Plug-in type resin insulation dry transformer without tapping

A dry-type transformer, plug-in technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of unstable operation of the transformer, complicated connection and installation process, and easy oxidation of the contact interface, so as to reduce electric shock by hand The possibility of simplifying the internal wiring of the coil and the effect of convenient connection and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

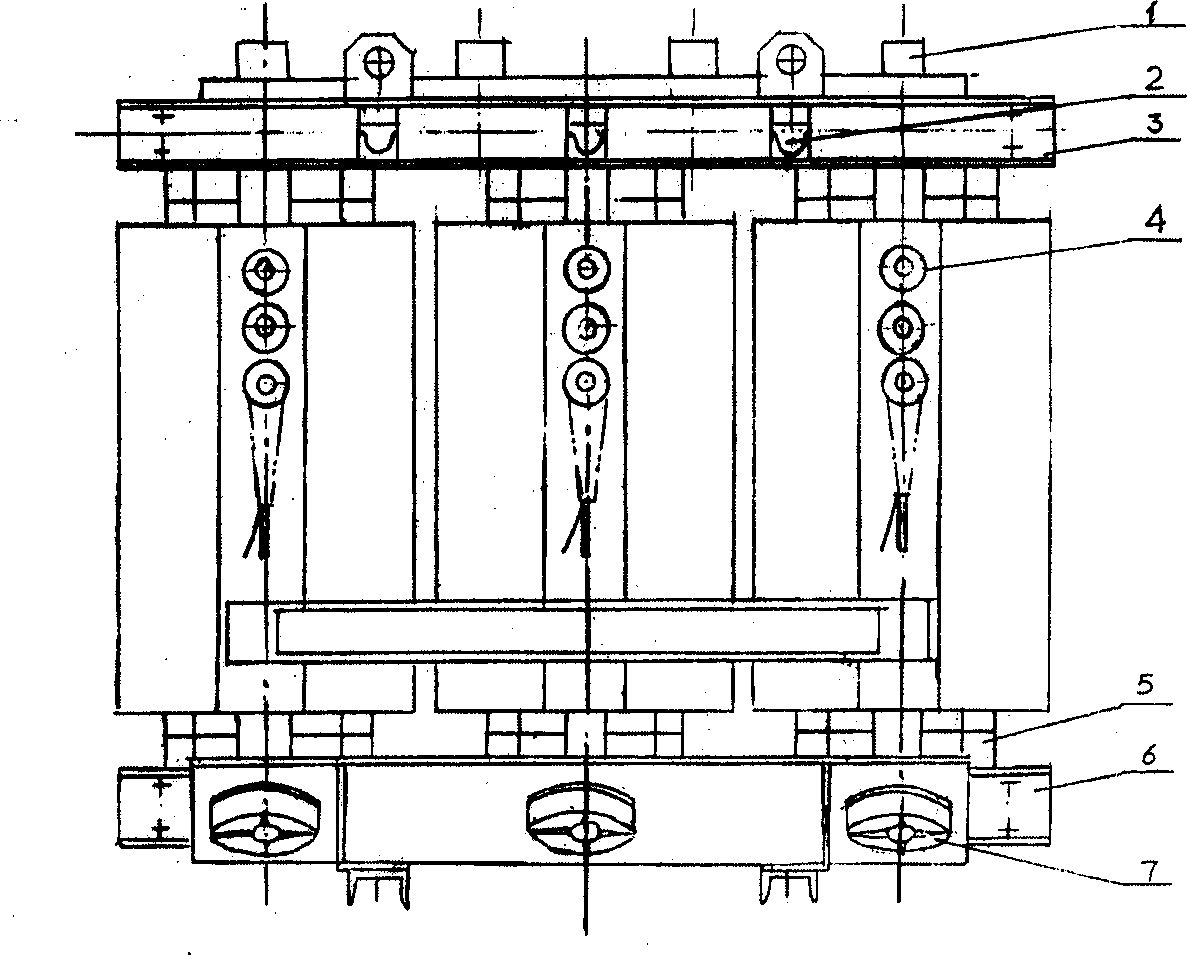

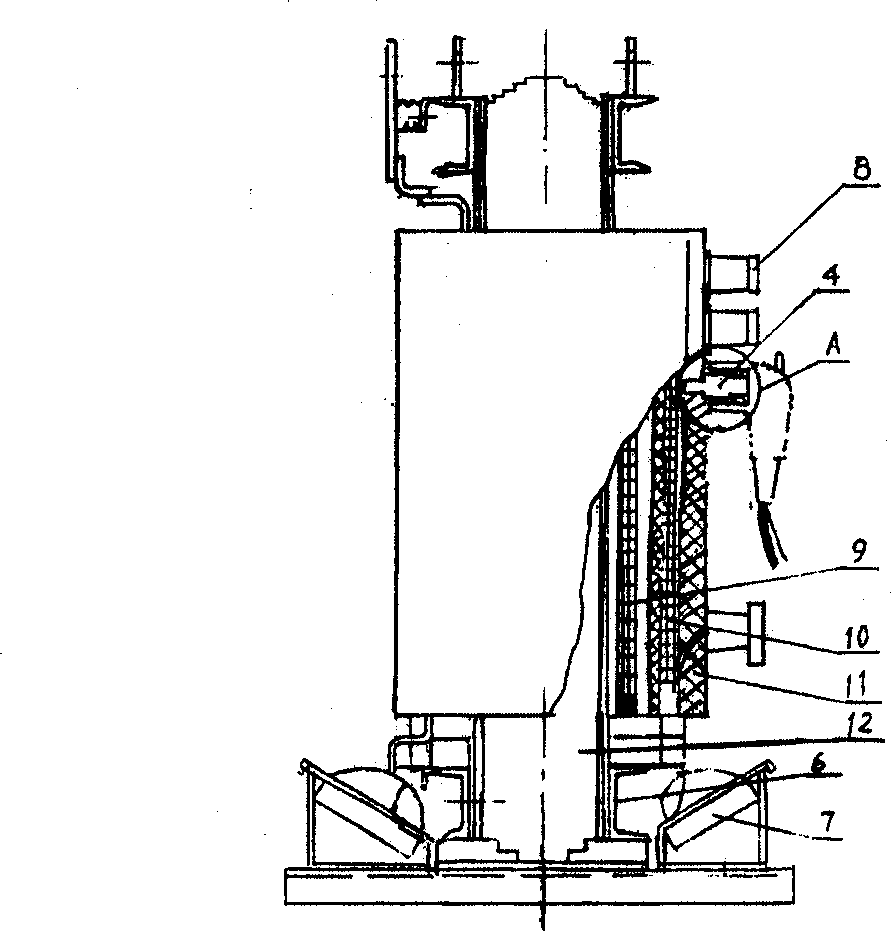

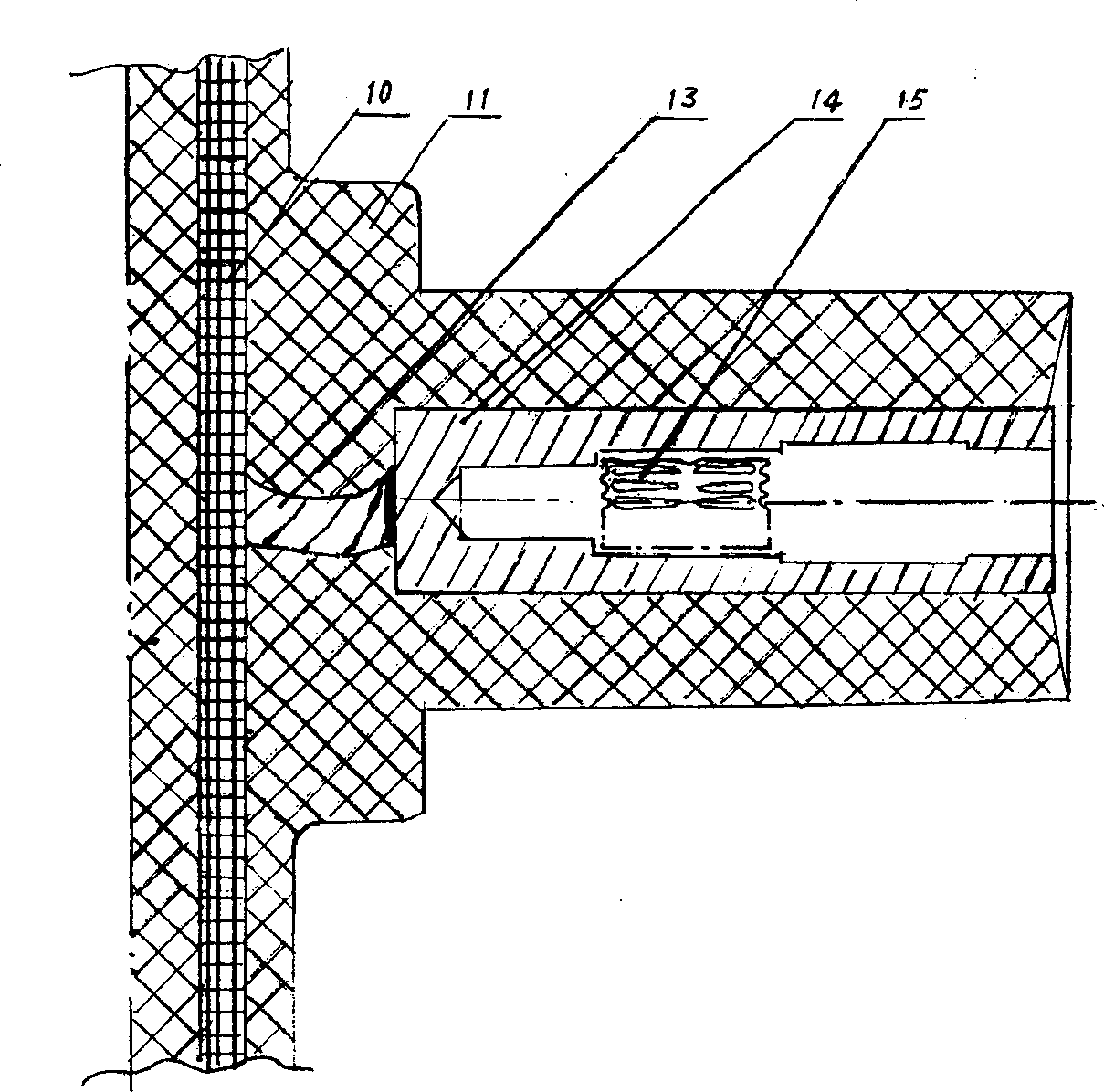

[0015] Such as figure 1 , 2 , 3, and 4, Embodiment 1 of the present invention is a Y-connection non-tap plug-in resin-insulated dry-type transformer, which includes a low-voltage outlet terminal 1, a hook 2, an upper clamp 3, a socket 4, a pad 5, a lower Clip 6, fan 