Steel bar splicing device implantation welding construction method

A technology of connectors and construction methods, which is applied in the direction of manufacturing tools, welding equipment, workpiece edges, etc., can solve problems such as insufficient bonding strength, time and manpower consumption, and difficulty in bearing stress, so as to shorten construction time, save manpower, and The effect of high quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

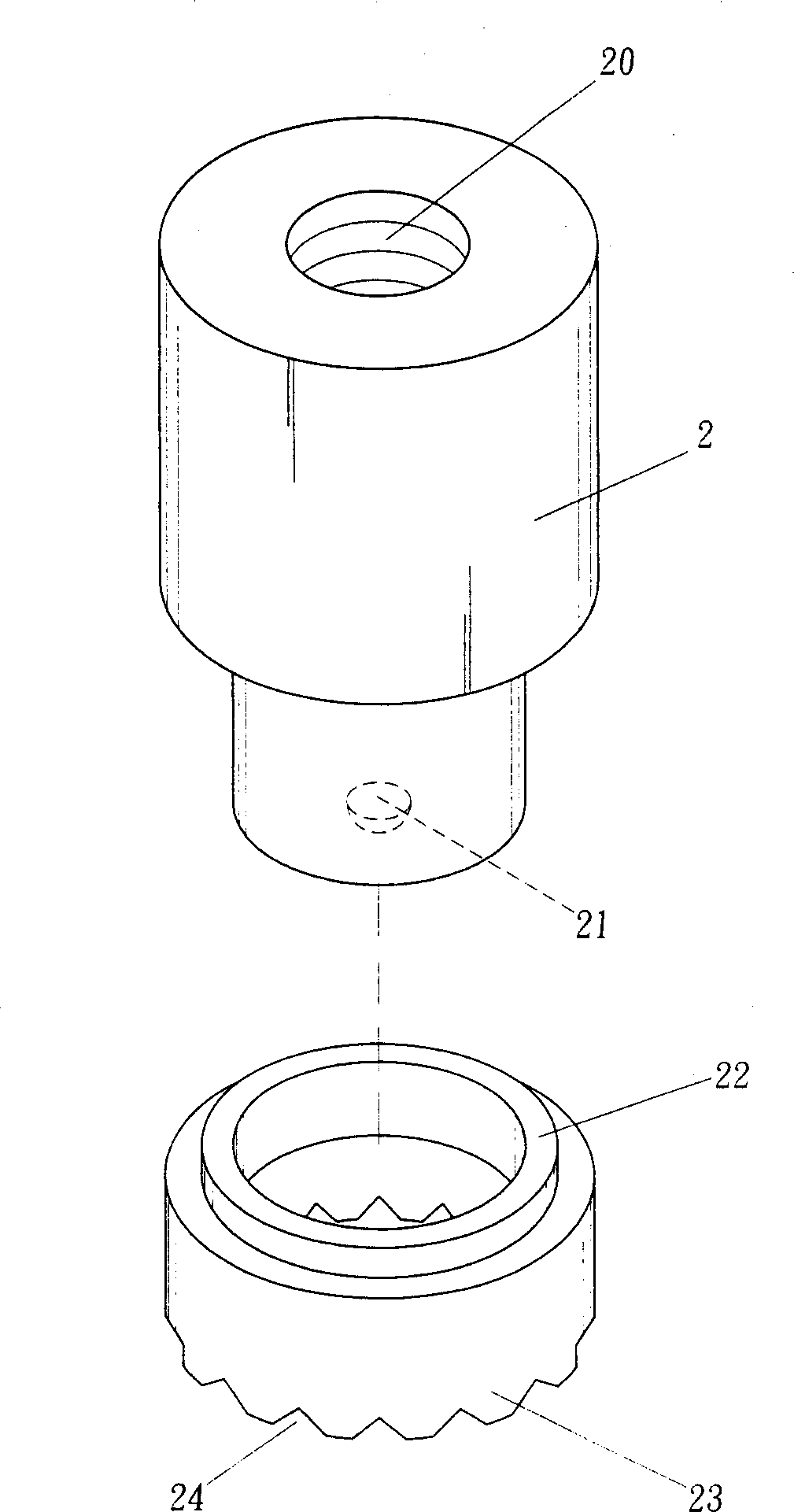

[0015] refer to image 3 , 4 As shown, the present invention is mainly provided with a screw hole 20 at the top of the steel bar connector 2, and a bead-shaped welding particle 21 is implanted at the bottom thereof, and the welding particle 21 is made of aluminum alloy, and then A protective ring 22 is inserted outside the steel bar connector 2. The protective ring 22 is made of materials such as high-temperature-resistant ceramics. A protective body 23 is arranged around the protective ring 22. Several wave-shaped Air vent 24.

