Patents

Literature

48 results about "Five phase induction motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

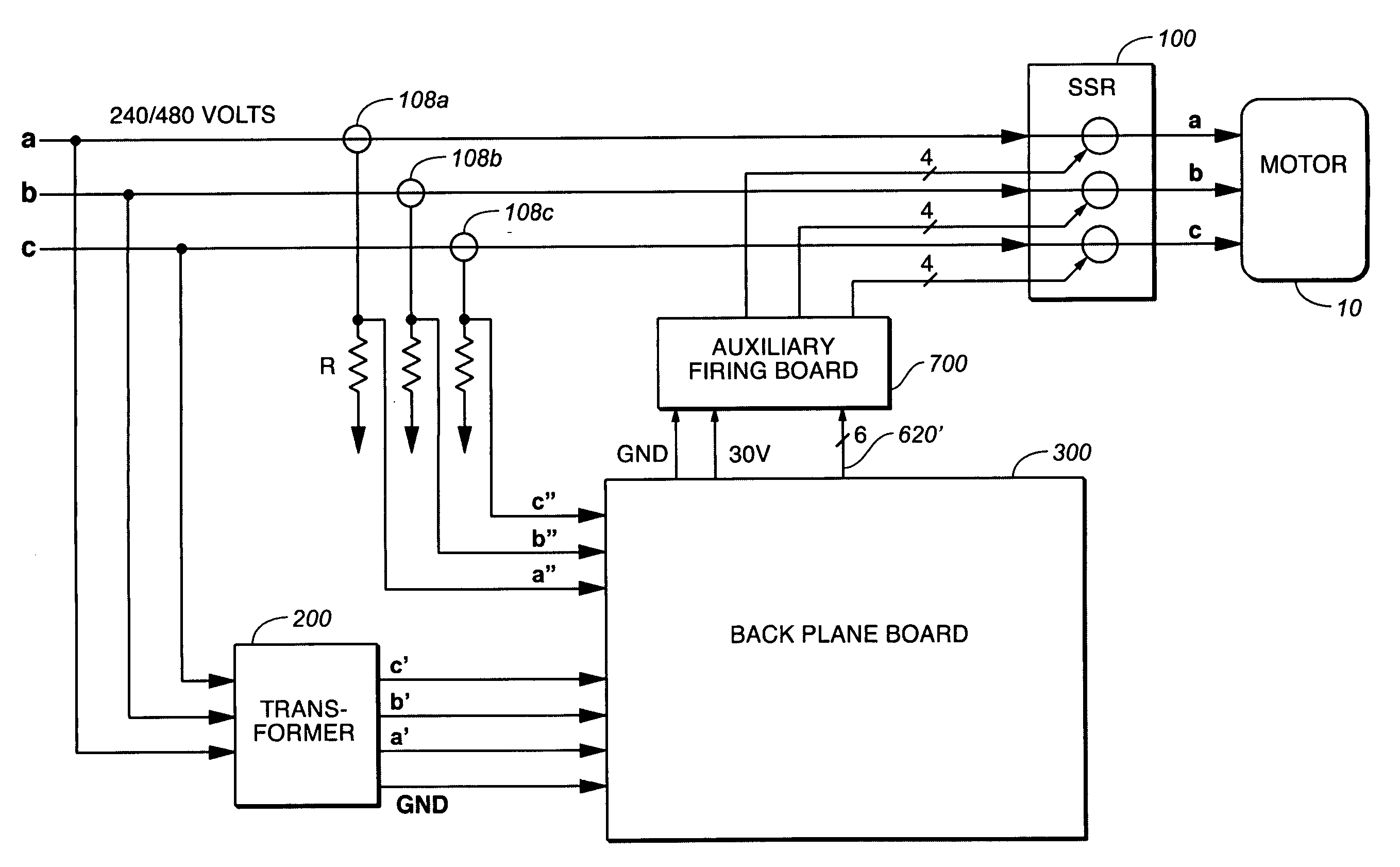

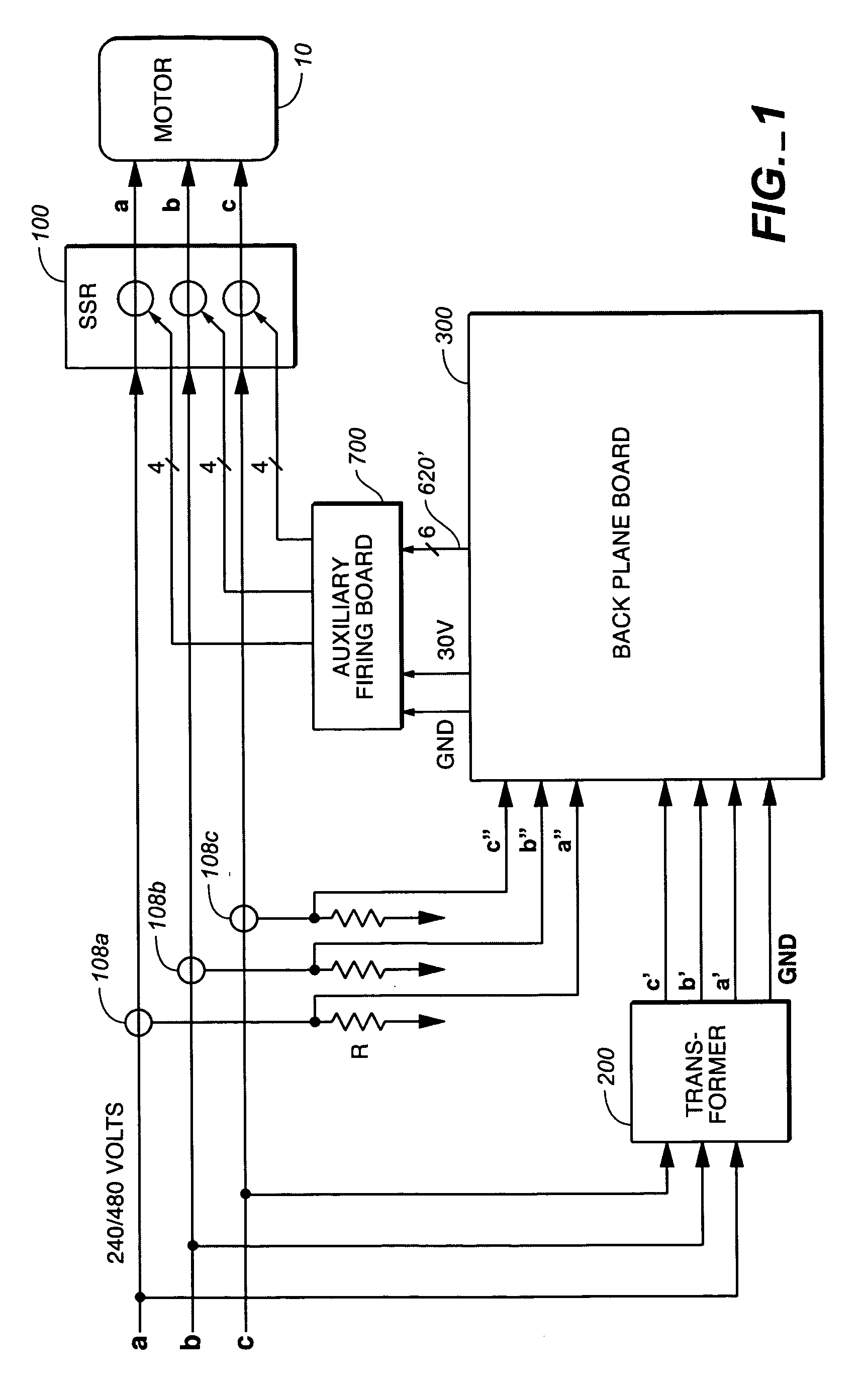

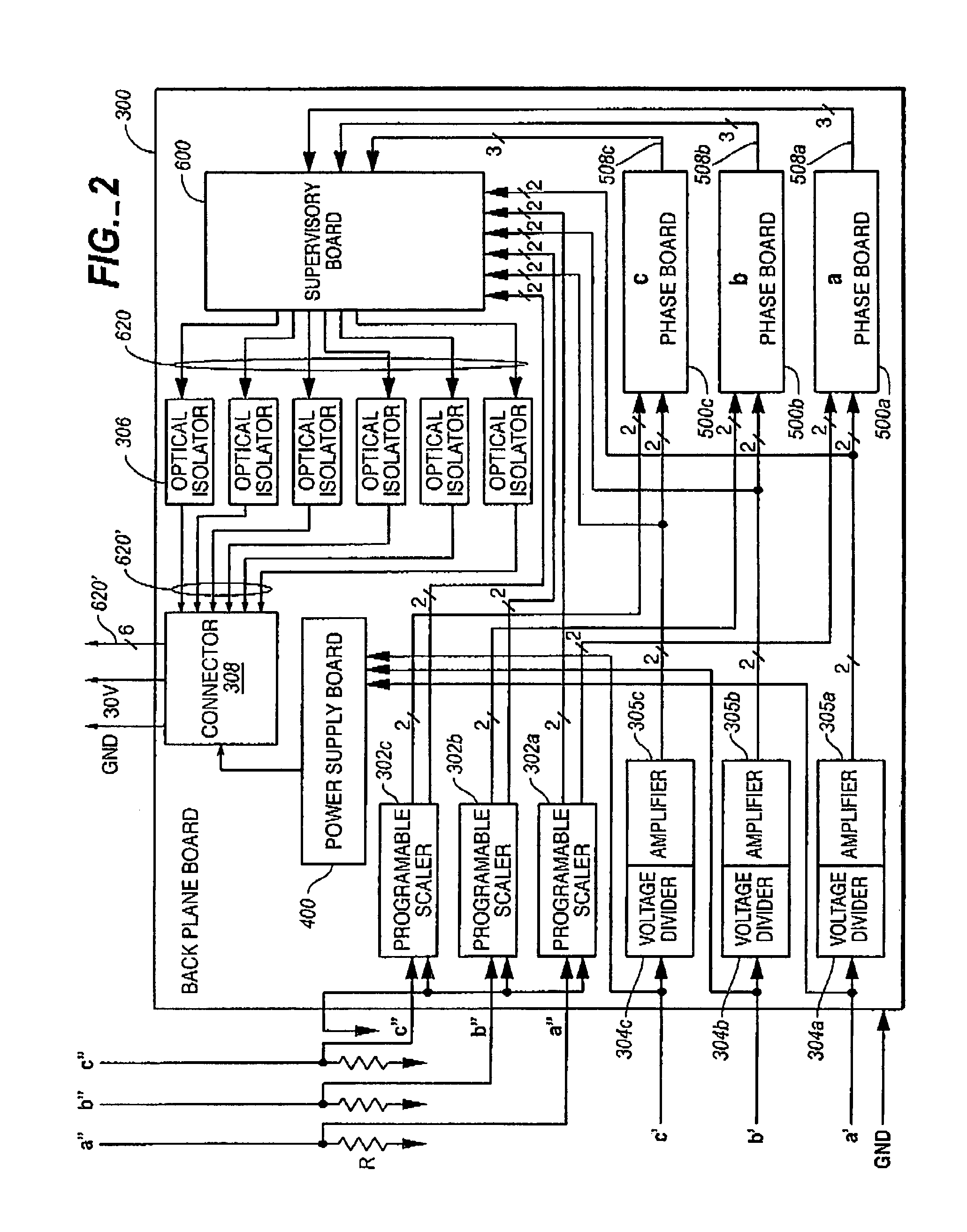

Method and apparatus using VAR measurements to control power input to a three-phase induction motor circuit

A method and apparatus are described for controlling the flow of power in each input line to a three phase AC inductive load in order to reduce the amount of VAR in the system, and thus increase the operational efficiency of the inductive load. Solid state relays are positioned in series in each of the three inductive load line inputs, and current allowed to flow to the inductive load only during the time during which the SSRs are in a conducting state. The calculation of VAR is achieved by processing data from each of the input lines using a separate controller boards each dedicated to each of the lines. The controller in turn, based on the calculated VAR, increments the time, either increasing or decreasing it from a predetermined value, during which the SSRs in that line remains in the non-conducting state.

Owner:ENVIRO WORLD SYST

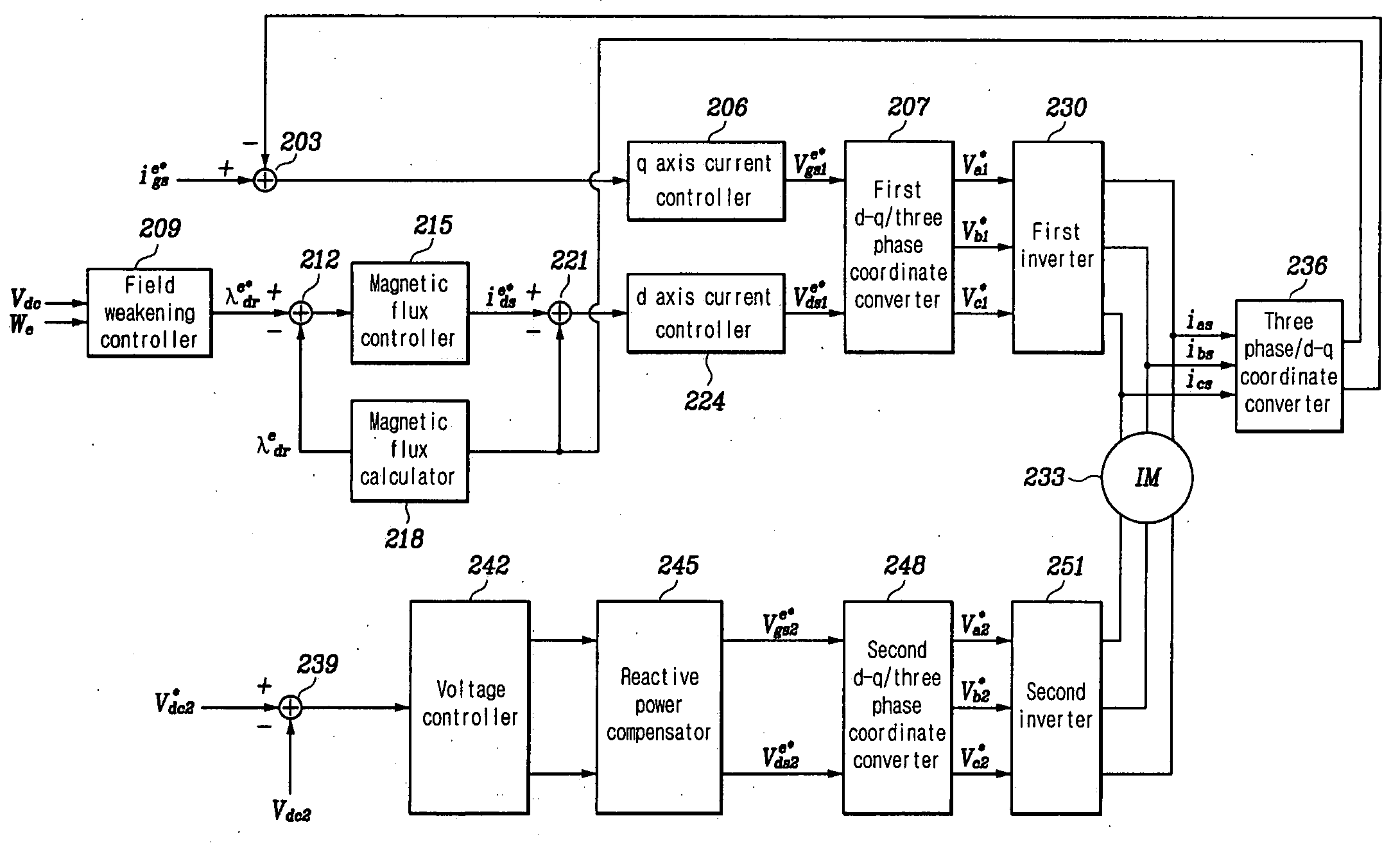

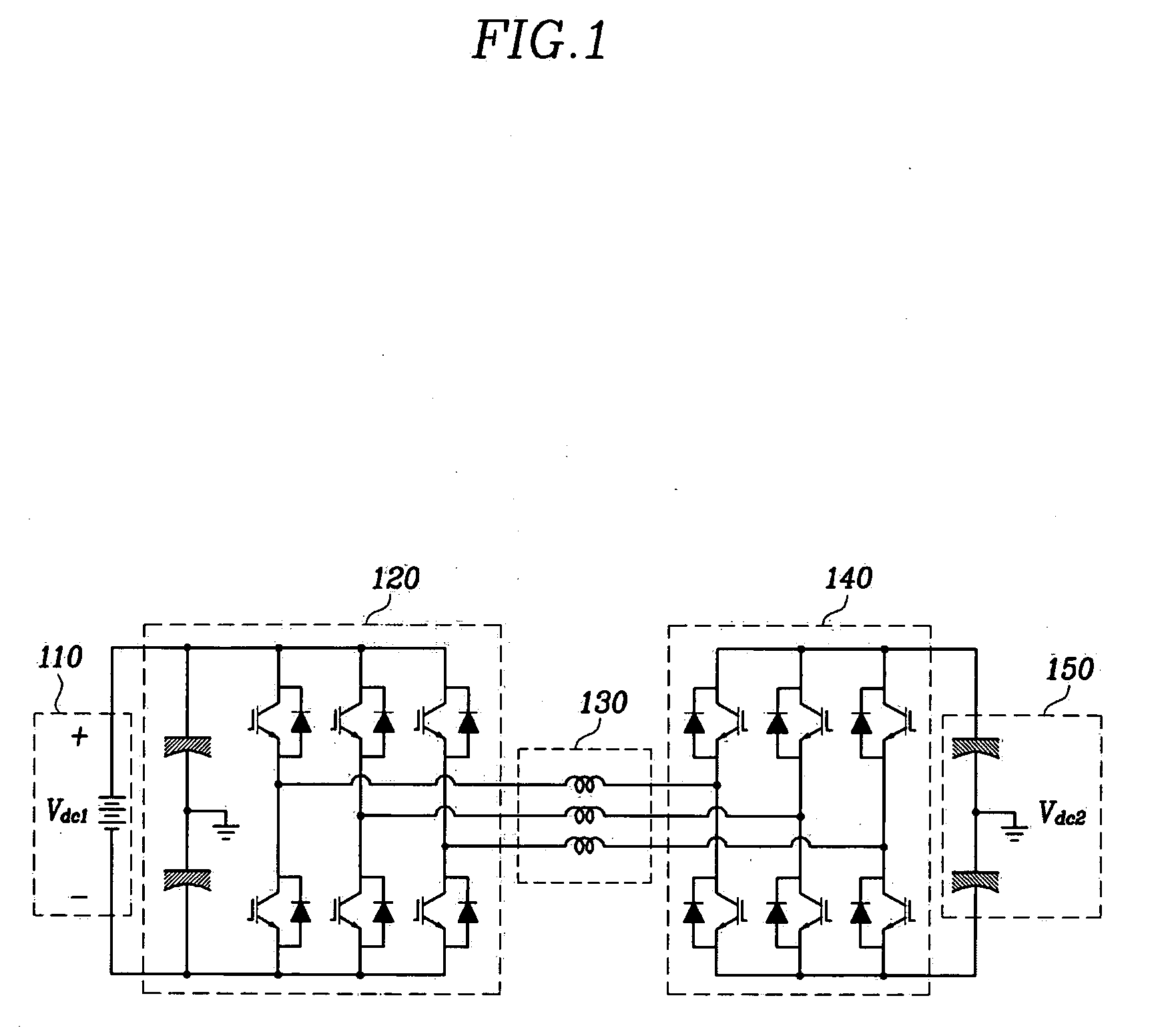

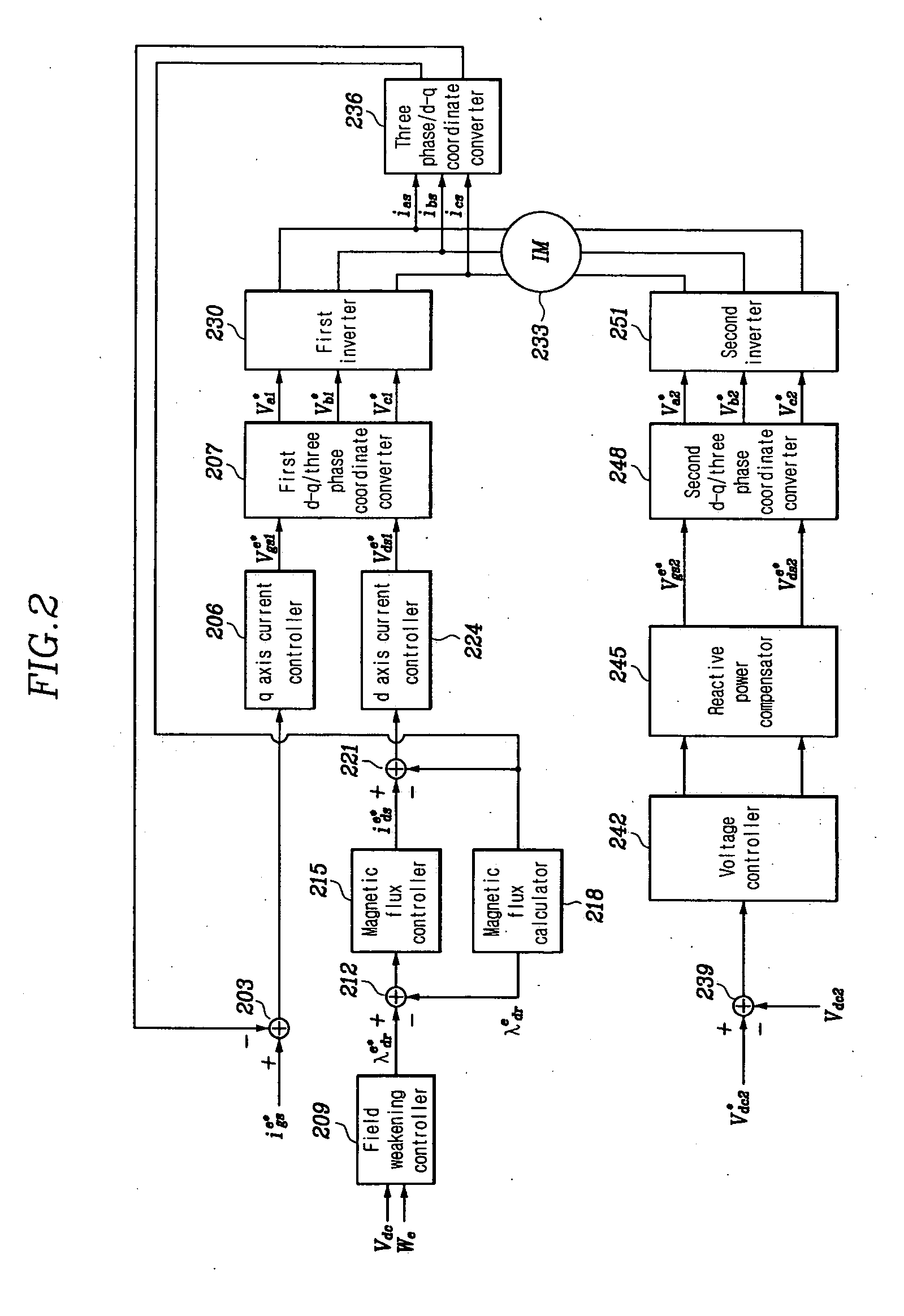

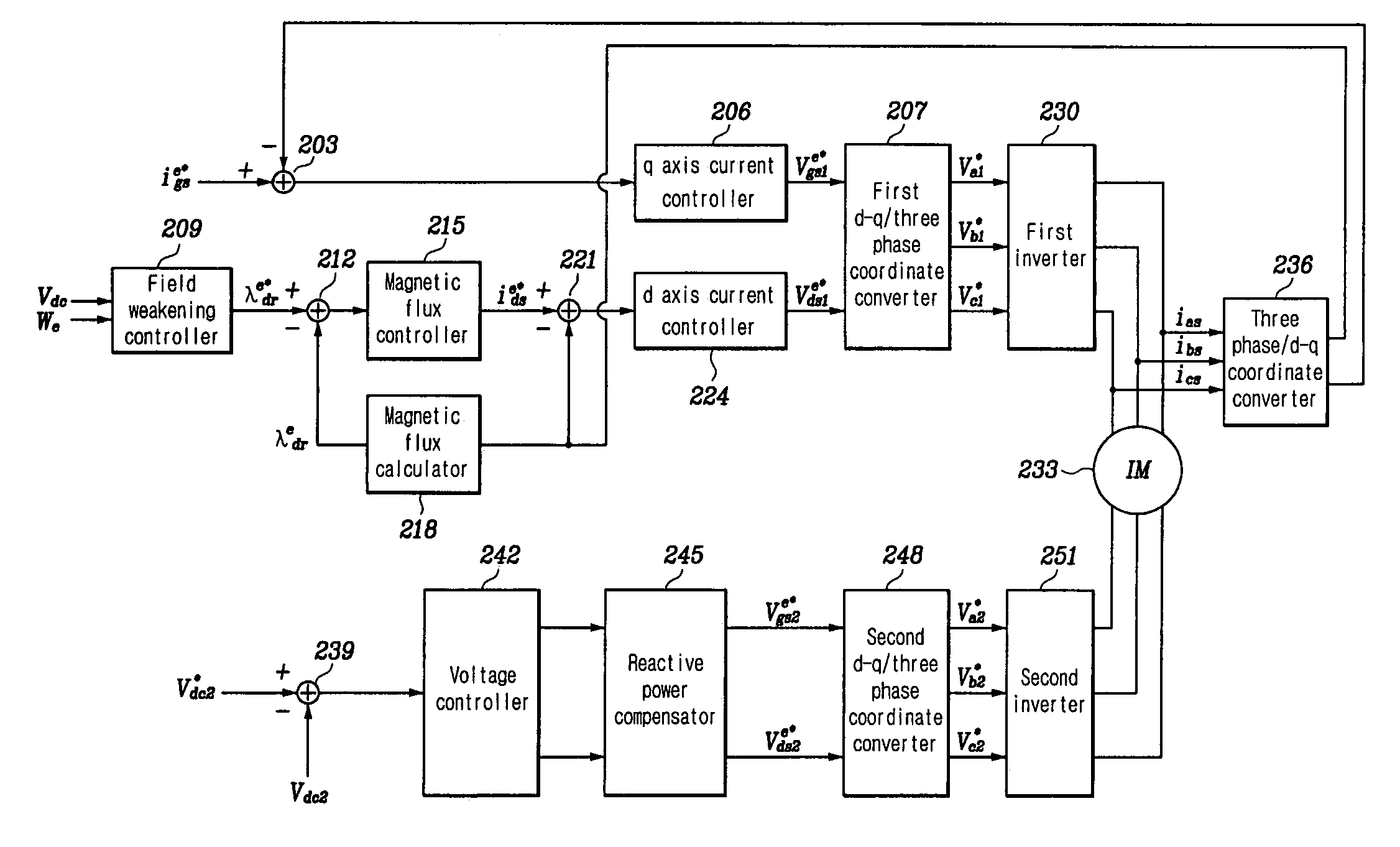

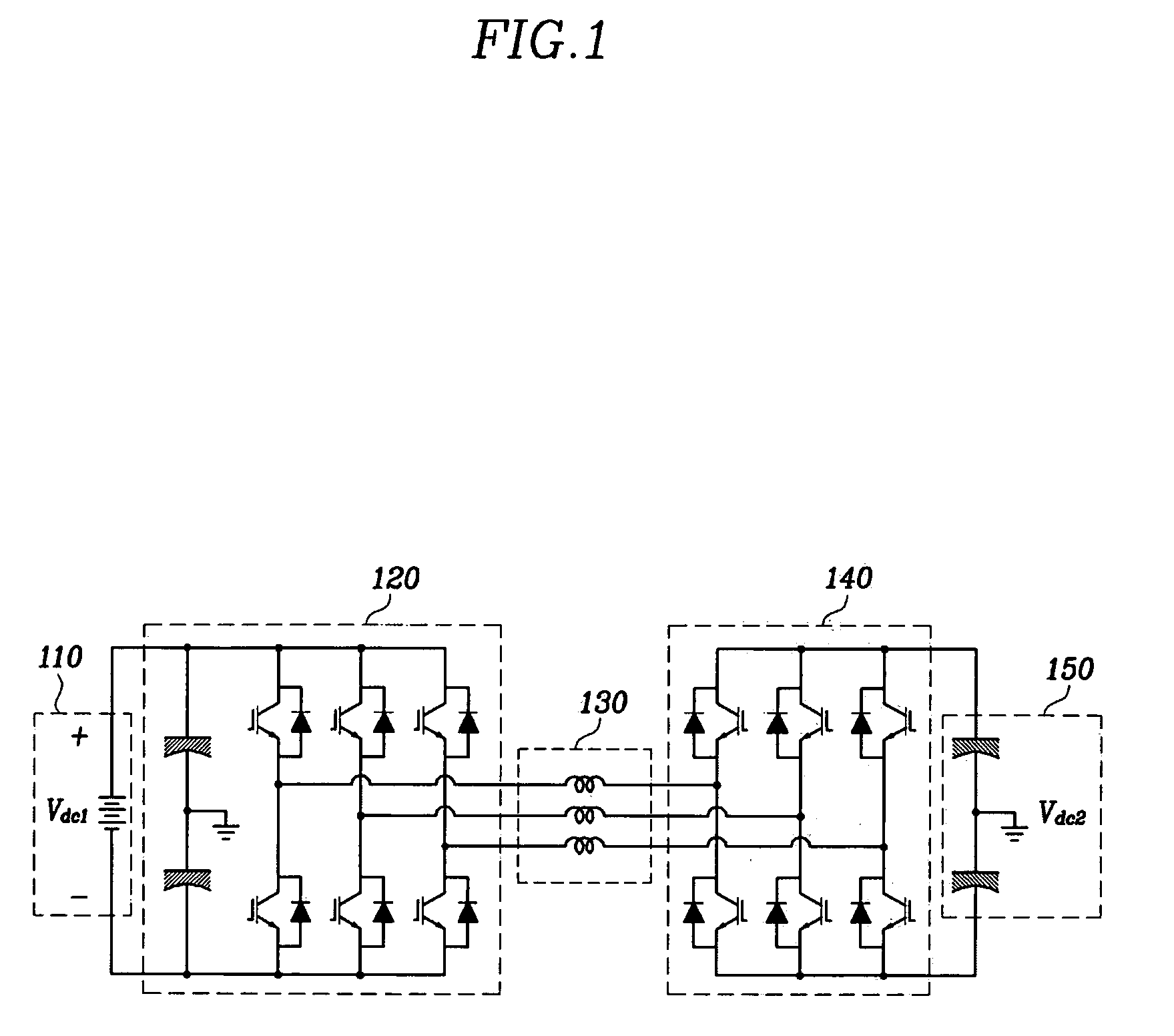

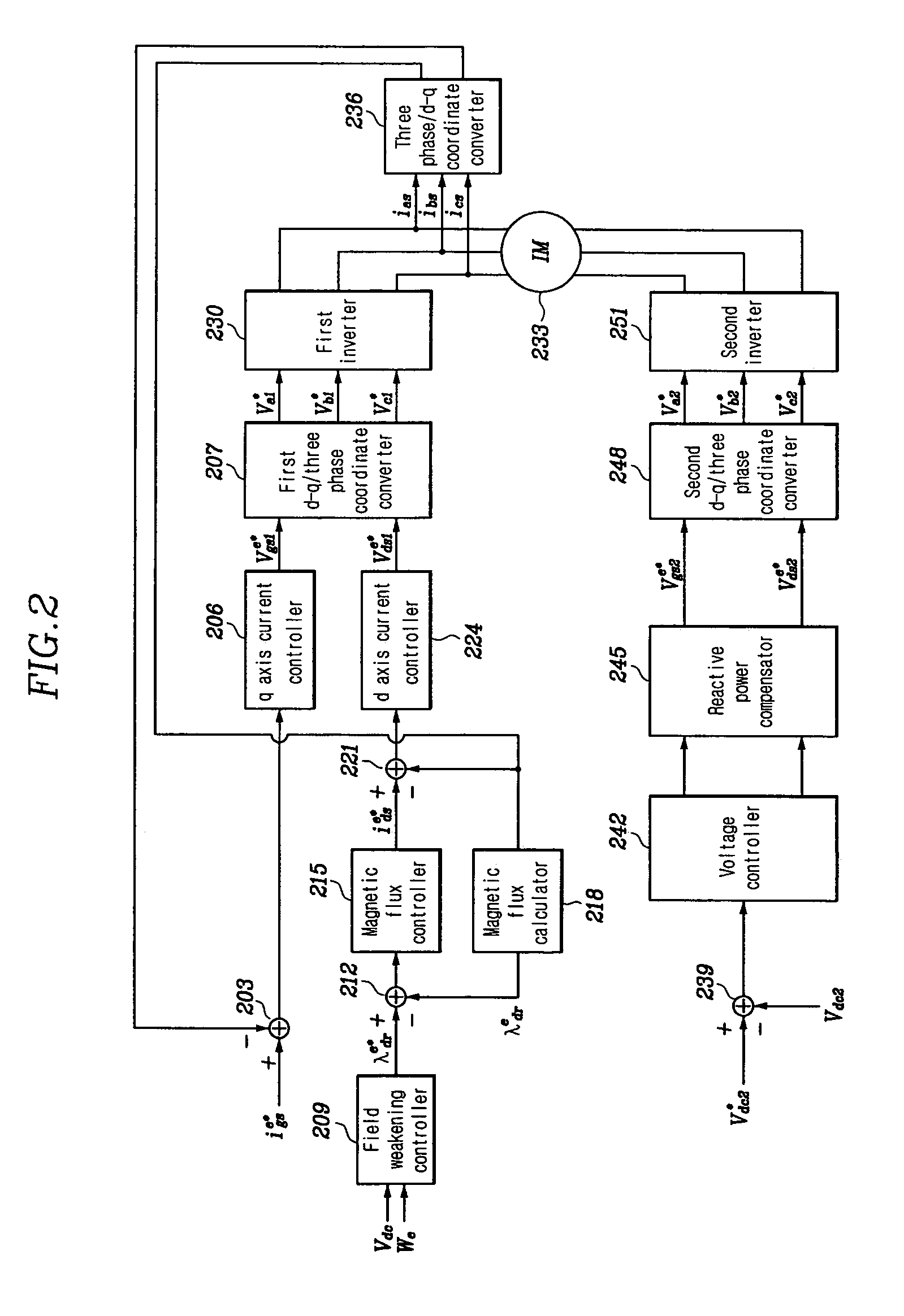

Vector-controlled dual inverter system and method for induction motor

InactiveUS20050002210A1Restrain output decreaseOutput power is preventedVector control systemsConversion with intermediate conversion to dcPower compensationControl vector

A vector-controlled, dual inverter system for a three-phase induction motor is disclosed. The inverter system comprises a first inverter system which is connected to one end of three phase windings of a stator and performs compensation of a back electromotive force; and a second inverter system which is connected to the other end of the three windings of the stator and performs reactive power compensation.

