Closure body for beverage container

A beverage container and container body technology, applied to drinking vessels, non-detachable lids/covers, packaging, etc., can solve the problems of unable to close the lid, unable to block the air hole, etc., and achieve the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

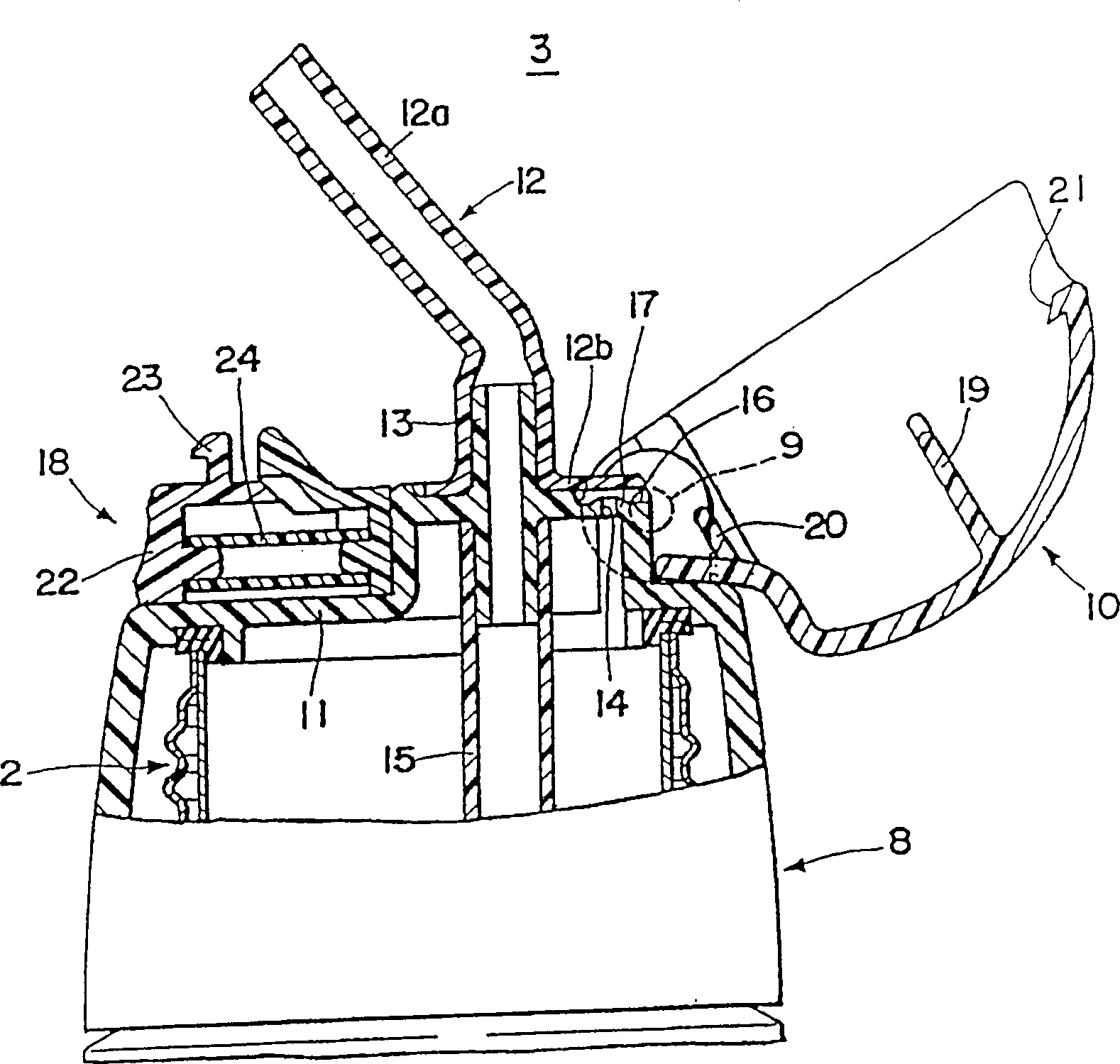

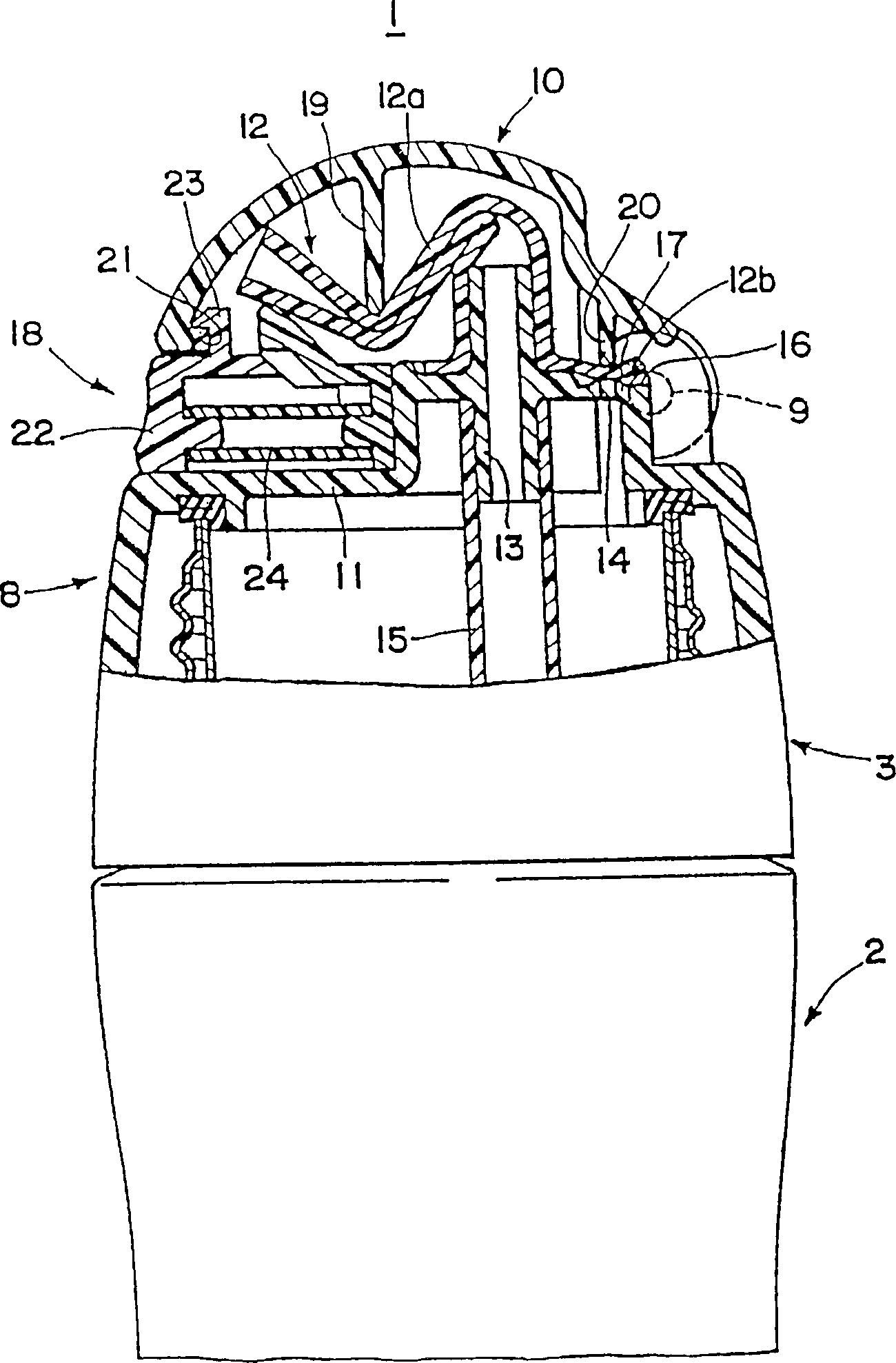

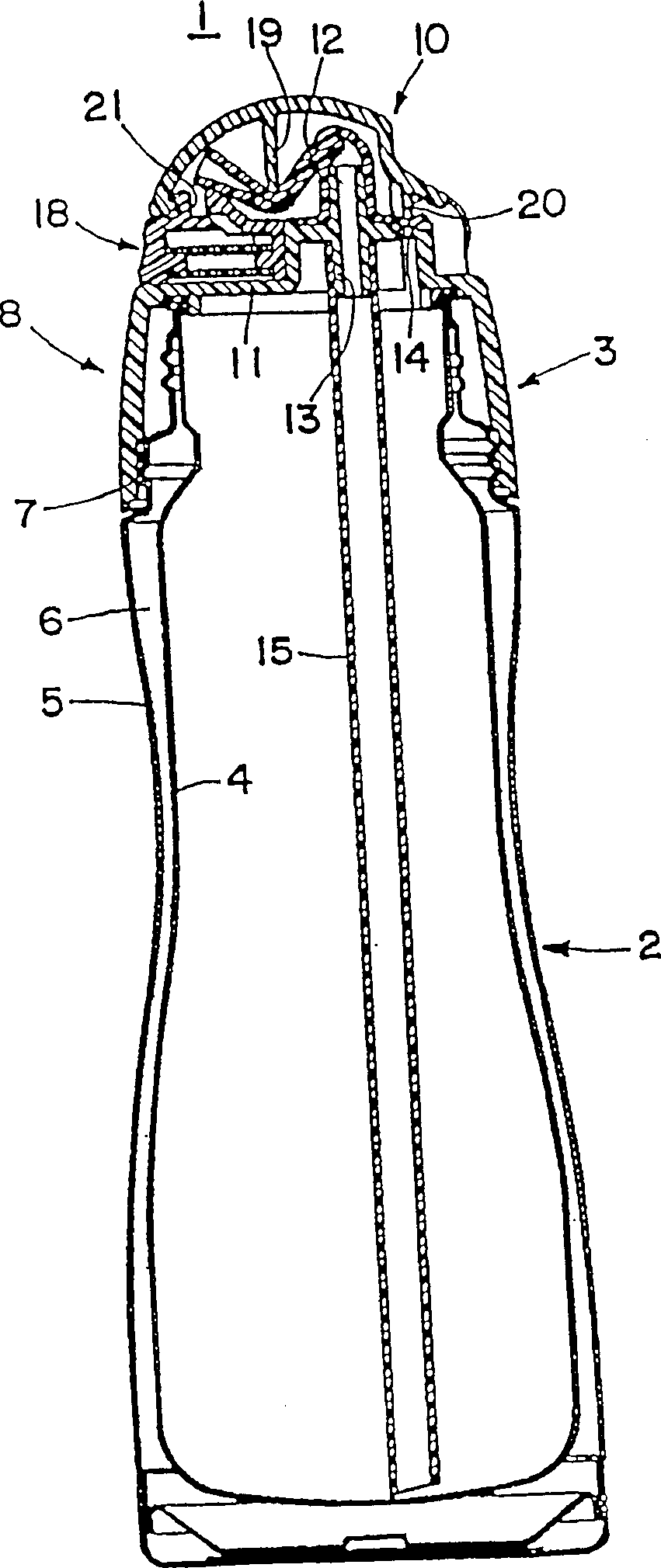

[0016] The present invention adopts the thermos bottle plug as a preferred embodiment, and its accompanying drawings are described in detail. Figure 1 to Figure 4 What is shown is the first preferred embodiment of the present invention. The beverage container 1 is composed of a container body 2 with a thermal insulation structure and a detachable plug body 3 installed on the upper part of the container body 2 . The container body 2 is formed by integrally joining the upper ends of the metal inner container 4 with an opening at the upper end and the upper end of the outer container 5, and has a heat insulating part 6 of a vacuum insulation structure between the two containers 4, 5, and only needs to be kept The inner diameters of the upper and lower parts of the main body can be easily deformed at the minimum inner diameter.

[0017] The plug body 3 has a cap body 8 that can be freely rotatably attached to and detached from the shoulder threaded portion 7 of the container body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com