Three-phase induction motor and its speed regulating method

A technology of induction motor and speed regulation method, which is applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve problems such as cost increase, harmonic pollution, influence of three-phase induction motors, etc., and achieves low cost, high reliability, The effect of increasing the number of speed control stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

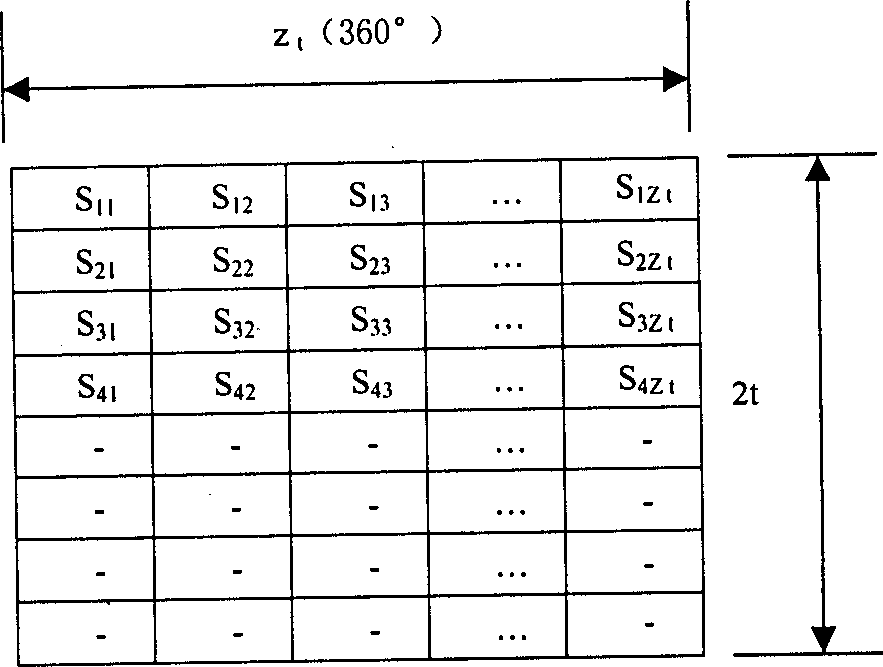

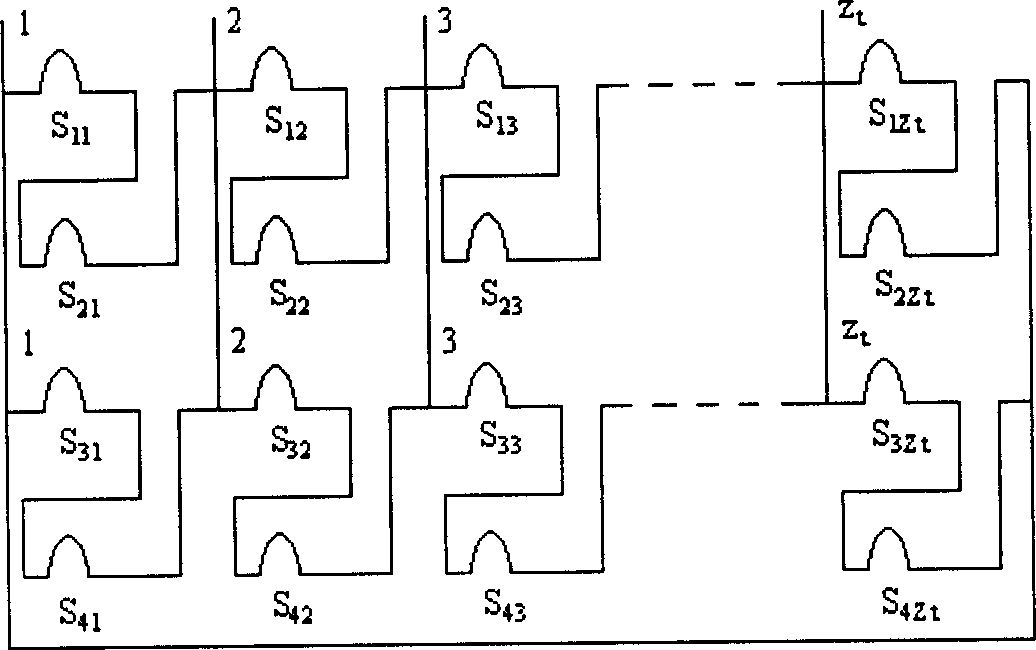

[0054] Embodiment 1 t Embodiment when it is an even number (take the stator 36-slot 4-pole three-phase induction motor as an example)

[0055] 1. The structure, phase belt, connection method and number of outgoing wires of the stator winding

[0056] (1) The structure, phase belt, connection method and number of outgoing wires of the phase-fixed winding

[0057] The phase-fixed winding adopts a double-layer stacked winding structure, and the pitch is y 1= 8 slot distances, 60° phase belt, triangle connection (i.e. Δ connection), one outgoing line for each phase, a total of three outgoing lines. The specific design of the phasing winding is the same as that of the ordinary single-speed three-phase induction motor stator winding design, which is omitted here.