Owner:HYUNDAI MOTOR CO LTD +1

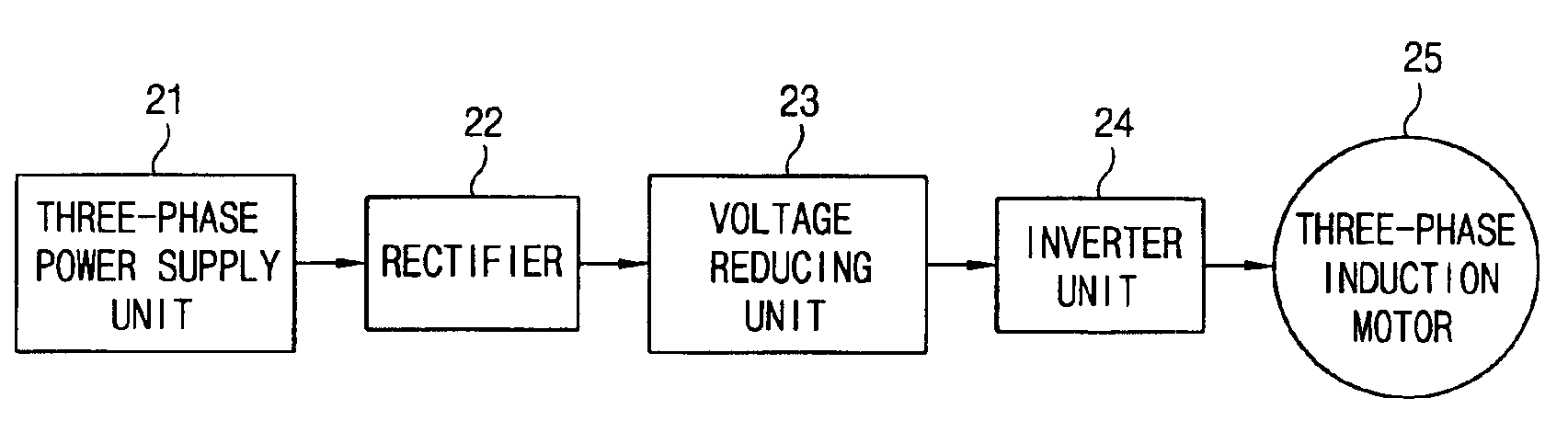

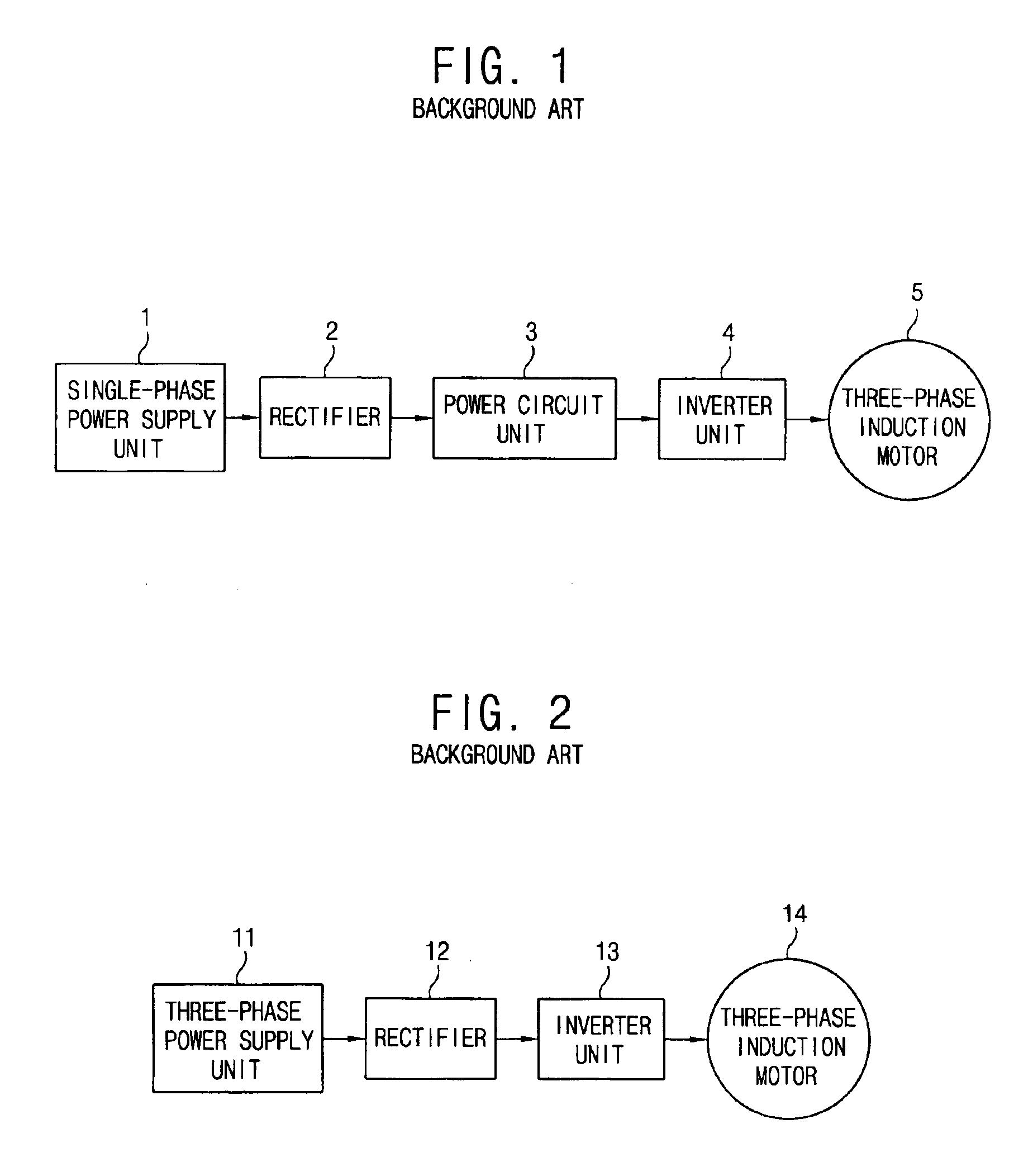

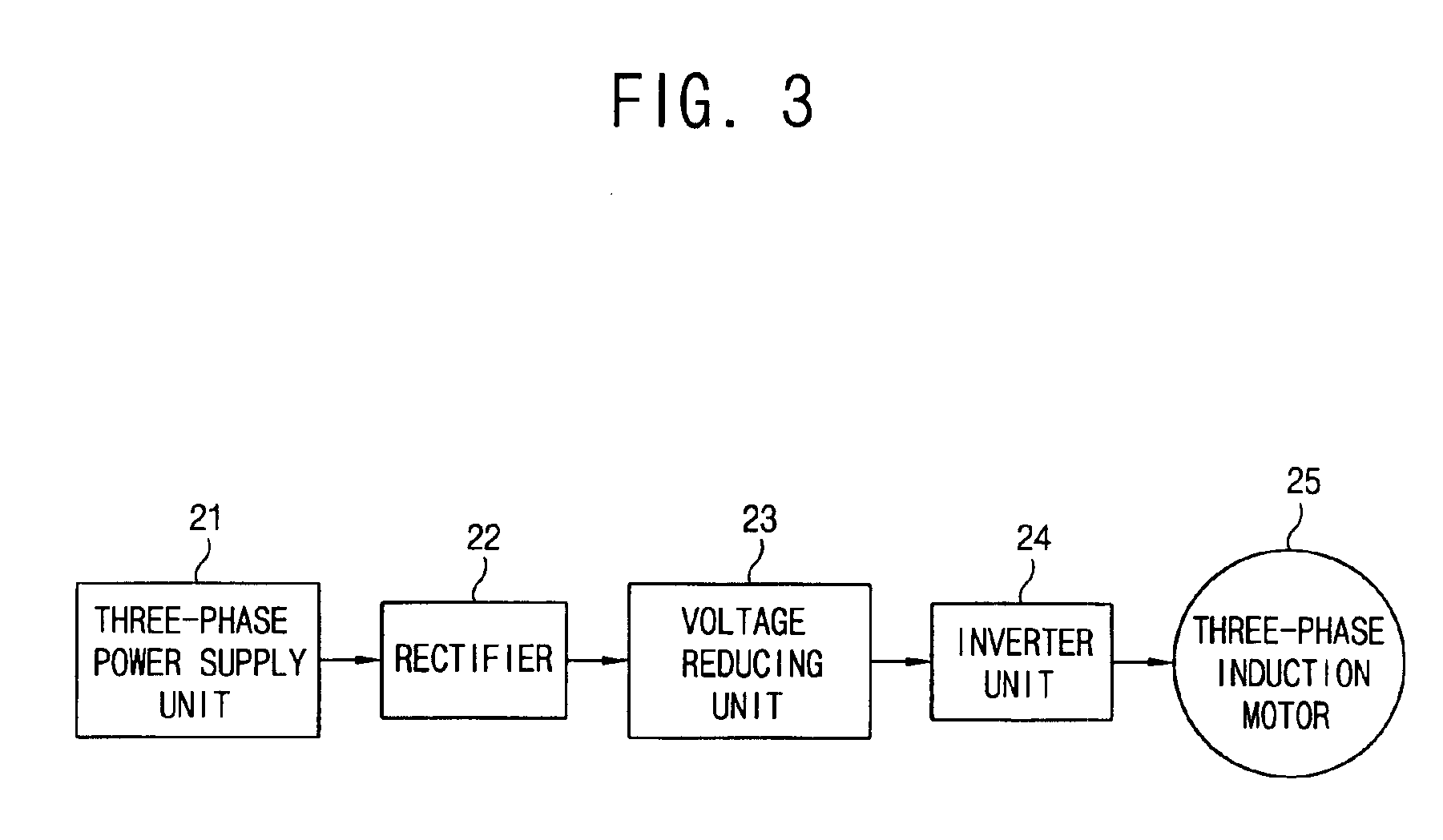

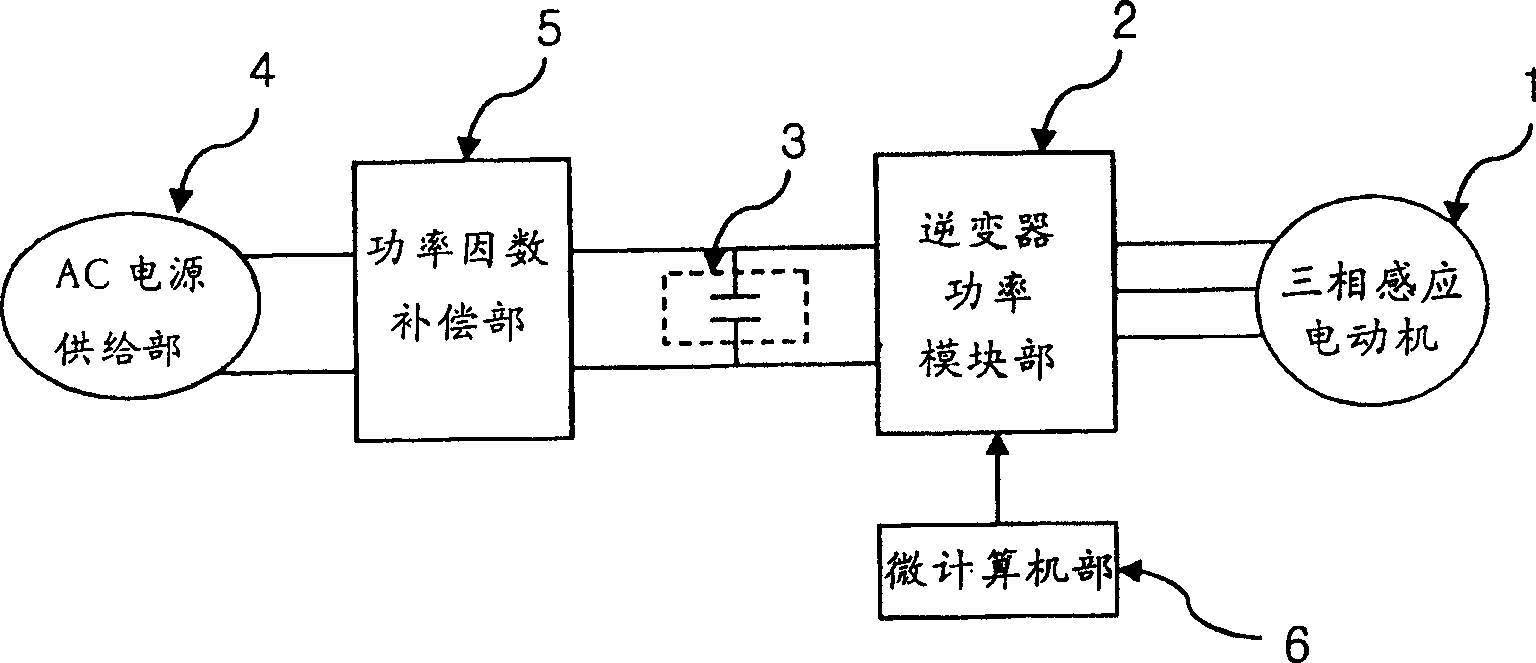

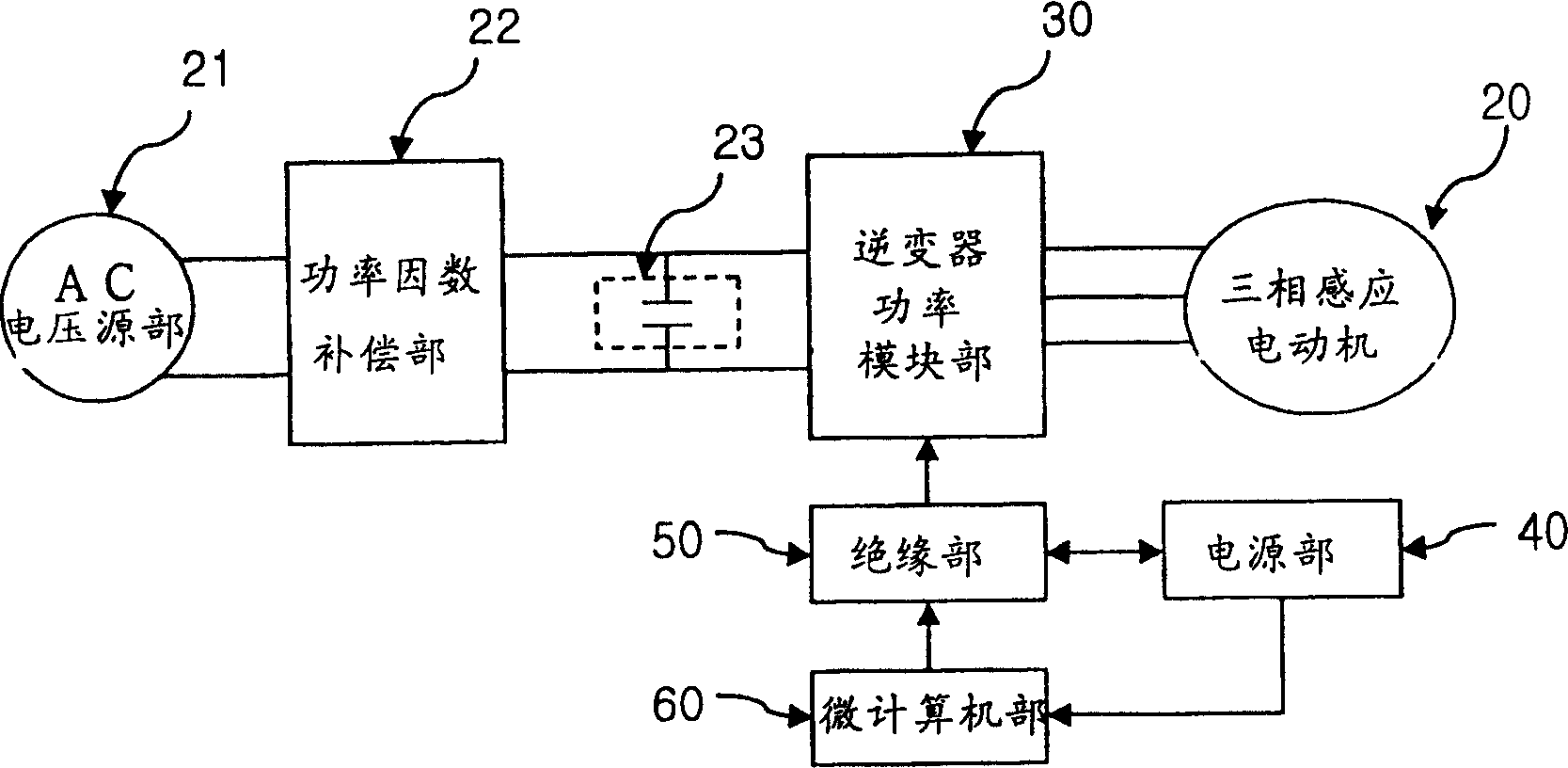

Driving apparatus and method of three phase induction motor

InactiveUS6876171B2Prevent degradationReduce expensesSingle-phase induction motor startersMotor/generator/converter stoppersInduction motorPower factor

A driving apparatus of a three-phase induction motor includes: a three-phase power supply unit for supplying three-phase power; a rectifier for rectifying the three phase voltage supplied from the three phase power supply unit; a voltage reducing unit for reducing a DC voltage generated from the rectifier and outputting a stabilized DC voltage; and an inverter unit for varying the DC voltage outputted from the voltage reducing unit to a three-phase AC voltage and driving a three-phase induction motor. A power-factor degradation generated during supplying a DC voltage to the inverter to drive the three-phase induction motor is prevented, a harmonic wave is removed, and because a high-priced inverter component is not necessary, its relevant expense is reduced.

Owner:LG ELECTRONICS INC

Vector-controlled dual inverter system and method for induction motor

InactiveUS7009856B2Vector control systemsConversion with intermediate conversion to dcControl vectorEngineering

A vector-controlled, dual inverter system for a three-phase induction motor is disclosed. The inverter system comprises a first inverter system which is connected to one end of three phase windings of a stator and performs compensation of a back electromotive force; and a second inverter system which is connected to the other end of the three windings of the stator and performs reactive power compensation.

Owner:HYUNDAI MOTOR CO LTD +1

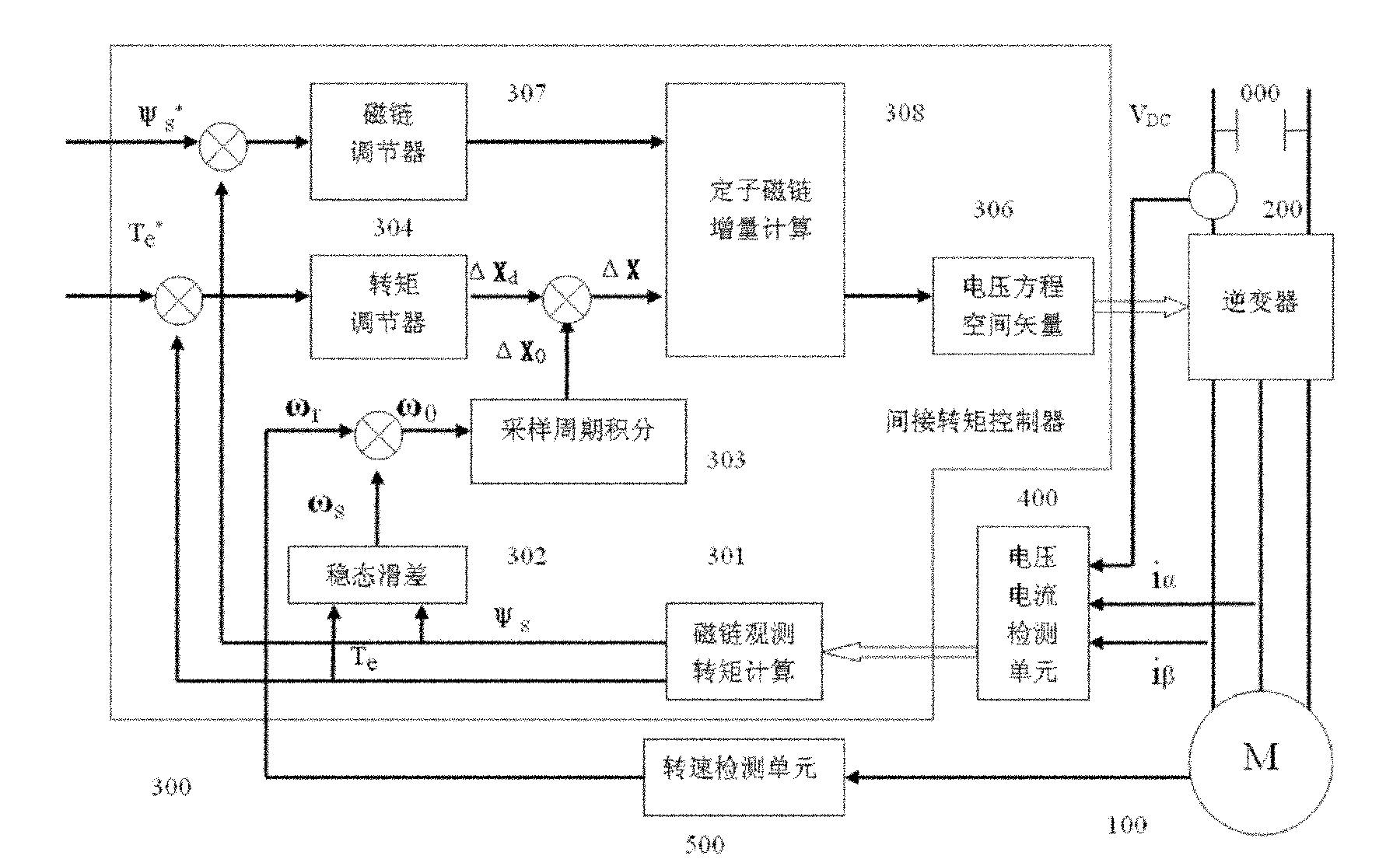

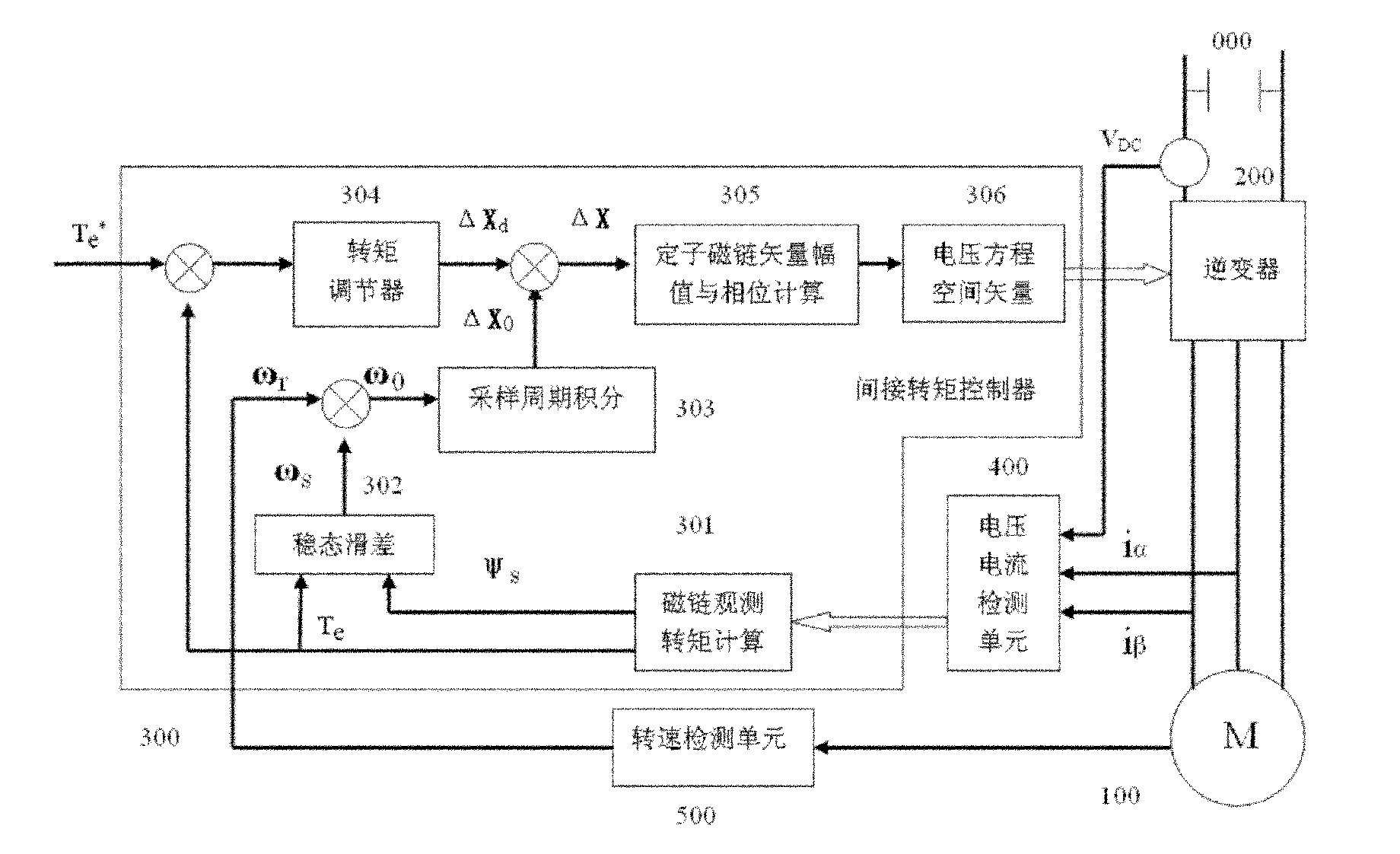

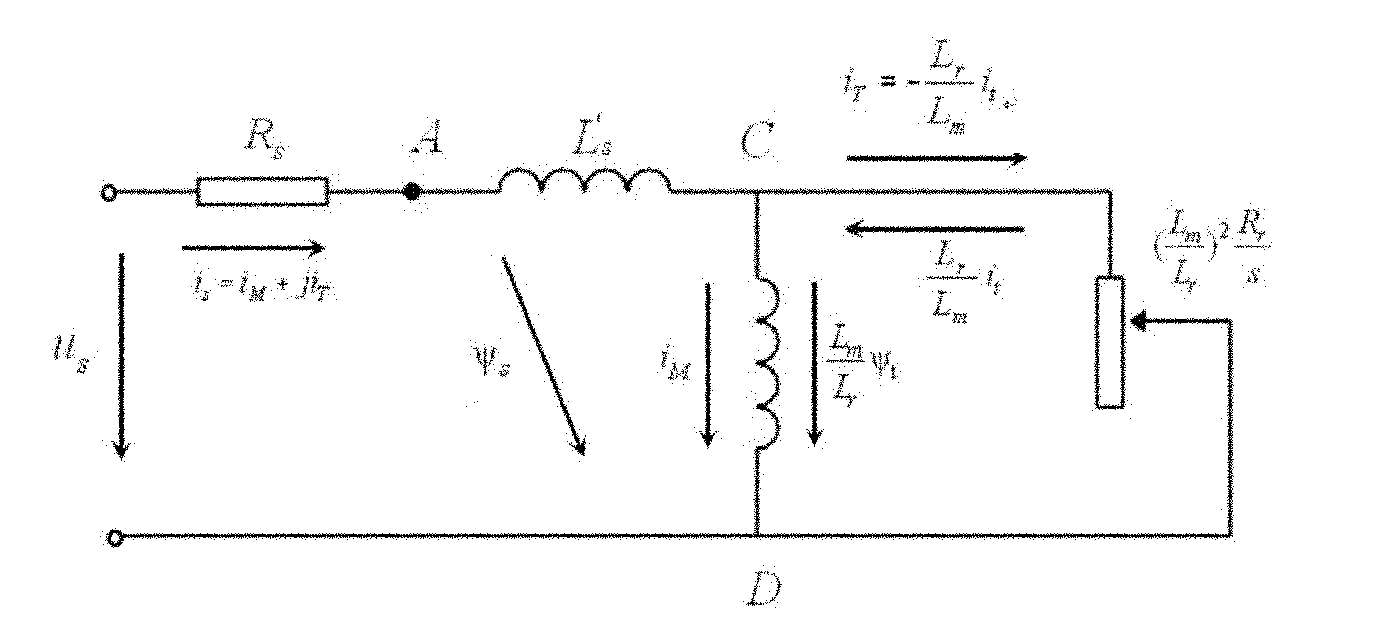

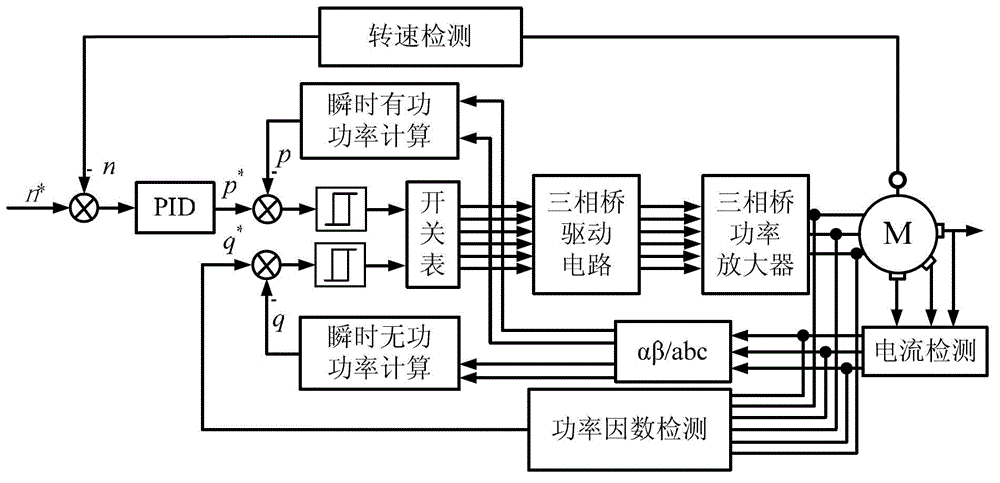

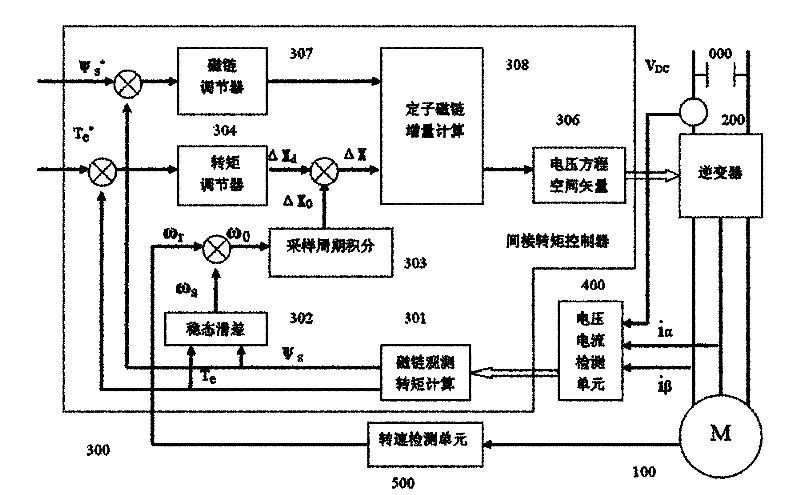

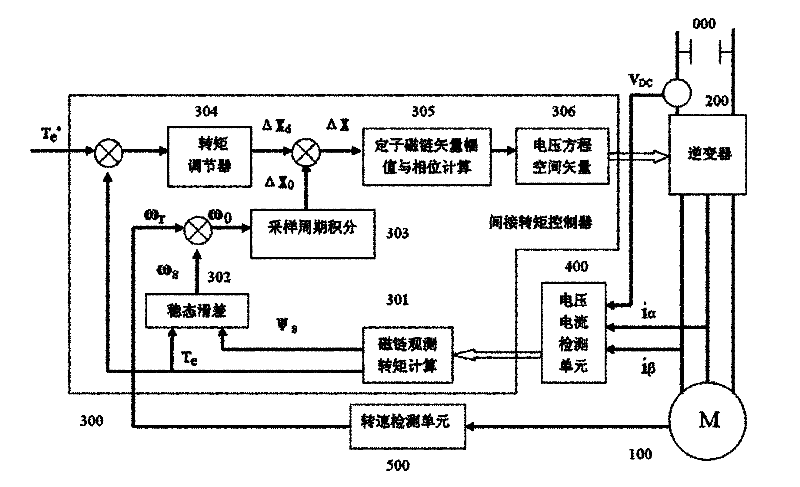

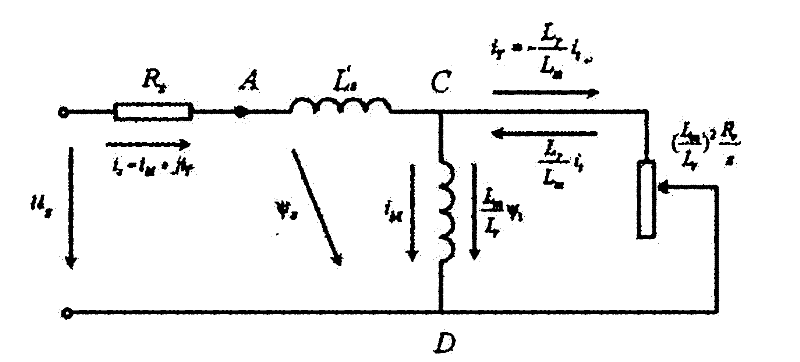

System and method for controlling indirect torque of single regulating loop of three-phase induction motor

ActiveCN102055401AHigh performance controlSimple structureElectronic commutation motor controlVector control systemsCycle controlElectromotive force

The invention discloses a system and method for controlling an indirect torque of a single regulating loop of a three-phase induction motor and relates to the technical field of motor drive and alternated current speed regulation. The system is provided with an indirect torque controller, a 32-bit digital signal processor used as the core of the system and a corresponding peripheral circuit. The software of the system comprises a flux linkage observation and torque calculation unit, a steady slip calculation unit, a revolving speed sampling period integral unit, a torque regulator unit, a stator flux linkage vector amplitude and phase calculation unit and a space voltage vector calculating and outputting unit. Through the method provided by the invention, the space voltage vector of controlling the motor in the next period can be acquired by utilizing the efficient value formula of each-phase electromotive force of a motor stator (UE is equal to 4.44kfNF), namely the ratio of the voltage vector amplitude to the phase gain is maintained as a constant when the motion track of a stator flux linkage vector is a flux linkage circle. In the invention, only the torque single proportional-integral (PI) regulating loop is required, thus the system structure is simplified, the dynamic property of the system is enhanced, and the high-performance control of the driving system of the three-phase induction motor is realized.

