Method for mfg. personal boy doll

A production method and doll technology, which can be used in entertainment, toys, etc., can solve the problem that dolls are difficult to meet the needs of consumers, and achieve the effect of good plasticity and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

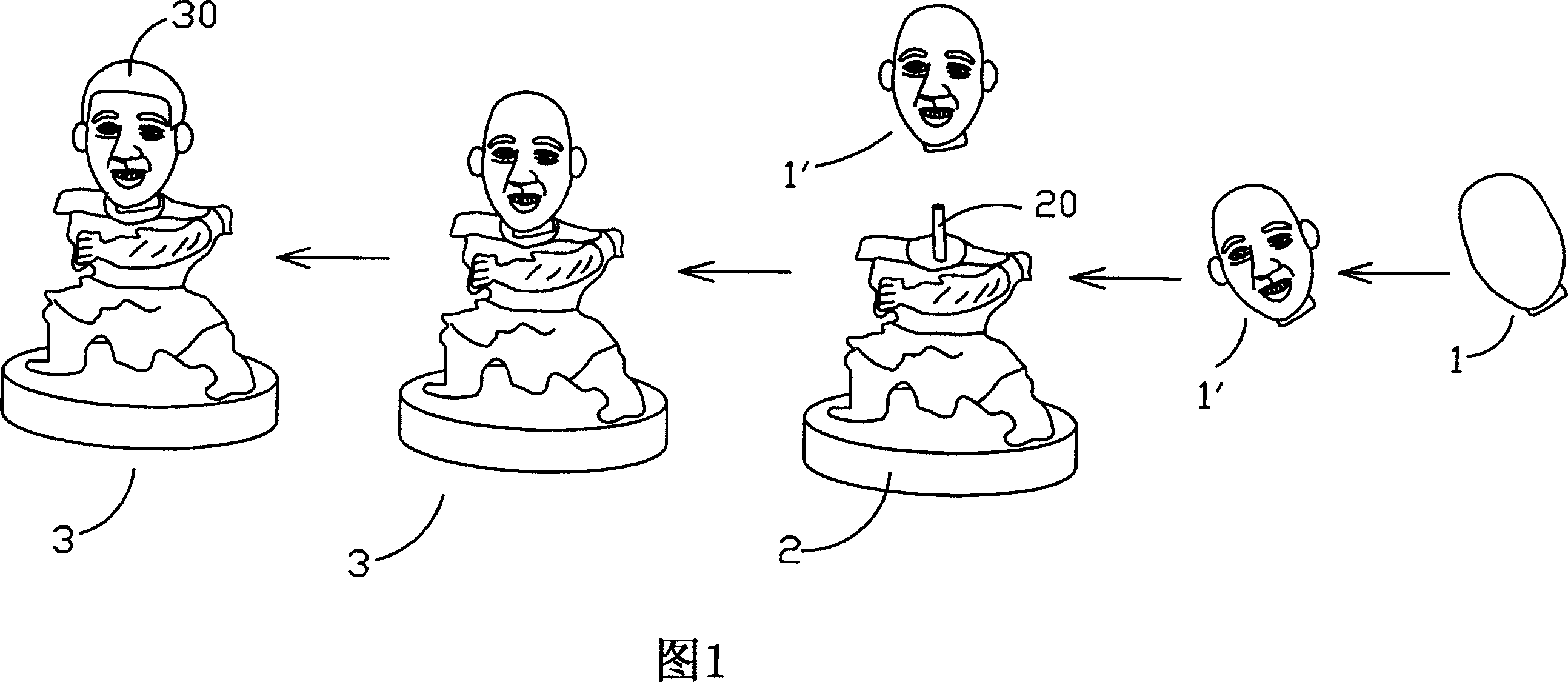

[0021] According to the characteristics of the human head, various head models 1 are made with soft clay. At this time, the head model 1 does not have hair and facial features, and the lower body 2 of various shapes is made of polyethylene material, and the lower body is inserted with a head for connecting with the head. The connecting iron core 20 connected to the external model.

[0022] After the customer provides the photo, select the head model 1 and the lower body 2 according to the photo and customer requirements, and fine-tune the soft head model 1 according to the photo to make it similar to the face in the photo, then outline the facial features, and make ears with clay , nose, eyes, mouth, and eyebrows to make them as similar to the photo as possible to complete the head production.

[0023] Connect the finished head model 1' with the connecting iron core 20 of the lower body model 2 to form a whole 3, after adjustment, put it into the oven and bake for 10 minutes a...

Embodiment 2

[0027] According to the characteristics of the human head, various head models 1 are made with soft clay. At this time, the head model 1 does not have hair and facial features, and the lower body 2 of various shapes is made of polyethylene material, and the lower body 2 is inserted with a The connecting iron core 20 to which the head model 1 is connected.

[0028] After the customer provides the photo, select the head model 1 and the lower body 2 according to the photo and customer requirements, and fine-tune the soft head model 1 according to the photo to make it similar to the face in the photo, then outline the facial features, and make ears with clay , nose, eyes, mouth, and eyebrows to make them as similar to the photo as possible to complete the head production.

[0029] Connect the finished head model 1' with the connecting iron core 20 of the lower body model 2 to form a whole 3, after adjustment, put it into the oven and bake for 30 minutes at 80°C to evaporate the wa...

Embodiment 3

[0033] According to the characteristics of the human head, various head models 1 are made with soft clay. At this time, the head model does not have hair and facial features, and the lower body 2 of various shapes is made of polyethylene material, and the lower body 2 is inserted with a head for connecting with the head. The connecting iron core 20 connected to the external model 1.

[0034] After the customer provides the photo, select the head model 1 and the lower body 2 according to the photo and customer requirements, and fine-tune the soft head model 1 according to the photo to make it similar to the face in the photo, then outline the facial features, and make ears with clay , nose, eyes, mouth, and eyebrows to make them as similar to the photo as possible to complete the head production.

[0035] Connect the finished head model 1' with the connecting iron core 20 of the lower body shape 2 to form a whole 3, after adjustment, put it into the oven and bake for 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com