Liquid crystal cell gap adjusting device, pressure packaged device and manufacture method for liquid crystal display

A gap adjustment device and liquid crystal cell technology, applied in static indicators, nonlinear optics, optics, etc., can solve problems such as time extension, liquid crystal device can not obtain display characteristics, plate-shaped member 90 uneven thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

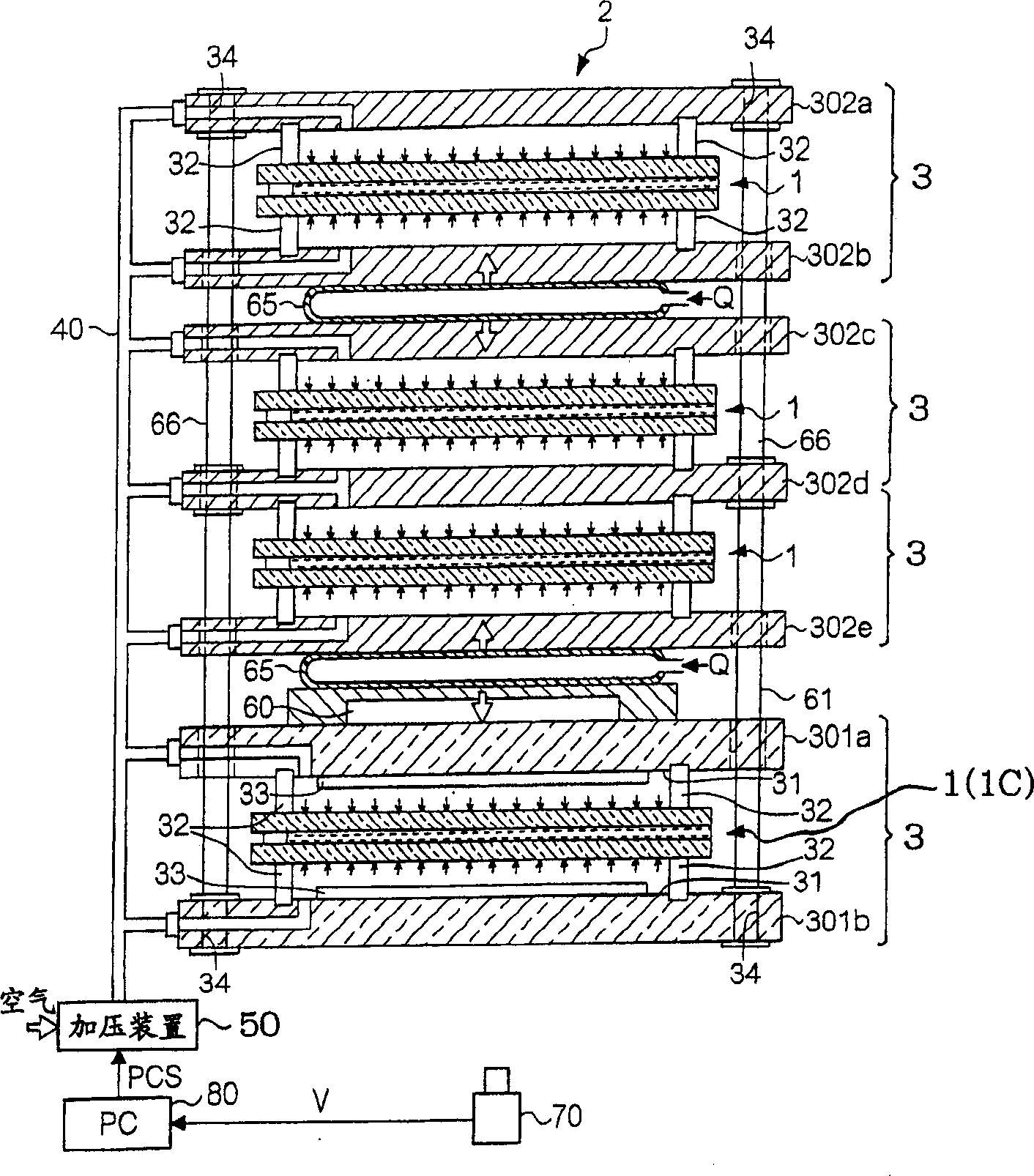

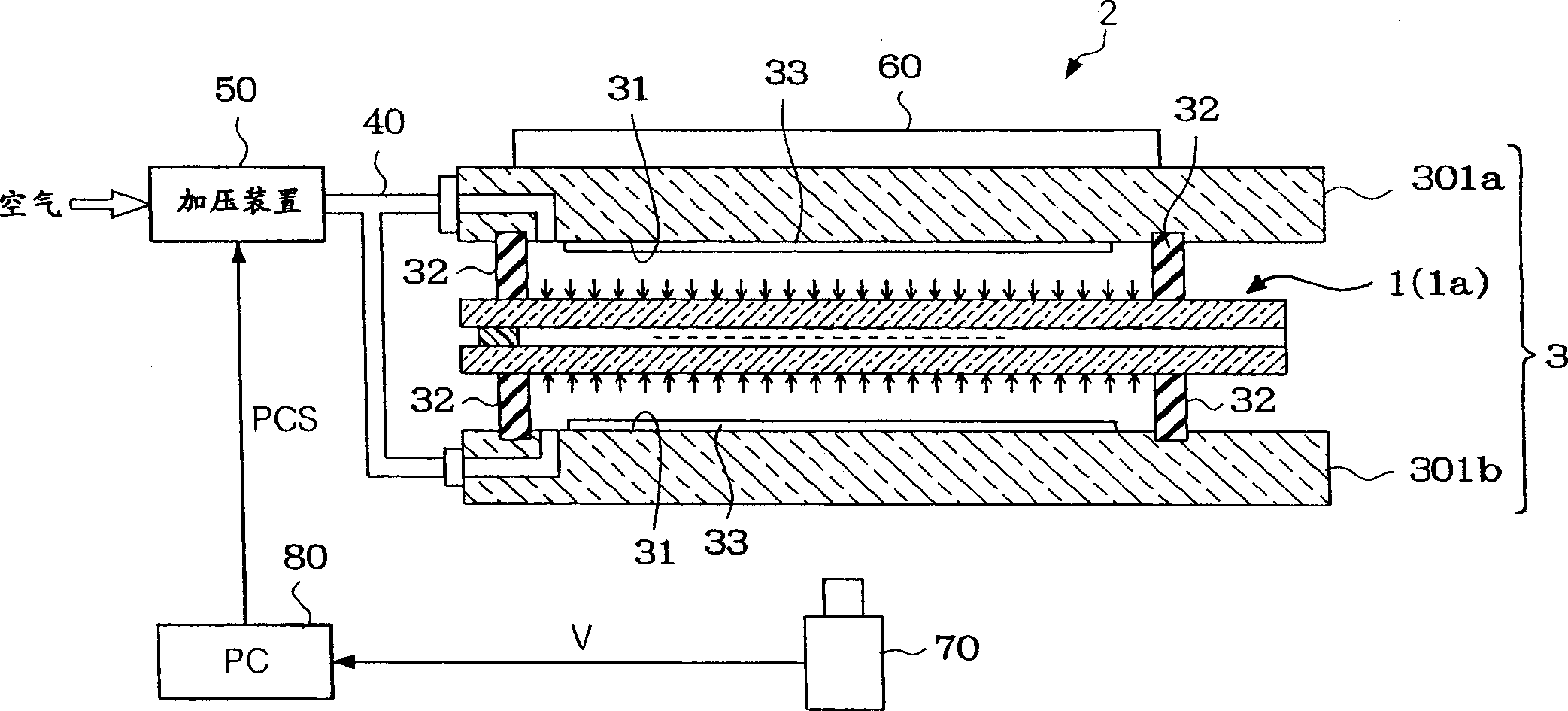

[0092] In the above-mentioned embodiment, such as figure 2 As shown, the light intensity of each monochromatic light emitted from the light source 60 and transmitted through the detection liquid crystal cell 1C is detected by the color CDD camera 70, and the liquid crystal cell gap (d) is obtained from the detection result. Here, with respect to the liquid crystal cell 1C for detection without a color filter, the liquid crystal cell gap (d) can be accurately obtained by such a method. However, when the liquid crystal cell gap (d) of the liquid crystal cell 1C for detection with a color filter is obtained by this method, since the light received by the color CDD camera 70 is light that can pass through the color filter , so the chromaticity coordinates on the CIE chromaticity diagram change with the characteristics of the color filter, which leads to the problem that the gap (d) of the liquid crystal cell may not be accurately obtained. In order to avoid such a problem, when ...

Deformed example 2

[0102] In the above-mentioned embodiment, it is assumed that the substrate surface of the liquid crystal cell group 1 and the sealing member 32 for sealing have a Image 6 In the case of the positional relationship shown above, the positional relationship is not limited to this, and the following relationship may be used.

