Method and equipment for reducing water evaporation

A technology for evaporating water and water consumption, which is applied in the field of recovering distilled water or other water vapor, which can solve the problems of reducing evaporative water and evaporative water loss, and achieve the effect of reducing water consumption and saving evaporative water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

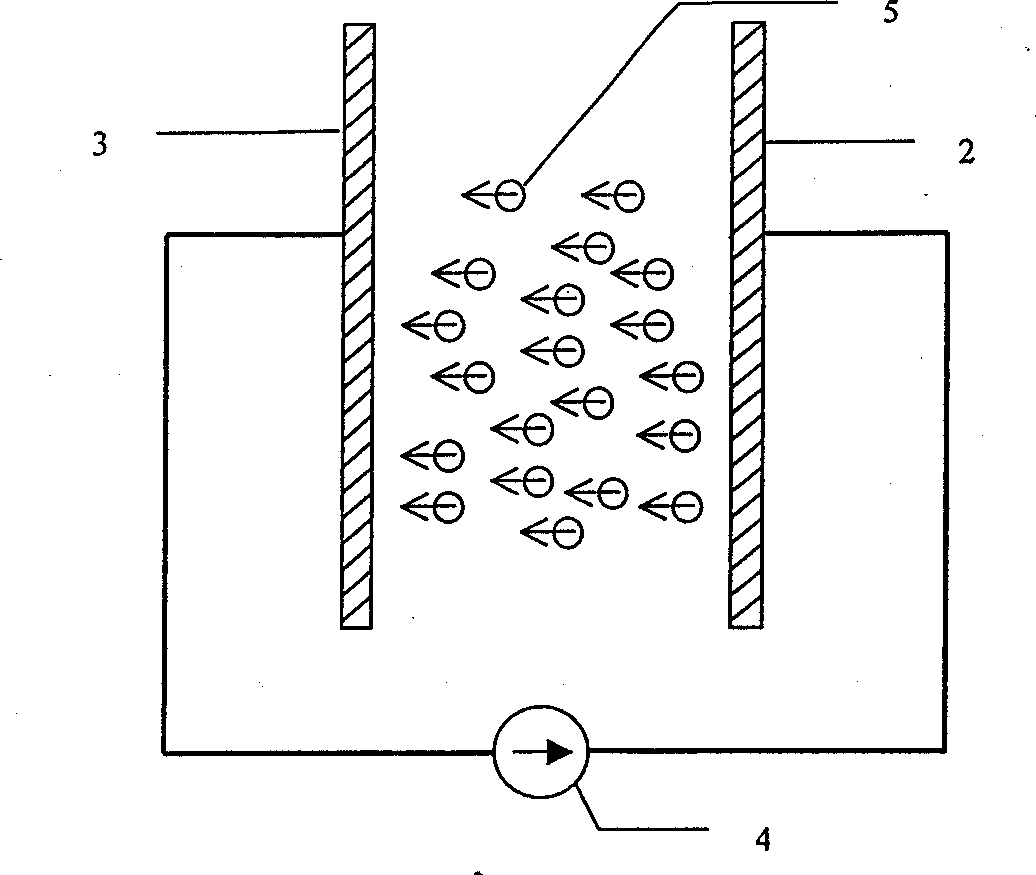

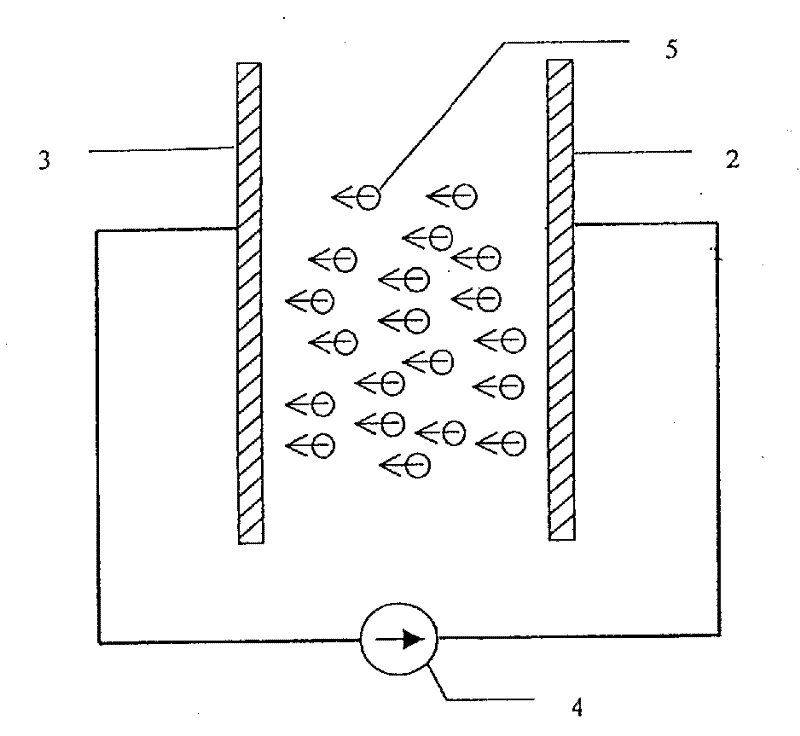

[0010] like figure 1 As shown, the principle of the present invention is: the evaporated water mist 5 is composed of countless tiny water droplets. When these tiny water particles pass through a high-voltage electric field, they are charged and become charged water particles. Under the