Owner:武汉菱电汽车电控系统股份有限公司

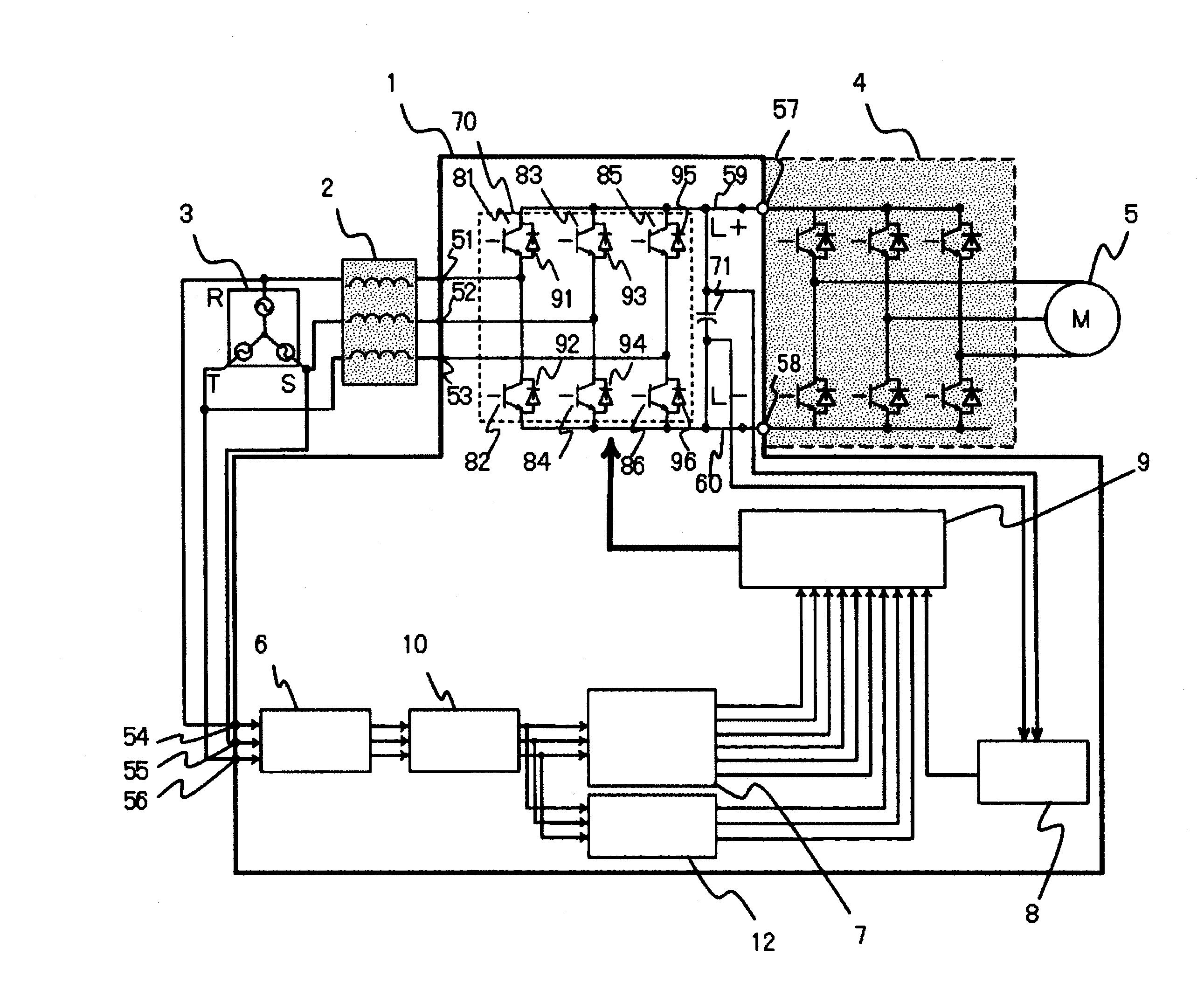

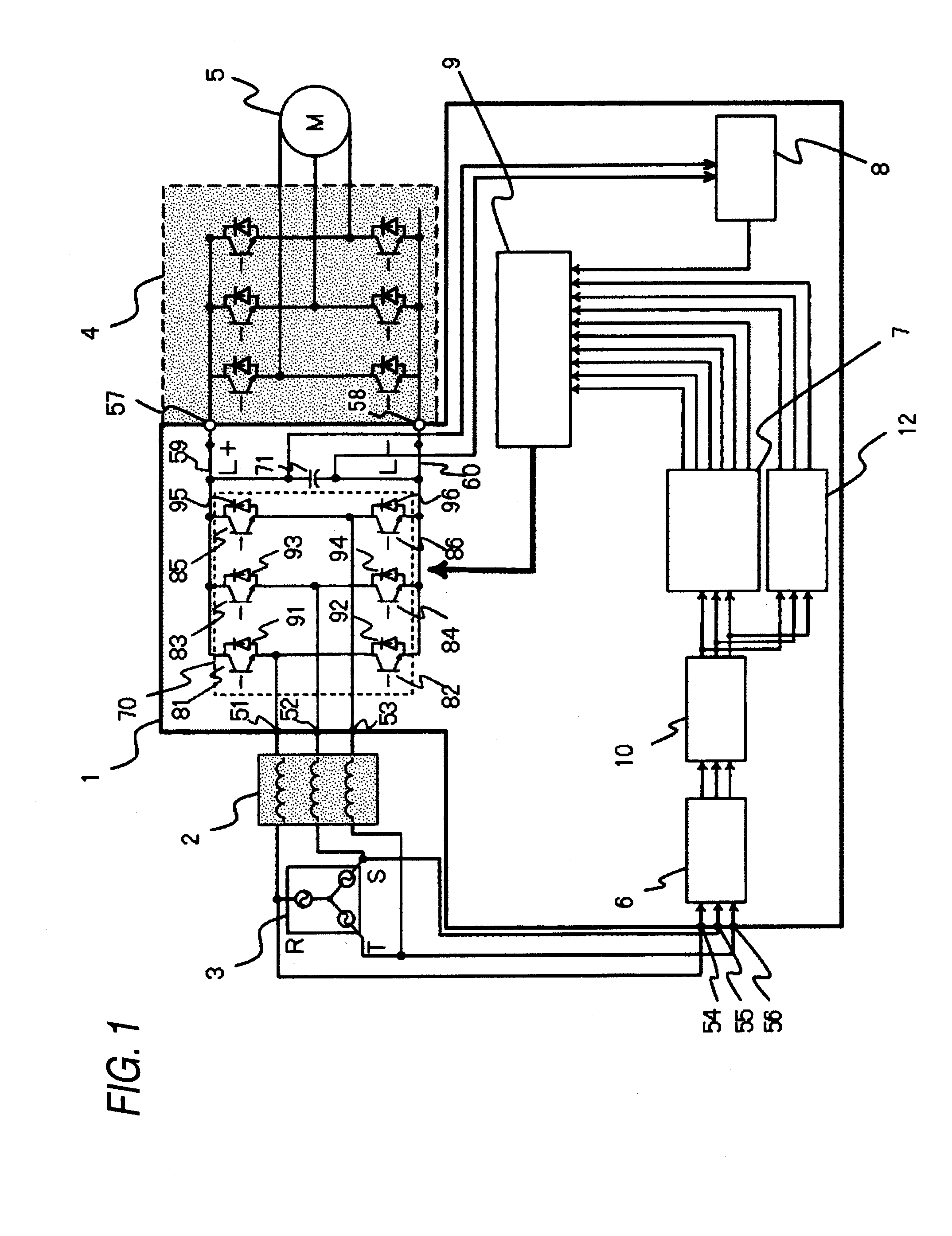

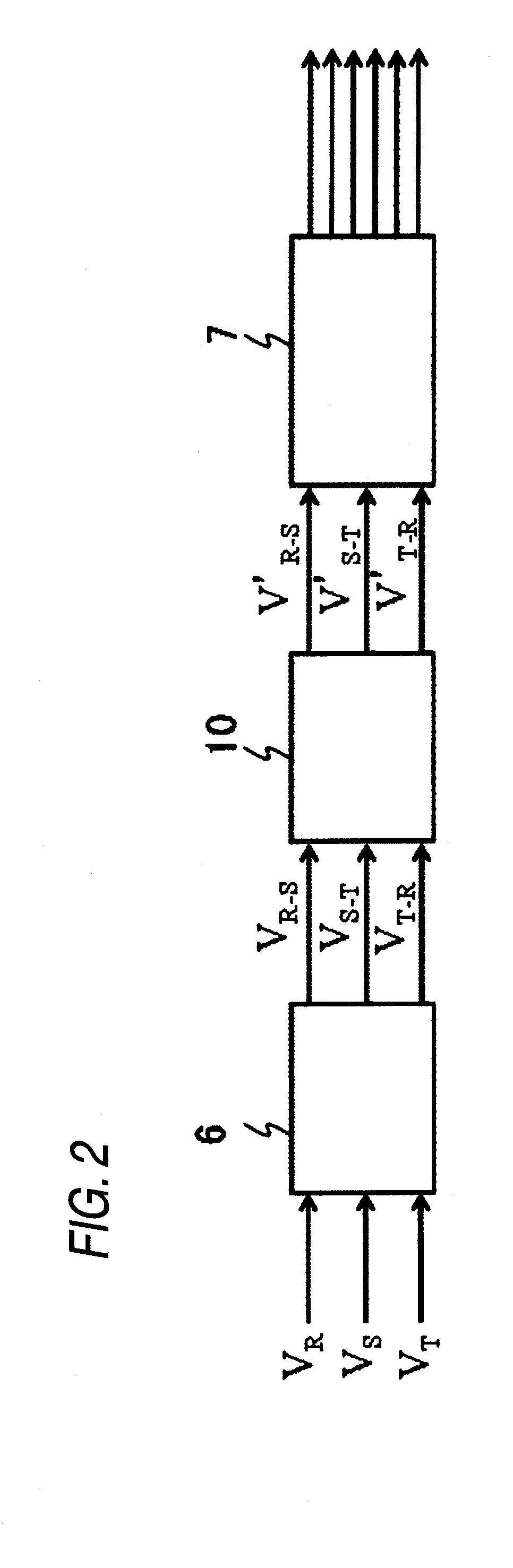

Power regenerative converter

ActiveUS20100052598A1Accurate detectionHindering a system from being stoppedAC motor controlElectric motor controlTerminal voltageEngineering

There are provided a smoothing capacitor (71) for storing an induced electromotive force generated by a three-phase induction motor (5), a regenerative transistor (81 to 86) for switching a terminal voltage of the smoothing capacitor to carry out a power regenerating operation over a three-phase AC power supply (3), a line voltage detecting portion (6) for detecting a line voltage of the three-phase AC power supply, a fundamental waveform generating portion (10) for generating, from a signal output from the line voltage detecting portion, a fundamental waveform defined to be a line voltage waveform of the three-phase AC power supply in which a source voltage distortion component is not mixed, a base driving signal creating portion (7) for creating a base driving signal to be used for an ON / OFF control of the regenerative transistor based on a signal output from the fundamental waveform generating portion, and a base driving signal output portion (9) for outputting the base driving signal.

Owner:MITSUBISHI ELECTRIC CORP

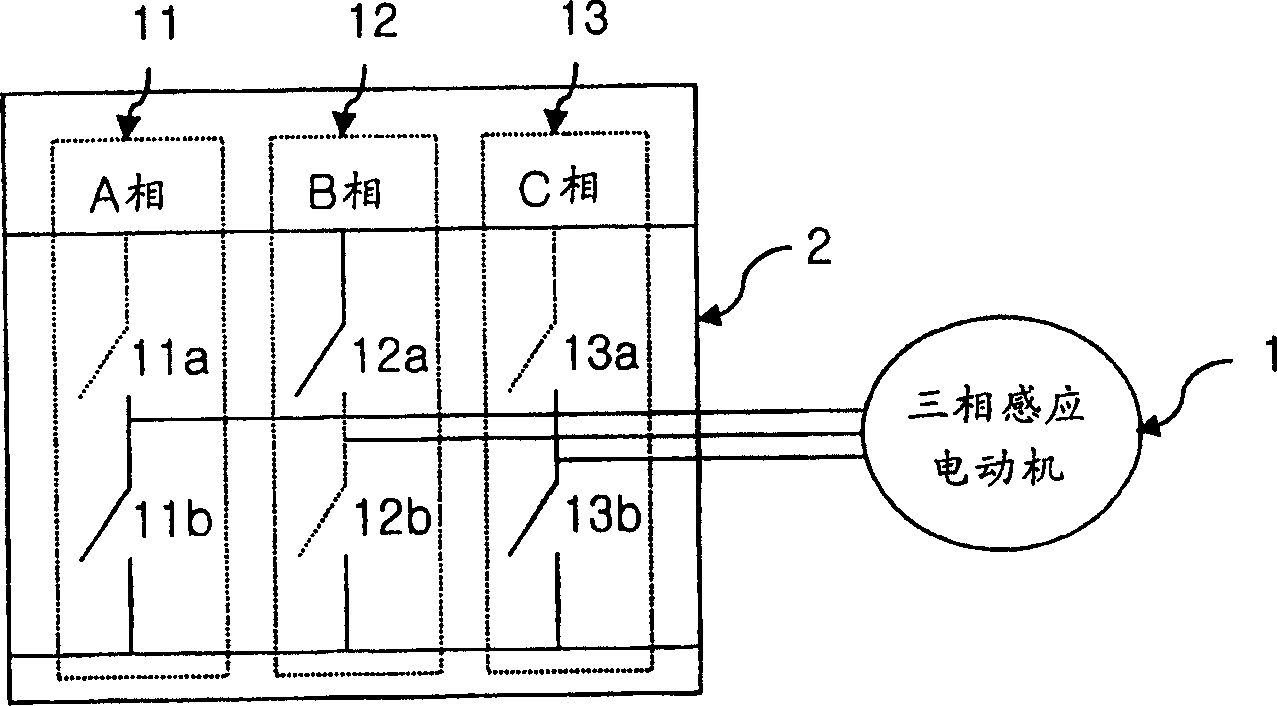

Three-winding parallel single-phase induction motor

InactiveCN102005880AImprove efficiencyIncrease powerAsynchronous induction motorsCapacitancePower factor

The invention relates to a three-winding parallel single-phase induction motor. A stator winding of the single-phase induction motor adopts a three-winding parallel connection mode, so when the single-phase induction motor operates under a rated load, the single-phase induction motor has an approximately symmetrical air gap field, has the efficiency closer to that of a same-capacity three-phase induction motor and higher power factor and is small in volume and light in weight. The single-phase induction motor comprises a shell, wherein a stator is arranged inside the shell; a rotor is arranged on a rotating shaft; the stator winding is divided into three phases A, B and C which spatially form an angle of 120 degrees respectively in turn; the phase B and the phase C are respectively connected in series with a respective capacitor; and the phase A is connected in parallel with the phase C and is reversely connected in parallel with the phase B to form a composite parallel branch so as to be connected to a single-phase power supply.

Owner:SHANDONG UNIV

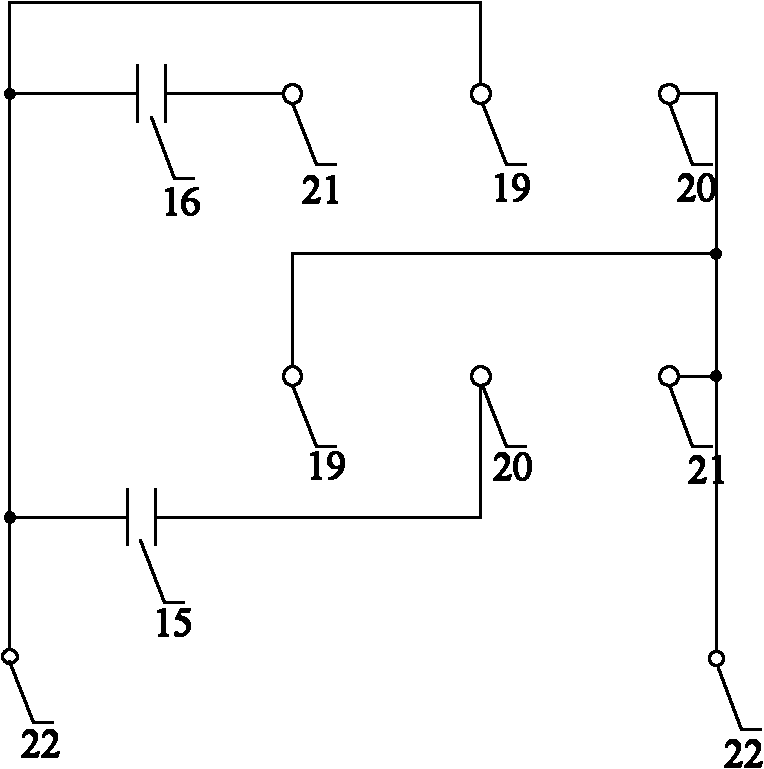

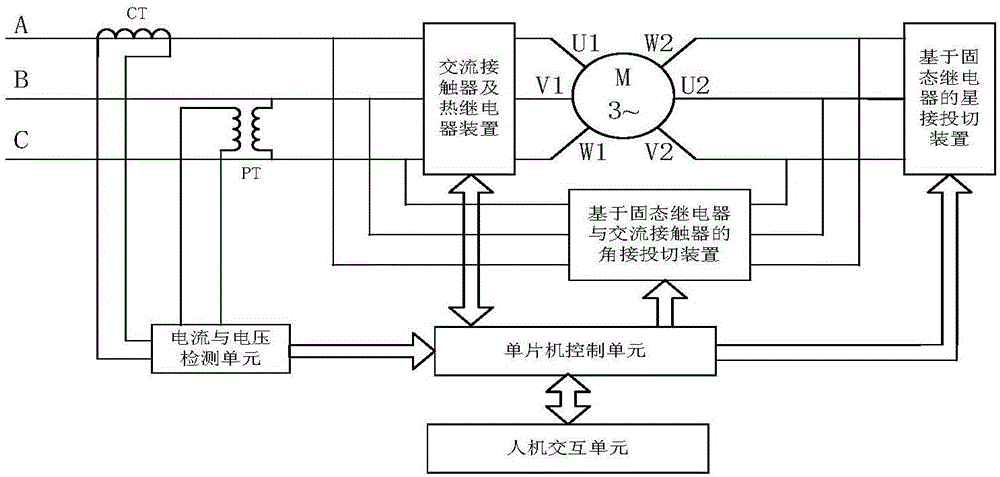

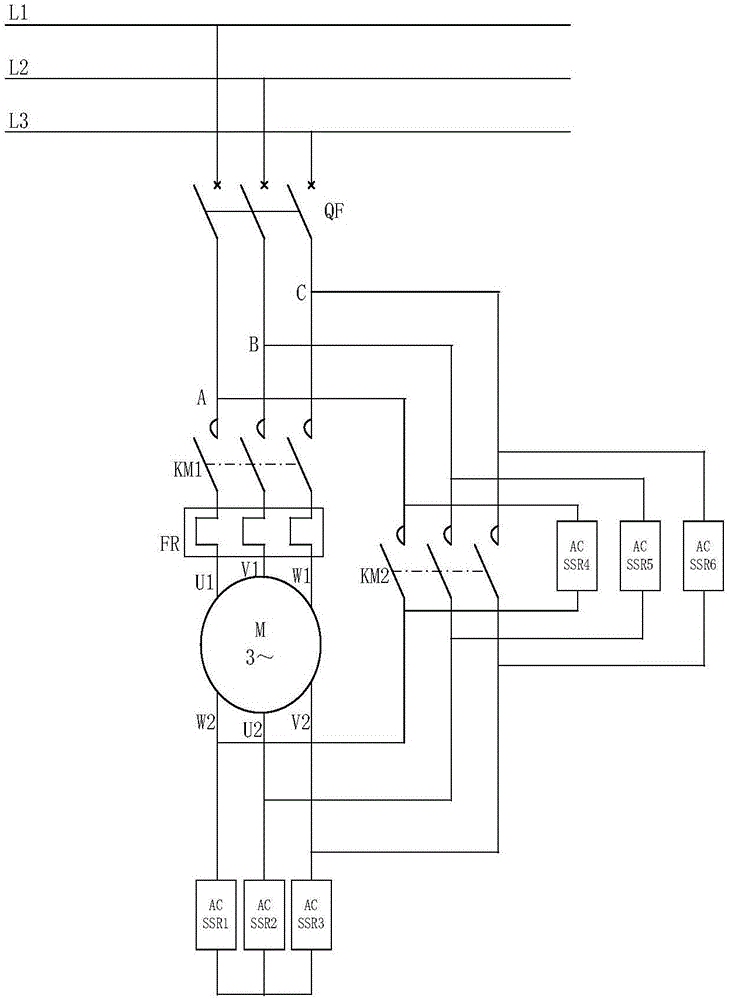

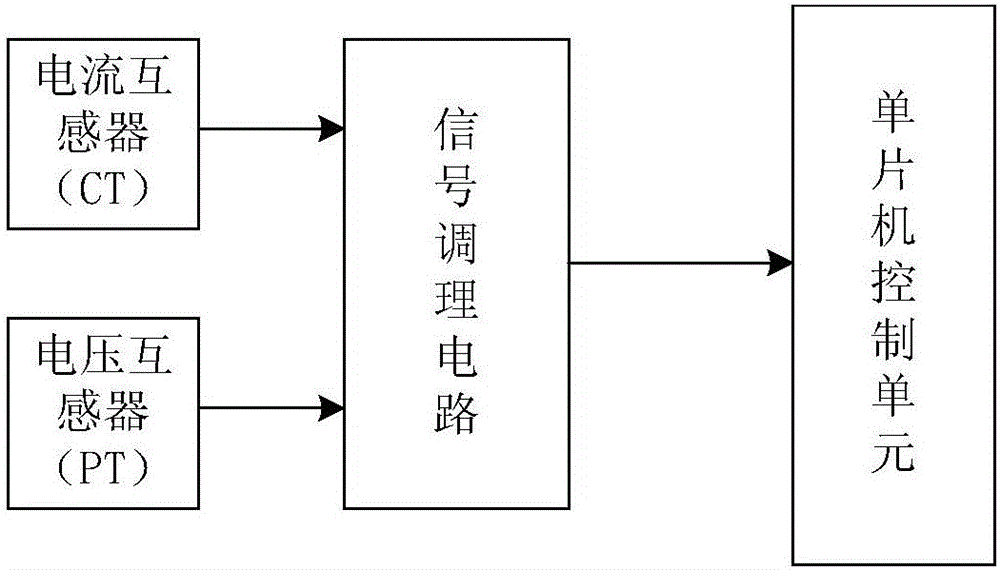

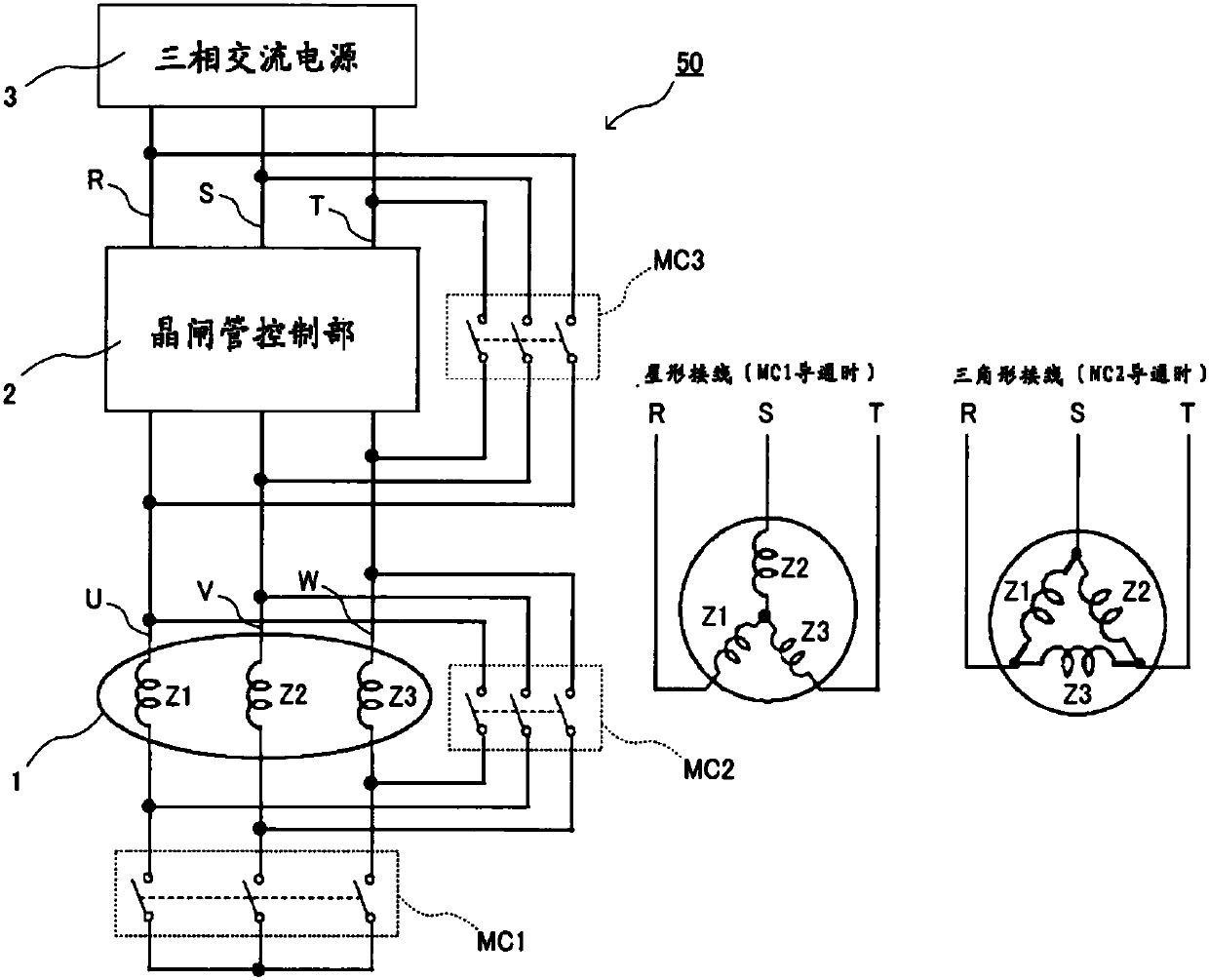

Three-phase induction motor star-delta starter and starting method thereof

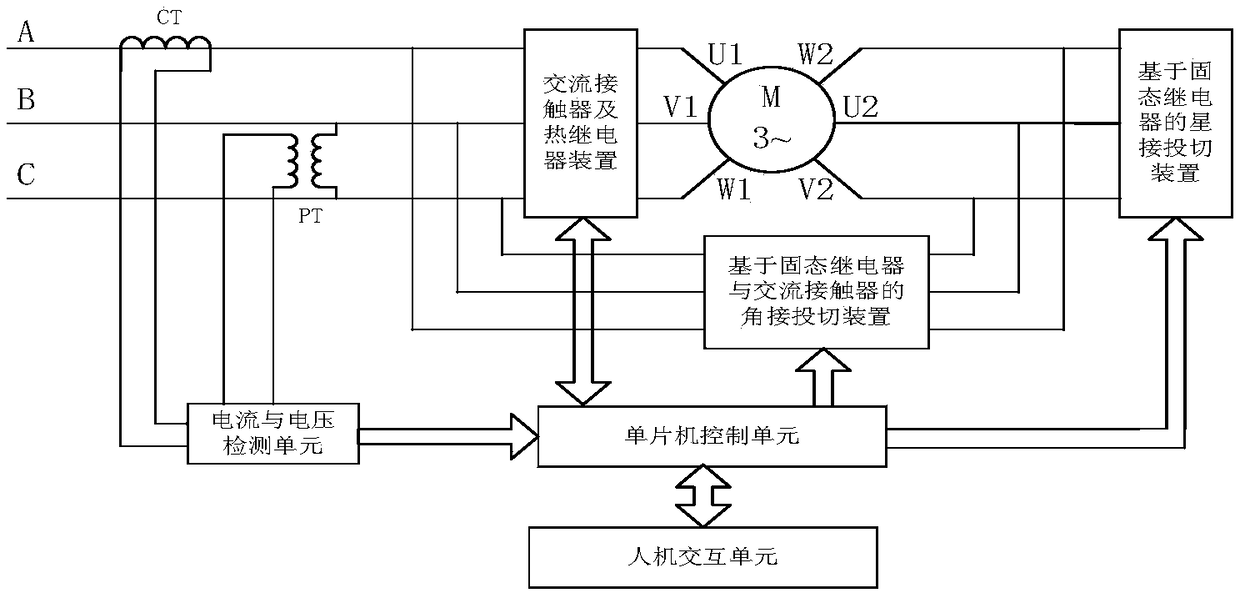

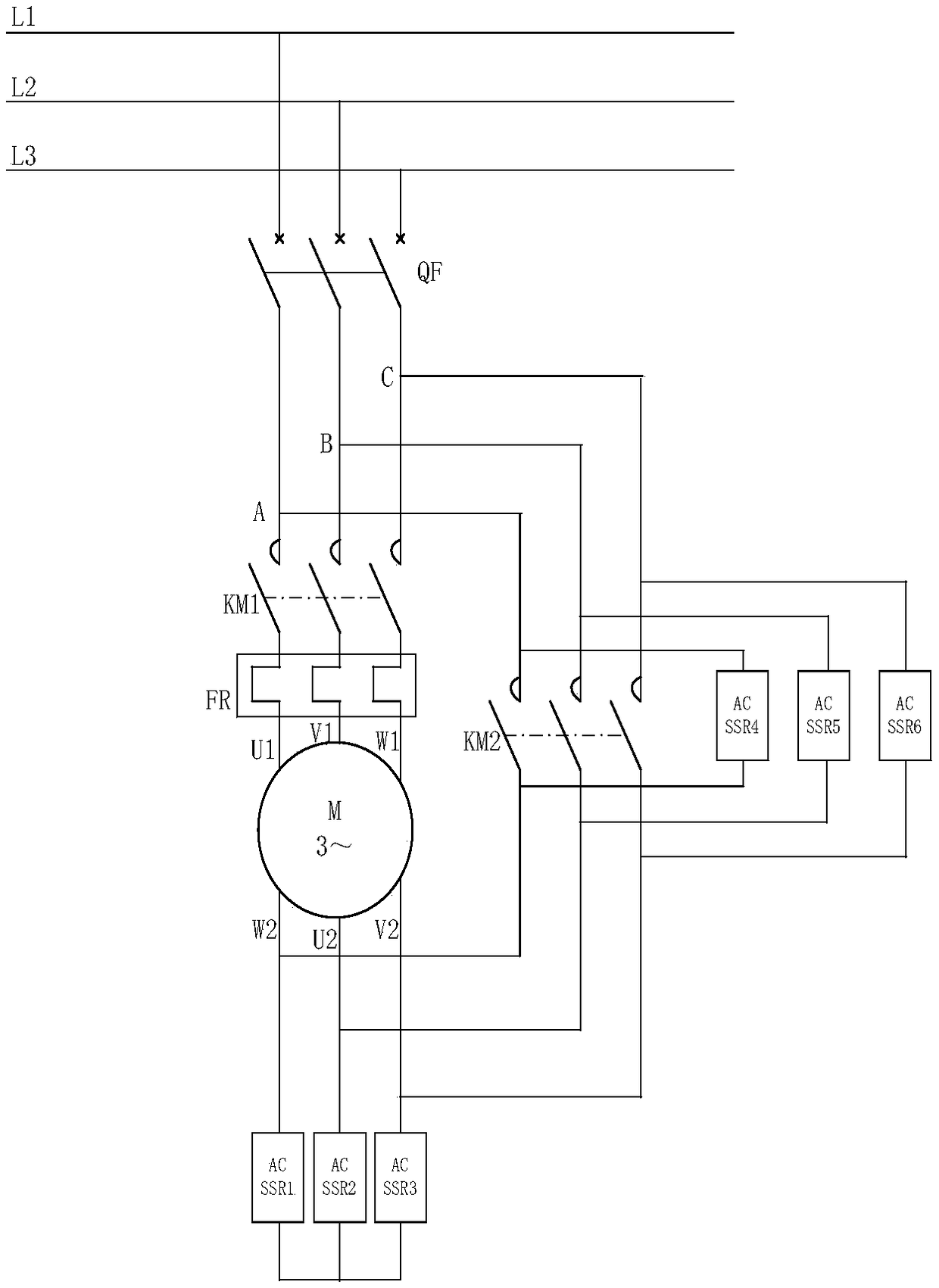

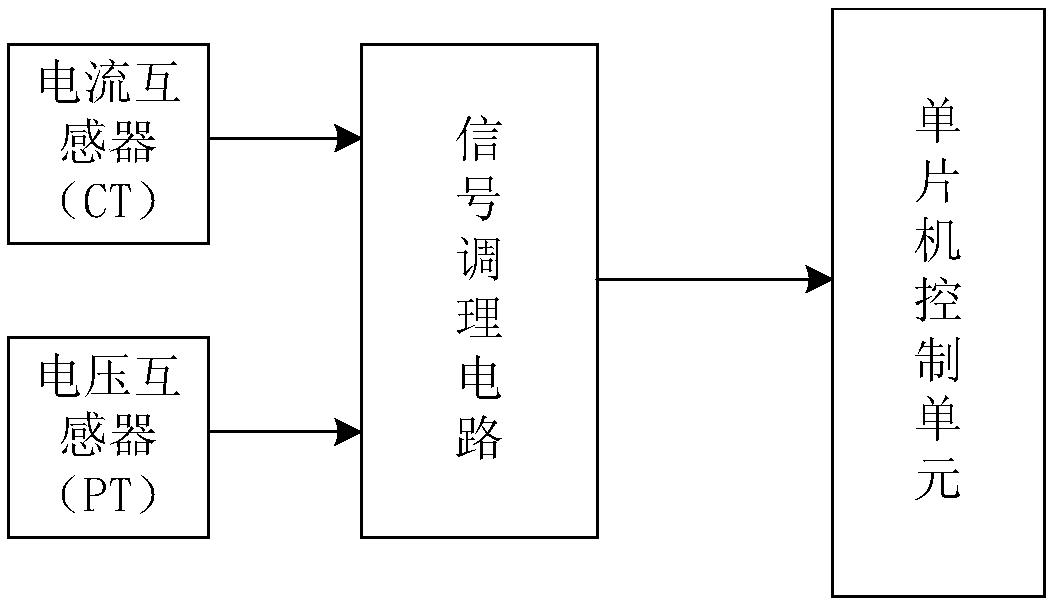

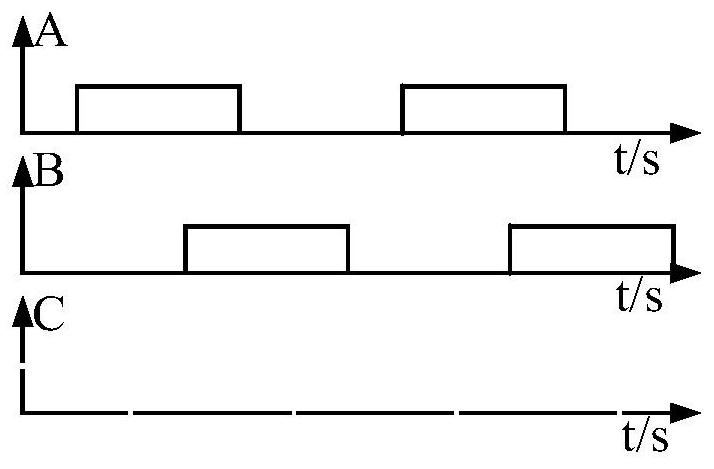

InactiveCN106452199AReduce current shockInhibit starting currentPolyphase induction motor starterMicrocontrollerPower flow

The invention provides a three-phase induction motor star-delta starting control method and device. The device comprises a current and voltage detection unit, a single-chip microcomputer control unit, a human-computer interaction unit, a delta connection switching device based on a solid-state relay and an AC contactor, a star connection switching device based on the solid-state relay, a main circuit AC contactor and a thermal relay device. The current and voltage detection unit is connected on a bus and used for detecting power current and power voltage signals in real time so as to act as the basis of trigger control of the single-chip microcomputer control unit. The single-chip microcomputer control unit is connected with the current and voltage detection unit. The human-computer interaction unit is connected with the single-chip microcomputer control unit. Starting current of the starting instant of star connection can be effectively suppressed so that the current impact of star-delta switching can be reduced, the electromagnetic interference caused by disconnection of a stator winding in the star-to-delta process can also be reduced and thus noise and vibration of starting of an asynchronous motor can be greatly reduced.

