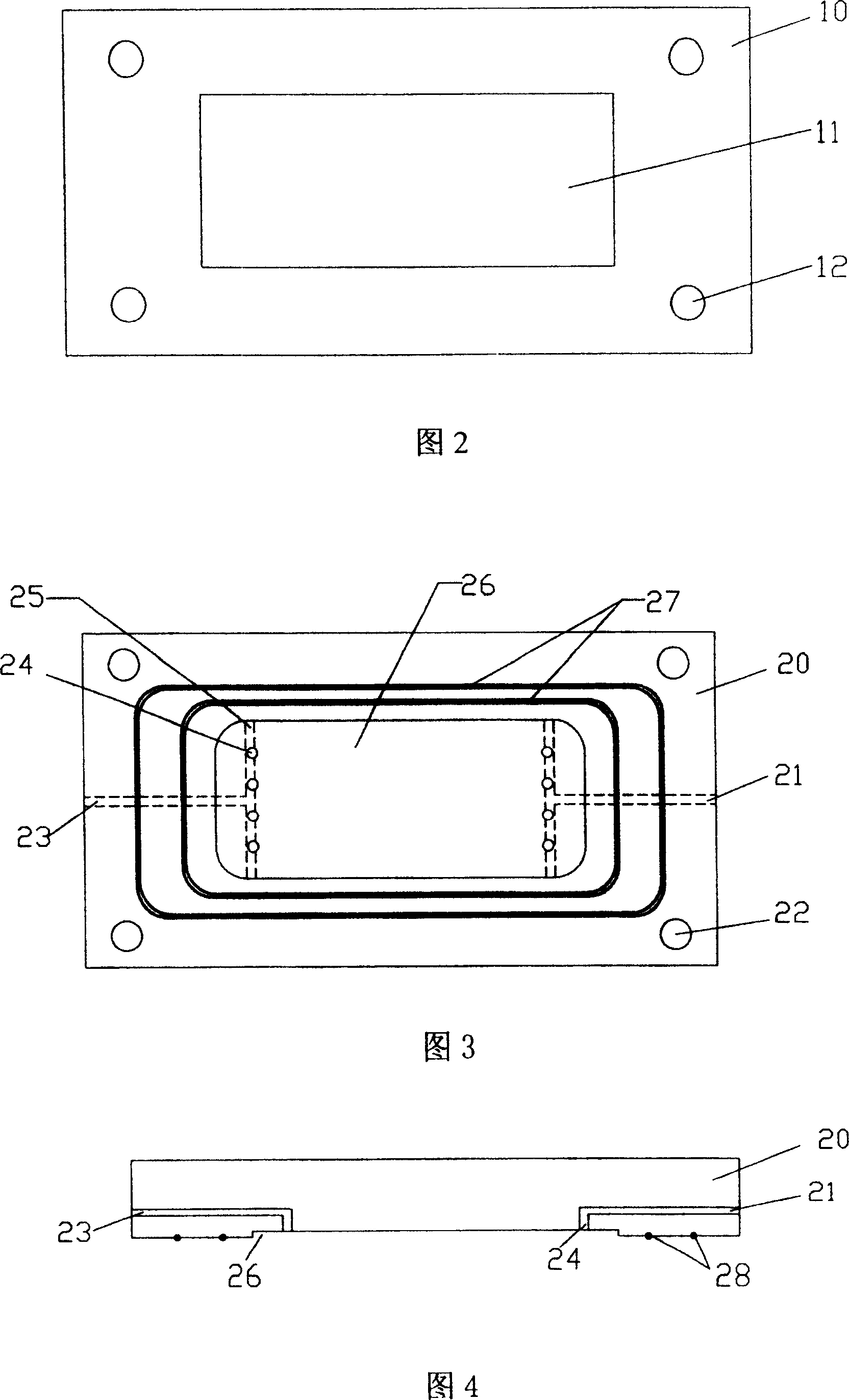

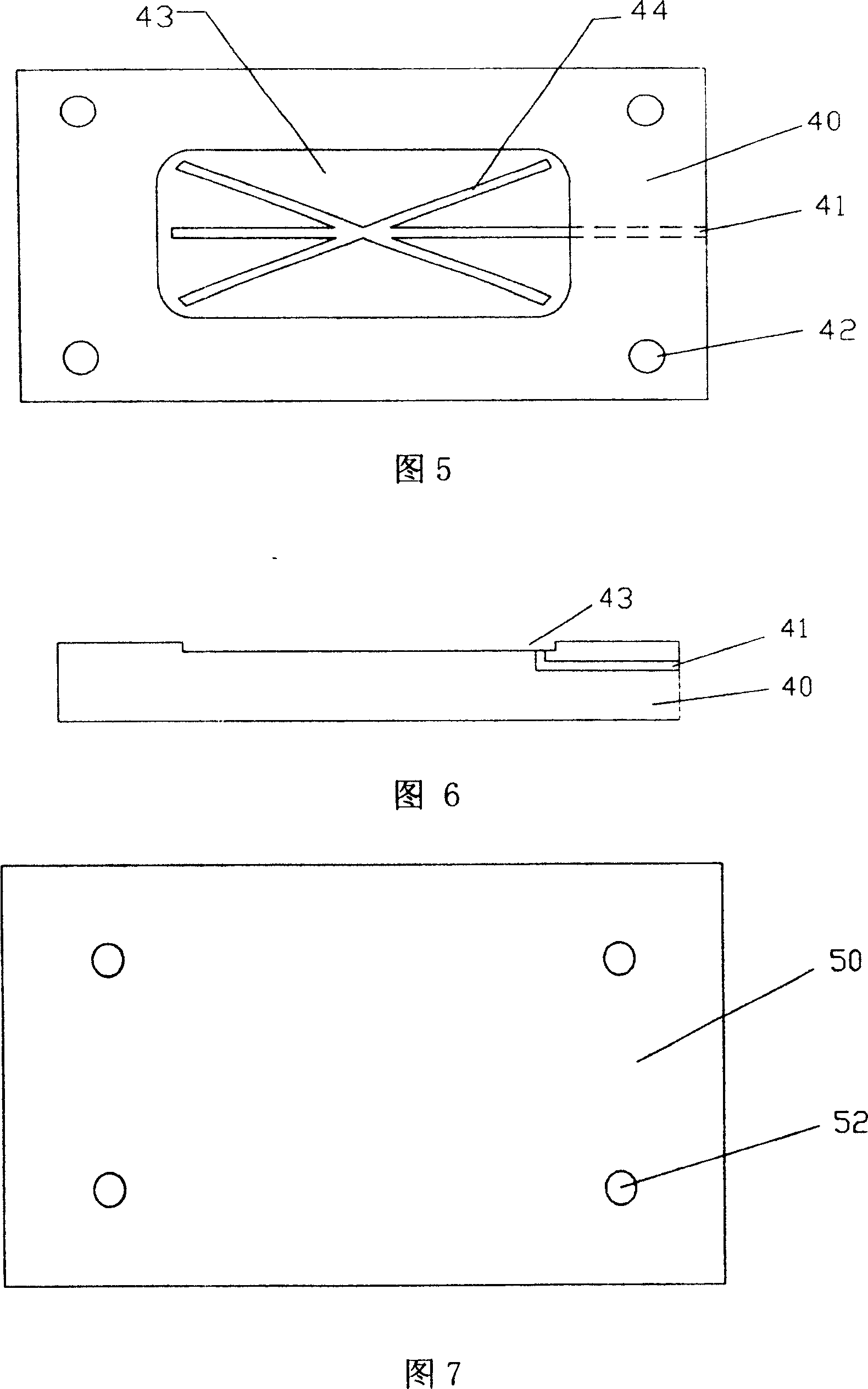

[0018] The present invention designs a film product detection assembly (see Figures 1, 2, and 3), which includes a protective plate 10, an upper plate 20, a lower plate 40 and a base 50 that can be sequentially fixed and assembled as a whole detection assembly by screws through connecting holes; There is a liquid flow channel 26 in the center of the bottom surface of the upper plate 20, and the two sides of the liquid flow channel 26 communicate with the liquid inlets and outlets 21 and 23 through the liquid distribution holes 24 and the liquid flow grooves 25 respectively; the upper plate 20 and the lower plate 40 There is a microporous plate 30 and a sealing ring 28 between them; a diversion groove 44 is provided on the lower plate 40 of the lower part of the microorifice plate 30, and the diversion groove 44 communicates with the permeate outlet 41 on one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com