Lightning protector for low voltage electric equipment

A lightning protection device, low-voltage electrical technology, applied in circuit devices, emergency protection circuit devices, electrical components, etc., can solve the problems of imperfect lightning protection devices, combustion, fire, etc., to achieve easy maintenance in time, simple structure configuration, protection high-capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

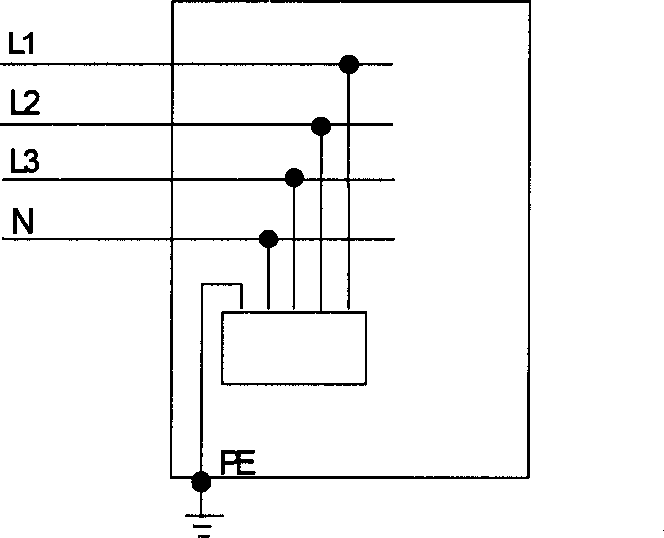

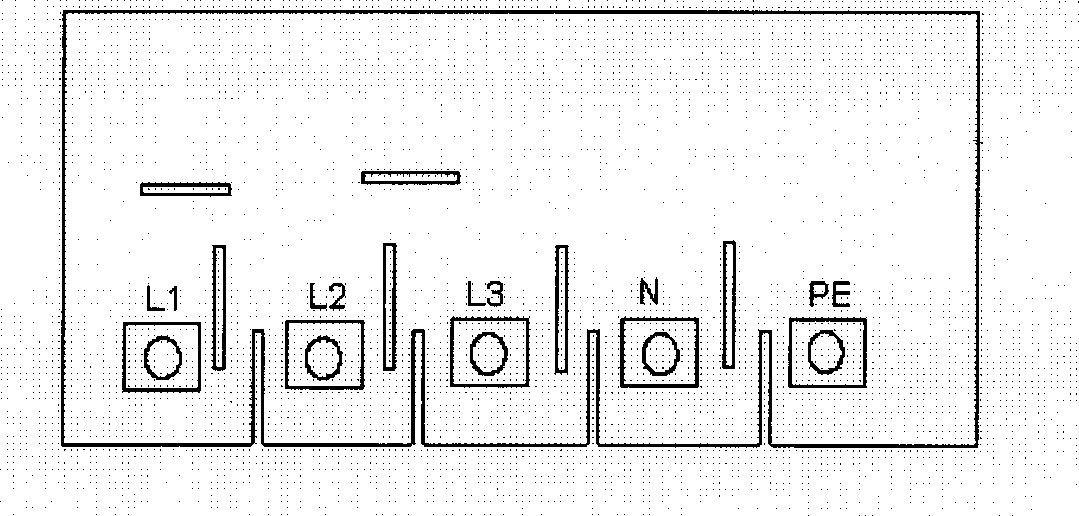

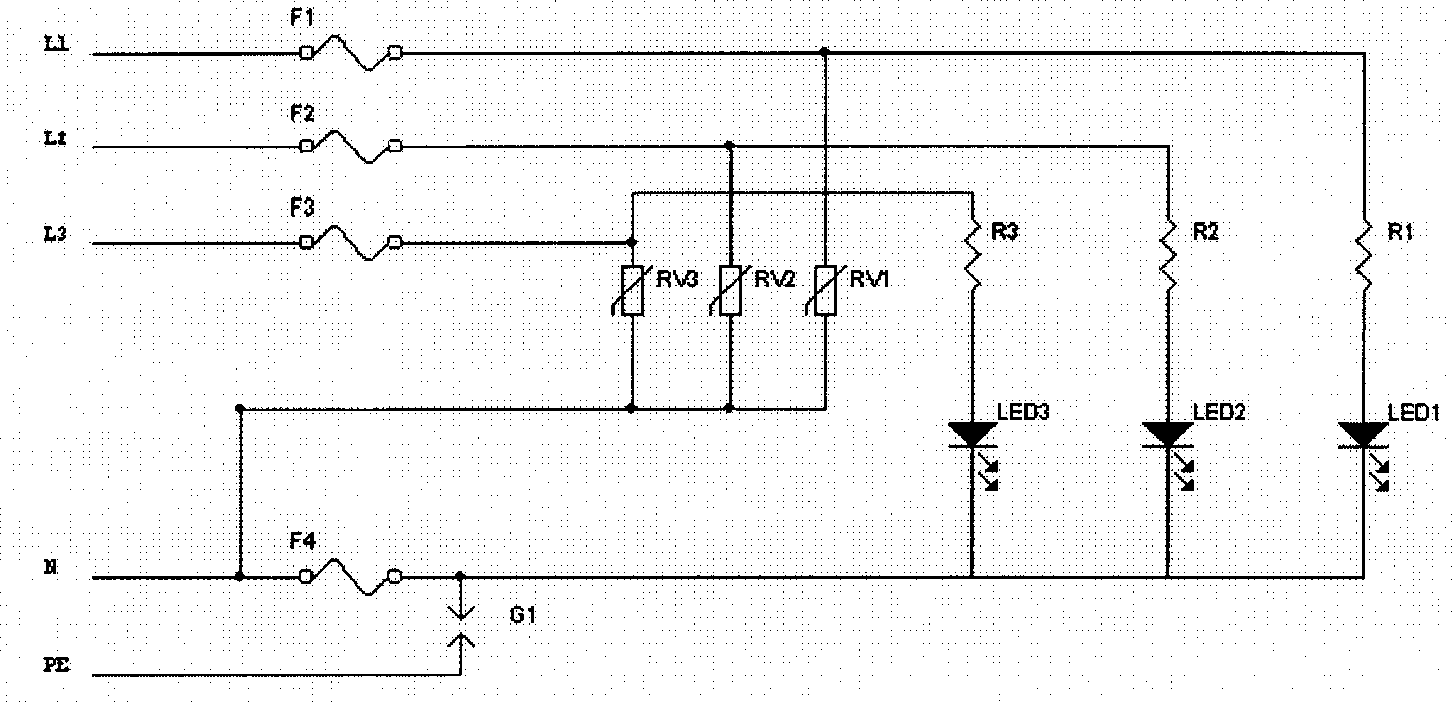

[0027] like Figure 1-Figure 5 As shown, this embodiment includes

[0028] A common mode lightning protection circuit consists of three piezoresistors RV1, RV2, RV3 respectively connected between the three phase lines L1, L2, L3 and the neutral line N and one connected between the neutral line N and The gas discharge tube G1 between the ground wire PE is used to improve the protection level of the device;

[0029] An overcurrent protection device consists of three overcurrent protectors F1, F2, F3 connected in series on the phase lines L1, L2, L3 in front of the varistors RV1, RV2, RV3 respectively and a gas discharge tube G1 connected in series The overcurrent protector F4 on the front neutral line N, wherein the overcurrent protectors F1, F2, F3, and F4 all use fuses to prevent lightning protection components such as piezoresistors and gas discharge tubes from appearing Phenomenon of explosion or combustion;

[0030] A lightning protection warning indicating device, which...

Embodiment 2