Owner:凌海科诚电气有限责任公司

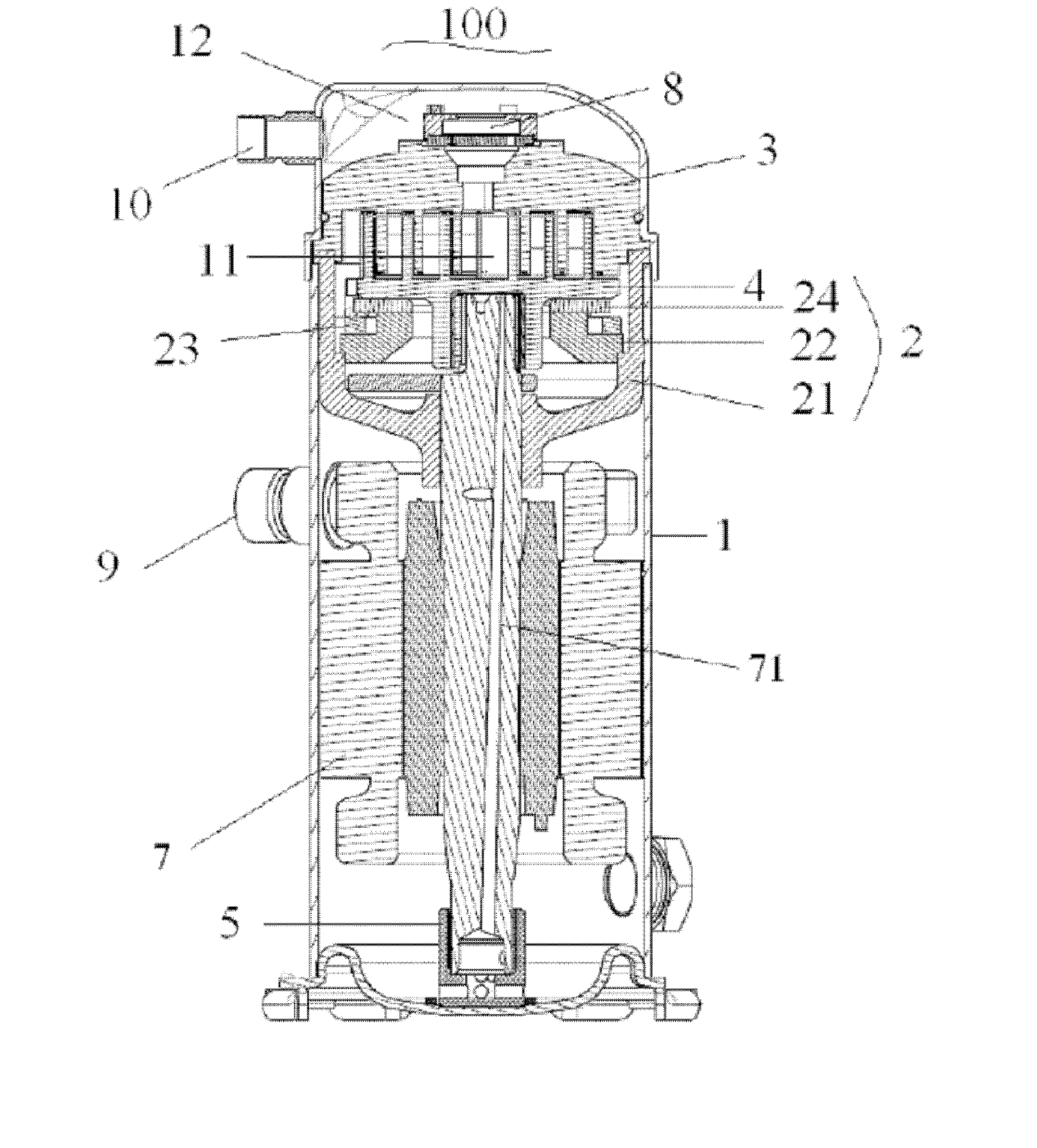

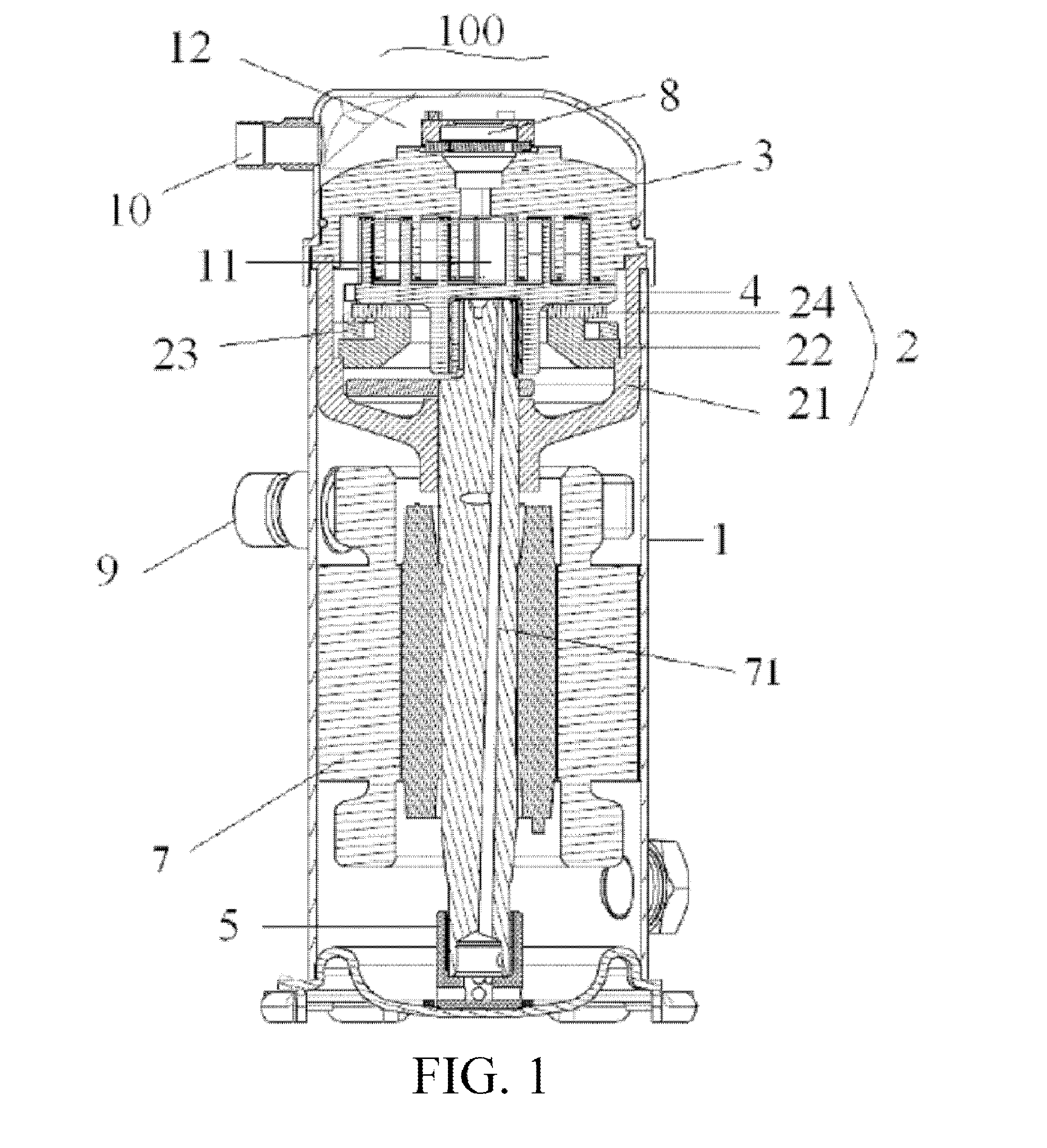

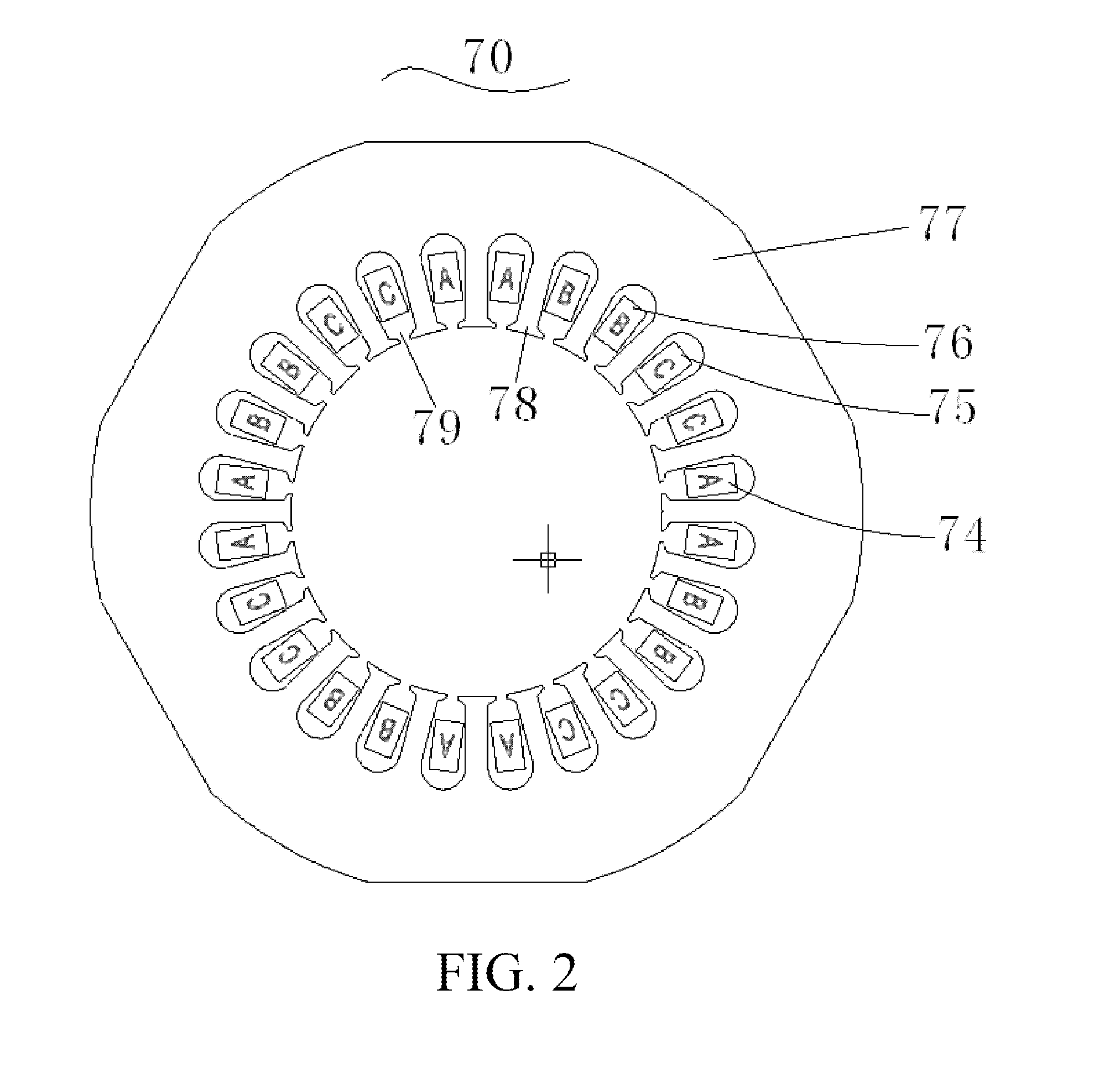

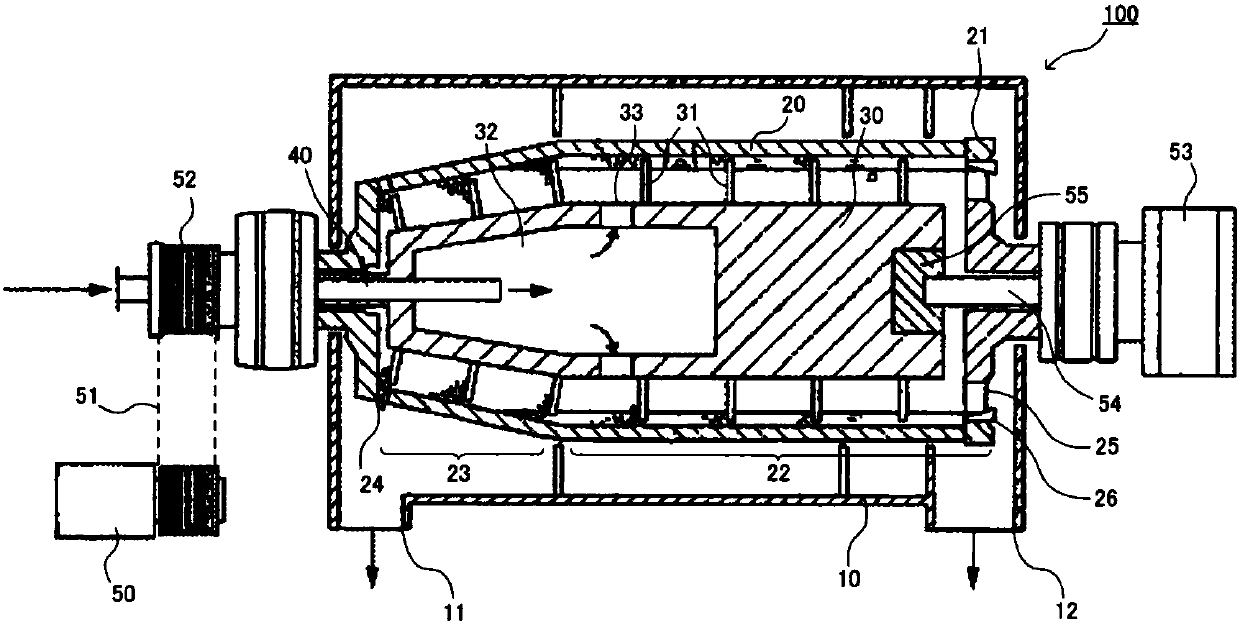

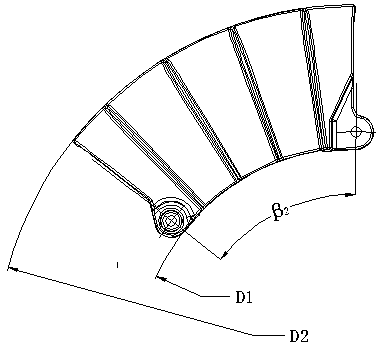

Stator, three-phase induction motor, and compressor

InactiveUS20150010414A1Reduce material costsRotary/oscillating piston combinations for elastic fluidsWindings insulation shape/form/constructionInduction motorFive phase induction motor

The present invention provides a stator, a three-phase induction motor and a compressor. The stator is applied to a three-phase induction motor of a compressor. The stator includes: a stator iron core; a plurality of stator teeth extending inwards along a radial direction of the stator; stator slots distributed between the plurality of stator teeth; and three phases of windings wound around the stator teeth to generate a rotating magnetic field, where a coil of each phase of winding in the three phases of windings is made of a composite wire. The composite wire includes a wire core made of a first conductive metal material, and an outer layer wrapping an outer circumferential surface of the wire core and made of a second conductive metal material, wherein the first conductive metal material and the second conductive metal material have different electrical conductivities.

Owner:DANFOSS (TIANJIN) CO LTD

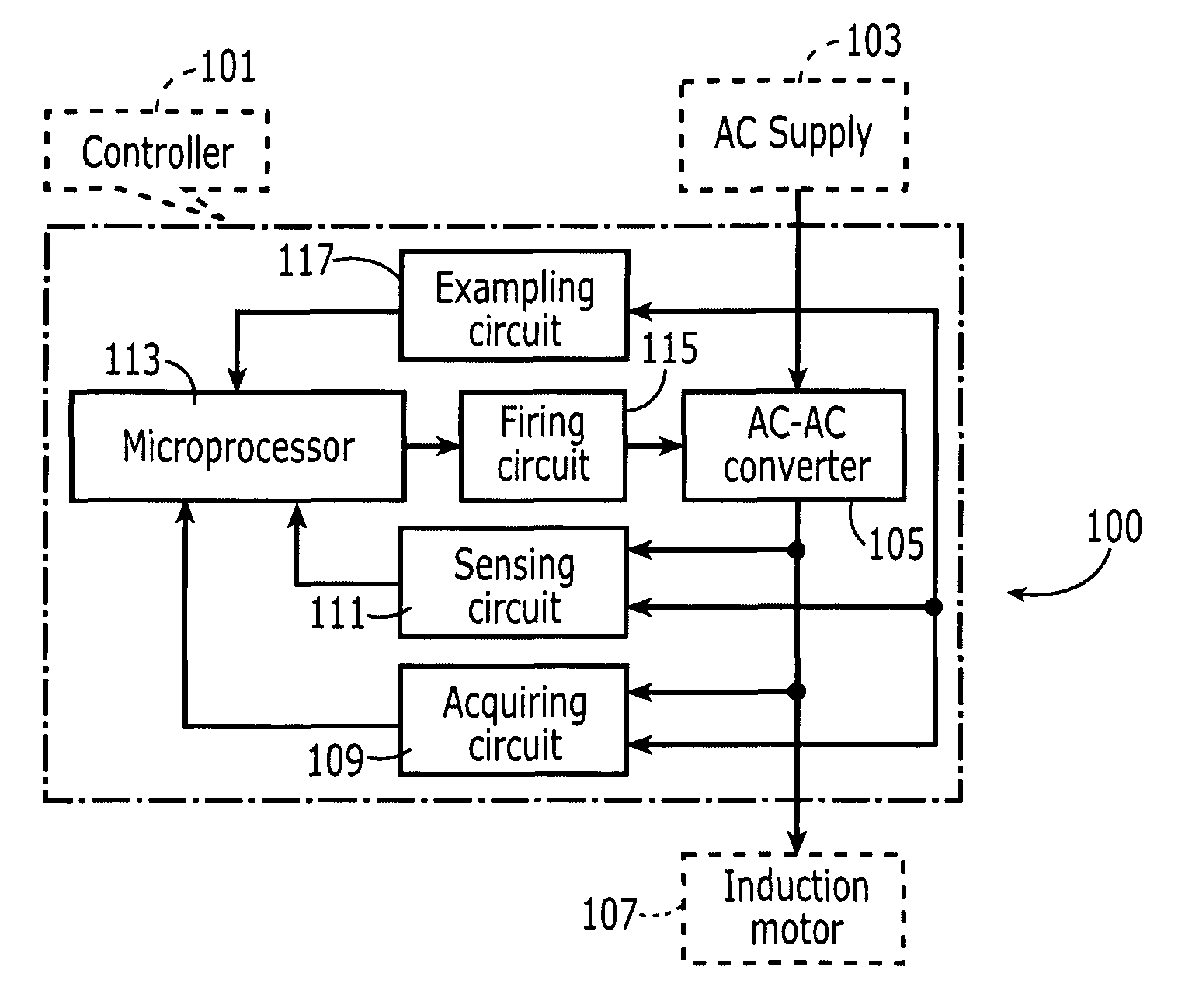

Energy-saving controller for three-phase induction motors

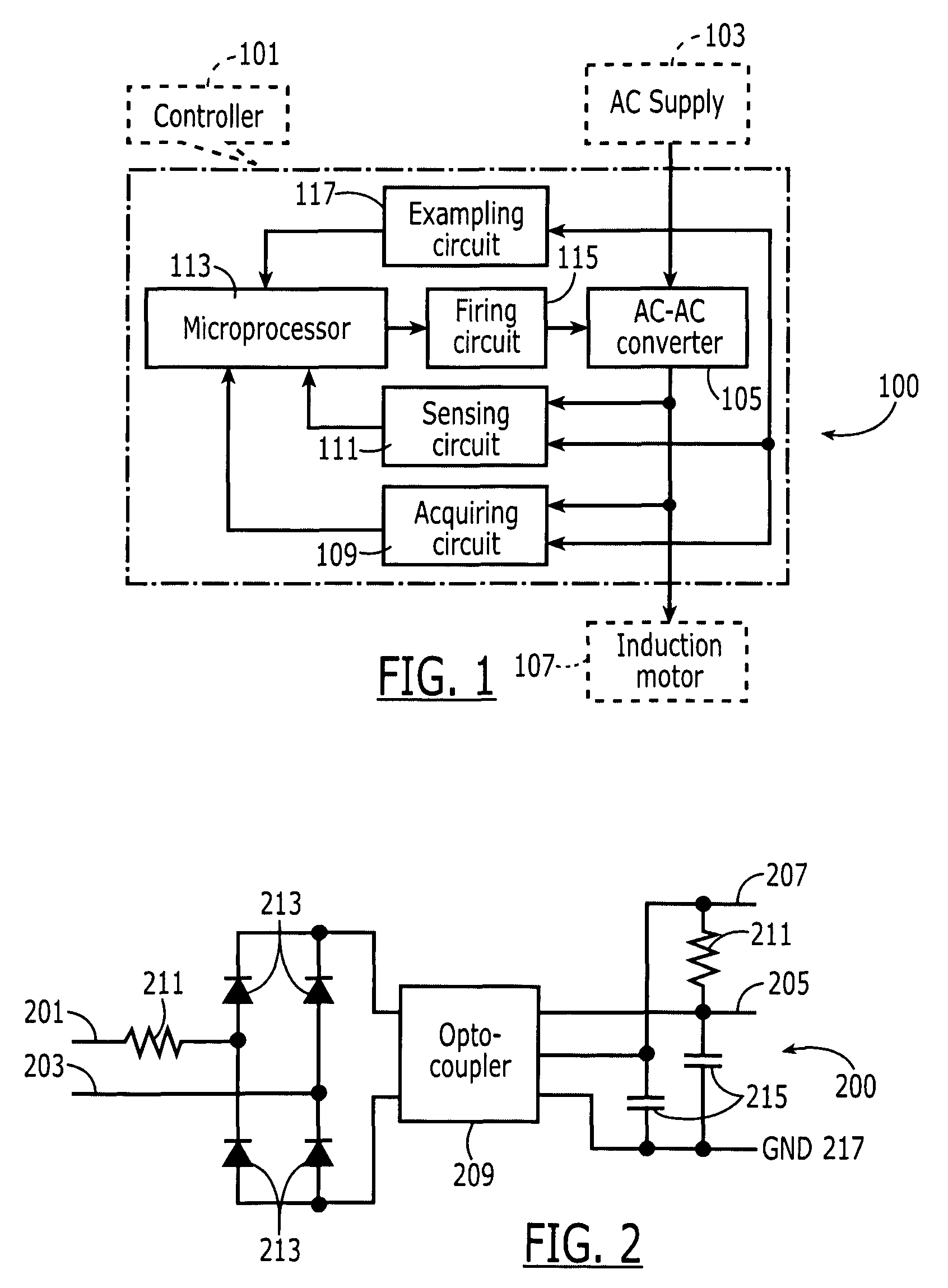

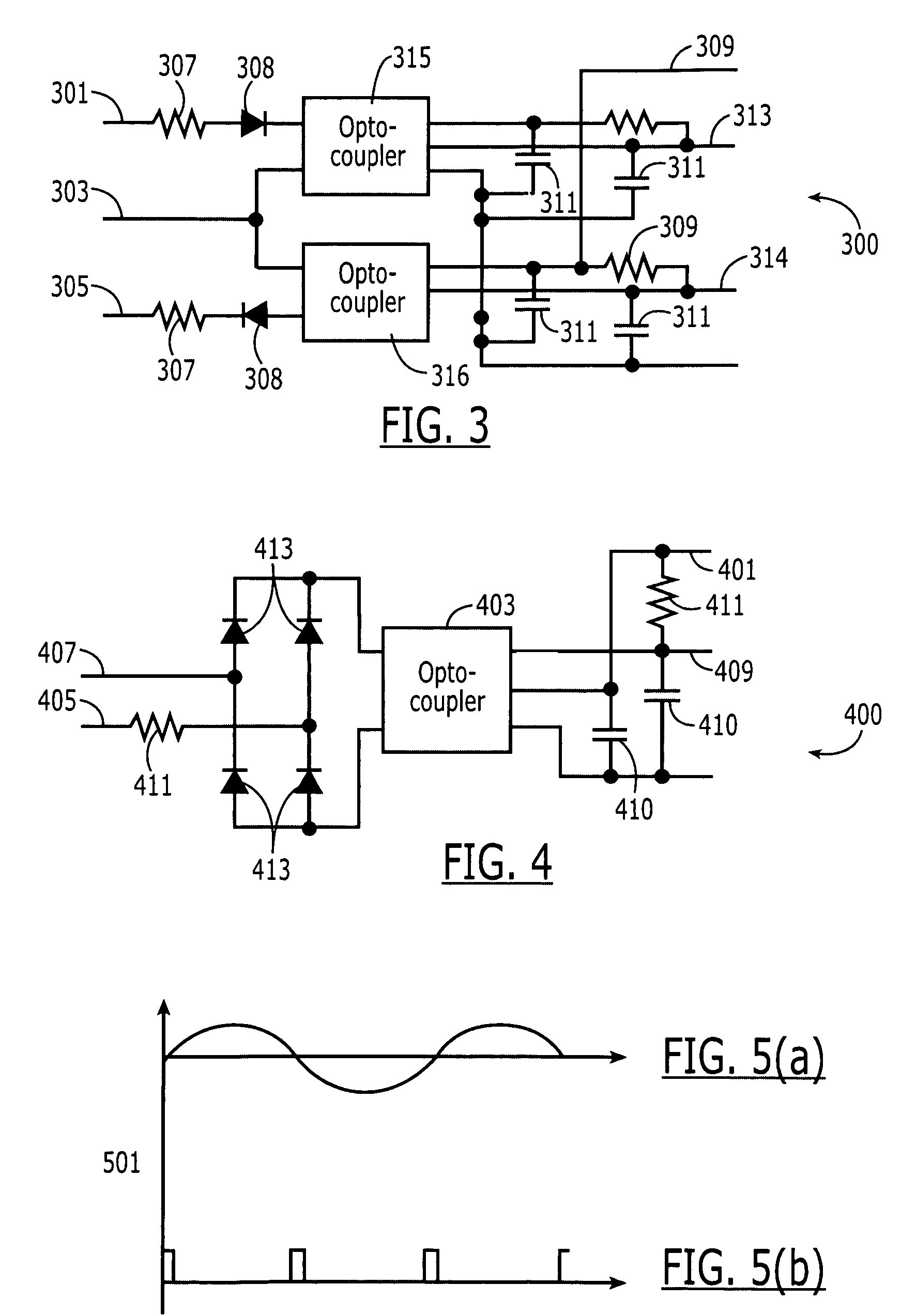

ActiveUS8217618B2High operating power factor and efficiencyLower ratioSingle-phase induction motor startersMotor control for low load efficiencyPower factorEngineering

The present invention relates to an energy-saving system for three-phase induction motors and is based on the principle of variable voltage control at constant speed. It is composed of a microprocessor, exampling circuit, sensing circuit, acquiring circuit, firing circuit, and AC to AC converter. The system is to automatically adjust the voltage to the induction motor with the variation in the motor load, in order to obtain high operating power factor and efficiency. The system will result in considerable energy-savings when a three-phase induction motor runs under constant light-load or variable-load with low duty ratio.

