Tri-phase induction motor driving system and driving method thereof

A technology of induction motor and drive system, which is applied in the direction of suppressing motor vibration control, motor generator control, AC motor control, etc., and can solve problems such as interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

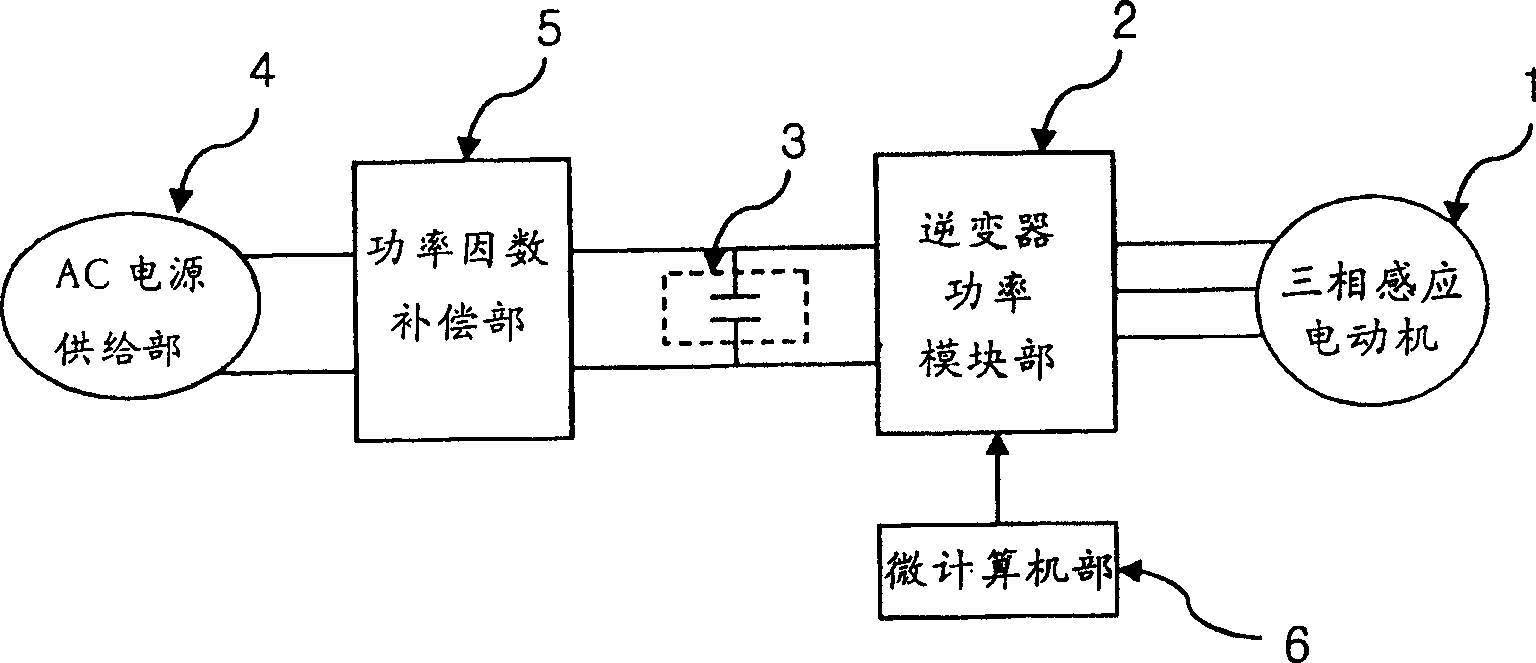

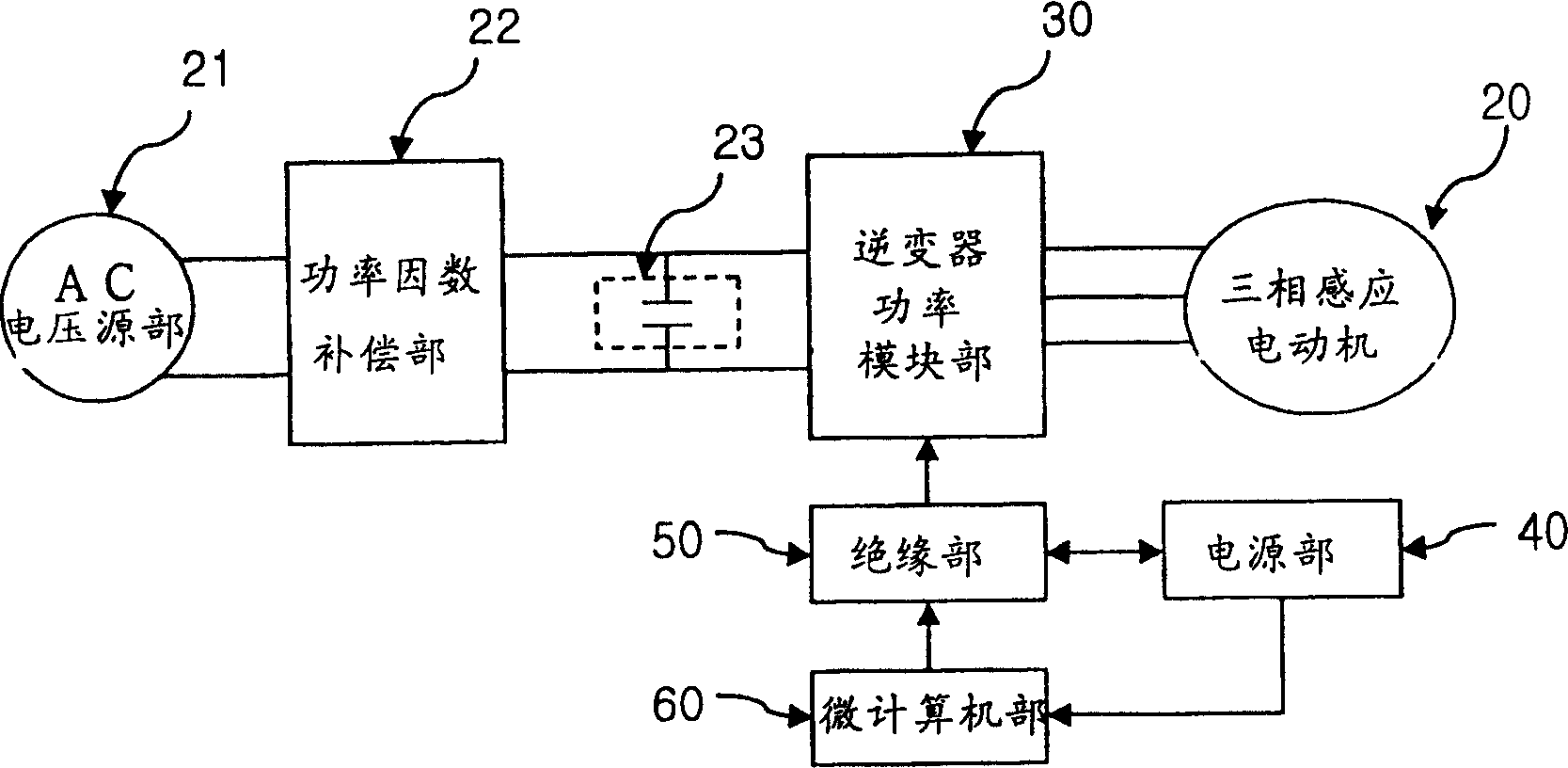

[0018] Such as image 3 As shown, the three-phase induction motor drive system of the present invention consists of a three-phase induction motor 20 driven by three-phase voltages of A phase, B phase, and C phase, and an AC voltage as a voltage source of the three-phase