Plunger type epicenter controllable osillator

A plunger type and vibrator technology, which is applied in the field of petroleum seismic exploration equipment, can solve the problems of increased design and processing difficulty, lower vibrator fixed frequency, and large gland bearing, so as to reduce design and processing difficulty and reduce oil passage volume , Improve the effect of vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation

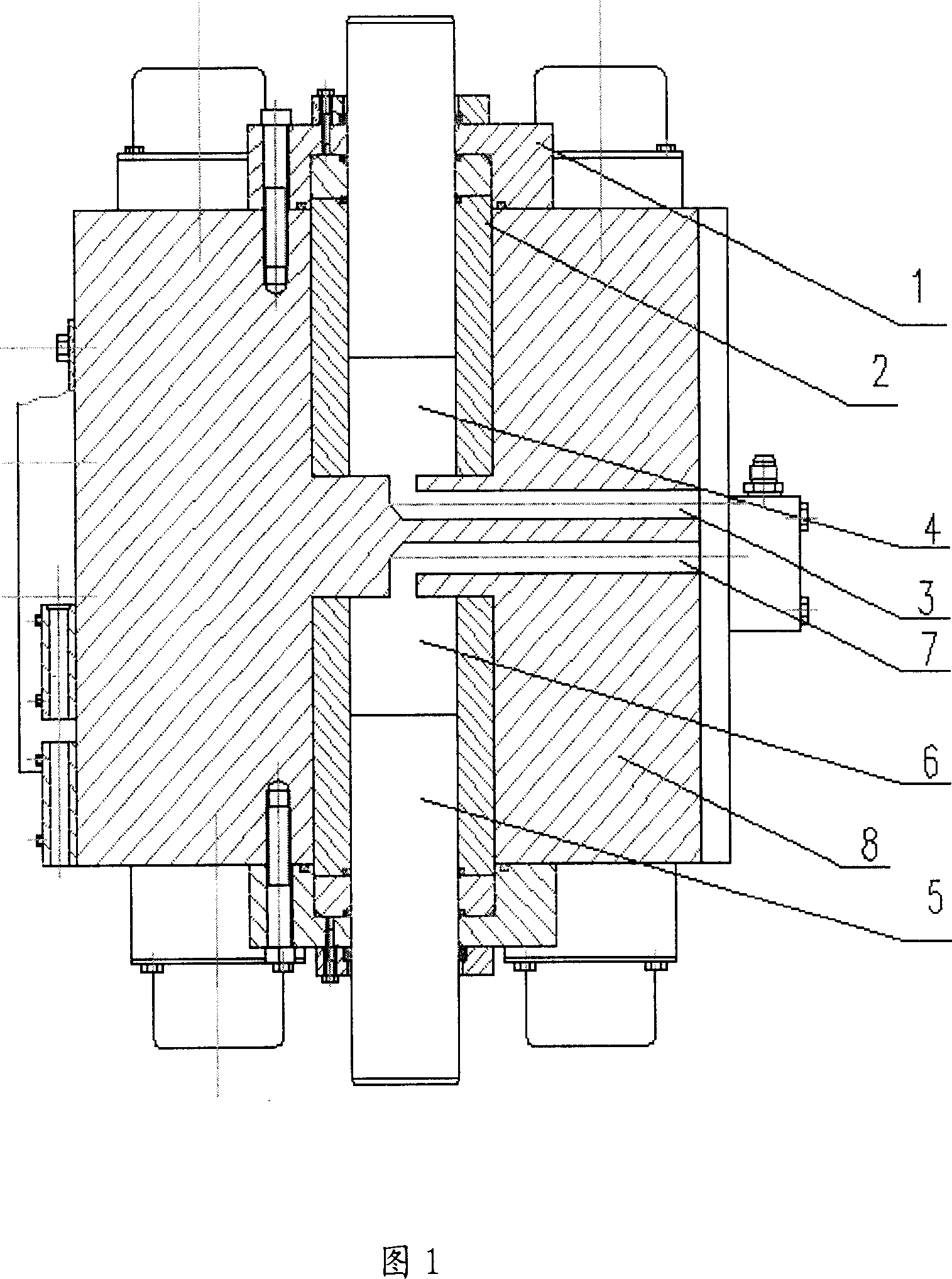

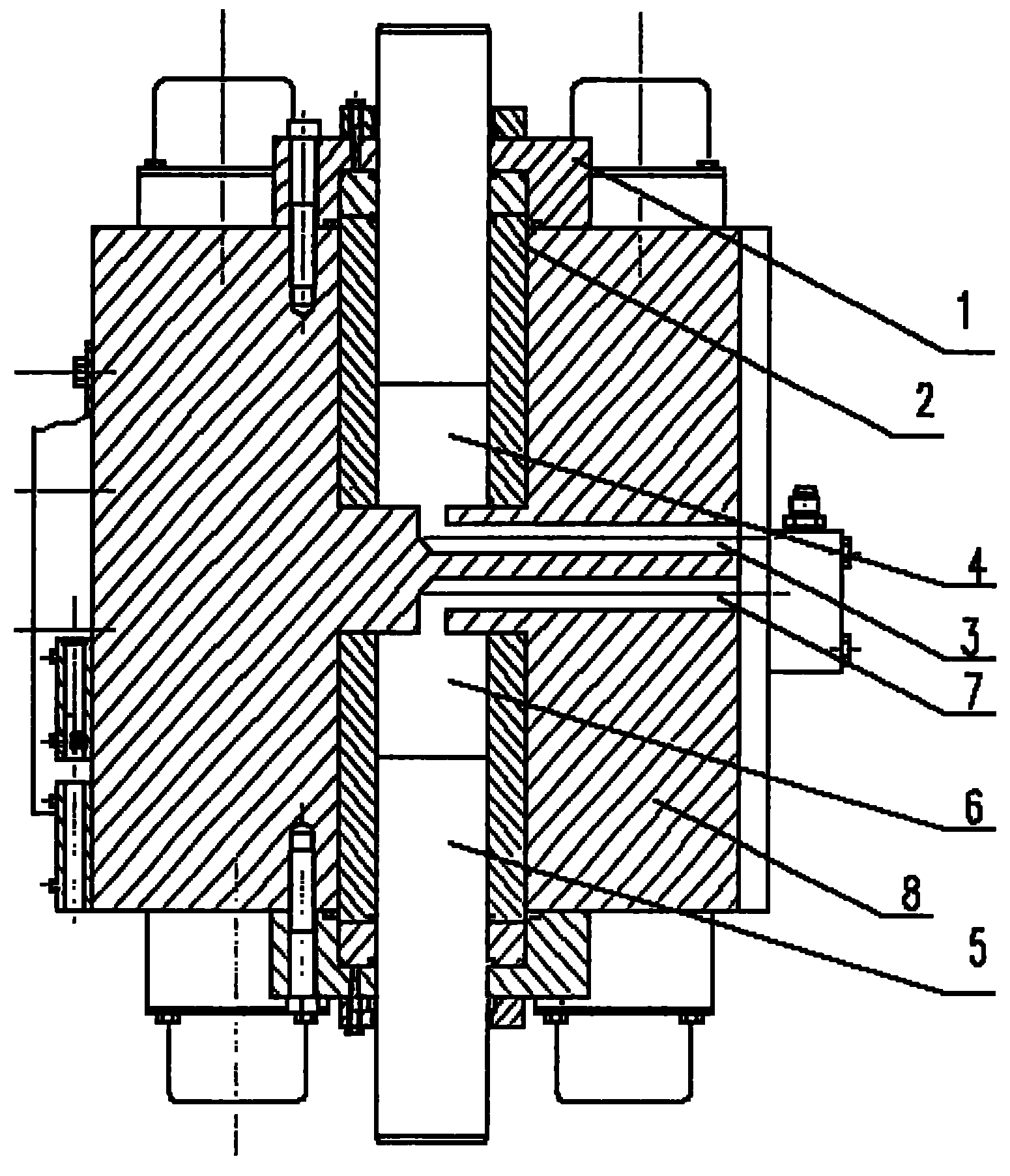

[0018] As shown in Figure 1, the working principle is basically different from the existing traditional vibrator in that the upper and lower plungers 5 replace the original pistons and are fixed, and the thrust generated by the hydraulic pressure acts on the plunger 5 and the hammer body 8 respectively. , no longer acting on the hammer body 8 through the transmission of the copper sleeve 2 as in the traditional vibrator.

[0019] This application is mainly made up of hammer body 8, plunger 5, gland 1 etc. The hammer body 8 is a rectangular steel block with two circular blind holes symmetrical up and down and the same axis in the center; the plunger 5 is cylindrical, as shown in Figure 1 after assembly, the hammer body 8 and the plunger 5 are combined to form Cylindrical working oil chamber, the hammer body 8 has a working oil passage, so that the working oil chamber communicates with the external control valve. Plunger 5 is fixed with other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com