Owner:THE HONG KONG POLYTECHNIC UNIV

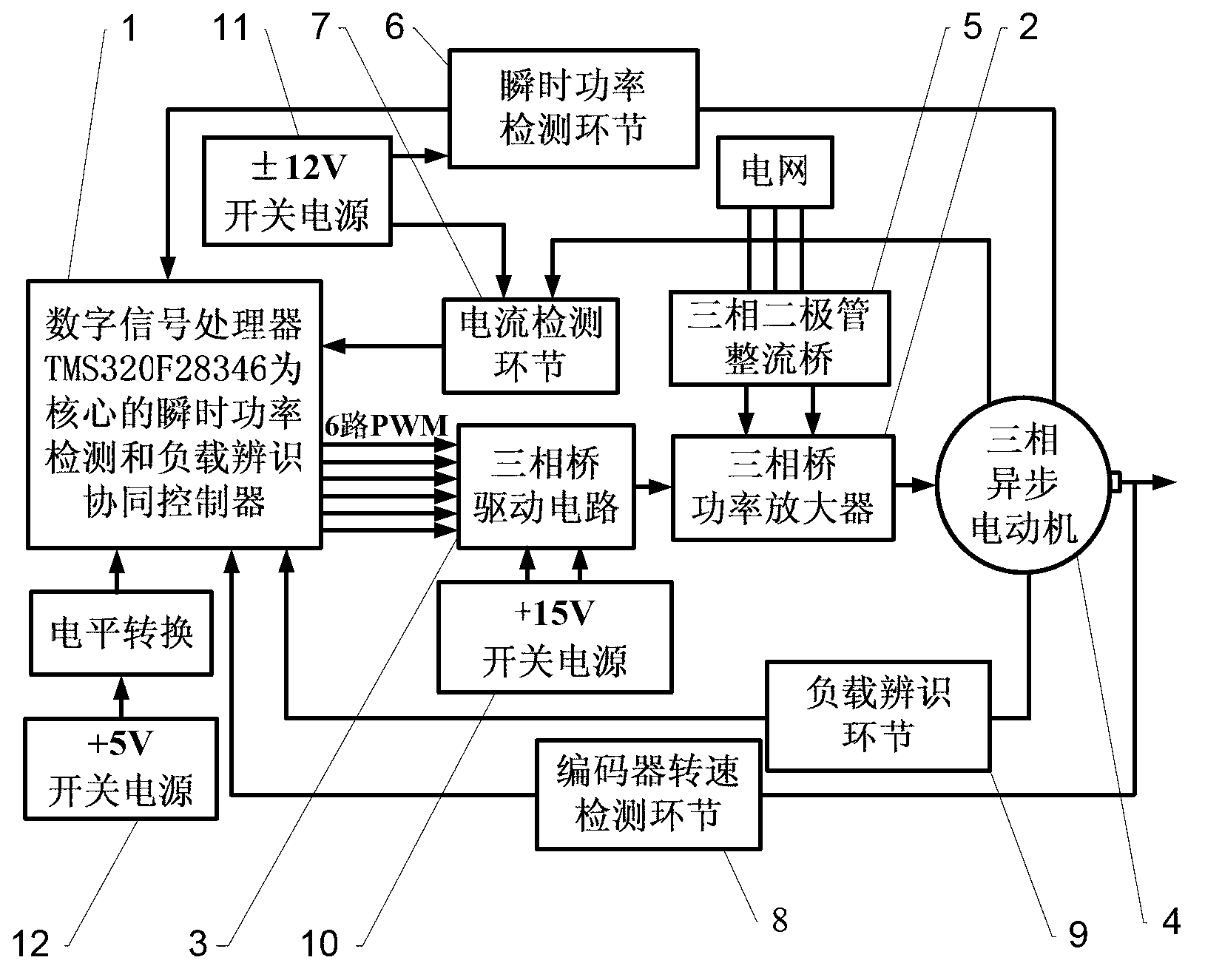

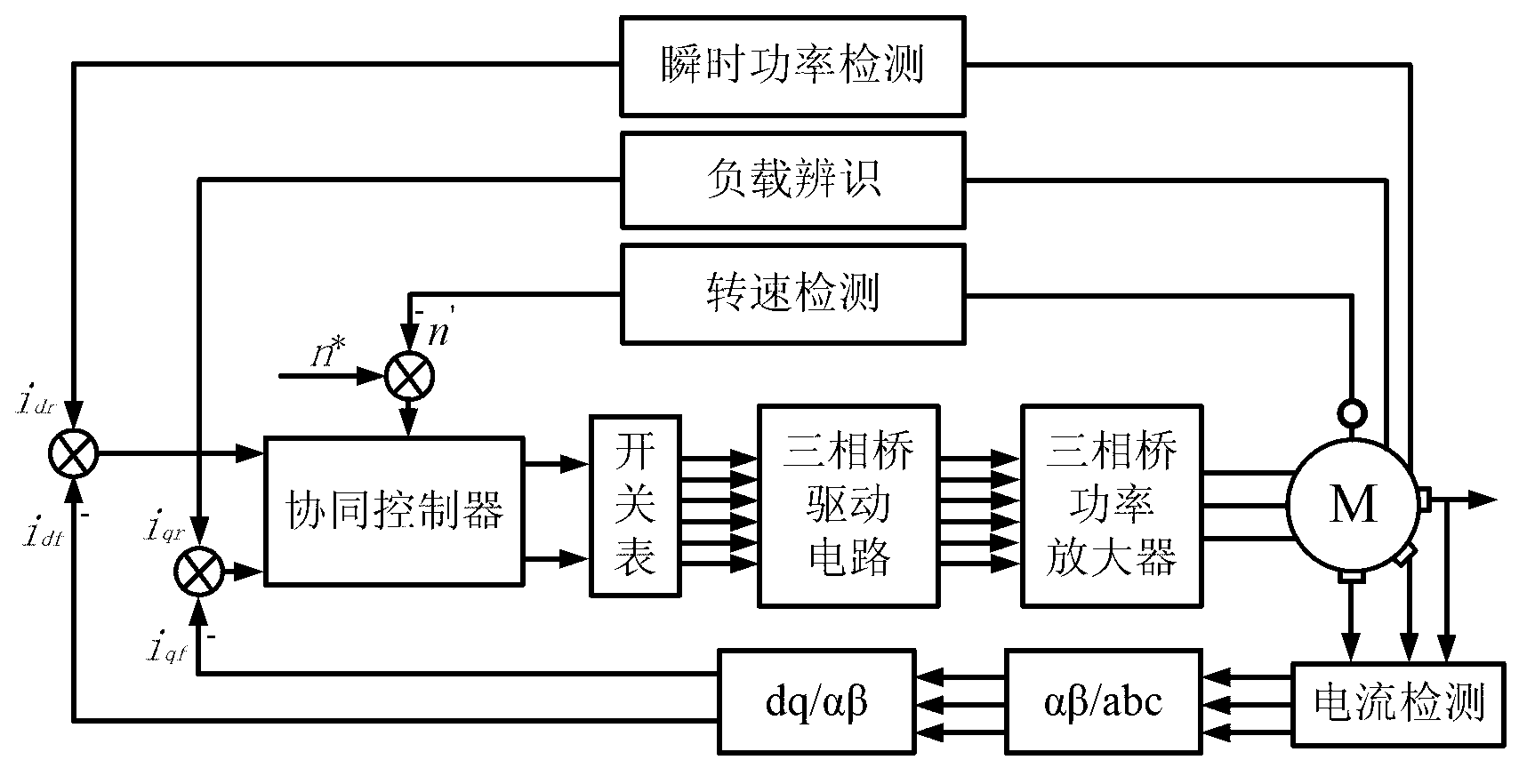

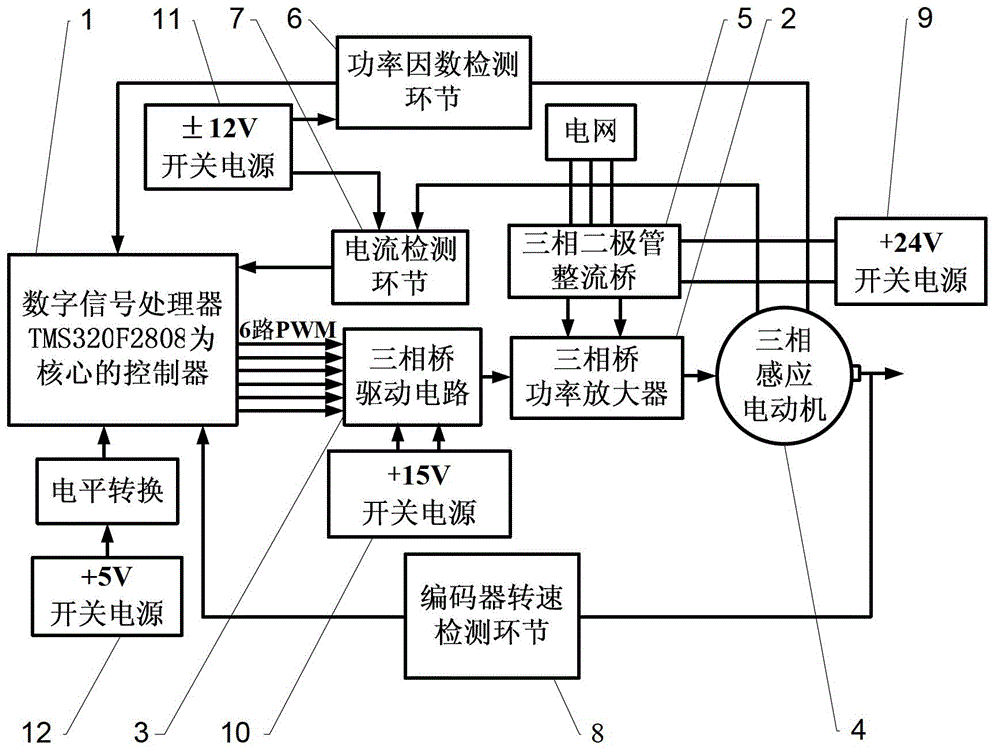

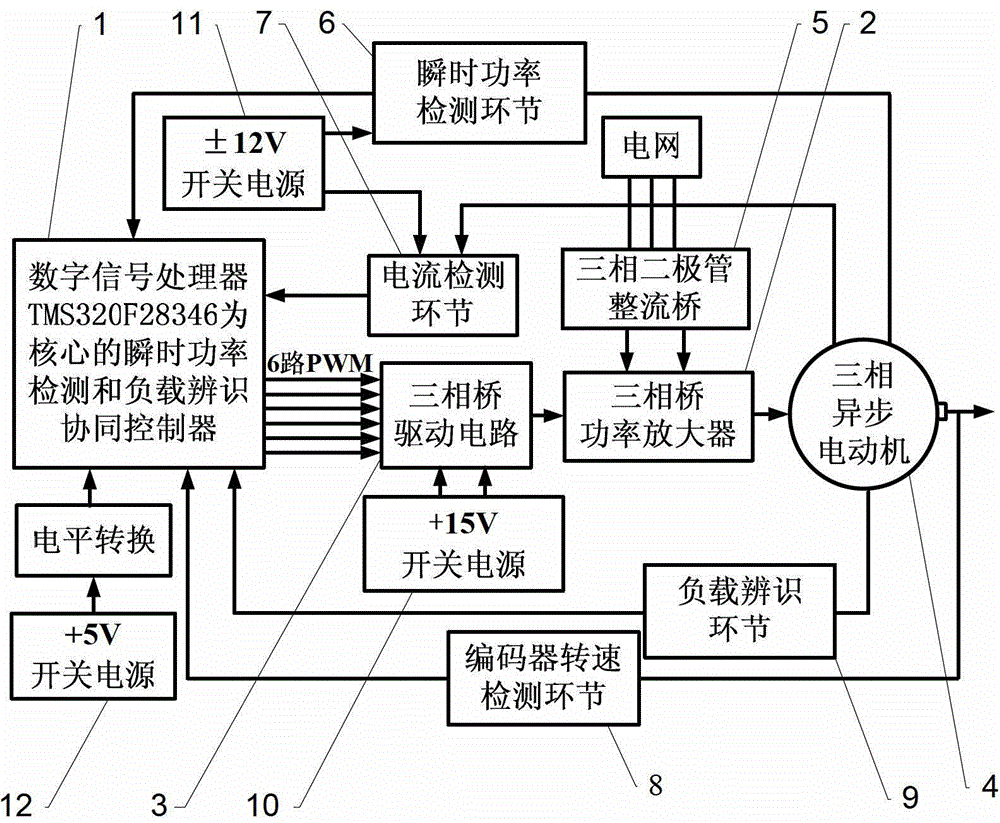

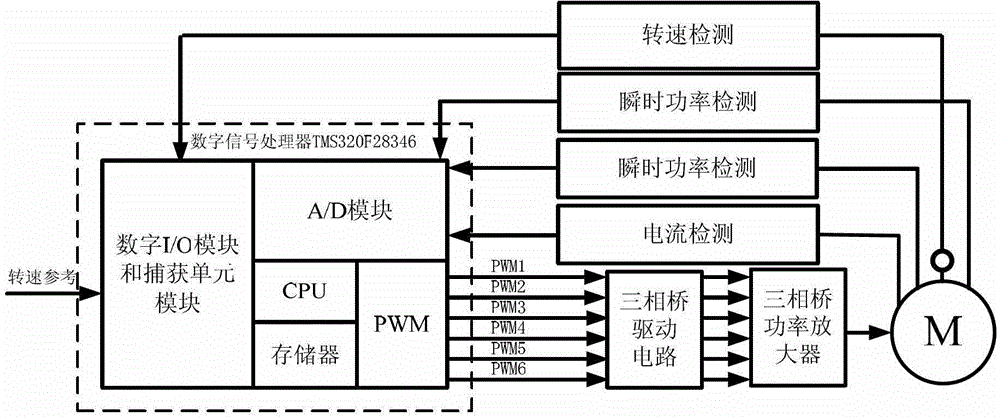

Instantaneous power detection and load identification based induction motor cooperative control system

ActiveCN103023420ARealize power-saving operationWith load following capabilityElectronic commutation motor controlAC motor controlDigital signal processingPower factor

The invention discloses an instantaneous power detection and load identification based induction motor cooperative control system which realizes energy-saving control on a light-loaded or unloaded three-phase induction motor and mainly comprises an instantaneous power detection and load identification cooperative controller using a digital signal processor TMS320F28346 as a core, a three-phase bridge power amplifier, a three-phase bridge driving circuit, the three-phase induction motor, a three-phase diode rectifier bridge, an instantaneous power detection link, a current detection link, a coder rotating speed detection link, a load identification link, a +24V switch power source, a +15V switch power source, a + / -12V switch power source, a +5V power source and the like. An instantaneous power detection and load identification based induction motor cooperative control method is adopted to control stator exciting current of the light-loaded or unloaded three-phase induction motor, and power factors of the three-phase induction motor are adjusted by load rate obtained on the basis of load identification, so that operating efficiency of the three-phase induction motor is effectively improved, and good electricity-saving effect is achieved.

Owner:BEIJING HONGHUI INT ENERGY TECH DEV CO LTD

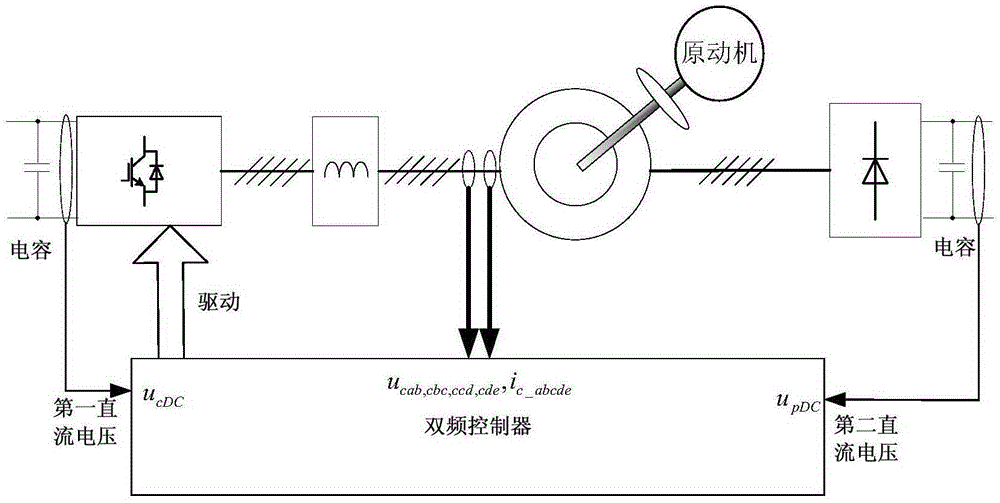

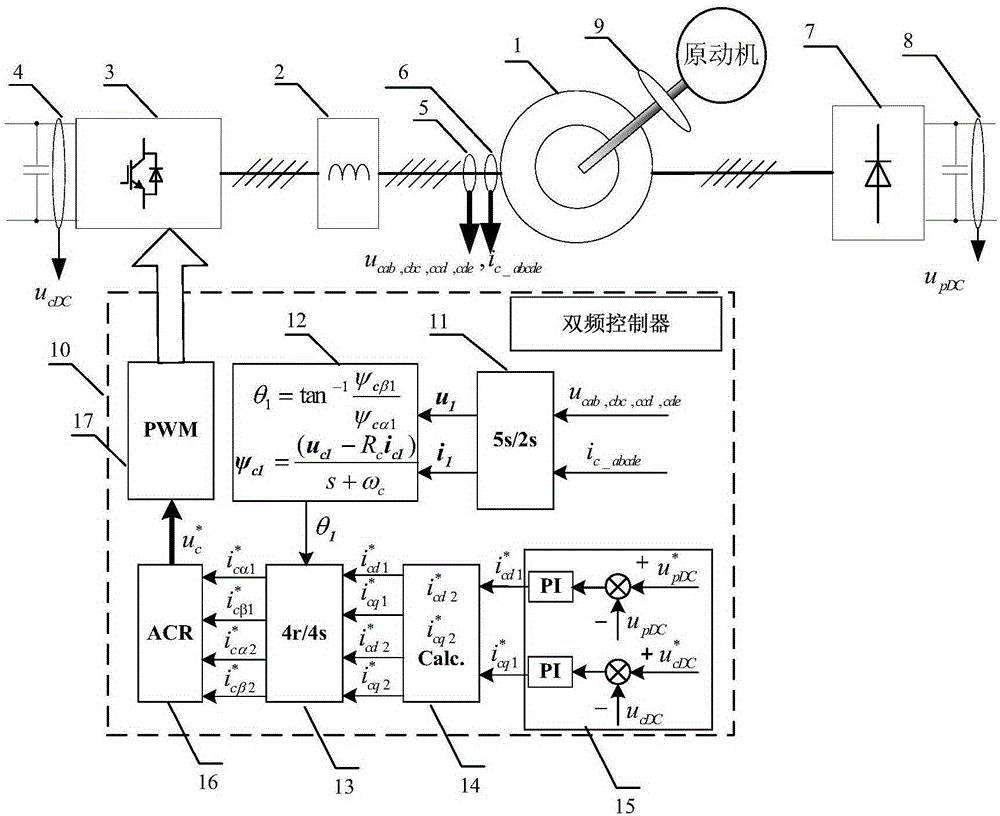

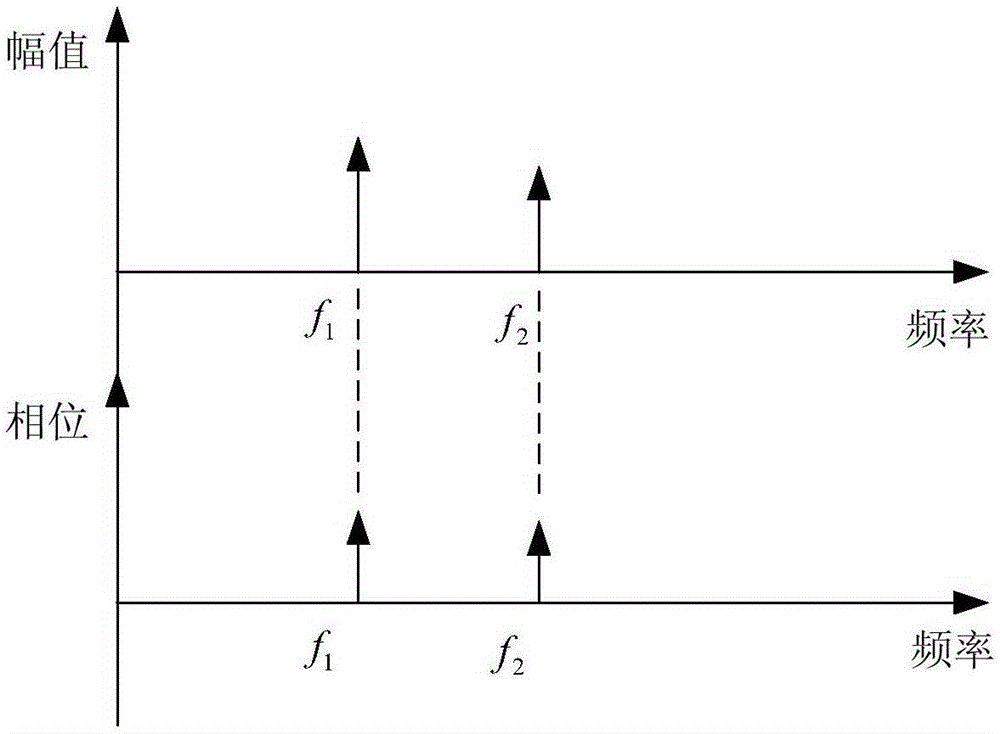

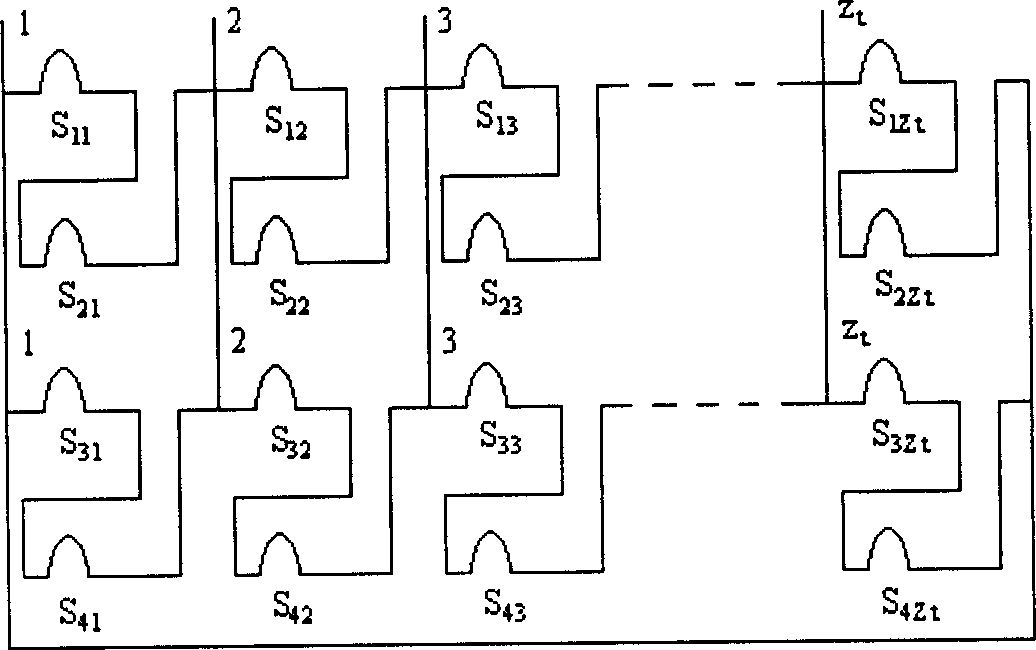

Control system and control method for double-frequency stator double-winding five-phase induction generation system

ActiveCN105186955APowerfulImprove efficiencyAsynchronous generator controlGenerator control by field variationPhase currentsControl system

The invention discloses a control method for a double-frequency stator double-winding five-phase induction generation system. The method comprises the following steps: collecting line voltage and phase current of a dual stator winding five-phase induction motor, first direct current voltage of a control winding side and second direct current voltage of a power winding side; respectively converting the line voltage and the phase current into a two-phase static coordinate system; calculating given current of a first frequency and the given current of a second frequency; calculating a phase signal of the first frequency, and converting the given current of the first frequency and the given current of the second frequency into a four-phase static coordinate system from a four-phase rotating coordinate system; and calculating given voltage in the static coordinate system and outputting a pulse width modulation voltage signal. According to the control method, control on optimal output of double-frequency signals and energy of the generation system under double frequencies can be achieved from the perspective of a control strategy on the basis of not changing generator hardware. The invention further discloses a control system for the double-frequency stator double-winding five-phase induction generation system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

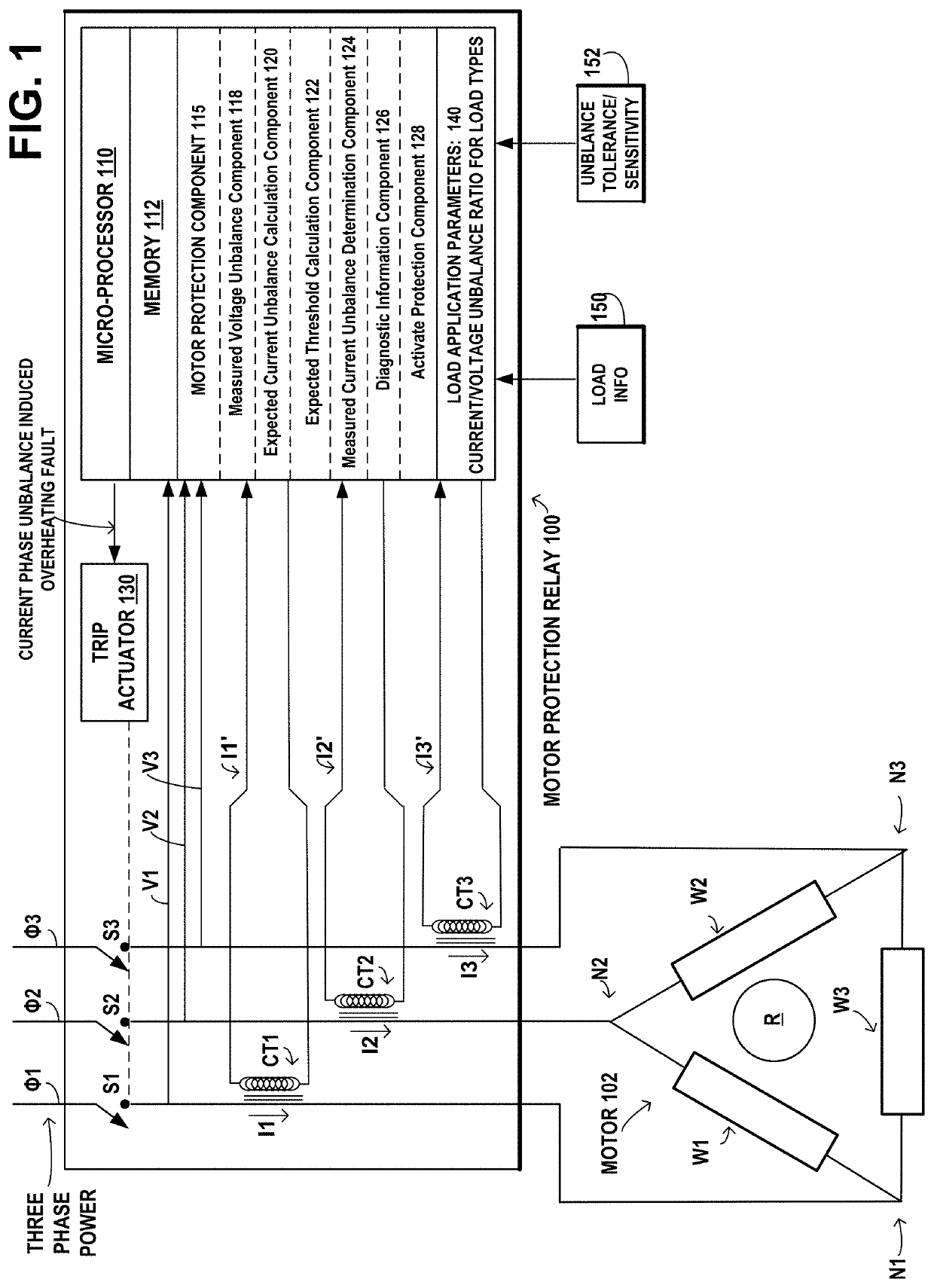

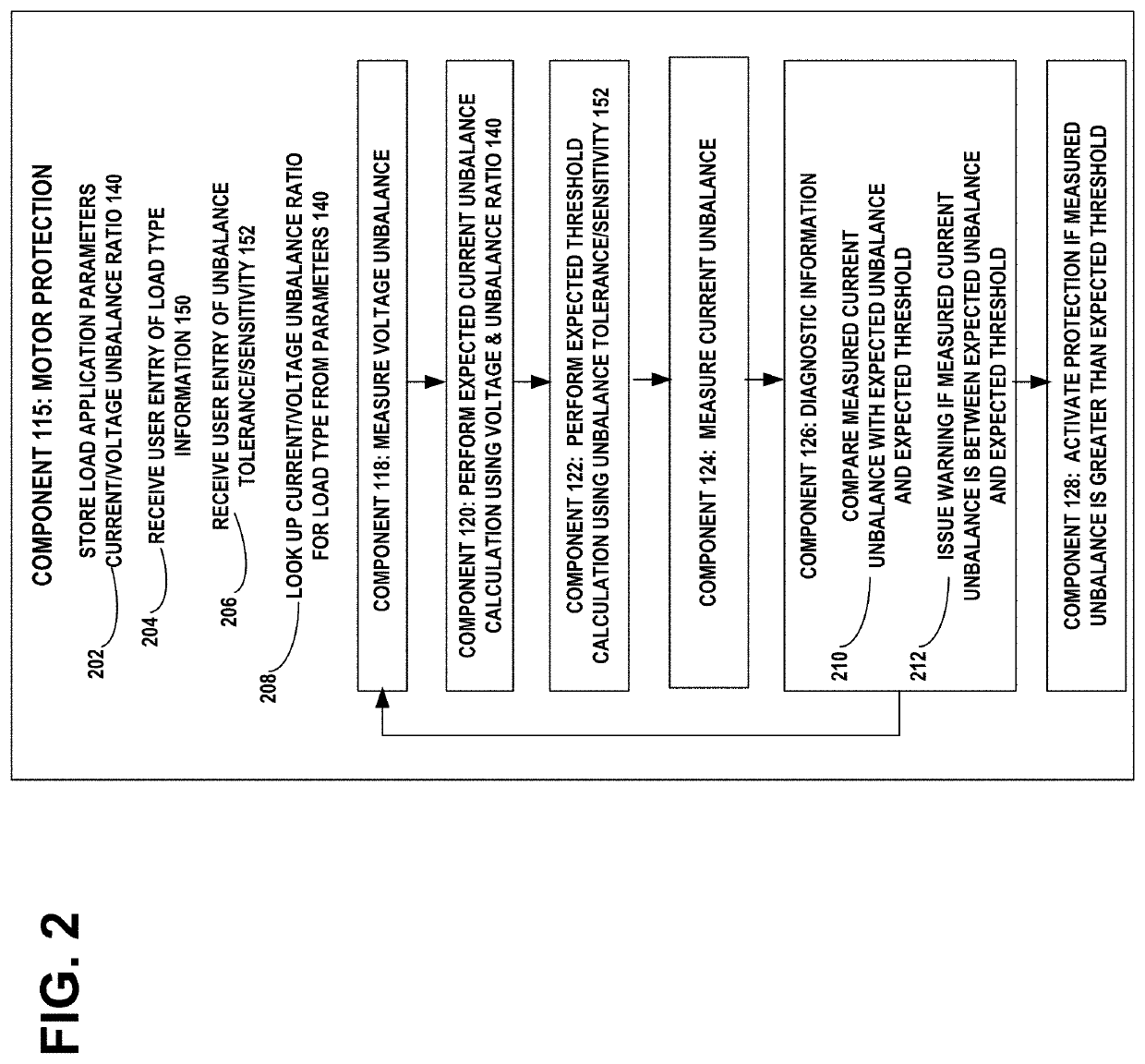

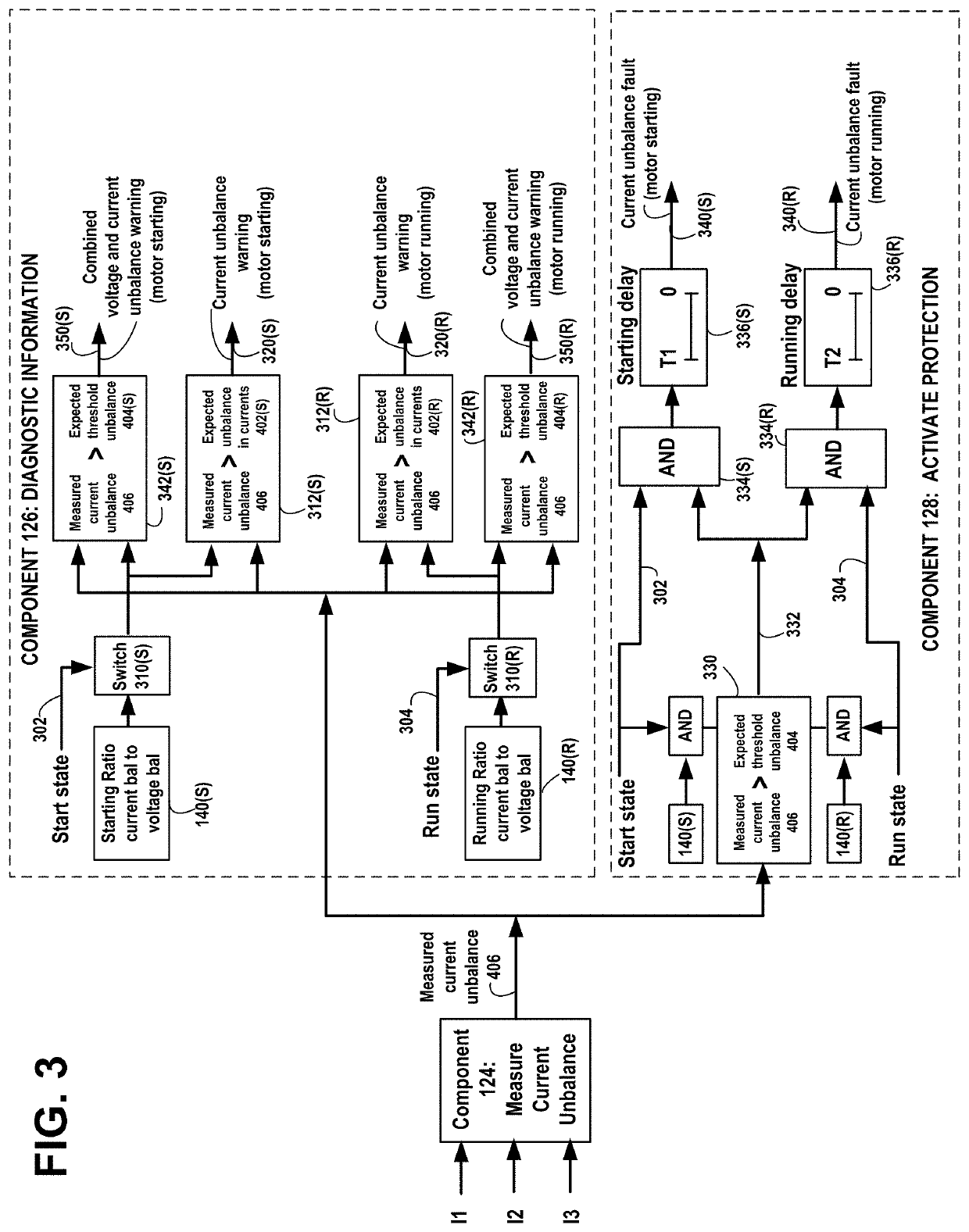

Motor branch circuit health monitoring method

ActiveUS20200403537A1Electric motor controlPolyphase induction motor starterEmergency medicineHealth well being

Techniques for monitoring the health of a three-phase induction motor are provided. An expected threshold value is calculated as a function of an expected ratio of current unbalance to voltage unbalance for the three-phase motor. Embodiments determine whether a measured current unbalance exceeds the expected threshold value. Responsive to the measured current unbalance exceeding the expected threshold value, a remedial action may be taken, such as generating diagnostic information or activating one or more protection operations for the three-phase induction motor.

Owner:SCHNEIDER ELECTRIC USA INC

Three-phase induction motor and its speed regulating method

InactiveCN1367567ALow costImprove reliabilityAsynchronous induction motorsWindings conductor shape/form/constructionPhase shiftedPhase difference

The present invention is a three phase induction motor and its speed regulating method which is called modified line phase shift speed regulating method. The three phase induction motor consists of astator and a rotor, of which there is a fixing phase winding with fixed phase shaft and a moving phase winding with movable phase shaft on stator. Each of these two winding will produce a rotary magnetic field and these two rotary magnetic fields having space phase difference will produce two induction potentials having time phase difference accordingly. To move phase shaft of woving phase winding by changing outlet line of moving phase winding to change space phase difference between two rotary magnetic fields and further to change time phase difference between two induction potentials in rotor guide strip, hence the current and composite induction potential in rotor guide strip will be changed and accordingly the rotor rotating speed and electromagnetic torque of three phase induction motor will be change too. The speed can be regulated in multistaze with no harmonic wave pollution.