[0034] like Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that a varistor RV7 is connected in series between the overcurrent protector F4 on the neutral line N and the gas discharge tube G1, and the varistors RV1, RV2 The short contacts of RV3 and varistor RV7 are connected to the connection point of the gas discharge tube G1, and the short contacts of the three sets of lightning protection and alarm indication circuits are connected to the connection points of the varistor RV7 and the overcurrent protector F4. That is to say, in this embodiment, the varistor RV7 is connected in series with the discharge tube G1 between the neutral line N and the ground line PE to act as a current limiting resistor, because some remote rural power grids are unstable, and the neutral line N The potential may shift to a higher value, which will have a certain impact on the arc extinguishing of the gas discharge tube G1. Connecting the varistor RV7 in series can n...

Embodiment 3

[0036] like Figure 7-Figure 8 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the present invention also includes a differential-mode lightning protection circuit, and the differential-mode lightning protection circuit consists of three phase lines L1, L2, and L3 respectively. The varistors RV4, RV5, and RV6 between the two phase lines are composed of the varistor RV4 connected between the phase lines L1 and L2, the varistor RV5 connected between the phase lines L2 and L3, and the varistor RV6 is connected across phase lines L1 and L3. The main difference between this embodiment and the functions of Embodiment 1 and Embodiment 2 is that in Embodiment 1 and Embodiment 2, the combination of varistors RV1, RV2, and RV3 is mainly used to protect the connection between the phase lines L1, L2, and L3. Differential mode lightning strikes, that is, the differential mode lightning strikes between L1 and L2 are protected by RV1+RV2, the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com