Detection system of sheet glass for making display

A technology for inspection systems, flat glass, used in the field of inspection systems to solve problems such as soiling surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

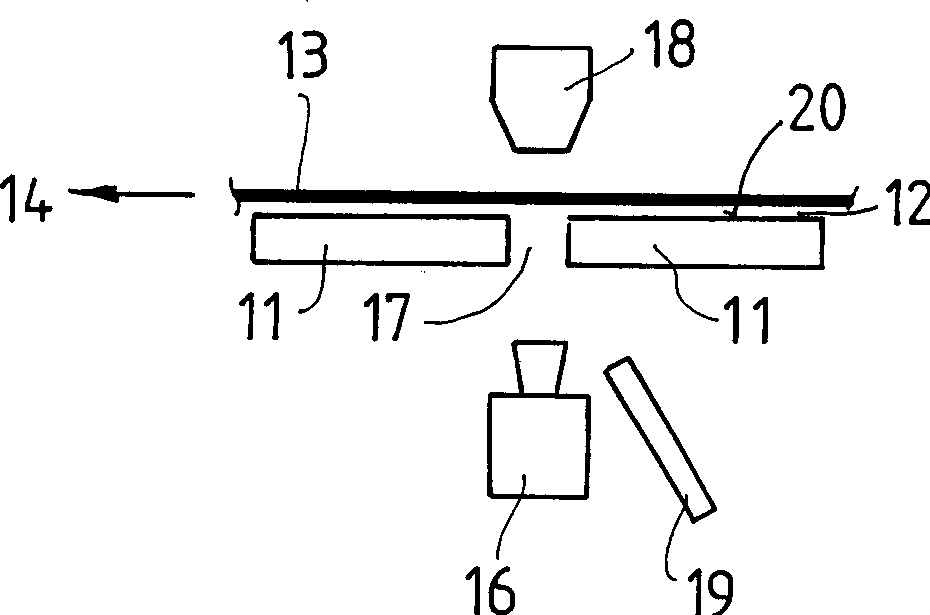

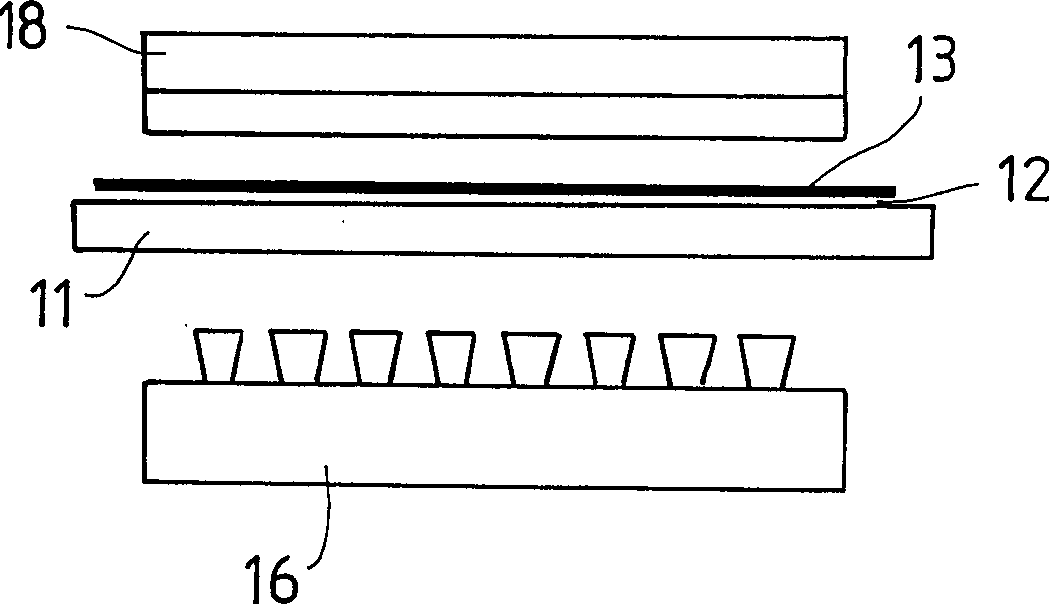

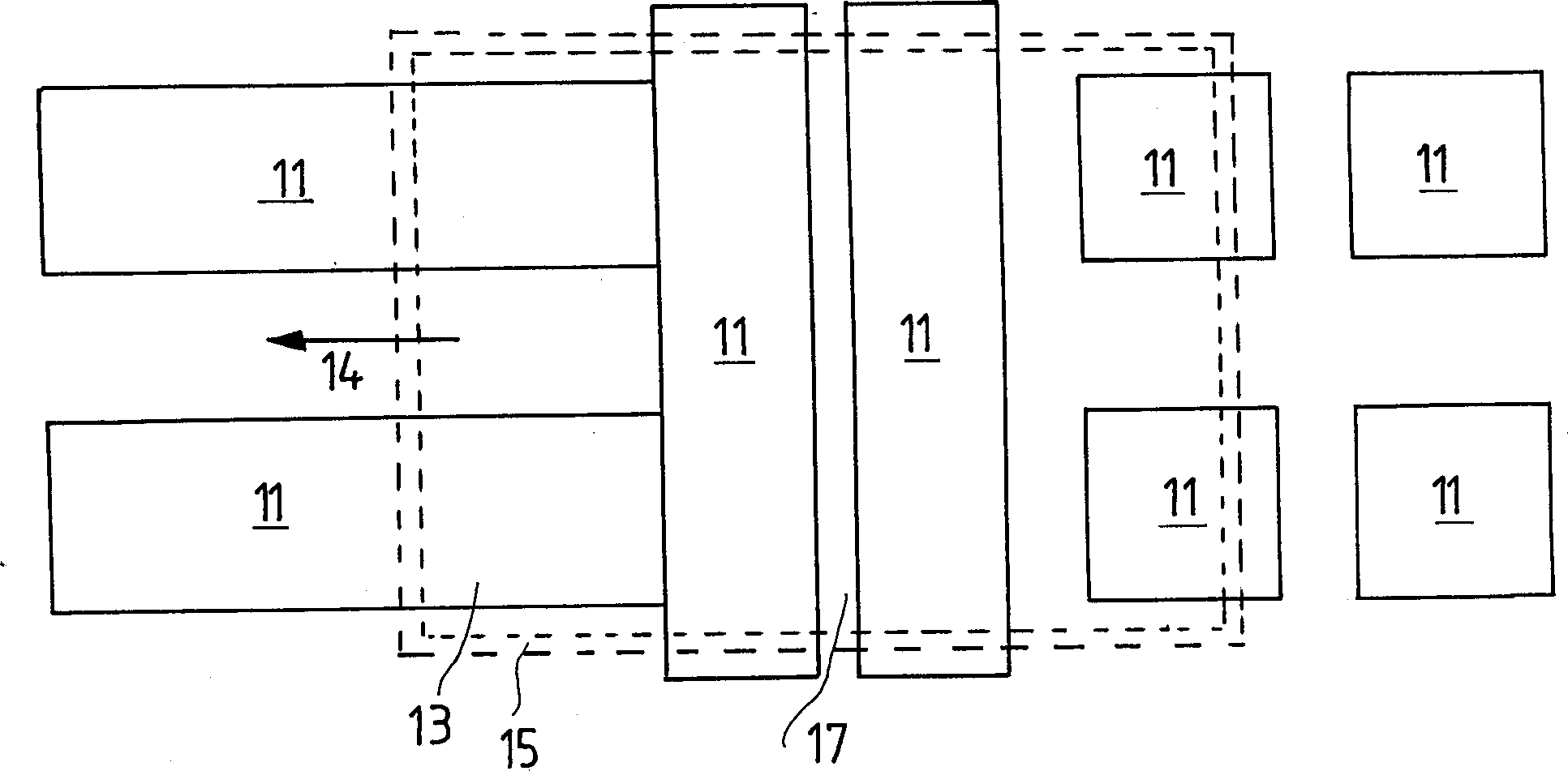

[0024] The inspection system shown in the figure has a plurality of plates 11 which can be fed with compressed air from their rear sides. In order to make the figure clear, half of the required air compressor and the casing for distributing the compressed air behind the panel and the pipelines for conveying the compressed air are not shown. Plate 11 is made of a porous sintered metal material. Air is thereby allowed to pass through the gaps in order to form the supporting air cushion 12 against or above the surface 20 of the object under examination.

[0025] The air cushion formed serves to support the flat glass 13 as it is moved past the scanning device by a not shown conveyor. The conveying movement takes place linearly in the direction of the arrow 14 . The board and air cushion are in such a position that they are arranged at an angle of 0° or inclined to almost vertical orientation. Here, the transfer device rests against the operating edge 15 of the plate glass.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com