7, insulating cover 8, low voltage coil 9, high voltage coil 10, insulating casting body 11, iron core 12, lead wire 13. In this embodiment, the outlet terminal and tap terminal of each phase of the high-voltage coil of the traditional insulated dry-type transformer are combined into three sockets 4 at the beginning of the coil. Such as image 3 As shown, the socket 4 is composed of a conductive rod 14 and a static contact 15. The conductive rod 14 is provided with a socket inner cavity. The louver is processed into a concave-convex louver shape. The two ends of the louver extend outwards and are inclined to the same side. When the static contact 15 is placed in the inner cavity of the conductive rod 14 socket, ...

Embodiment 2

[0019] Such as Figure 5 , 6 , 7, and 8, Embodiment 2 of the present invention is a D-connection non-tap plug-in resin-insulated dry-type transformer, and the difference from Embodiment 1 is as follows Figure 7 The shown elbow cable plug 17 is also provided with an intermediate plug 16 to form a plug assembly.

[0020] Regardless of the connection group of the transformer, there are at least 2 sockets on the high-voltage coil of each phase of the transformer. The number is determined according to the magnitude of the grid voltage change. Generally, 3 sockets can meet the requirements. For example, if the rated voltage of the grid is 10000V, and there are 3 taps as an example, when the actual voltage of the grid is close to it, the elbow cable plug should be inserted into the middle socket. If the actual voltage of the grid is higher or lower than the rated value for a long time 5%, the elbow cable plug should be inserted into the socket located above or below. After adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com