Composite thermal insulation concrete wall and its assembled template

A technology of thermal insulation concrete and composite thermal insulation, which is applied in the direction of formwork/formwork/work frame, walls, building components, etc., to achieve the effects of accurate size, increased structural strength and stability, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The polystyrene insulation material in the present invention can adopt the high-density polystyrene foam plastics that density is 30KG / M

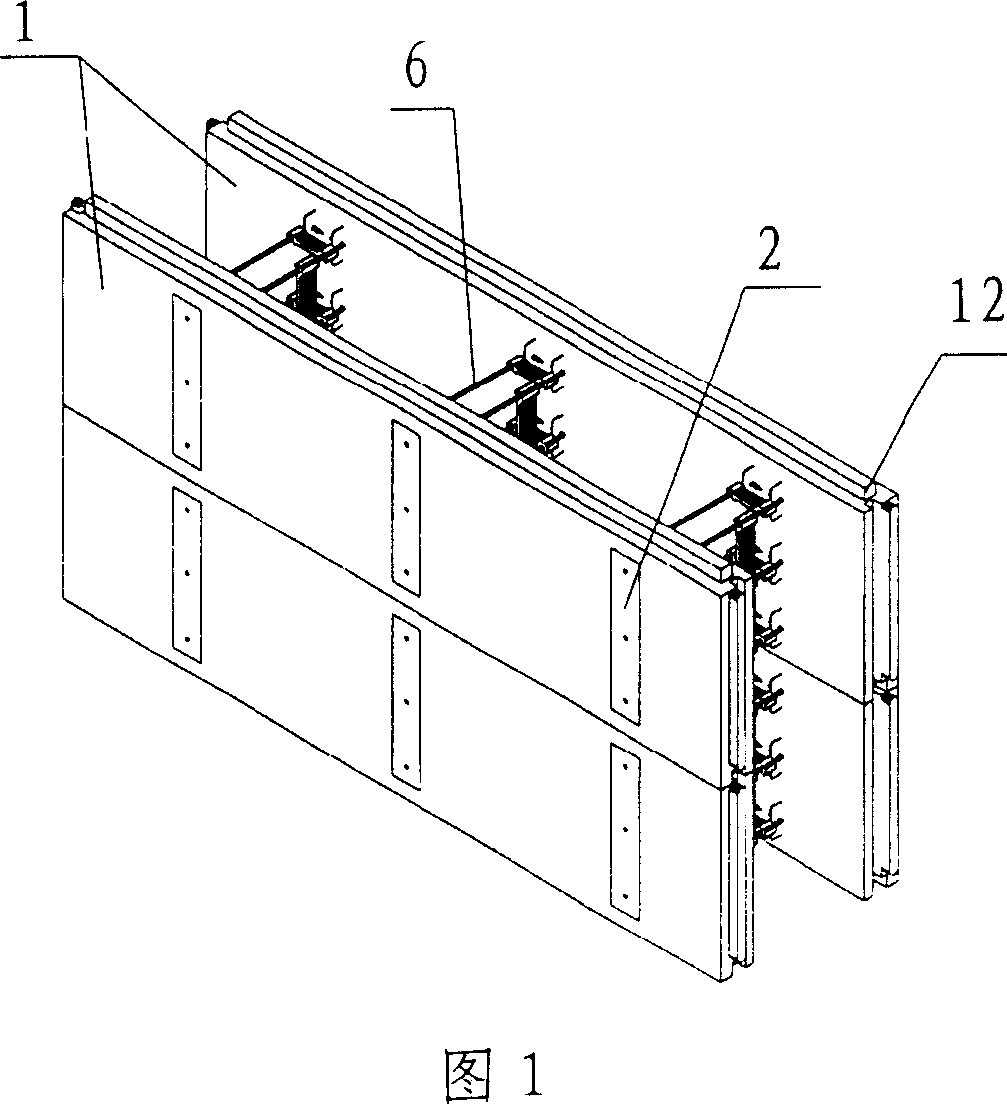

[0032] Referring to FIG. 1 , the double-row double-folded steel sheets 2 pre-installed in the prefabricated formwork 1 are connected through connectors 6 to form formwork on both sides of the wall. There are tongue and groove 12 on the edge of the prefabricated template. The prefabricated formwork can be connected with the adjacent prefabricated formwork by way of tongue and groove. The vertical joints of different layers of formwork are staggered from each other. The length of the assembled template is 900mm-1500mm, preferably 1200mm; the height is 250mm-600mm, the best is 300mm; the thickness is 40mm-60mm, the best is 40mm, and the slots of the horizontal and vertical clamps match the shape of the connectors.

