System and method for flushing and processing photographic material including recovery of washing water

A photographic material and water washing technology, which is applied in the direction of photosensitive materials, processing equipment, liquid processing equipment, etc., can solve the problems of reducing volume and weight, and achieve the effect of reducing waste and rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0107] This is an embodiment of the present invention.

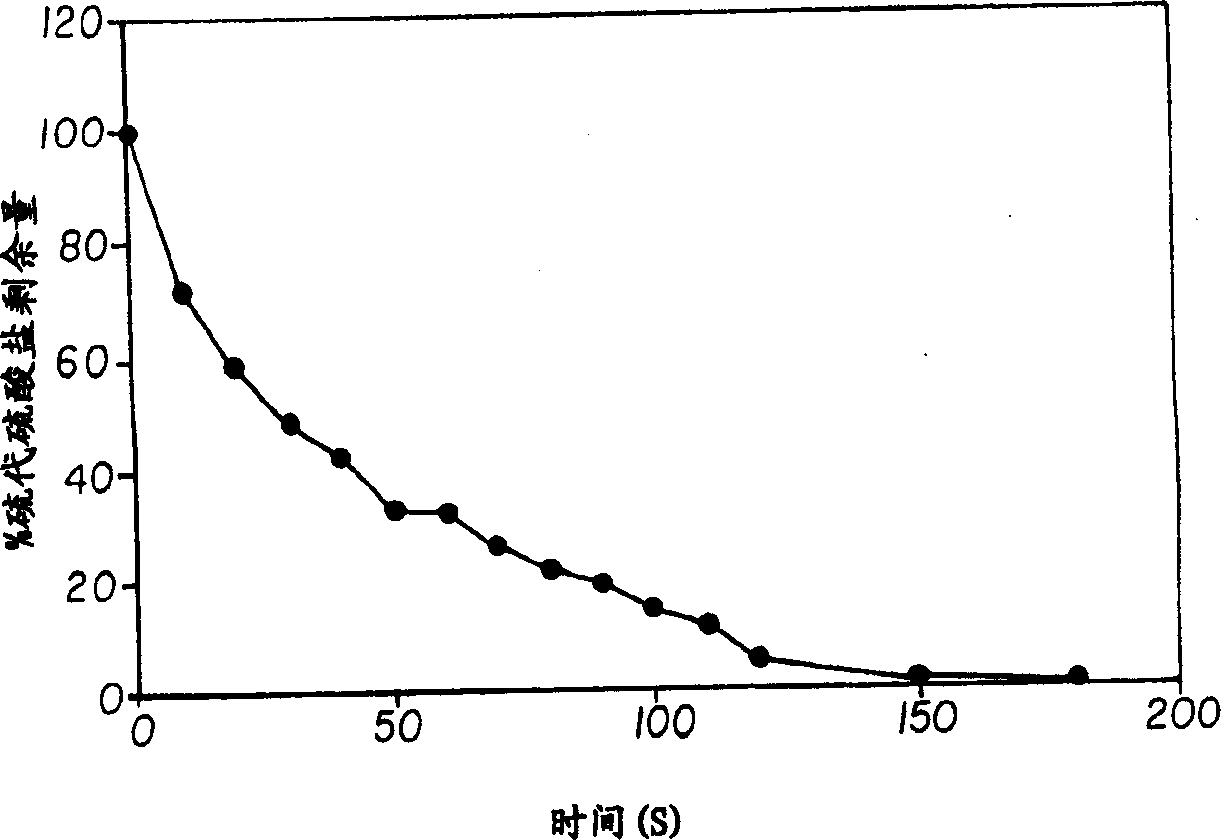

[0108] In this example, a portion of the water used in the water wash stage is recovered by ion exchange. The residual amount of ammonium thiosulfate in the 3.28 ml / length meter of fixer in the film and processing chamber is 264*1 / 1000*3.28=0.866 grams / length meter. While it is possible to remove it all by ion exchange, large quantities of ion exchange resin are required. A more economical utilization of the ion exchange resin is possible if a first water washing stage is performed and the water of this stage is drained off. Use the flushing cycle indicated in Table (8). The developing solution, bleaching solution and fixing solution are the same as in Example 1 above.

[0109] Table (8) Flushing cycle (B)

[0110] Develop 30 seconds 19.7ml / length meter 35mm film

[0111] Stop display for 10 seconds 13.1ml / length meter

[0112] remove liquid

[0113] Bleach 30 seconds 19.7ml / length meter

[0114] remove liquid

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com