[0058] (2) The structure, phase belt, connection method and number of outgoing wires of the moving phase winding

[0059] The moving phase winding adopts a double-layer stacked winding structure, and the pitch is y 1...

Embodiment 2

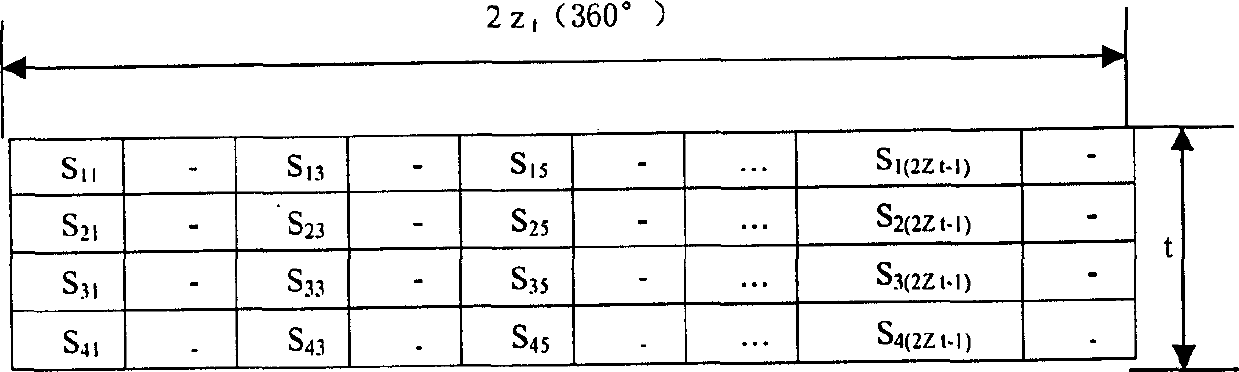

[0068] Embodiment two z t Embodiment when it is an odd number (take the stator 36-slot 8-pole three-phase induction motor as an example)

[0069] 1. The structure, phase belt, connection method and number of outgoing wires of the stator winding

[0070] (1) The structure, phase belt, connection method and number of outgoing wires of the phase-fixed winding

[0071] The phase-fixed winding adopts a double-layer stacked winding structure, and the pitch is y 1 = 4 slot distances, 60° phase belt, triangle connection (i.e. Δ connection), one outgoing line for each phase, a total of three outgoing lines. The specific design of the phasing winding is the same as that of the ordinary single-speed three-phase induction motor stator winding design, which is omitted here.

[0072] (2) The structure, phase belt, connection method and number of outgoing wires of the moving phase winding

[0073] The moving phase winding adopts a double-layer stacked winding structure, and the pitch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com