Owner:SOUTH CHINA UNIV OF TECH

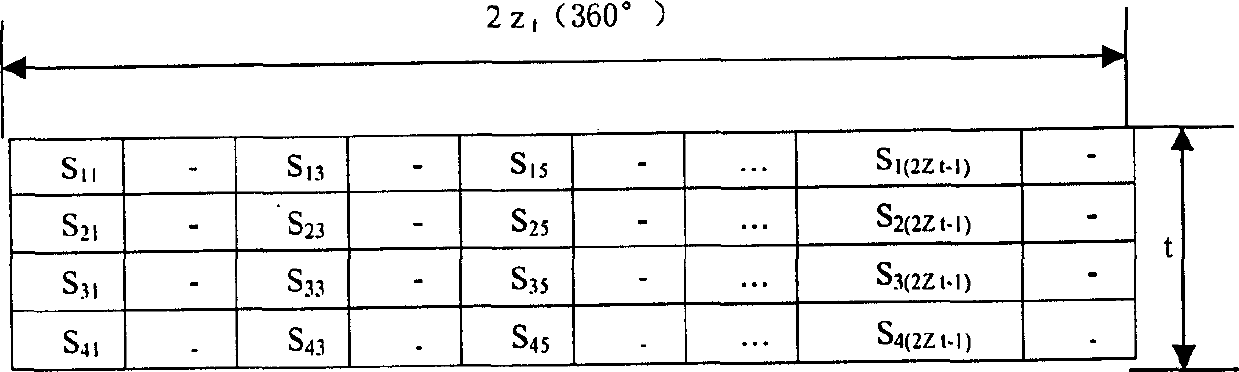

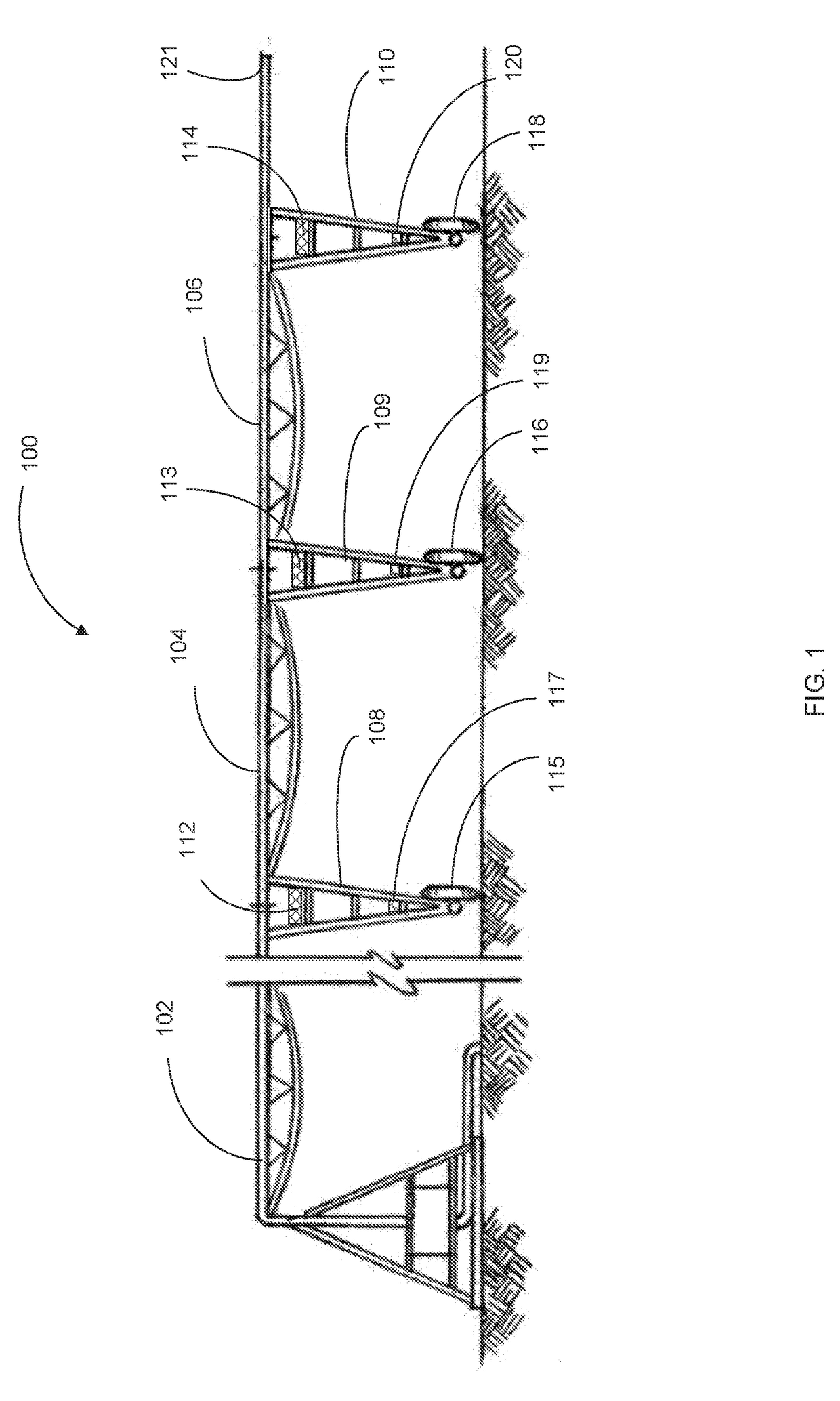

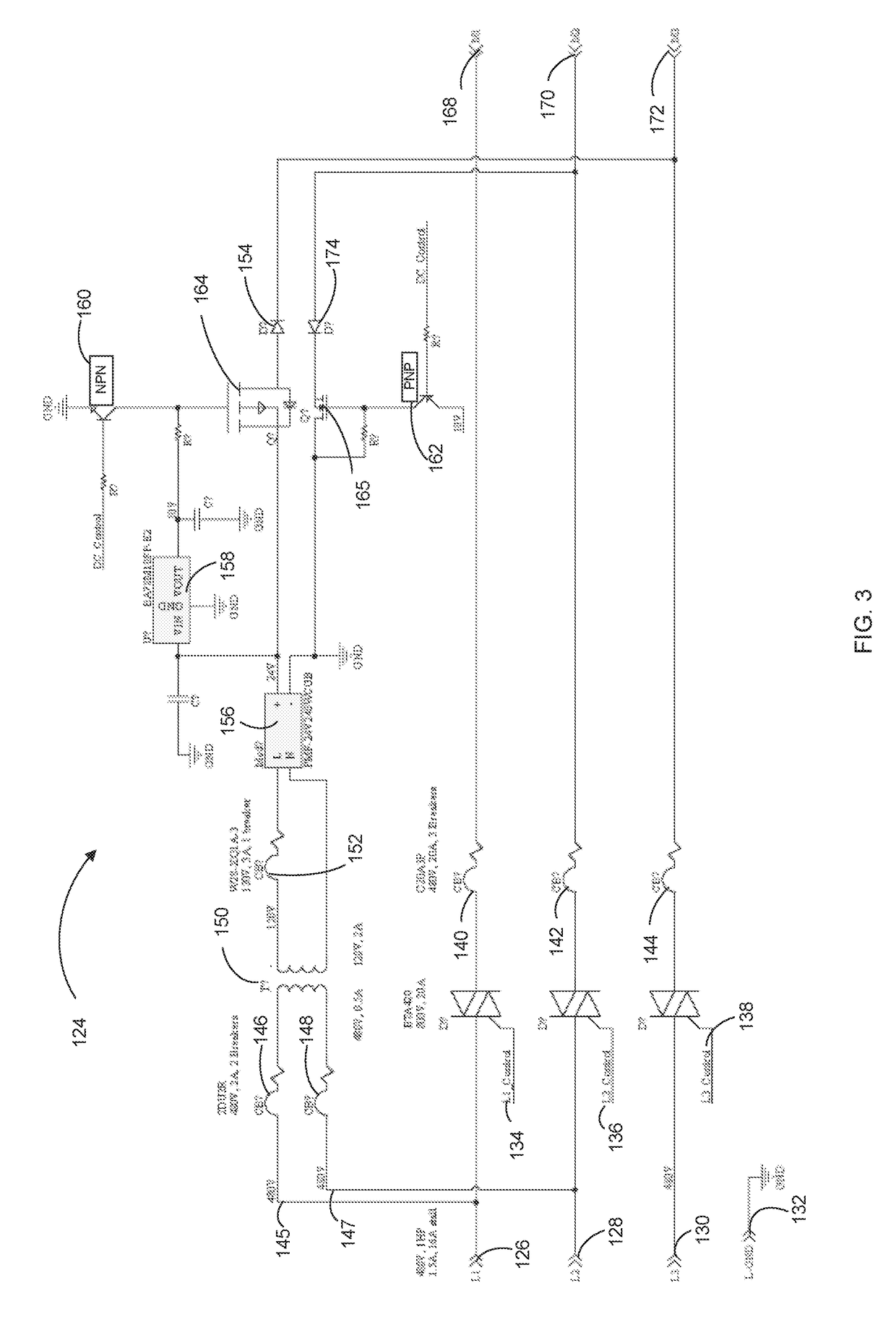

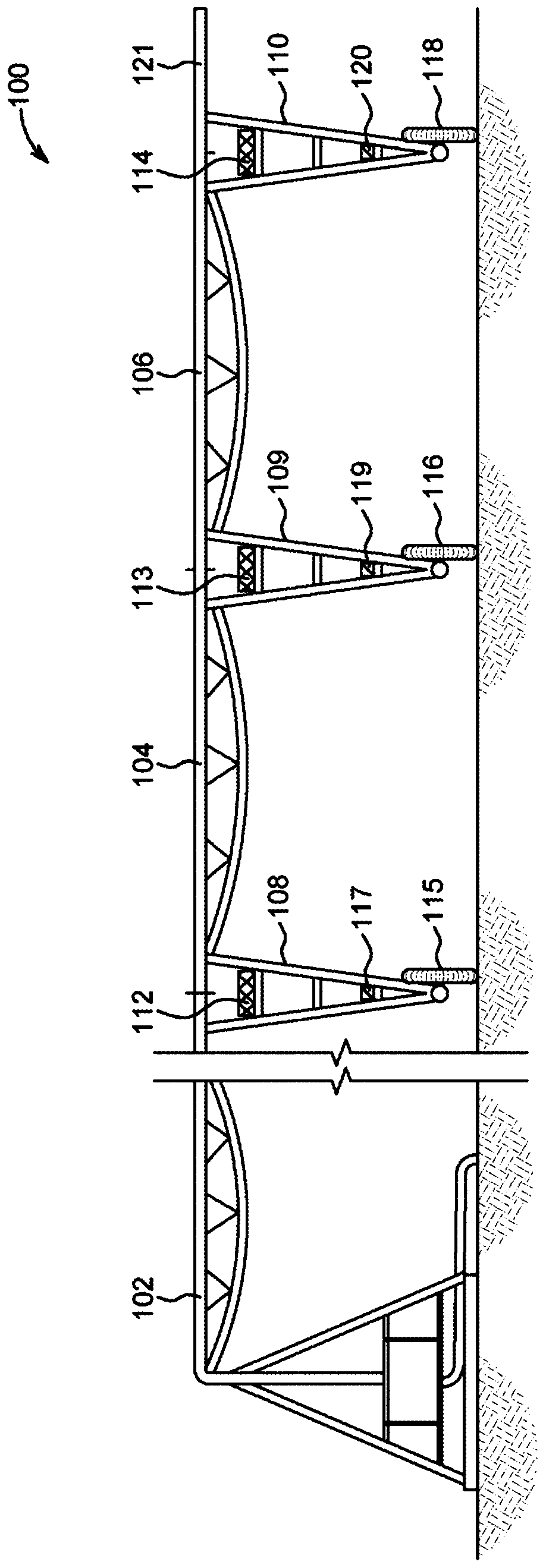

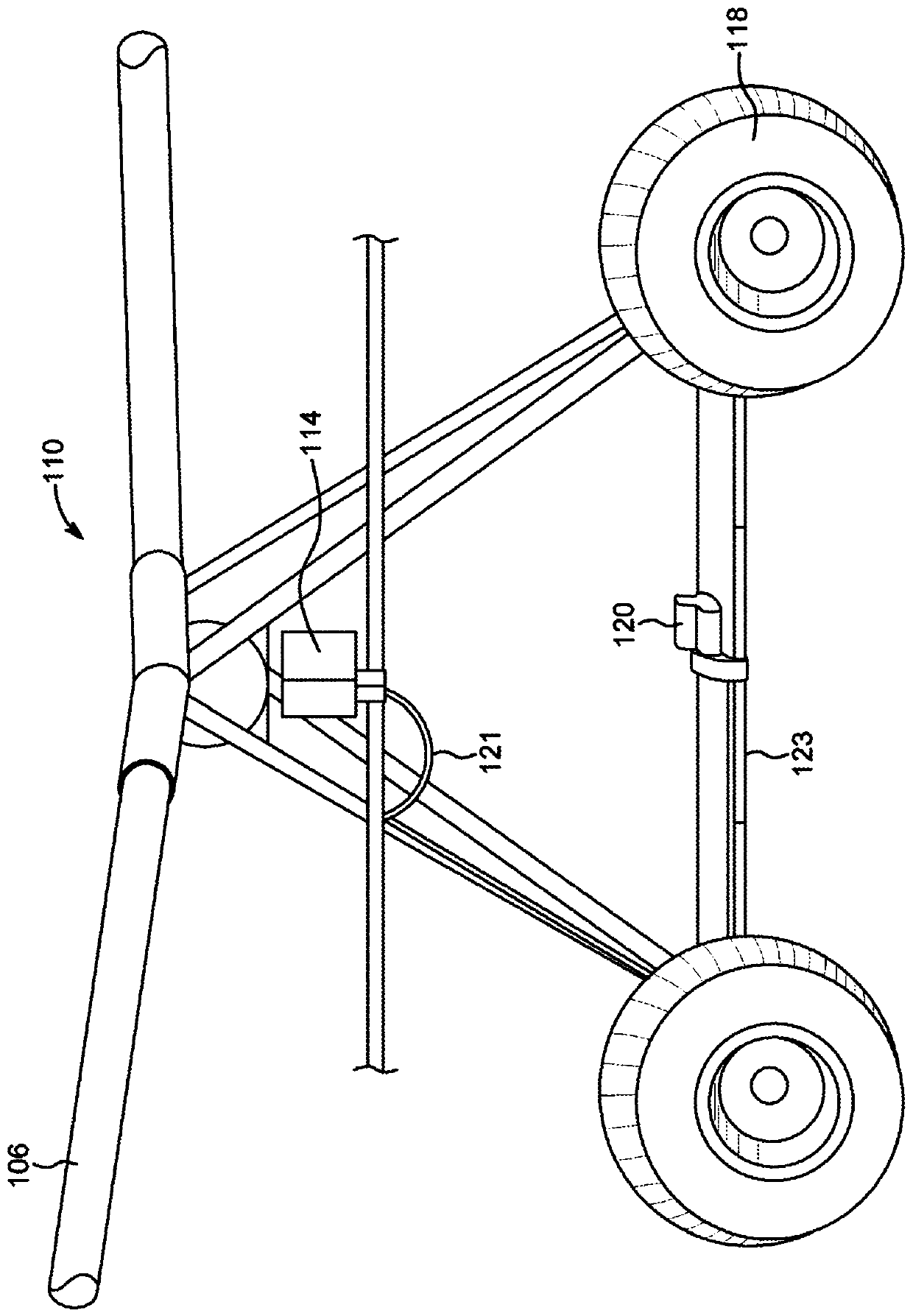

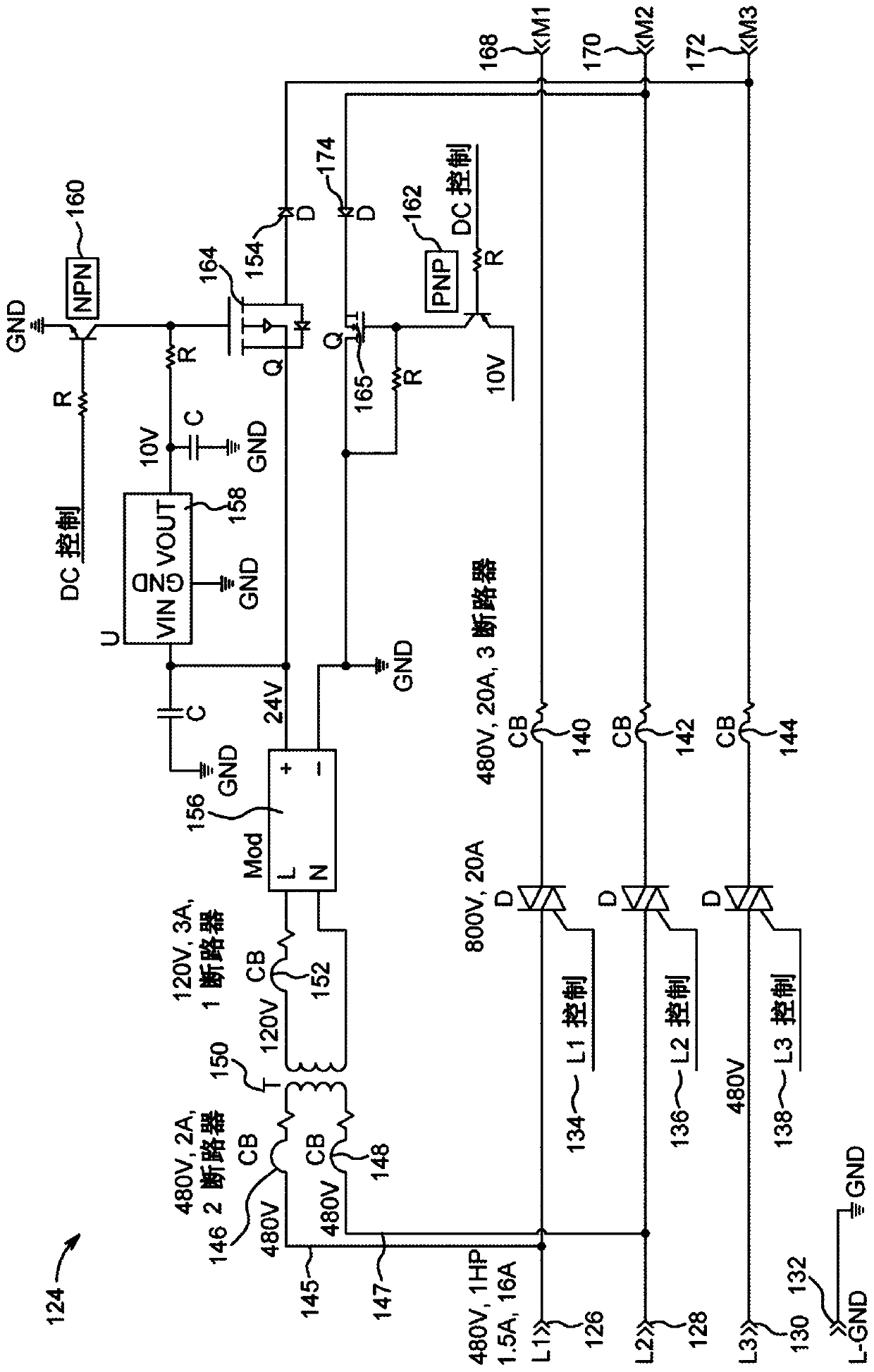

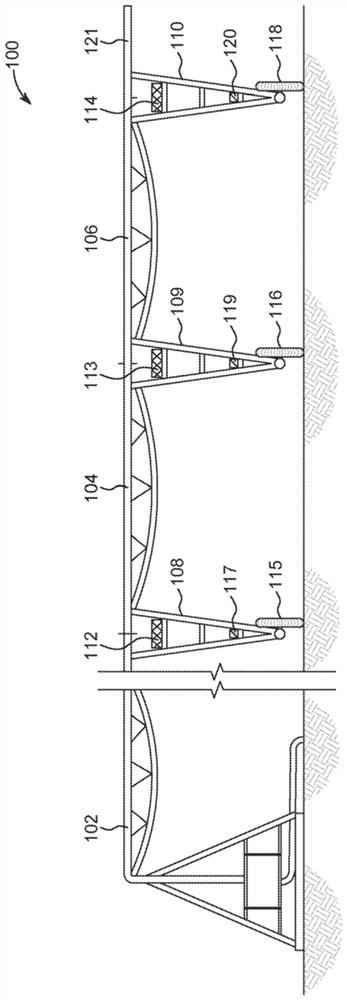

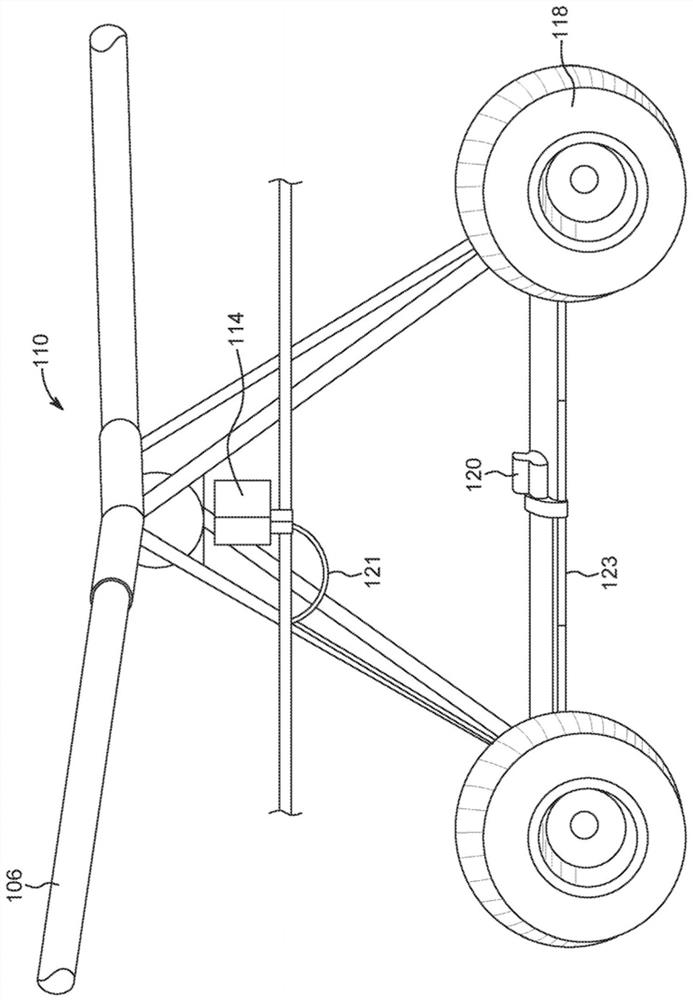

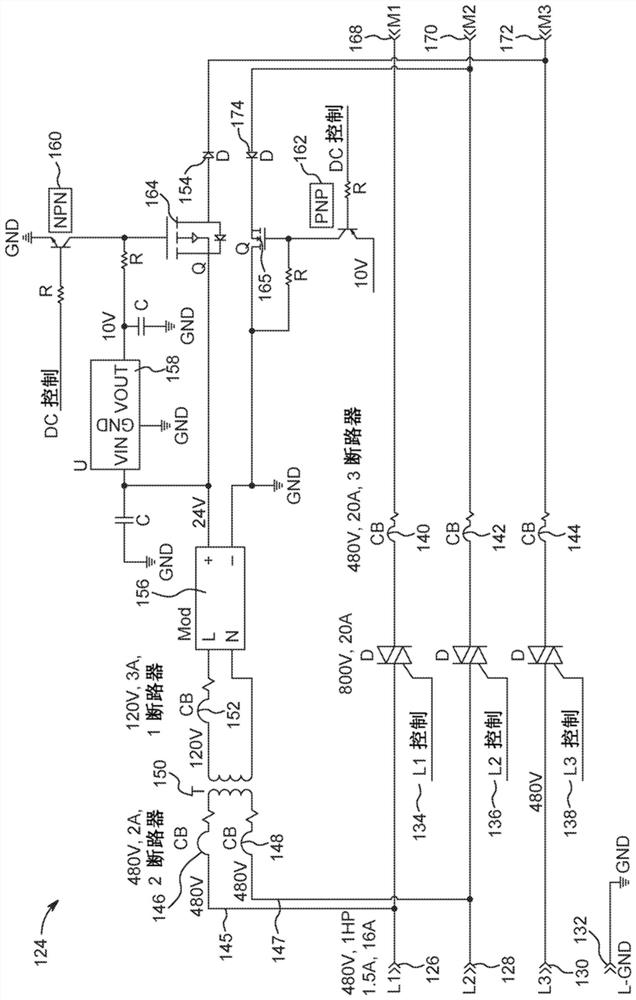

Electronic braking system for an irrigation machine

The present invention provides an electronic braking system for an irrigation machine. According to an exemplary preferred embodiment, the present invention includes a drive controller which includes a power supplying circuit which signals an ON condition when a motive power request is input into the drive controller and an OFF condition when motive power is not input into the system. According to a further preferred embodiment, the present invention further includes a 3-phase induction motor connected to apply torque to a drive shaft which is connected to a least one drive wheel. According to a further preferred embodiment, the power supplying circuit supplies 480V AC of motive power to the drive motor when the drive controller signals the ON condition and 10-80V DC of non-motive power to at least one phase of the motor when the drive controller signals the OFF condition. According to a further preferred embodiment, the application of the DC current is applied immediately after the motive power is removed from the drive motor and the application of non-motive power brakes and prevents the drive shaft from turning until the DC current is removed.

Owner:VALMONT INDUSTIES INC

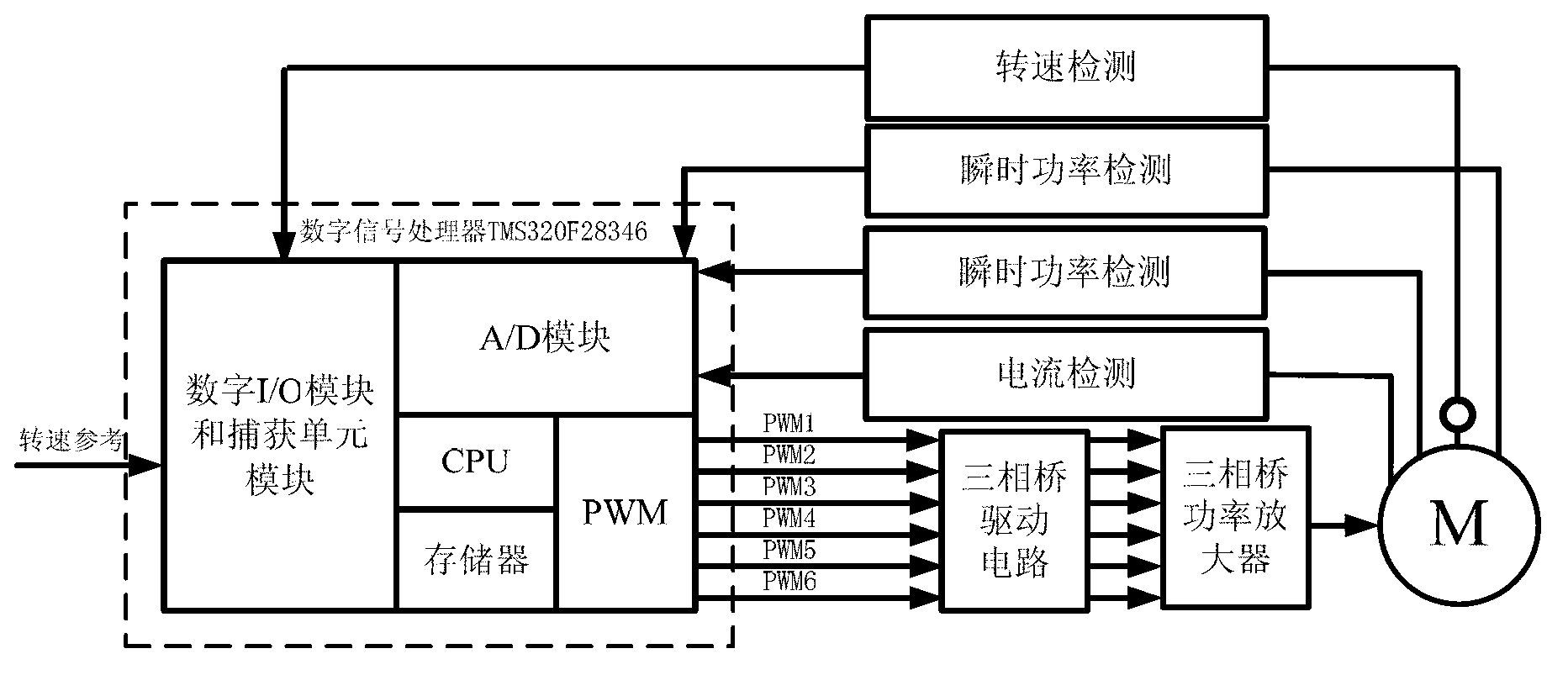

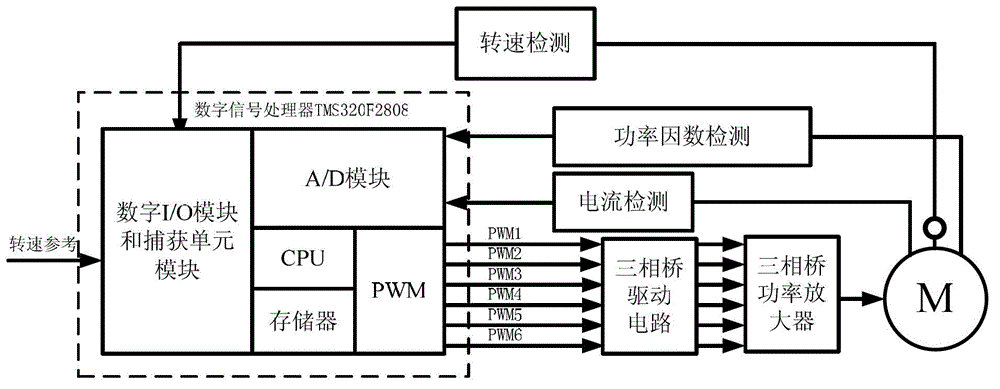

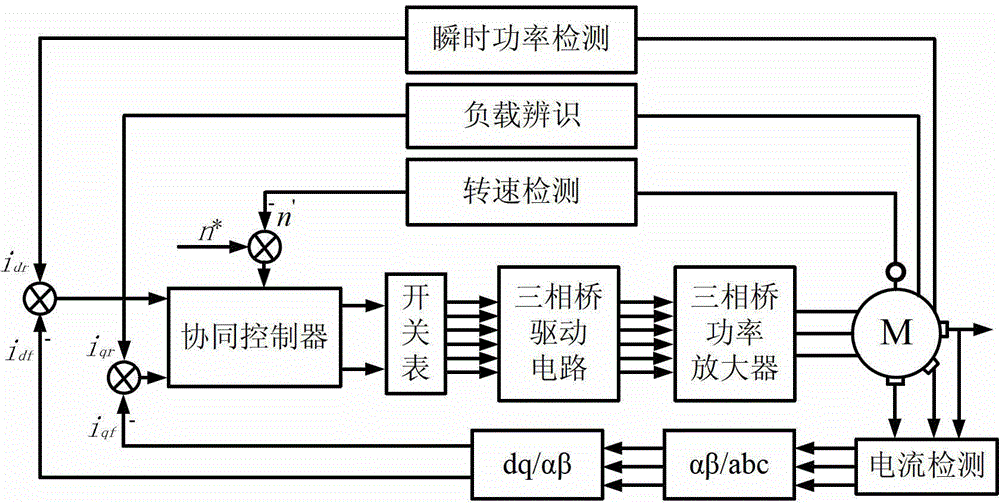

Direct power control system of high power factor induction motor

ActiveCN103066914ARealize energy savingReduce computationElectronic commutation motor controlVector control systemsDigital signal processingPower control system

A direct power control system of a high power factor induction motor realizes energy-saving control of a three-phase induction motor under the condition of light load or no load. The direct power control system of the high power factor induction motor comprises a controller using a digital signal processor TMS320F2808 as the core, a three-phase bridge power amplification device, a three-phase bridge driving circuit, the three-phase induction motor, a three-phase diode rectifier, a power factor detecting link, a current detecting link, an encoder rotating speed detecting link, a power factor measuring link, a + 24V switching power supply, a +15V switching power, a + / - switching power supply, a +5V switching power and the like. By means of the direct power control system applying power factor measurement, the stator flux linkage amplitude of the three-phase induction motor under the condition of light load or no load is controlled, instantaneous reactive power of the motor is adjusted, and therefore the motor power factor is effectively improved and a good energy-saving effect is achieved.

Owner:BEIJING HONGHUI INT ENERGY TECH DEV CO LTD

System and method for controlling indirect torque of single regulating loop of three-phase induction motor

ActiveCN102055401BHigh performance controlSimple structureElectronic commutation motor controlVector control systemsCycle controlVoltage vector

The invention discloses a system and method for controlling an indirect torque of a single regulating loop of a three-phase induction motor and relates to the technical field of motor drive and alternated current speed regulation. The system is provided with an indirect torque controller, a 32-bit digital signal processor used as the core of the system and a corresponding peripheral circuit. The software of the system comprises a flux linkage observation and torque calculation unit, a steady slip calculation unit, a revolving speed sampling period integral unit, a torque regulator unit, a stator flux linkage vector amplitude and phase calculation unit and a space voltage vector calculating and outputting unit. Through the method provided by the invention, the space voltage vector of controlling the motor in the next period can be acquired by utilizing the efficient value formula of each-phase electromotive force of a motor stator (UE is equal to 4.44kfNF), namely the ratio of the voltage vector amplitude to the phase gain is maintained as a constant when the motion track of a stator flux linkage vector is a flux linkage circle. In the invention, only the torque single proportional-integral (PI) regulating loop is required, thus the system structure is simplified, the dynamic property of the system is enhanced, and the high-performance control of the driving system of the three-phase induction motor is realized.

Owner:武汉菱电汽车电控系统股份有限公司

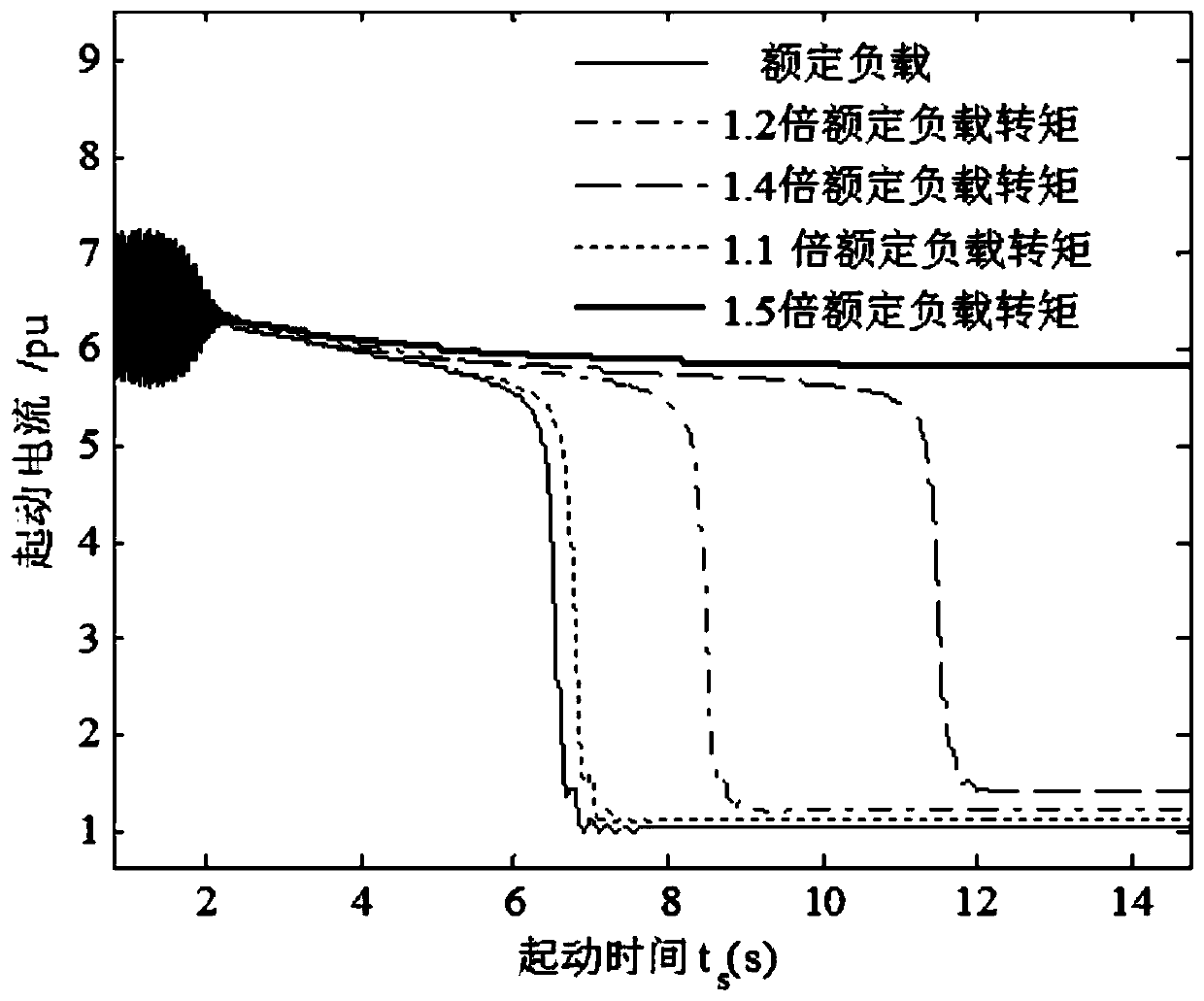

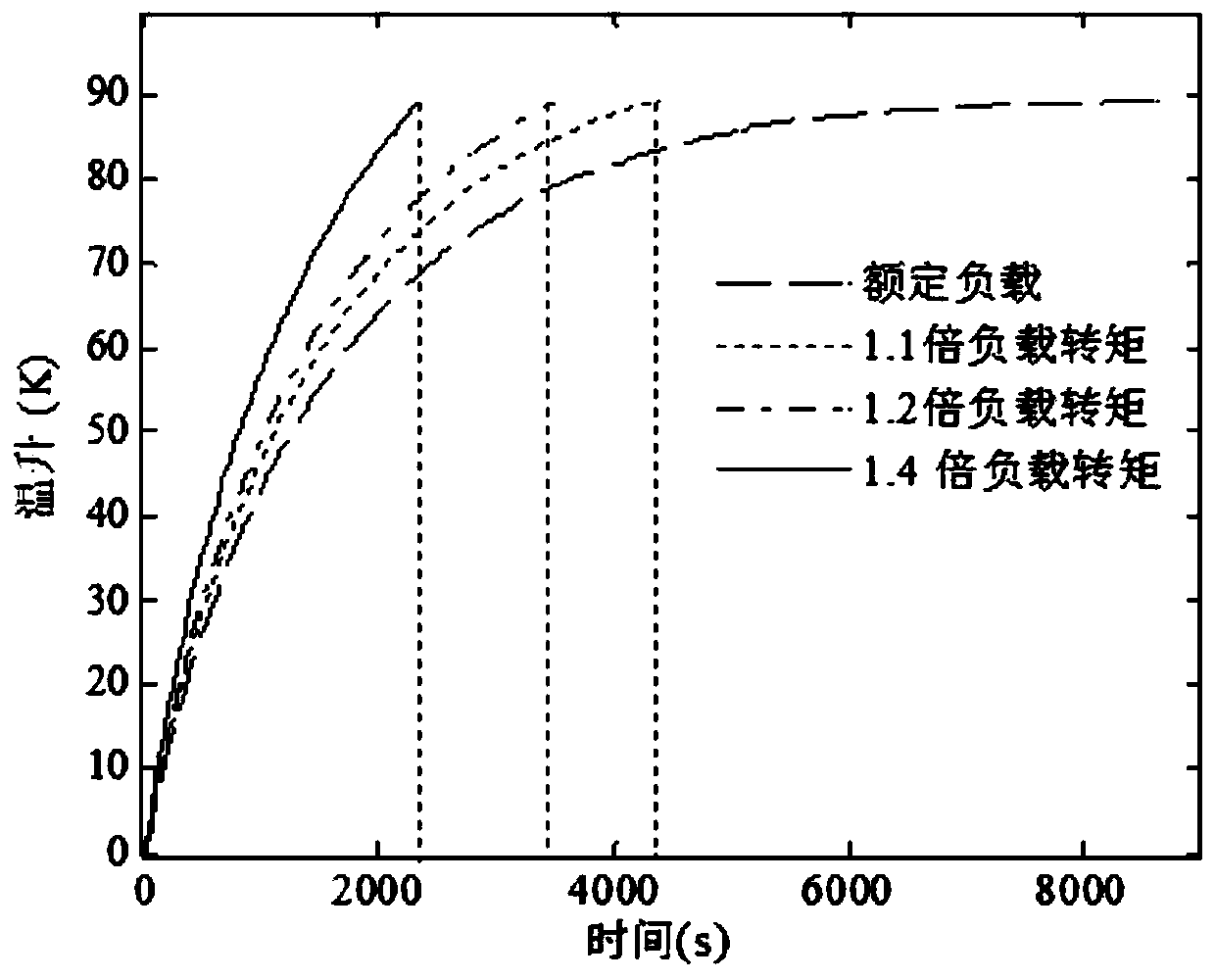

Starting method of 3-phase induction motor and decanter type centrifugal separator

InactiveCN107645252AReduce the riseCentrifugesPolyphase induction motor starterElectricityFive phase induction motor

The invention provides a starting method of a 3-phase induction motor. Compared with a basic starting method, the starting method is advantaged in that the temperature increase amplitude of the 3-phase induction motor during the starting process of a decanter type centrifuge can be reduced. By means of the starting method of the 3-phase induction motor, a revolving drum of a decanter type centrifugal separator carrying out centrifugal separation on an object to be processed rotates faster from a stop state to a target speed. The starting method is characterized in that by employing a star connection mode, a power supply is electrically connected with the 3-phase induction motor, a thyristor is employed to shear waveform of voltage supplied from the power supply to the 3-phase induction motor while the 3-phase induction motor is started, furthermore, when the current effective value of the 3-phase induction motor is reduced in the starting process, a process for increasing the conduction angle of the thyristor is carried out.