induction motor drive system of the present invention. source 21, a power factor compensating section 22 for compensating the power factor of the AC voltage supplied by the AC voltage source 21, a voltage source DC23 for outputting the voltage compensated by the power factor compensating section 22 as a DC voltage, and The DC voltage supplied by the DC voltage source 23 is configured as a three-phase voltage of A phase, B phase, and C phase to be applied to the induction motor 20 by the inverter power module unit 30 and the like.

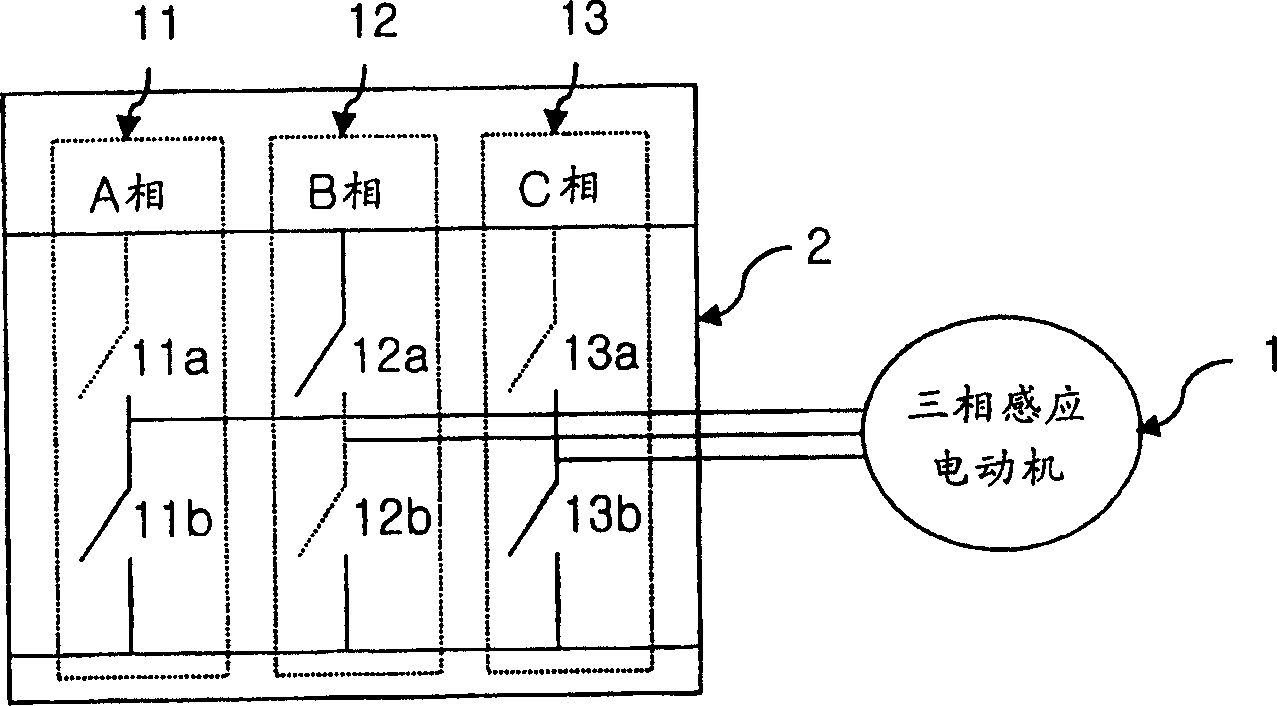

[0019] In addition, if Figure 4 As shown, the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com