Non-overflow drinking cup device

A non-spill and cup-free technology, applied in dispensing devices, applications, packaging, etc., can solve problems such as not being able to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

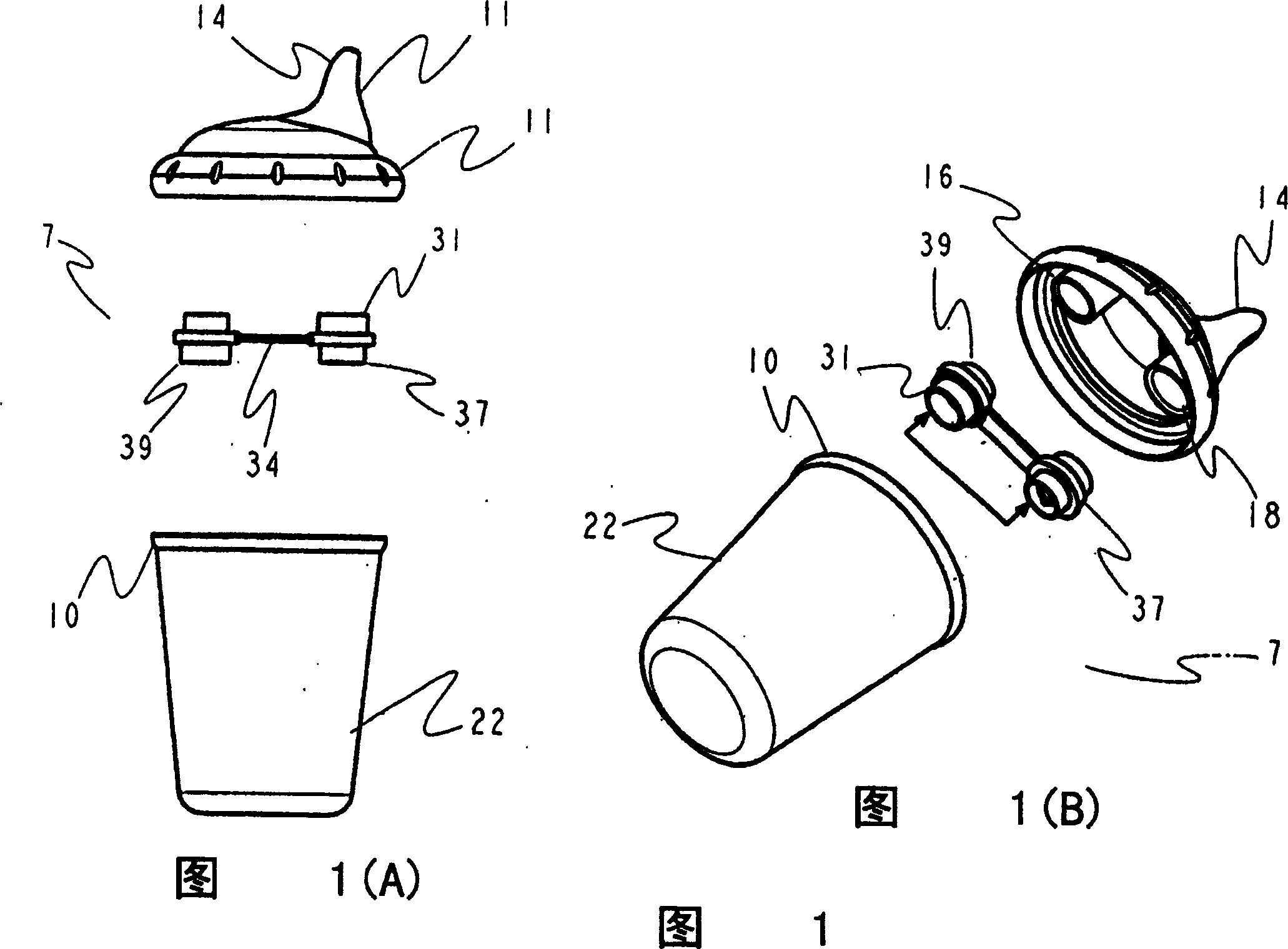

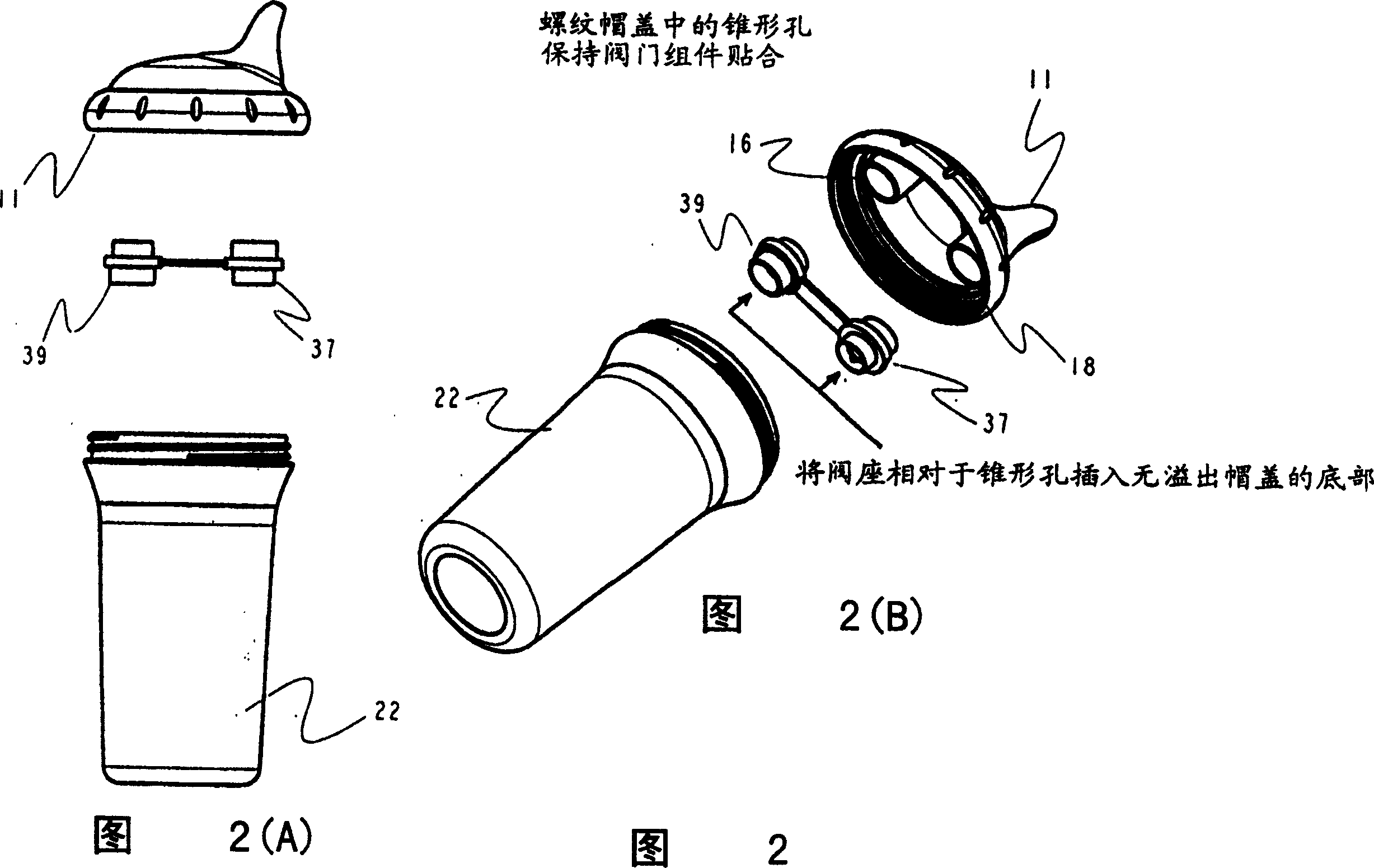

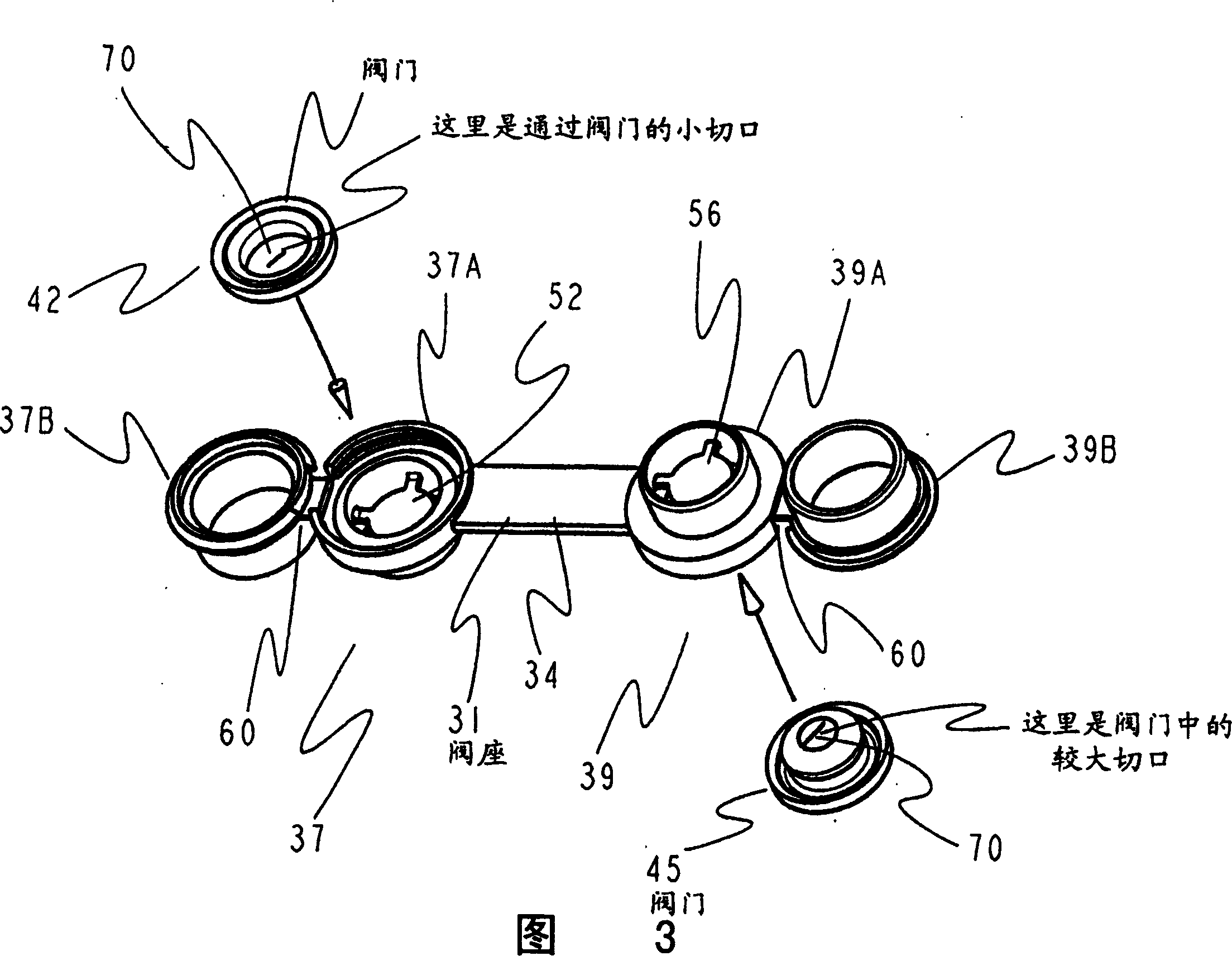

[0041] In conjunction with the accompanying drawings, a novel cup assembly will be disclosed to prevent accidental overflow of liquid. 1(a) and 1(b) are a front view and a perspective view, respectively, of an embodiment of a cup assembly according to the present invention. The volume of the cup or component containing the liquid portion can be adjusted as required. In one embodiment, as depicted in Figure 1, a 7 ounce drinking glass is provided. Additionally, Figure 2 illustrates a 9 oz drinking cup, although a 6.5 oz or other desired size cup could of course be provided.

[0042] In order for the user to hold the cup, the side of the cup may be provided with no handle, one handle, two handles or other number of handles. The handle is preferably sized to fit the child's hand. Additionally, the exterior and / or cap of the cup can be a single color, or printed with any desired graphics.

[0043] In another embodiment of the present invention, as shown in Figure 10, a non-spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com