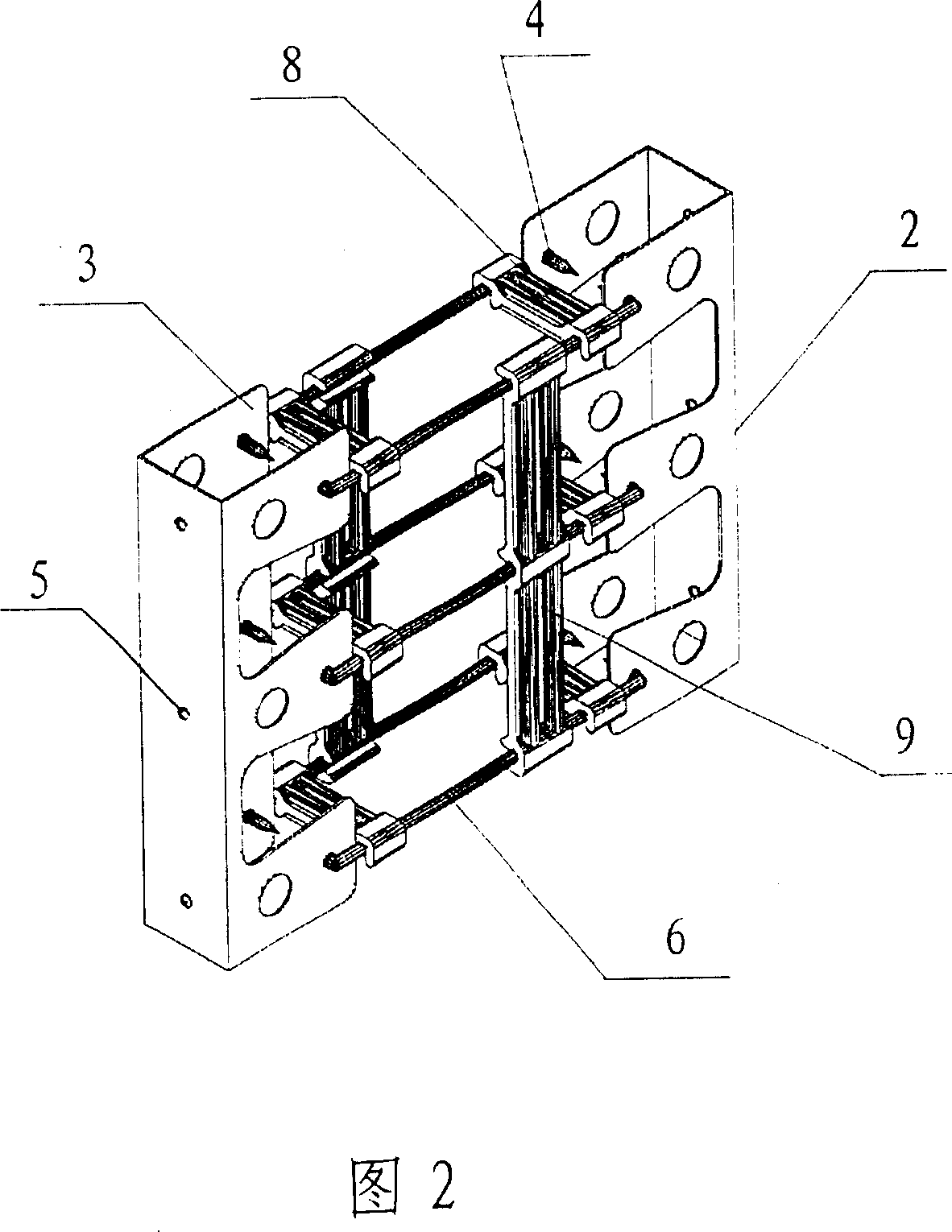

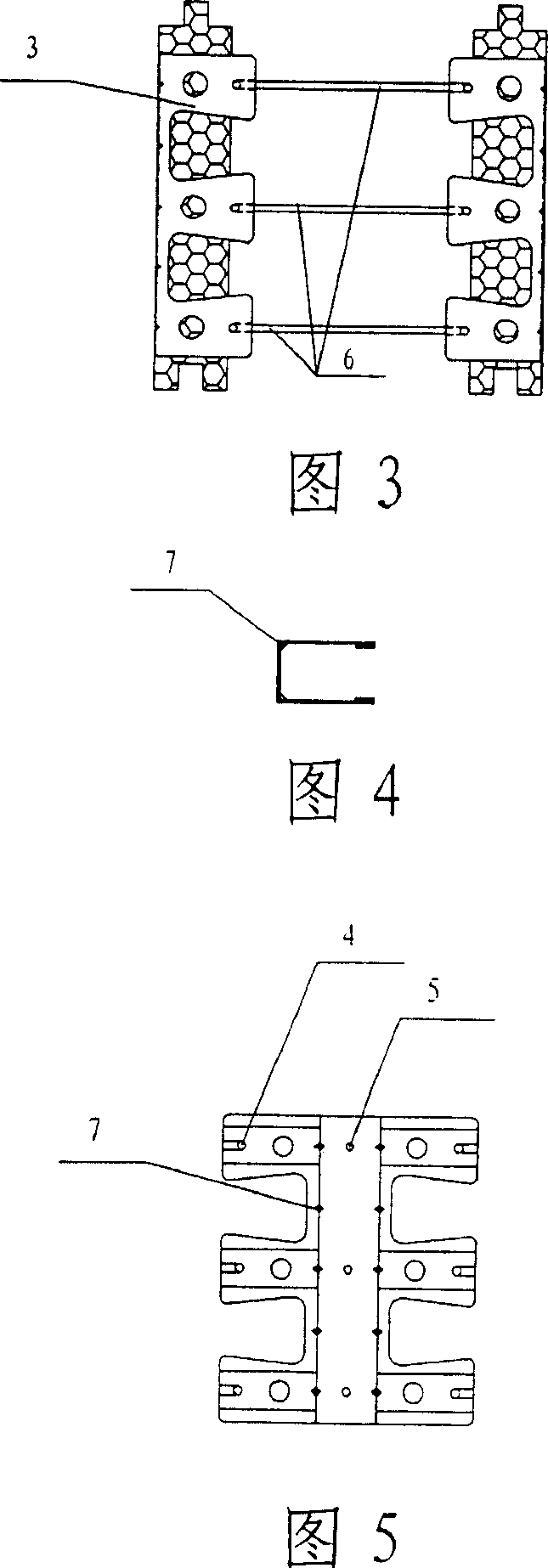

[0033] Referring to Figures 2, 3, and 4, the skeleton structure in the assembled formwork: the edges of the two side pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com