Owner:TOMOE ENGINEERING CO LTD

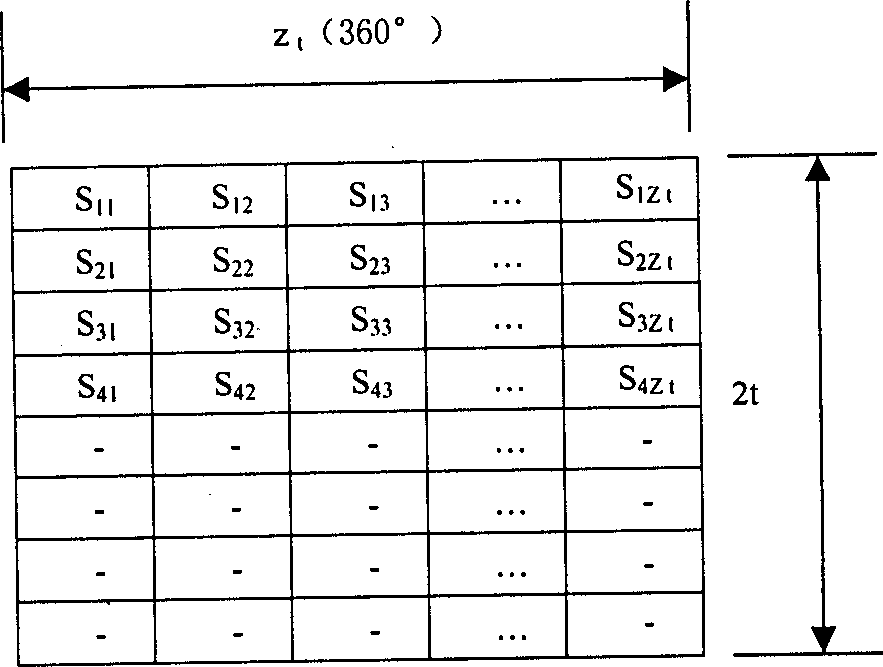

Method for determining threshold value of multi-working-system three-phase induction motor protection system

ActiveCN110224376ATake advantage ofAvoid malfunctions such as stallingEmergency protective circuit arrangementsStart timeMathematical model

The invention relates to a method for determining a threshold value of a multi-working-system three-phase induction motor protection system, belongs to the technical field of motor control, and solvesthe problem that an action value of an inherent protection control system of a motor does not allow the motor to operate in other load modes. The method comprises the following steps of calculating electromagnetic torque, and determining the overload capacity of the motor; establishing a dynamic mathematical model of the motor, and calculating the current of a winding; determining the loss in themotor; establishing a fluid-temperature temperature field three-dimensional coupling analysis model of the three-phase induction motor; driving the temperature rise values during different load operation according to the three-phase induction motor under the short-time working system, and determining the short-time working time limit when the motor drives the load to operate in an overload mode;and calculating the starting time and the running current during overload running of the motor, determining the threshold value of the protection action during short-time overload running of the motoraccording to the current value and the setting requirements of overload protection, over-current protection and short circuit protection of the motor, and determining the starting time value of the motor over-current protection required to be hidden. According to the method, the safety guarantee is provided for the operation of the motor in the multi-load mode.

Owner:HARBIN UNIV OF SCI & TECH

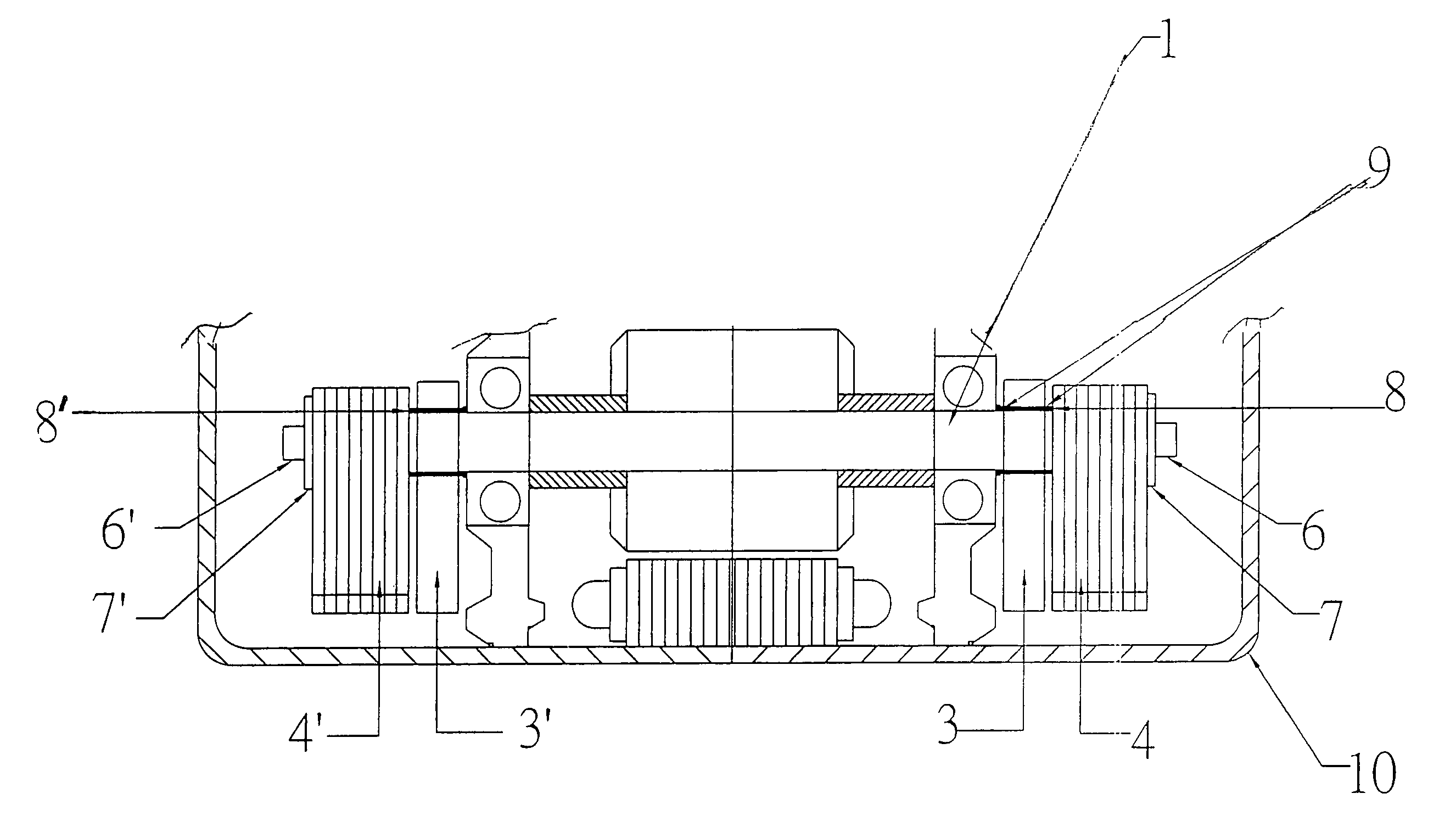

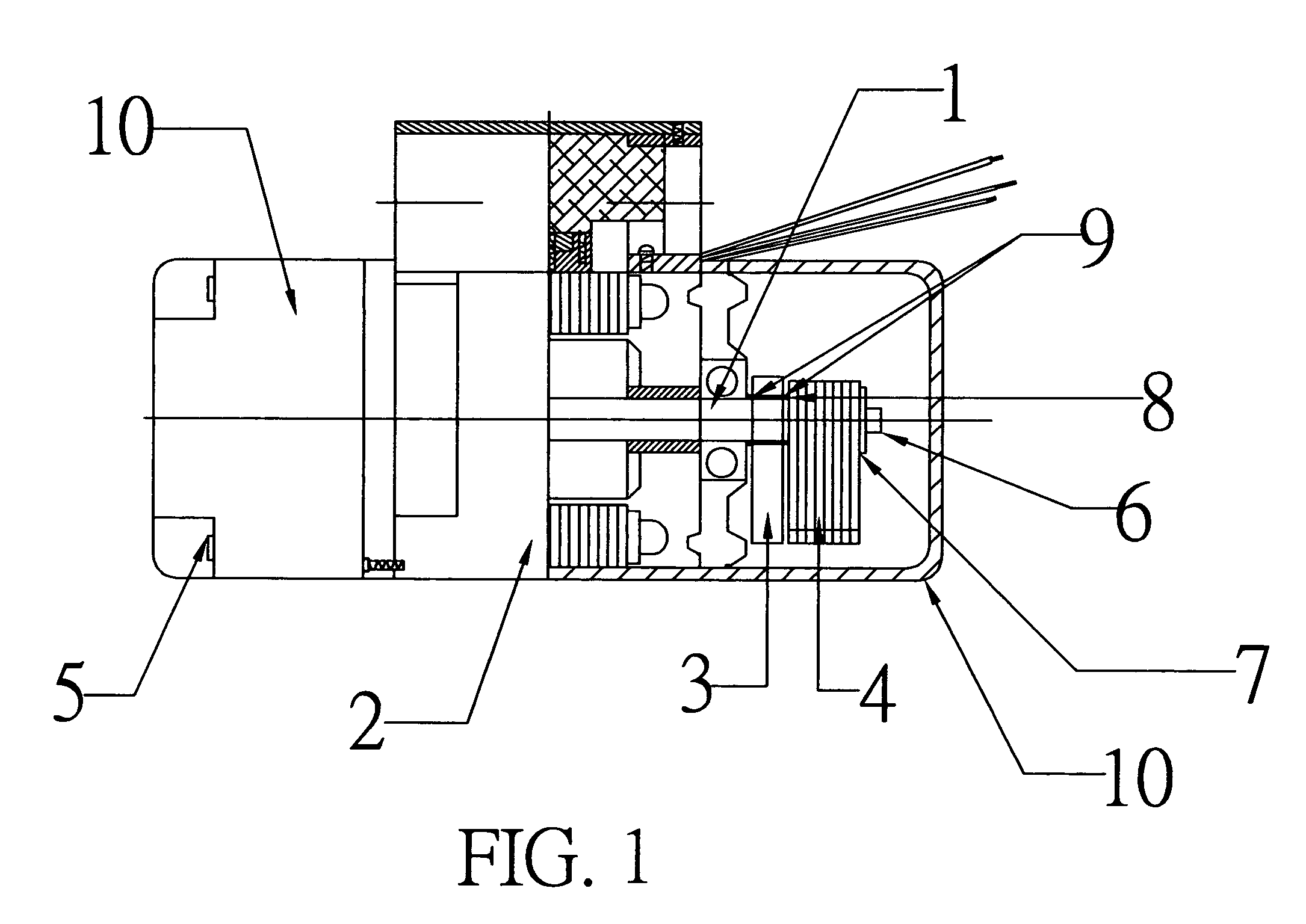

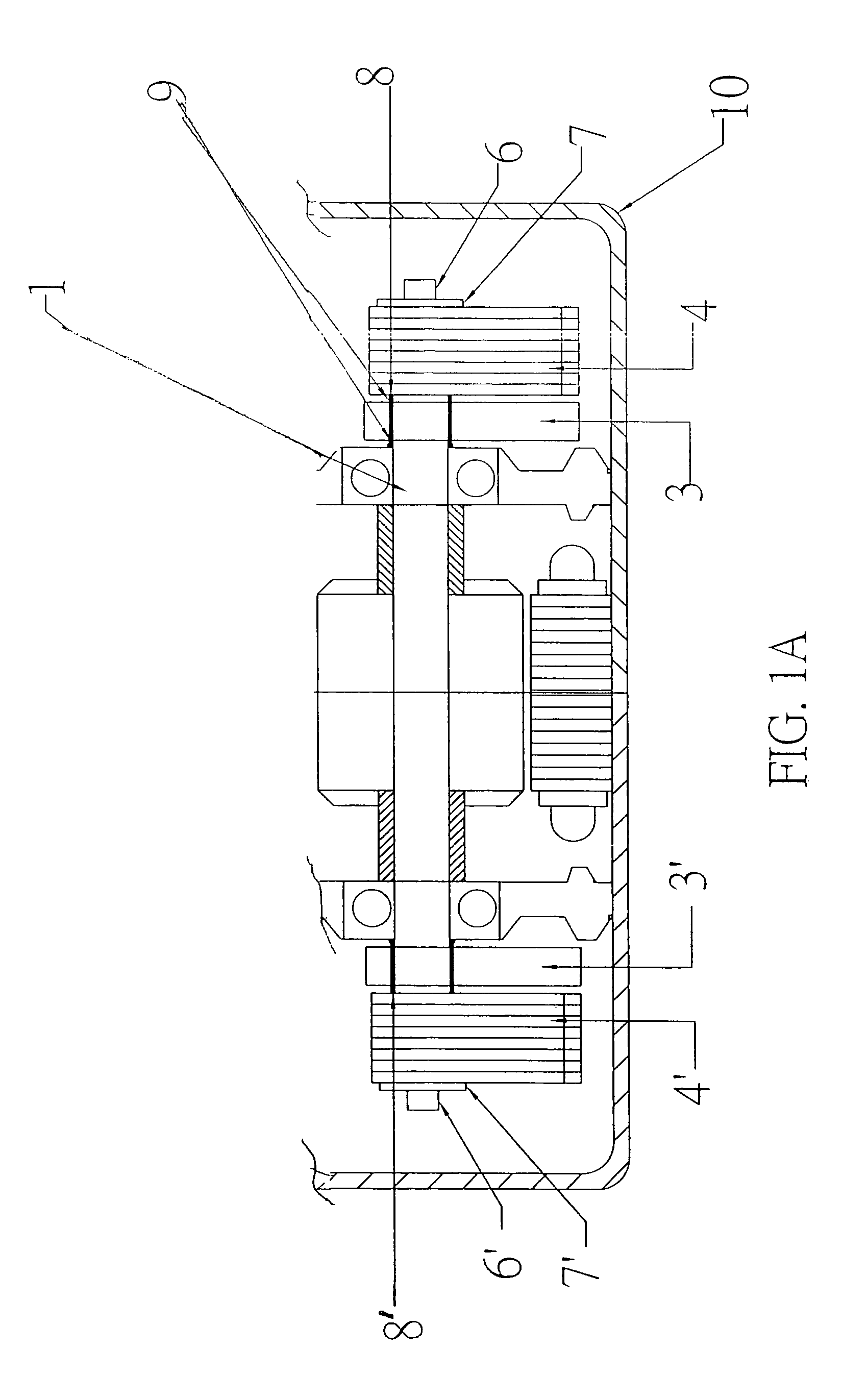

Three-phase induction motor

InactiveUS20070176522A1Chiropractic devicesAsynchronous induction motorsFrequency changerThree phase asynchronous motor

The preferred embodiment the invention proposes pertains to a three-phase induction motor, and operates on the premises of having the extension cords on two ends of the motor embedded with several balancing eccentric washers and a balancing eccentric block added, of which the eccentric block contains a sleeve bearing, and one end of the eccentric block is fitted with a bolt, with the bolt head covered with rubber; o-ring is fitted between the balancing eccentric washer and balancing eccentric block, whereby using the invention's frequency changer for controlling an AC 3-phase induction motor serves to generate multiple frequencies for generating different amplitudes, which can be use to control the speed and load emitted between the eccentric block and balancing eccentric washer.

Owner:PENG HUAN YAU

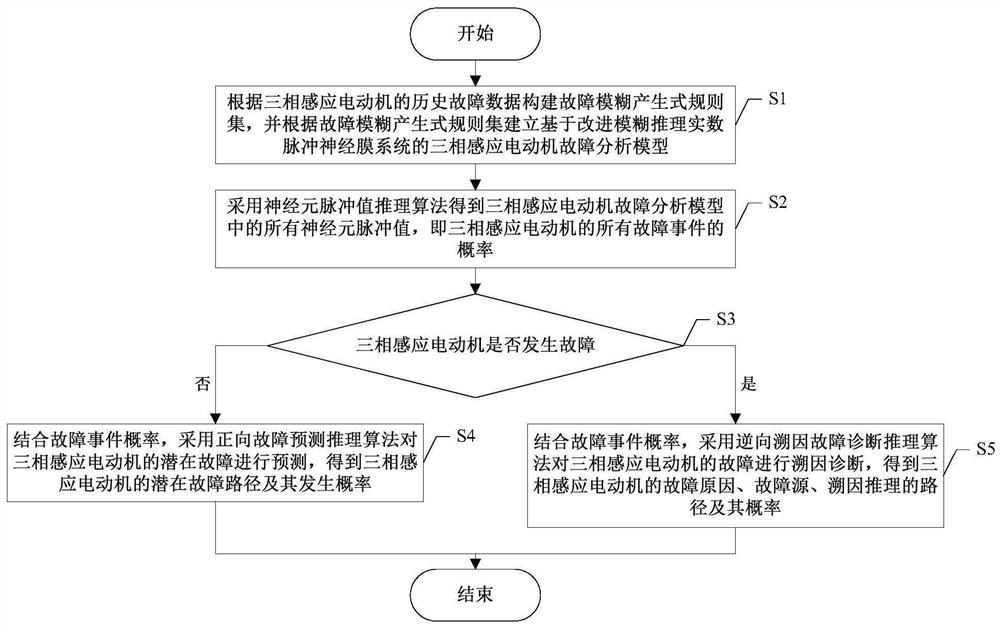

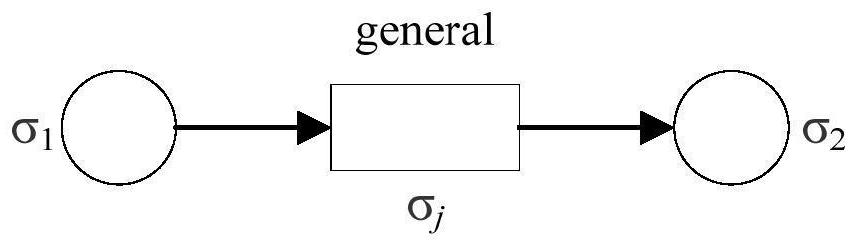

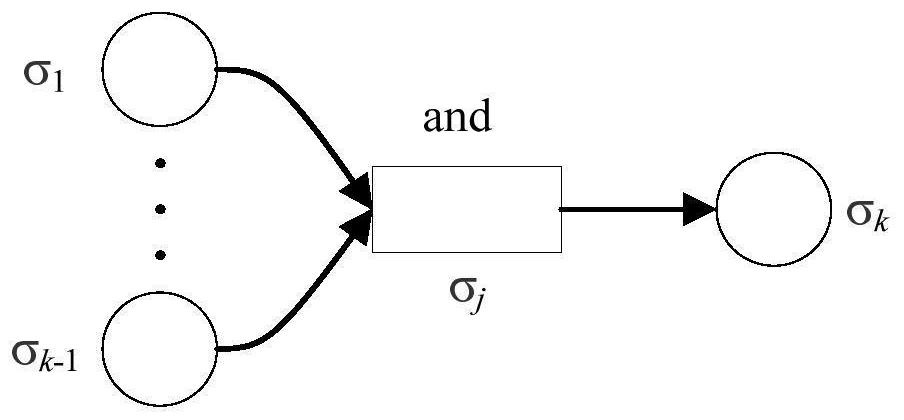

Three-phase induction motor fault analysis method based on spiking neural P system

The invention discloses a three-phase induction motor fault analysis method based on a spiking neural membrane system. A forward fault prediction reasoning algorithm and a reverse tracing fault diagnosis reasoning algorithm are provided based on an improved fuzzy reasoning real number spiking neural membrane system. Before the three-phase induction motor breaks down, a motor is started, fault prediction is performed on the three-phase induction motor through a forward fault prediction reasoning algorithm, so that possible faults of the three-phase induction motor can be effectively predicted; and after the three-phase induction motor breaks down, fault diagnosis is conducted on the three-phase induction motor through a reverse cause tracing fault diagnosis reasoning algorithm, and the fault cause and the fault source causing the fault can be effectively determined. The three-phase induction motor fault analysis model based on the improved fuzzy reasoning real number spiking neural membrane system is established from the perspective of the whole machine, and the defect that accurate fault causes and fault sources are difficult to find after faults occur in an existing method is effectively overcome.

Owner:XIHUA UNIV

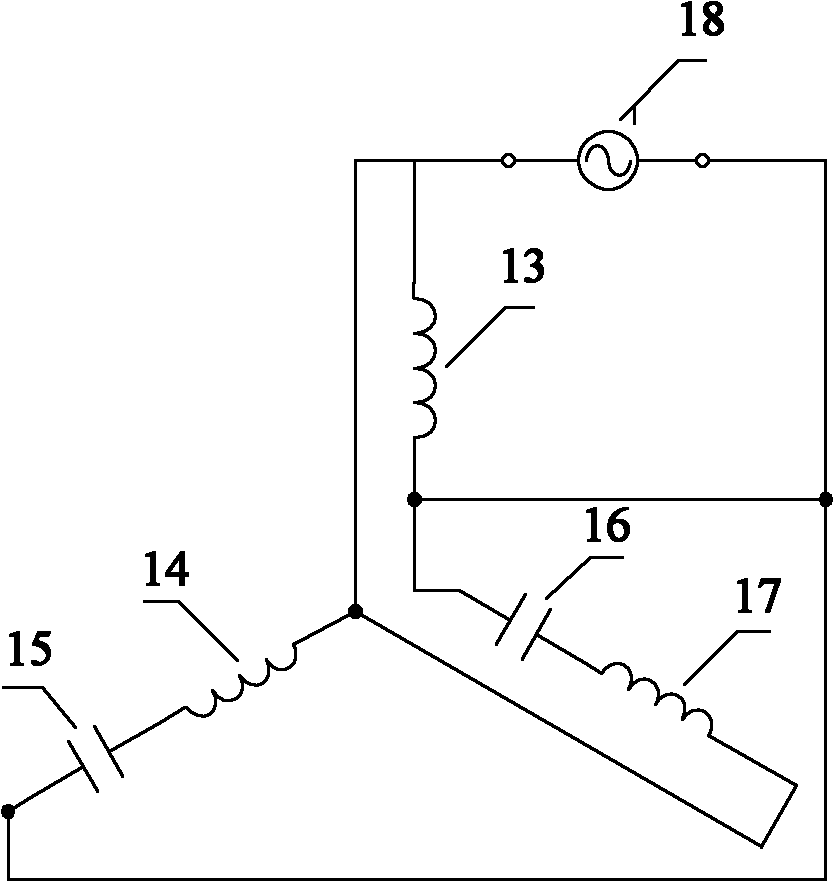

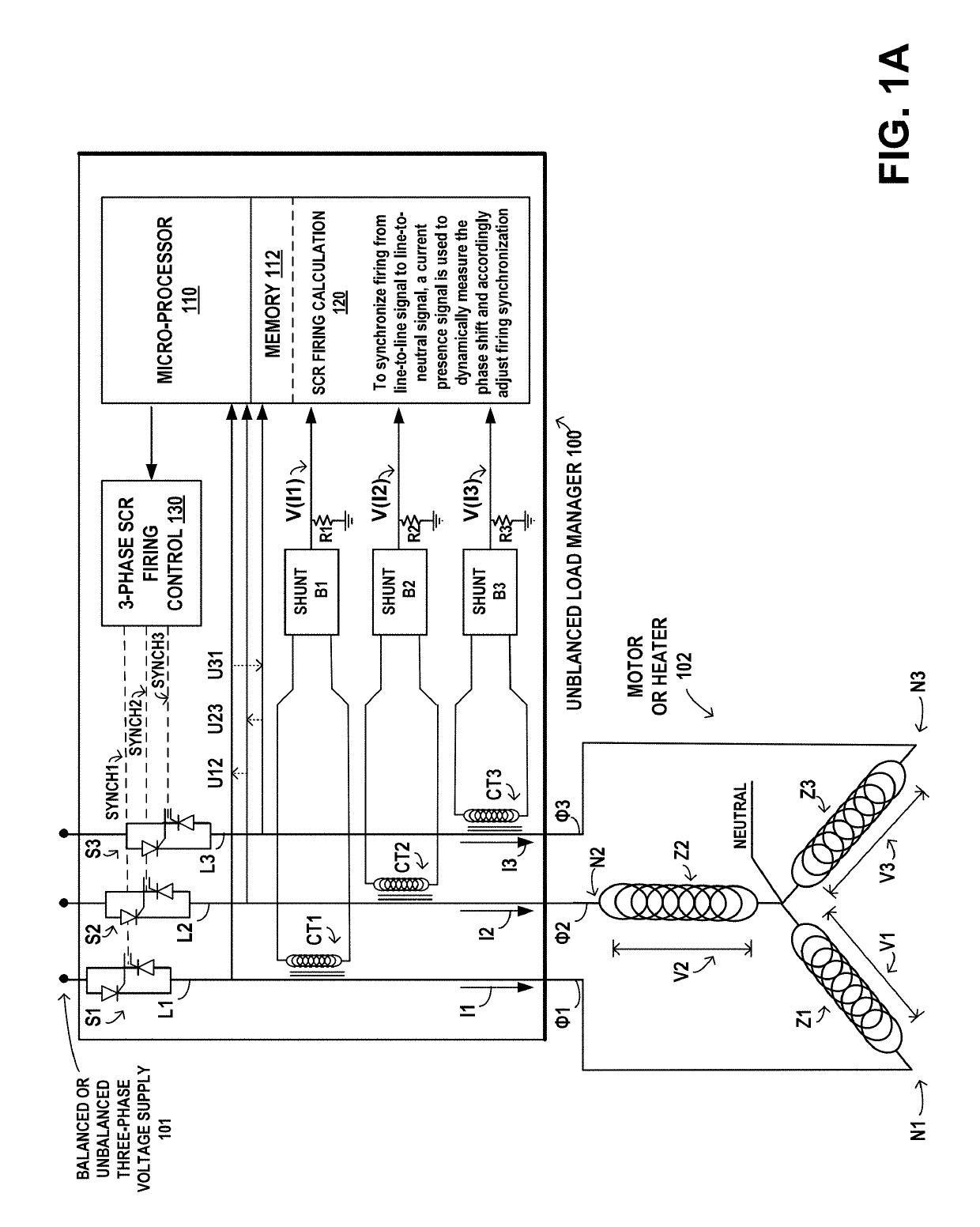

Method to drive a power control device connected to unbalanced three-phase loads when no neutral reference is available in an alternative electrical network

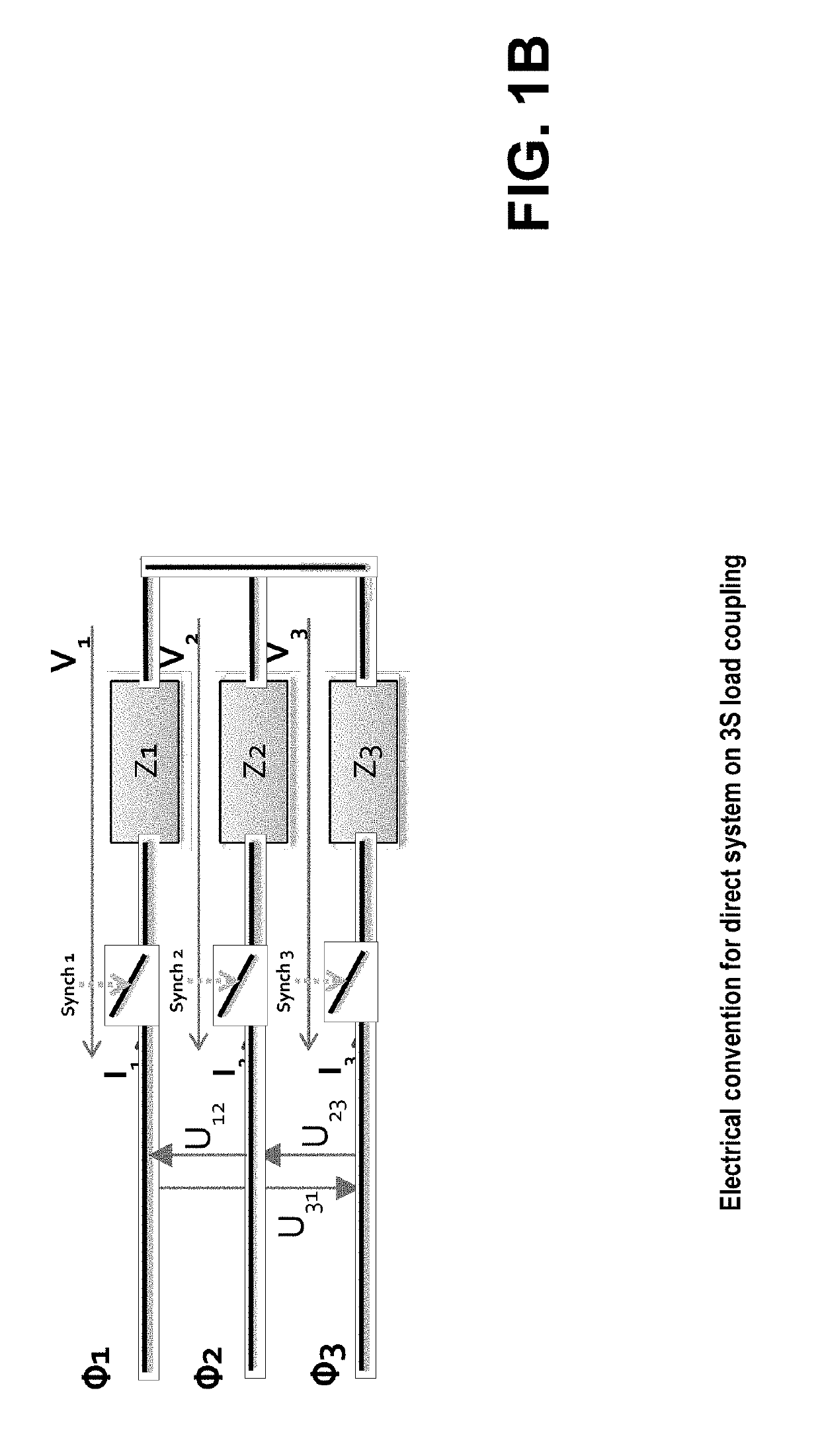

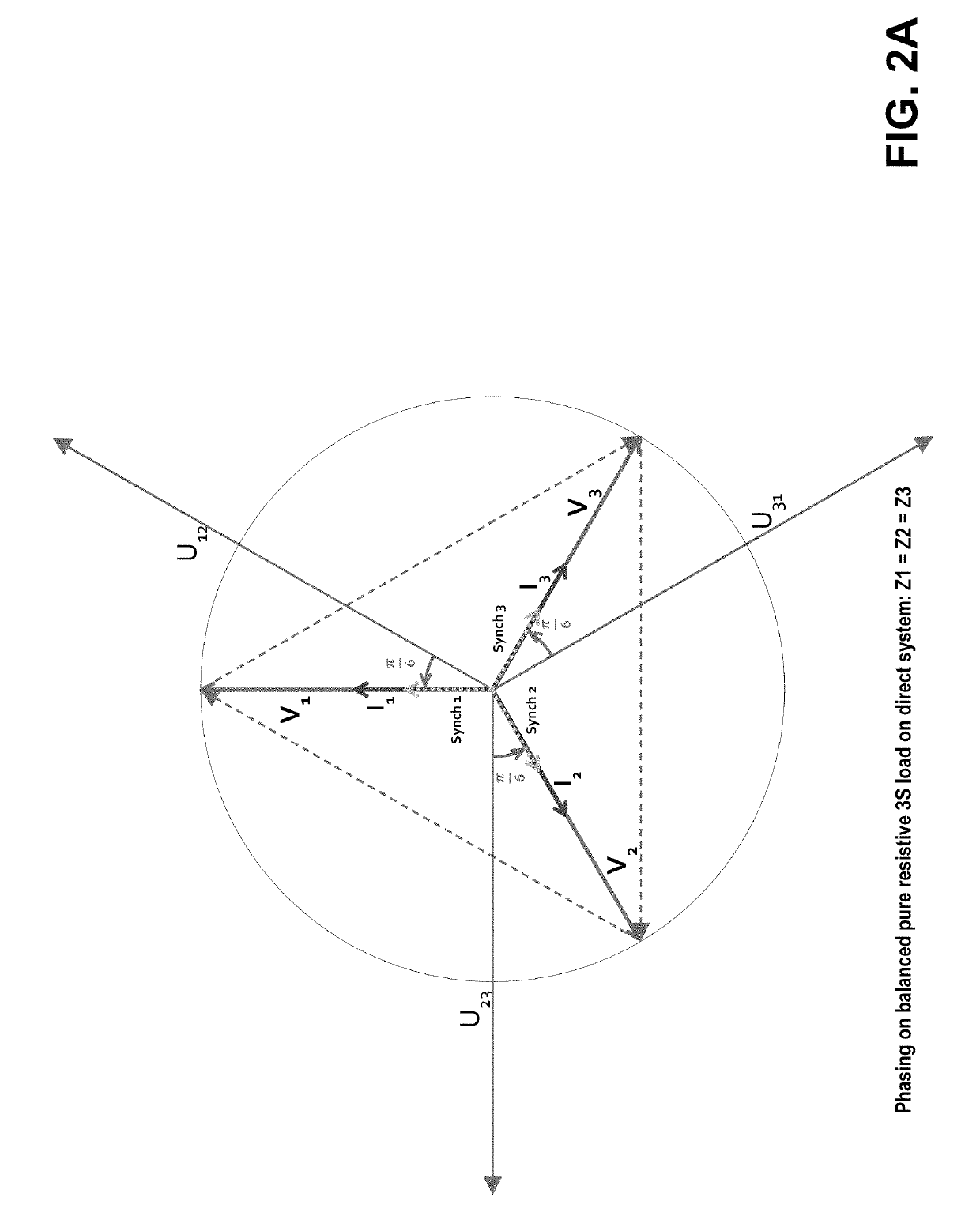

ActiveUS20190190267A1Power factor controlPolyphase network asymmetry elimination/reductionCurrent sensorEngineering

A method for operating an unbalanced load manager for a three-phase induction motor or heater, includes receiving, by a load manager, values representative of current flow sensed by current sensors and voltages sensed by voltage taps corresponding to phases of a three-phase power system providing power to the motor or heater. The method includes detecting, by the load manager, a transition from positive or negative to zero current, to measure a phase shift between line-to-line and current. The method further includes synchronizing, by the load manager, firing from line-to-line signal to line-to-neutral signal of phases of the three-phase power system, using the measured phase shift between line-to-line and current.