action of the electric field, the charged micro-water particles move to the opposite electrode and finally reach the opposite electrode. When the positively charged micro-water particles reach the electrode to a certain concentration, a water film is formed until it starts to flow, which can be recovered by containers or pipes. These are the water on the electrodes. The high-voltage power supply can be a high-voltage DC power supply or a low-frequency high-voltage AC power supply. The electrodes can be designed into arbitrary geometric shapes according to the structural characteristics of the equipment.

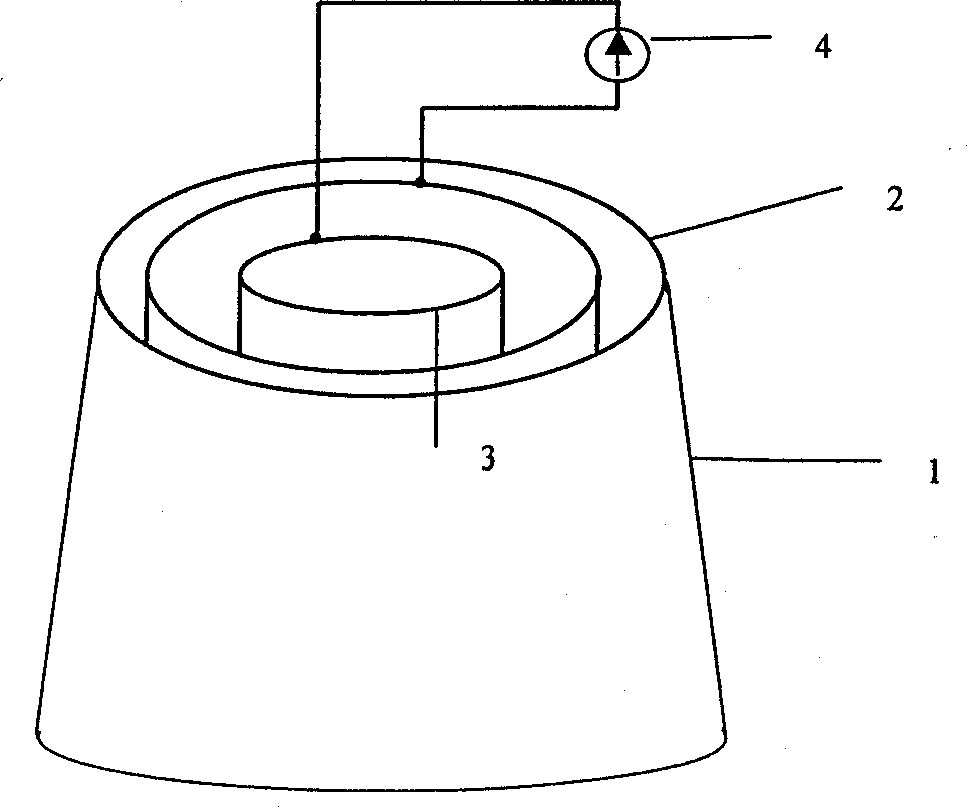

[0011] like figure 2 As shown, it is a cooling tower of a power plant, 1-cooling tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com