Magnetic rheology type flexible polisher with air bag

A flexible polishing and magnetorheological technology, applied in the direction of manufacturing tools, grinding/polishing equipment, wheels with flexible working parts, etc. problems such as low polishing efficiency, to achieve the effect of improving morphological accuracy, stable normal polishing force, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

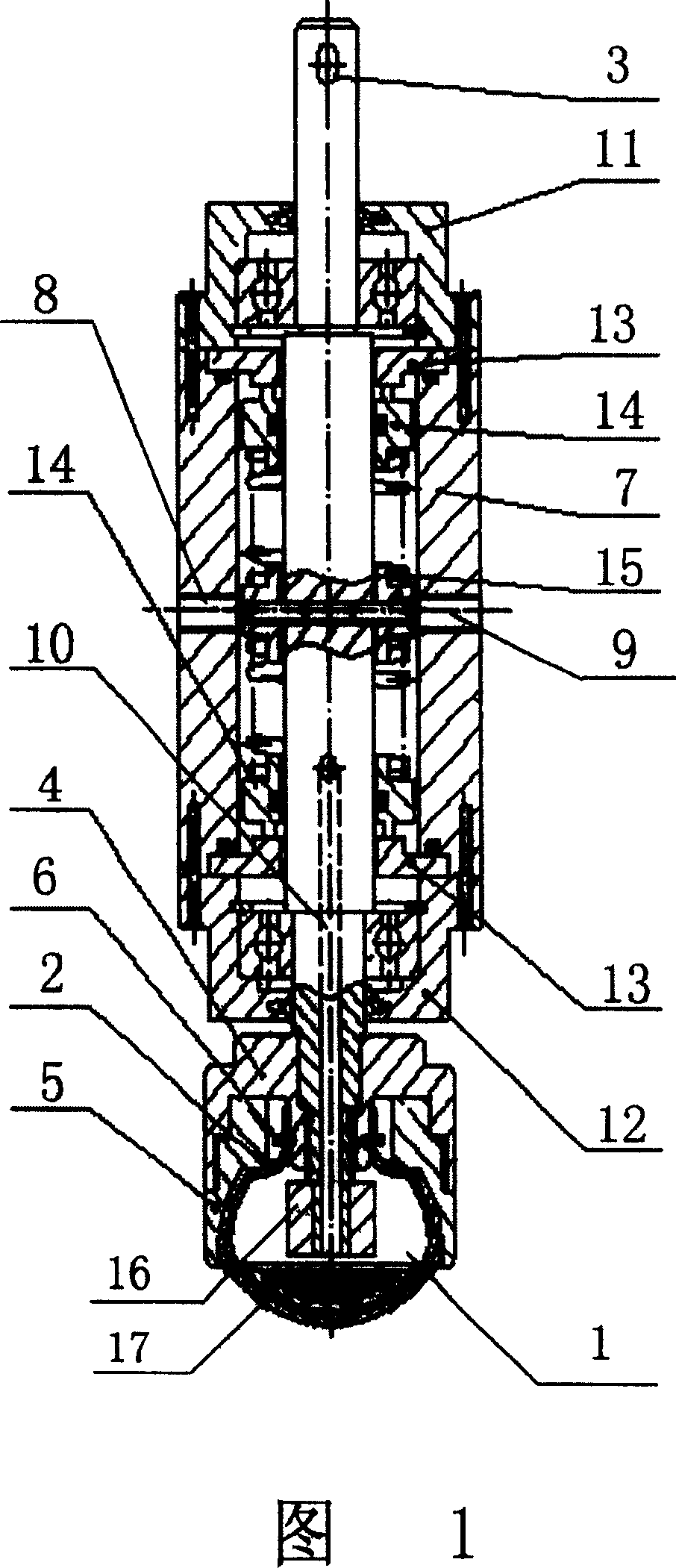

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] With reference to Fig. 1, a kind of magneto-rheological airbag flexible polishing tool, described polishing tool comprises an airbag 1, described airbag 1 front end has polishing cloth 2 as working surface, and described airbag 1 front end has an interlayer 17; The interlayer is filled with magnetorheological fluid; the airbag 1 is installed in a cage, and the cage is mounted on a rotating shaft 3 that can drive the cage to rotate. The cage includes a polishing head cover 4, a polishing The head inner cover 5 and the polishing head outer cover 4 are connected with the rotating shaft 3 through threads, and the polishing cloth 2 and the polishing head outer cover 4 are bonded into one body with resin, and are reinforced with a retaining spring 6. The polishing head inner cover 5 is the polishing cloth 2. The parts whose shape is determined and finalized are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com