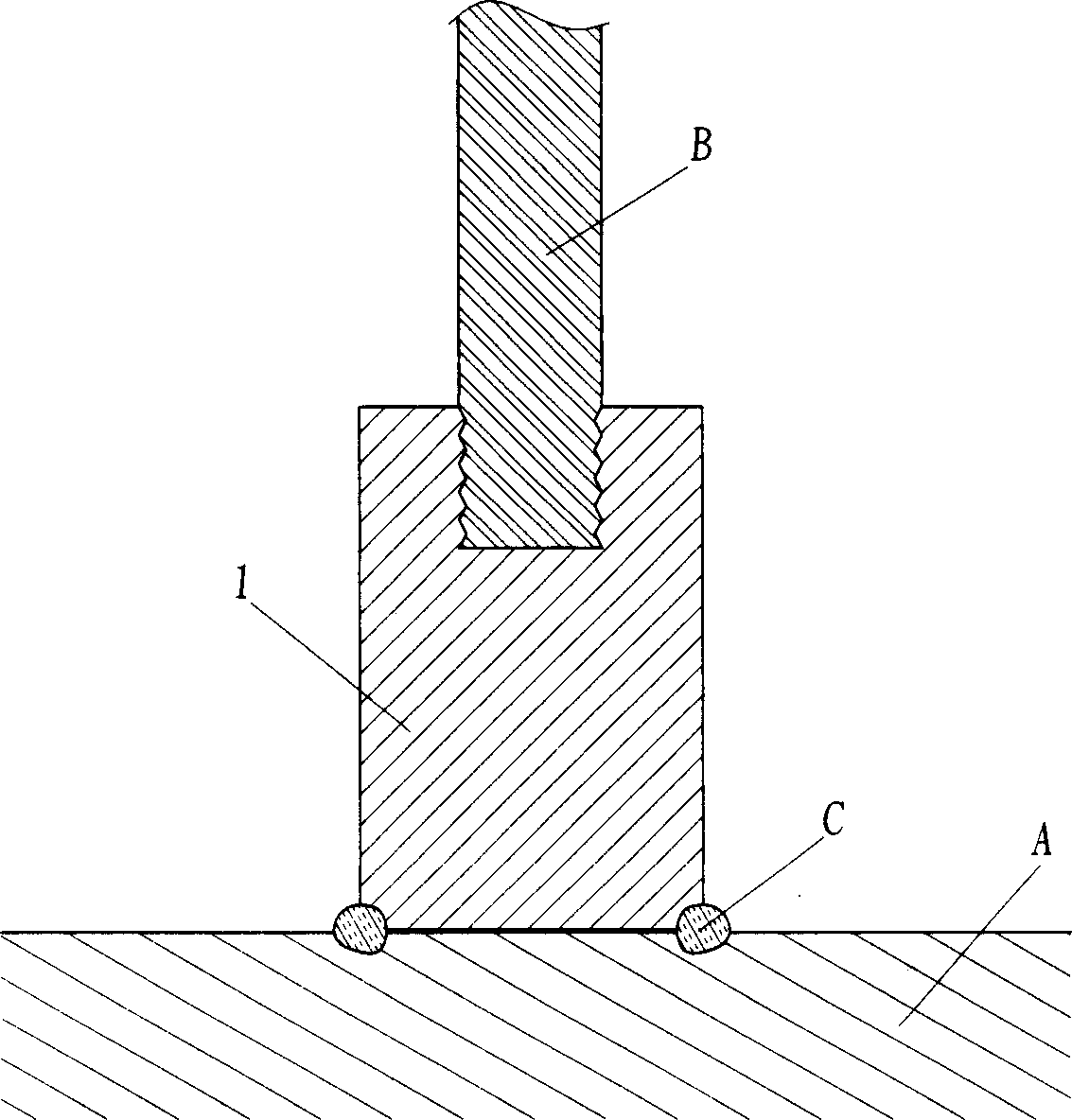

[0016] During construction, when the reinforcement connector 2 needs to be vertically welded to the steel structure A, the reinforcement connector 2 can be placed on the surface of the steel structure A, and then the protective ring 22 can be put on. Then, with the welding machine, the bottom of the steel bar connector 2 and the welding particles 21 are melted to form iron slurry by means of high-current instantaneous discharge. The iron slurry prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com