Owner:EUROTHERM

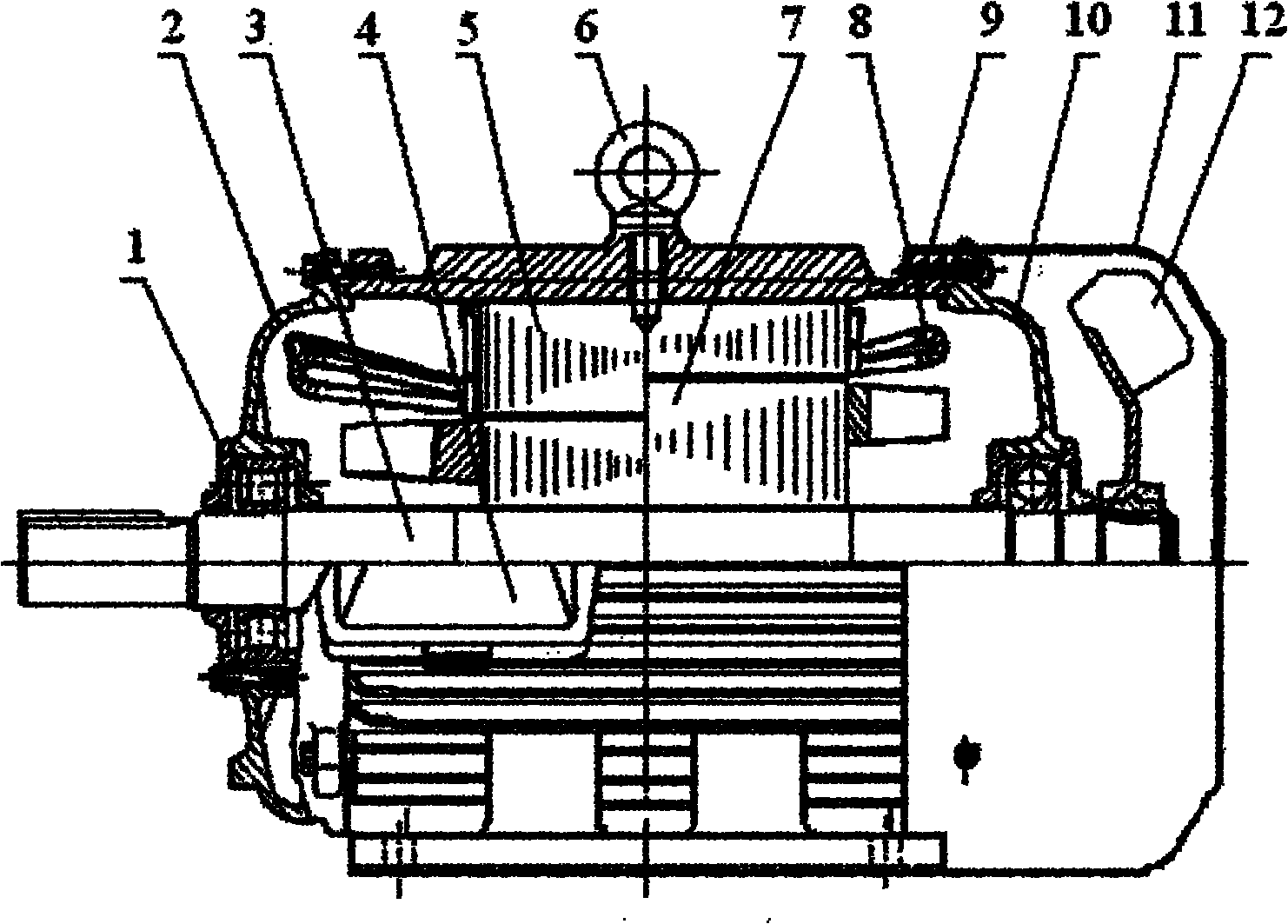

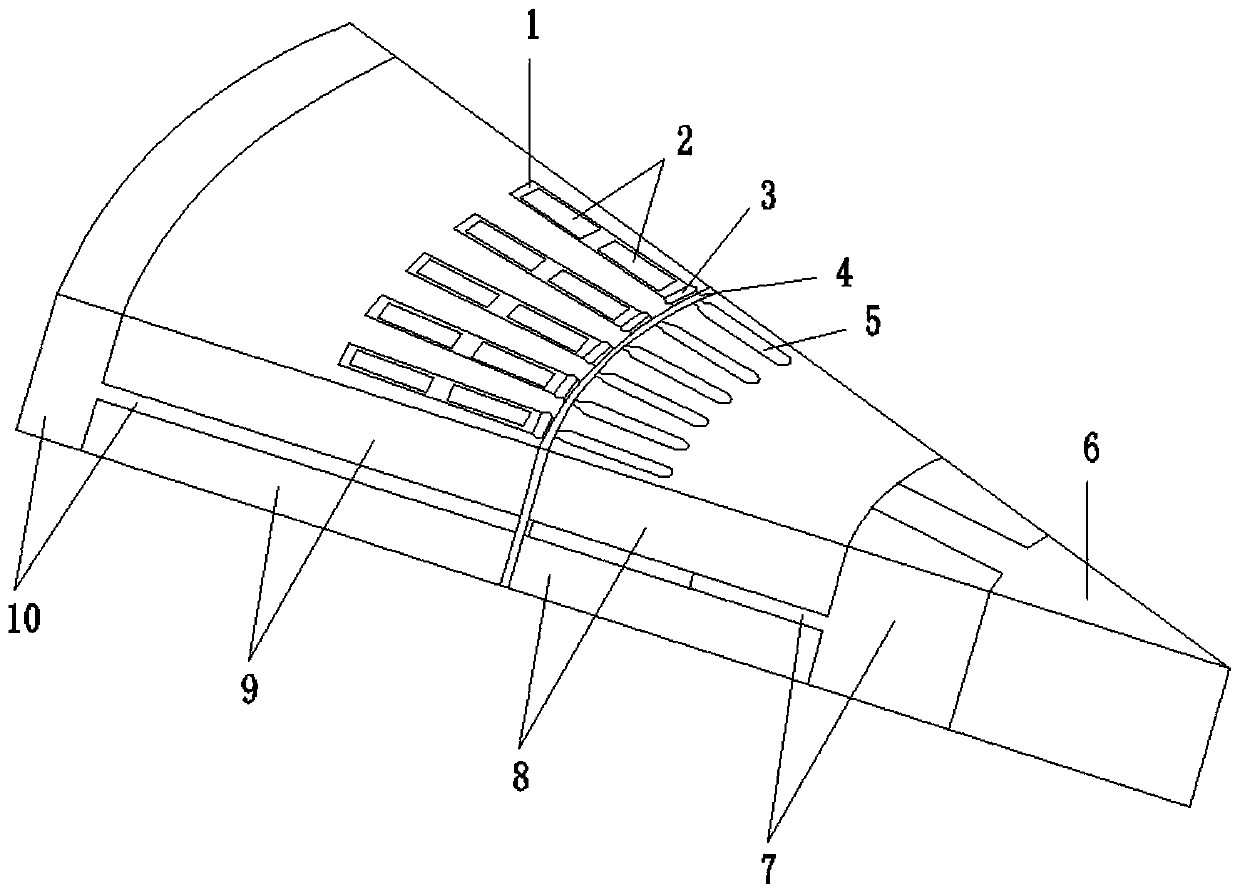

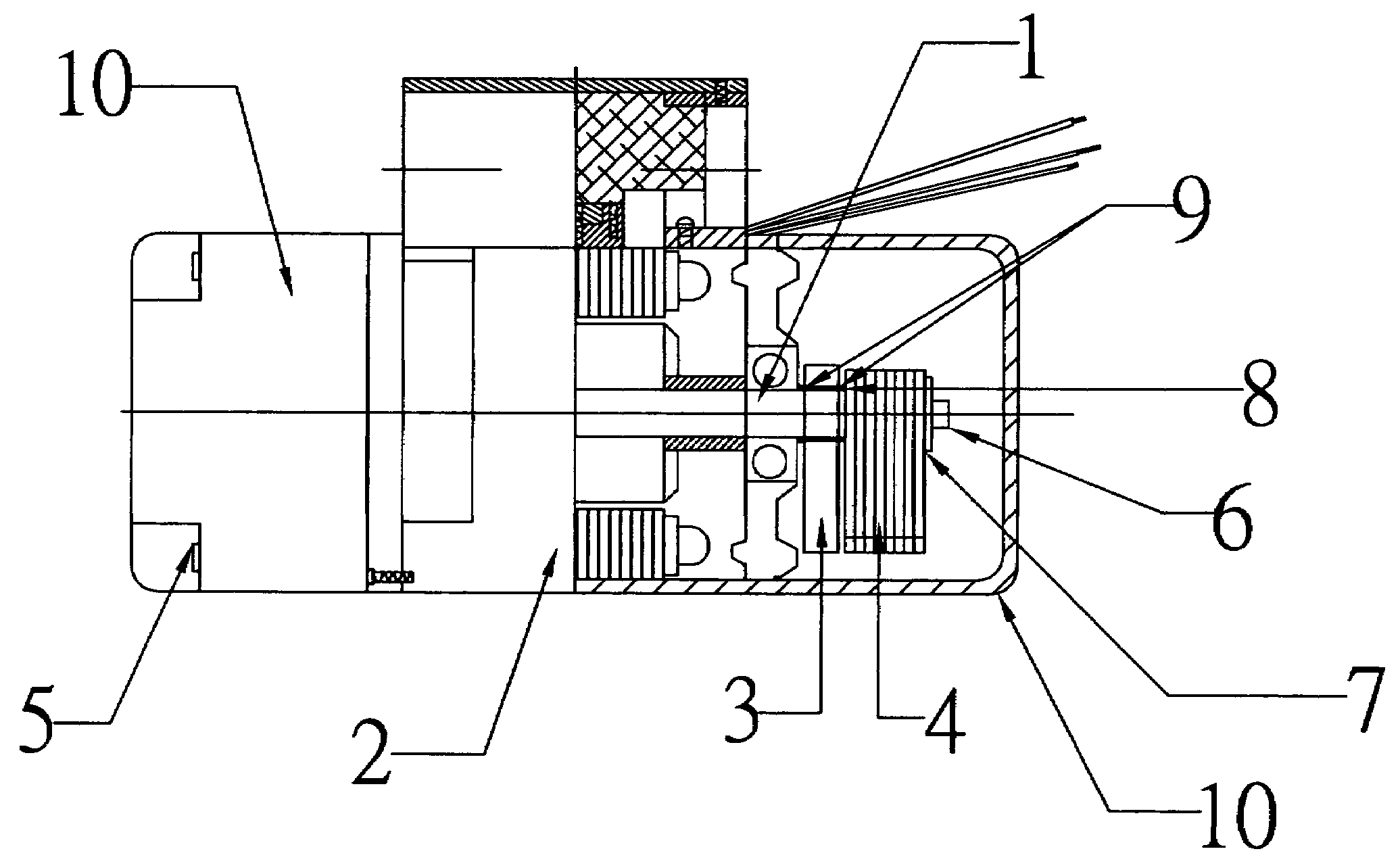

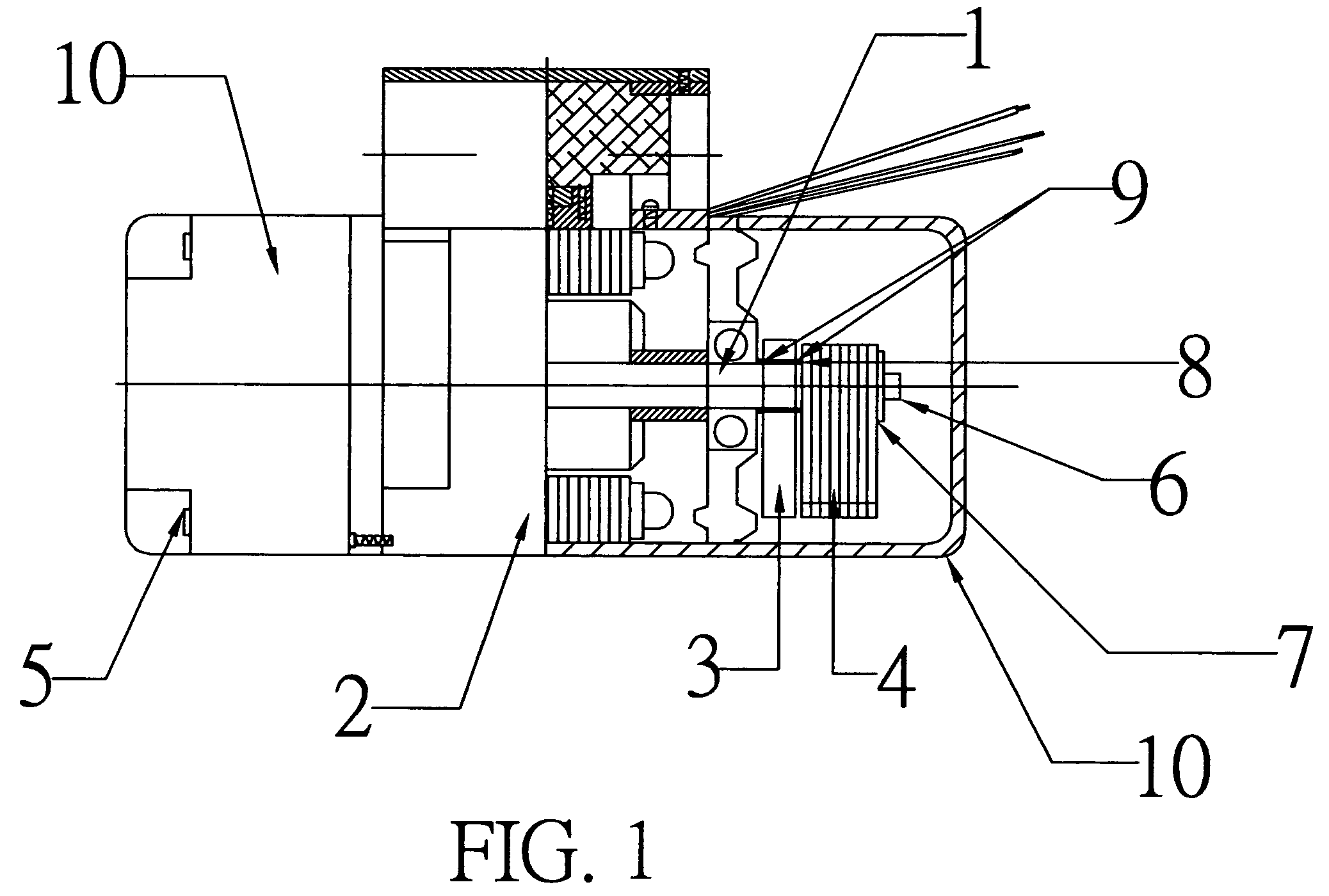

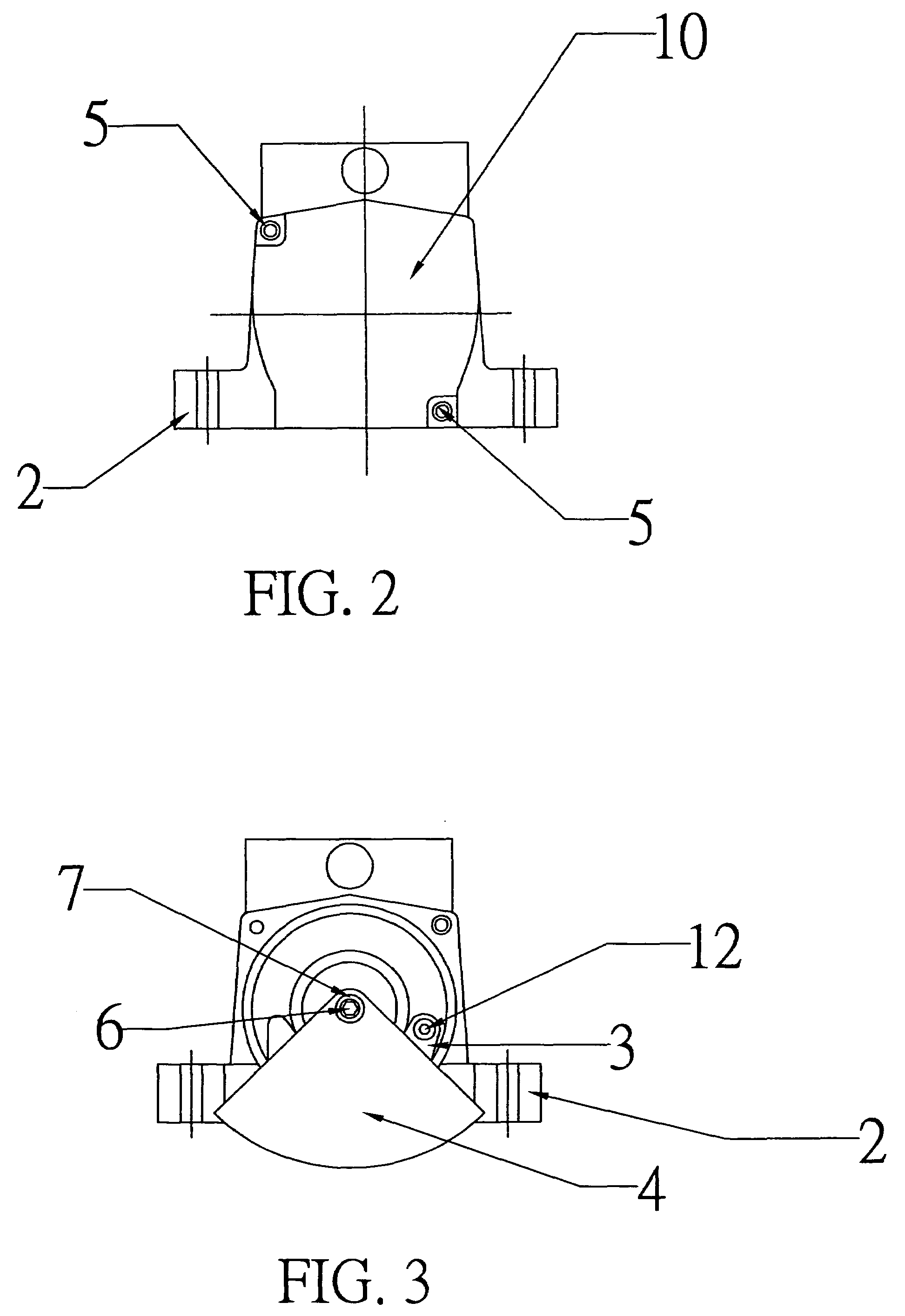

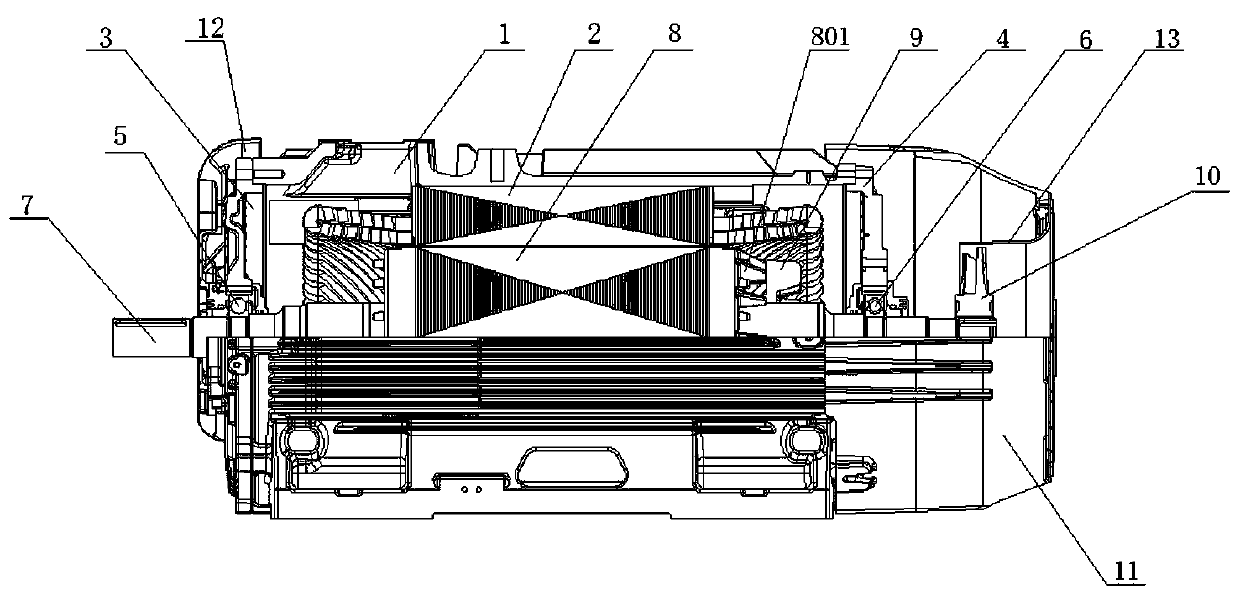

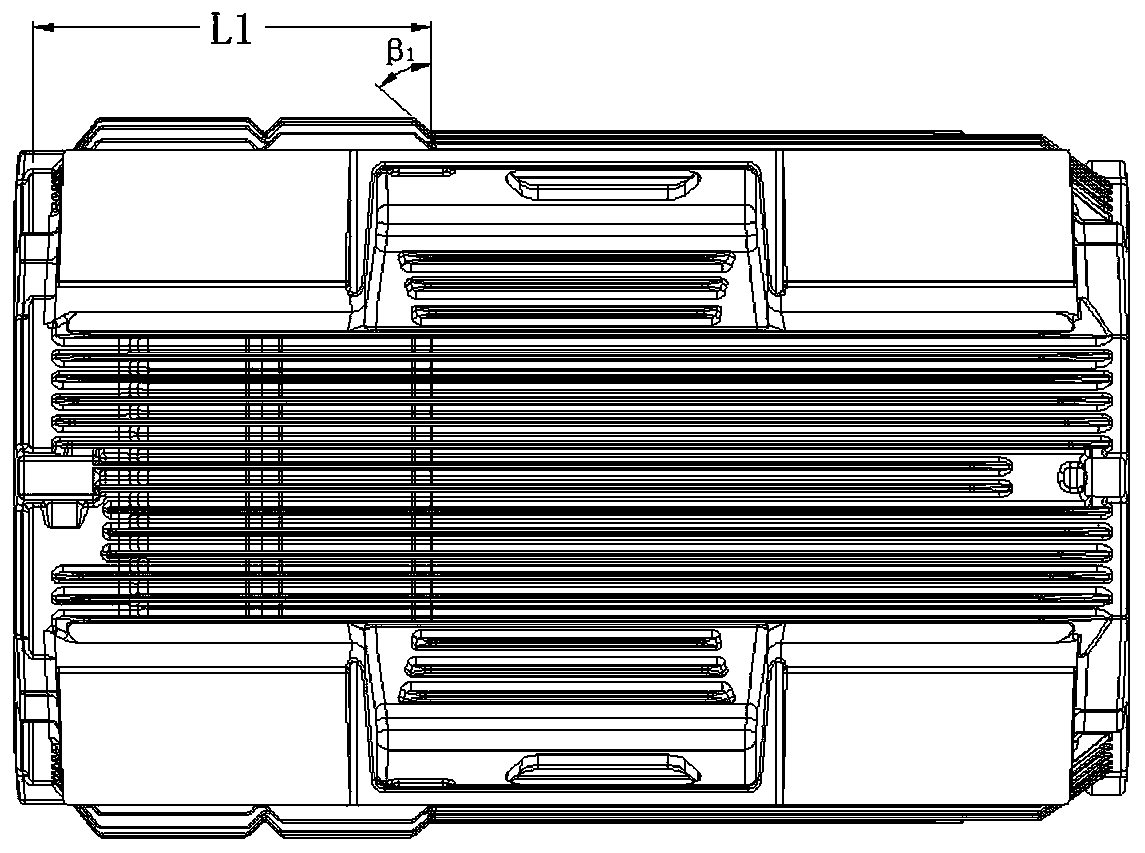

Compact low-noise three-phase induction motor

PendingCN111106704AReduce noiseLow costCooling/ventillation arrangementSupports/enclosures/casingsInduction motorElectric machine

The invention provides a compact low-noise three-phase induction motor which comprises a motor base. A stator is sleeved in the motor base in a heating mode. Front and rear end covers are installed atthe two ends of the motor base respectively, and a rotating shaft is installed in the motor base and supported and fixed through front and rear bearings. A rotor and an inner fan are sleeved on therotating shaft, andan outer fan is arranged at the tail end of the rotating shaft. A fan cover is installed at the rear end of the motor base. The compact low-noise three-phase induction motor is characterized in that the motor base is provided with novel heat dissipation ribs; the front end cover is provided with a novel guide plate; and rotor short-circuit ring blades and the inner fan form a novel inner fan device. Heat dissipation ribs are arranged on the surface of the fan cover, and a special air guide cylinder is installed in the 2P motor. The motor is compact in structure, low in noise, attractive in appearance, small in vibration and low in cost.

Owner:万高(南通)电机制造有限公司

Three-phase induction motor

InactiveUS7737588B2Chiropractic devicesVibration massageFrequency changerThree phase asynchronous motor

The preferred embodiment the invention proposes pertains to a three-phase induction motor, and operates on the premises of having the extension cords on two ends of the motor embedded with several balancing eccentric washers and a balancing eccentric block added, of which the eccentric block contains a sleeve bearing, and one end of the eccentric block is fitted with a bolt, with the bolt head covered with rubber; o-ring is fitted between the balancing eccentric washer and balancing eccentric block, whereby using the invention's frequency changer for controlling an AC 3-phase induction motor serves to generate multiple frequencies for generating different amplitudes, which can be use to control the speed and load emitted between the eccentric block and balancing eccentric washer.

Owner:PENG HUAN YAU

The starting method of the three-phase induction motor star-delta starter

InactiveCN106452199BInhibit currentShock suppressionPolyphase induction motor starterMicrocontrollerInduction motor

The invention provides a three-phase induction motor star-delta starting control method and device. The device comprises a current and voltage detection unit, a single-chip microcomputer control unit, a human-computer interaction unit, a delta connection switching device based on a solid-state relay and an AC contactor, a star connection switching device based on the solid-state relay, a main circuit AC contactor and a thermal relay device. The current and voltage detection unit is connected on a bus and used for detecting power current and power voltage signals in real time so as to act as the basis of trigger control of the single-chip microcomputer control unit. The single-chip microcomputer control unit is connected with the current and voltage detection unit. The human-computer interaction unit is connected with the single-chip microcomputer control unit. Starting current of the starting instant of star connection can be effectively suppressed so that the current impact of star-delta switching can be reduced, the electromagnetic interference caused by disconnection of a stator winding in the star-to-delta process can also be reduced and thus noise and vibration of starting of an asynchronous motor can be greatly reduced.

Owner:凌海科诚电气有限责任公司

Instantaneous power detection and load identification based induction motor cooperative control system

ActiveCN103023420BRealize power-saving operationWith load following capabilityElectronic commutation motor controlAC motor controlDigital signal processingPower factor

The invention discloses an instantaneous power detection and load identification based induction motor cooperative control system which realizes energy-saving control on a light-loaded or unloaded three-phase induction motor and mainly comprises an instantaneous power detection and load identification cooperative controller using a digital signal processor TMS320F28346 as a core, a three-phase bridge power amplifier, a three-phase bridge driving circuit, the three-phase induction motor, a three-phase diode rectifier bridge, an instantaneous power detection link, a current detection link, a coder rotating speed detection link, a load identification link, a +24V switch power source, a +15V switch power source, a + / -12V switch power source, a +5V power source and the like. An instantaneous power detection and load identification based induction motor cooperative control method is adopted to control stator exciting current of the light-loaded or unloaded three-phase induction motor, and power factors of the three-phase induction motor are adjusted by load rate obtained on the basis of load identification, so that operating efficiency of the three-phase induction motor is effectively improved, and good electricity-saving effect is achieved.

Owner:BEIJING HONGHUI INT ENERGY TECH DEV CO LTD

Tri-phase induction motor driving system and driving method thereof

InactiveCN1215642CAvoid interferenceDC motor speed/torque controlVector control systemsPower inverterInduction motor

A system and method for driving a three-phase induction motor, wherein an inverter power module is provided to supply voltages of three phases to the three-phase induction motor to drive it, a plurality of power supplies are provided to supply powers to a plurality of power devices constituting the inverter power module, and an insulator is provided to insulate the plurality of power supplies and the power module from each other. The present invention can minimize interferences based on a difference between voltages continuously applied to the inverter power module while the three phase voltages are supplied from the inverter power module to the three-phase induction motor. Furthermore, a plurality of photocouplers and a plurality of driving devices constituting the insulator are disposed on a printed circuit board in such a manner that they are spaced apart from one another, thereby minimizing interferences among powers, the amount of abnormal leakage and the effect of a voltage variation on the three-phase induction motor.

Owner:LG ELECTRONICS INC

Electronic braking system for an irrigation machine

The present invention provides an electronic braking system for an irrigation machine. According to an exemplary preferred embodiment, the present invention includes a drive controller which includesa power supplying circuit which signals an ON condition when a motive power request is input into the drive controller and an OFF condition when motive power is not input into the system. According toa further preferred embodiment, the present invention further includes a 3-phase induction motor connected to apply torque to a drive shaft which is connected to a least one drive wheel. According toa further preferred embodiment, the power supplying circuit supplies 480V AC of motive power to the drive motor when the drive controller signals the ON condition and 10-80V DC of non-motive power toat least one phase of the motor when the drive controller signals the OFF condition. According to a further preferred embodiment, the application of the DC current is applied immediately after the motive power is removed from the drive motor and the application of non-motive power brakes and prevents the drive shaft from turning until the DC current is removed.

Owner:VALMONT INDUSTIES INC

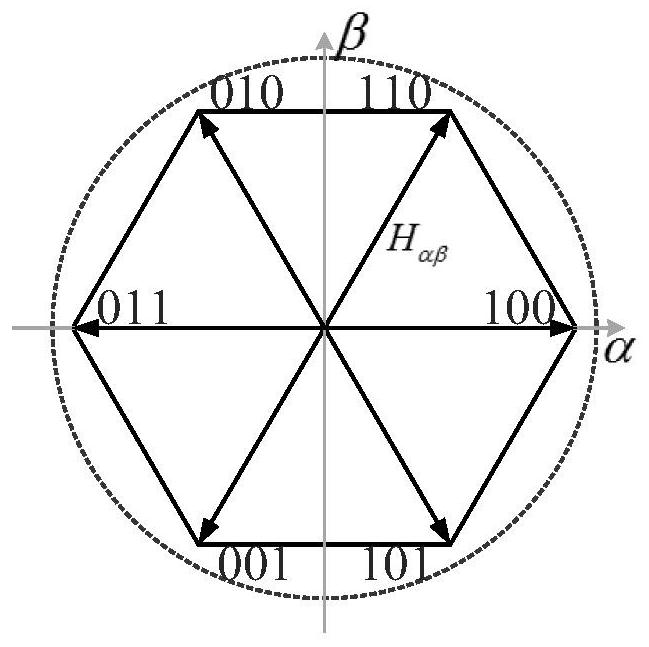

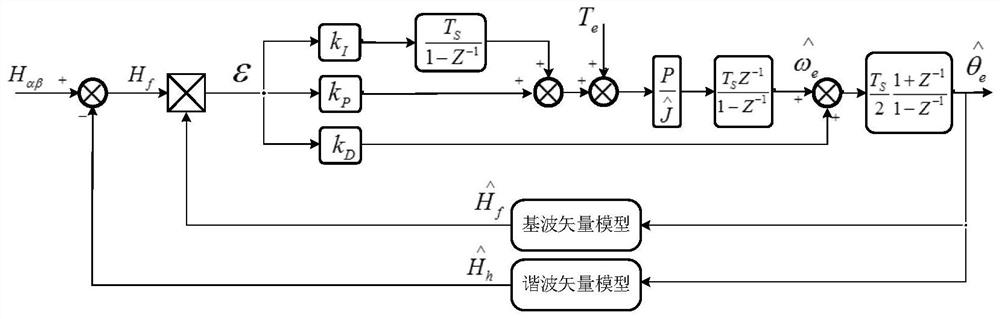

A vector observation method for electric forklift motor rotor position and speed estimation

ActiveCN109039202BLow costGood rate control characteristicsElectronic commutation motor controlVector control systemsVector trackingInduction motor

The invention discloses a vector observation method for estimating the rotor position and speed of an electric forklift motor, using a low-resolution motor rotor position sensor, such as a Hall element, a low-precision incremental photoelectric encoder of 80 or 100P / R, and constructing A vector observer realizes the indirect measurement of the rotor position angle and rotational speed of the phase induction motor; the present invention proposes an algorithm through harmonic decoupling, from the discrete rotational position vector H αβ The vector tracking observer, which extracts continuous rotor position information from the vector tracking observer, realizes the accurate estimation of the rotor position angle and the accurate measurement of the rotational speed of the three-phase induction motor using the low-resolution rotor position sensor.

Owner:凡己科技(苏州)有限公司

Electronic braking system for irrigation machines

The invention provides an electronic braking system for an irrigation machine. According to an exemplary preferred embodiment, the present invention includes a drive controller including a power supply circuit that signals an on-state when a power request is input into the drive controller, and when power is not input Signals a disconnected state when entering the system. According to another preferred embodiment, the invention also comprises a three-phase induction motor connected to apply torque to a drive shaft connected to at least one drive wheel. According to another preferred embodiment, the power supply circuit provides power of 480V AC to the drive motor when the drive controller sends an on-state signal, and provides 10-80V to at least one phase of the motor when the drive controller sends an off-state signal The DC's are non-powered. According to another preferred embodiment, the application of DC current is applied immediately after removal of power from the drive motor, and non-powered application of the brakes prevents the drive shaft from rotating until the DC current is removed.

Owner:VALMONT IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com