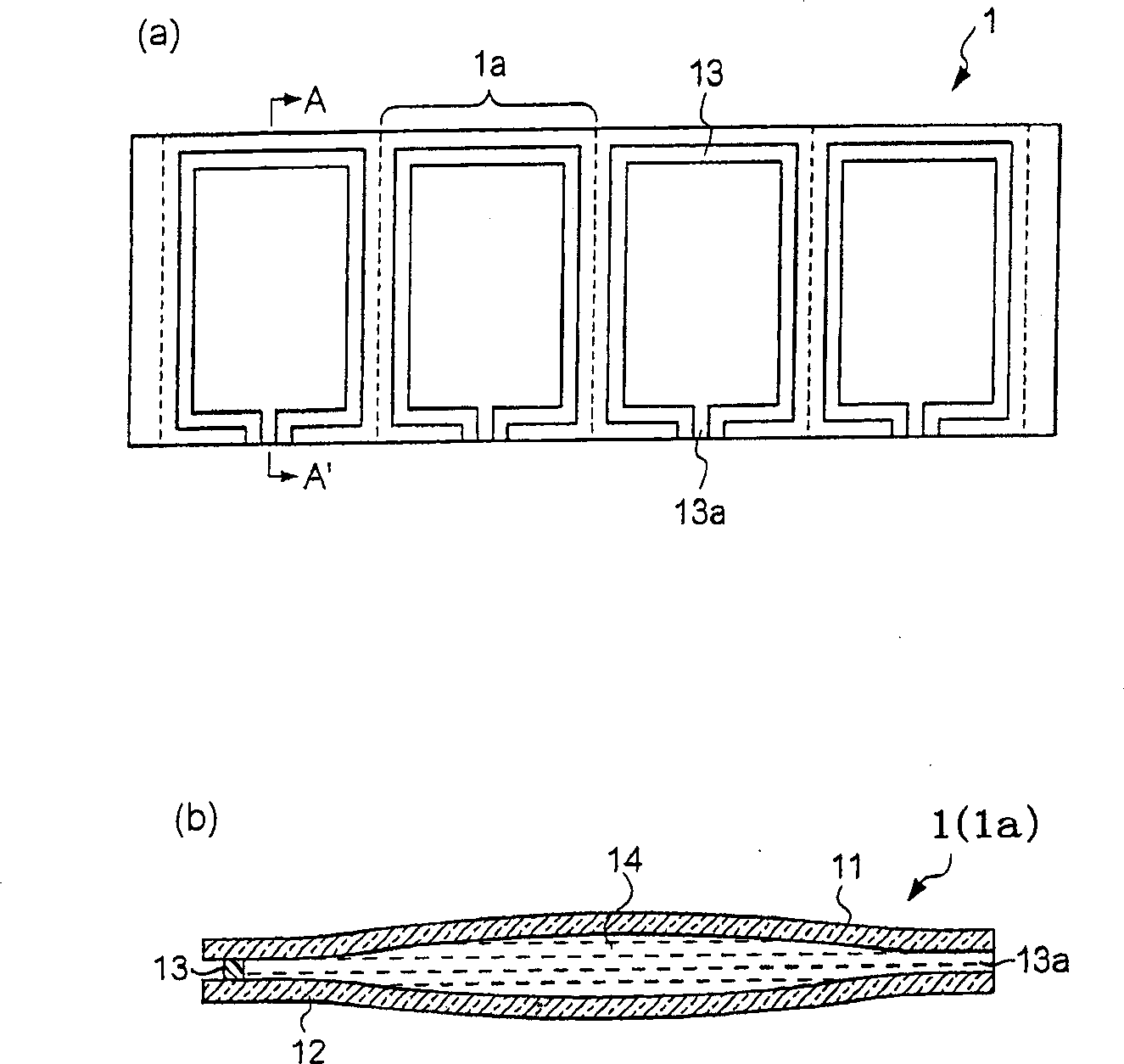

[0103] Figure 9 (a) shows that in this modified example, the liquid crystal cell group 1 and the seal for sealing when the liquid crystal cell group 1 is supported in the liquid crystal cell gap adjusting device 2 are viewed from a direction perpendicular to the substrate surface of the liquid crystal cell group 1. A plan view of the positional relationship of piece 32. in addition, Figure 9 (b) is Figure 9 Enlarged view of region C surrounded by dashed lines in (a). like Figure 9 As shown, in this modified example, at least a part of the sealing member 32 overlaps each sealing material 13 of the liquid crystal cell group 1 when viewed from a direc...

Deformed example 3

[0110] In the above-mentioned embodiment and each modified example, although the case where the sealing member has a shape that surrounds most of the substrate area of the liquid crystal cell group is given, in the case of adopting a shape that surrounds a part of the substrate area of the liquid crystal cell group In the case of the sealing member, a general-purpose sealing member (that is, a general-purpose liquid crystal cell gap adjustment device) can be used to process various groups of liquid crystal cells having different substrate sizes. In addition, in the following specific description about the above, in the case of processing various types of liquid crystal cell groups 1 having different sizes of substrates, the liquid crystal cell group 1 with the largest substrate area is referred to as "liquid crystal cell group 1". 1A", and the liquid crystal cell group 1 with the smallest substrate area is referred to as "liquid crystal cell group 1B".

[0111] like Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com