Non-return valve

一种单向阀、阀体的技术,应用在隔膜阀、控制阀、阀装置等方向,能够解决易于出现故障、成本高、阀门工作复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

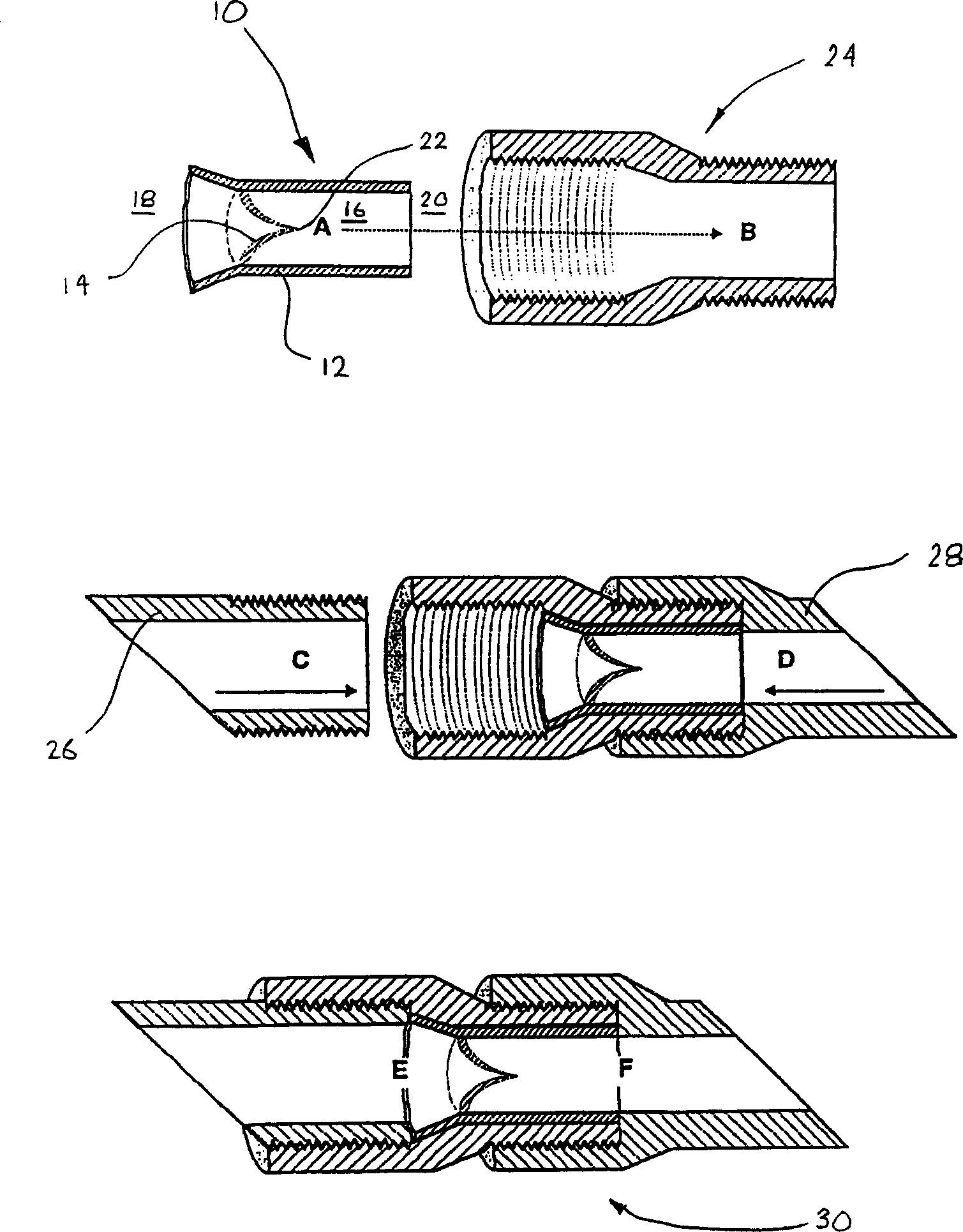

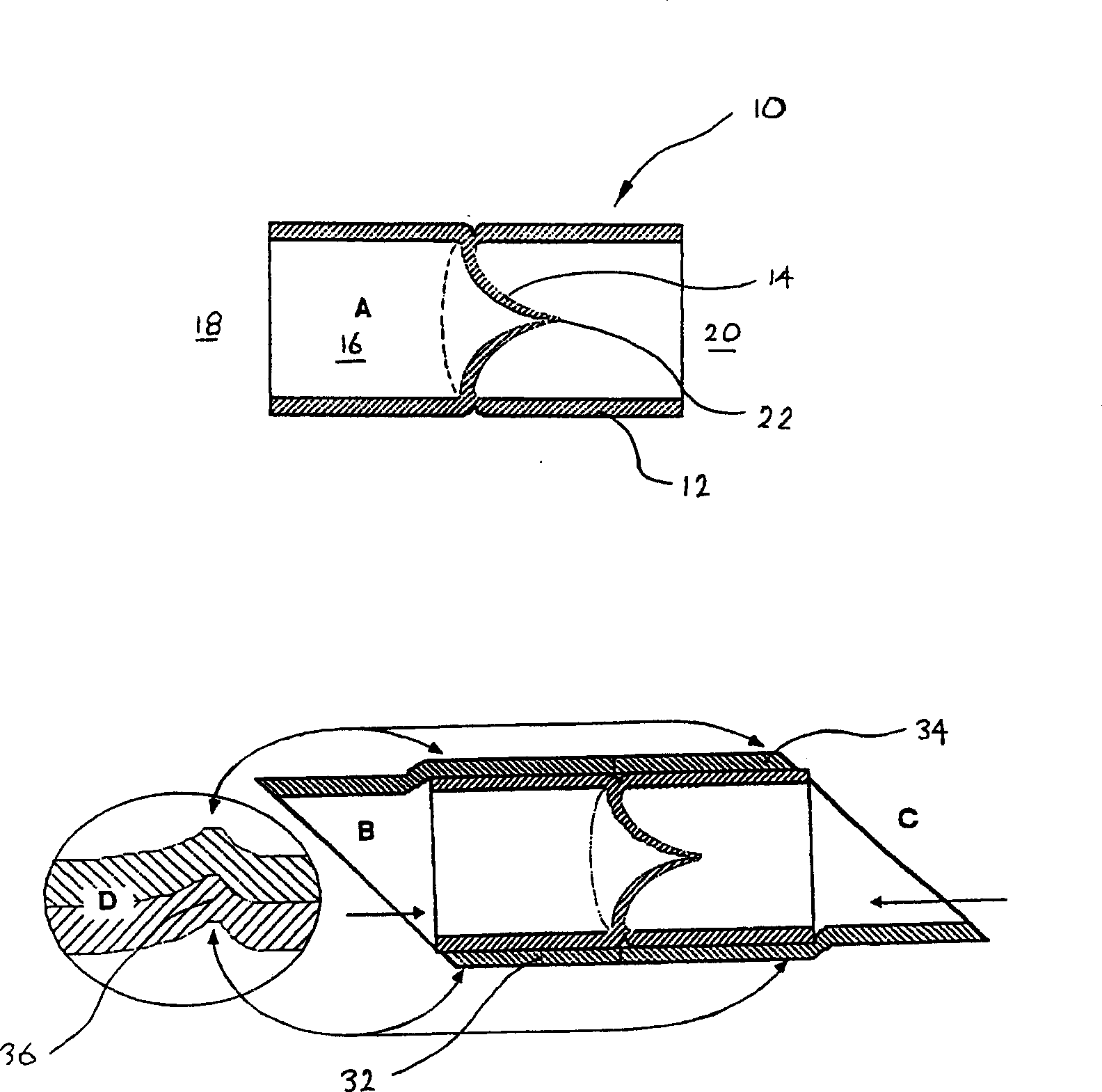

[0045] Such as Figures 2 to 5 As shown, various embodiments of a one-way valve, generally indicated at 10, constructed in accordance with an aspect of the present invention are shown. For ease of reference and to avoid repetition, similar elements are identified with the same reference numerals.

[0046] In each example, the one-way valve 10 includes a valve body 12 and a valve membrane 14 . Valve body 12 is generally tubular and includes an elongated passage 16 defining an inlet and an outlet at opposite ends 18 and 20 thereof, respectively.

[0047] The one-way valve 10 of these embodiments is molded from a polymeric material, preferably an elastomer such as rubber or a nylon-based material. Selection of suitable materials for valve 10 will be apparent to those skilled in the art without trial and experiment. The valve membrane 14 is a conical membrane formed integrally with the tubular valve body 12 . Diaphragm 14 is configured as a generally conical member having a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com