Electronic braking system for an irrigation machine

An irrigation system and power technology, applied in the field of irrigation machines, can solve the problems of high failure rate, high corrosion rate and wear rate of mechanical brake or mechanism, high maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

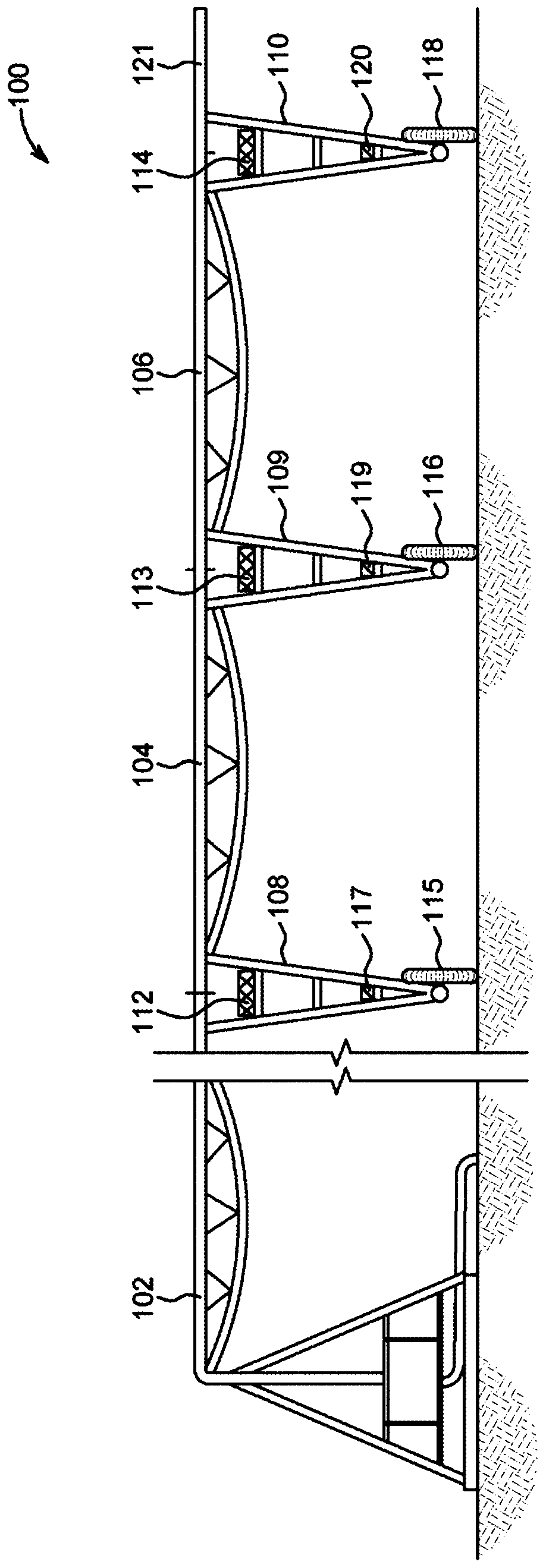

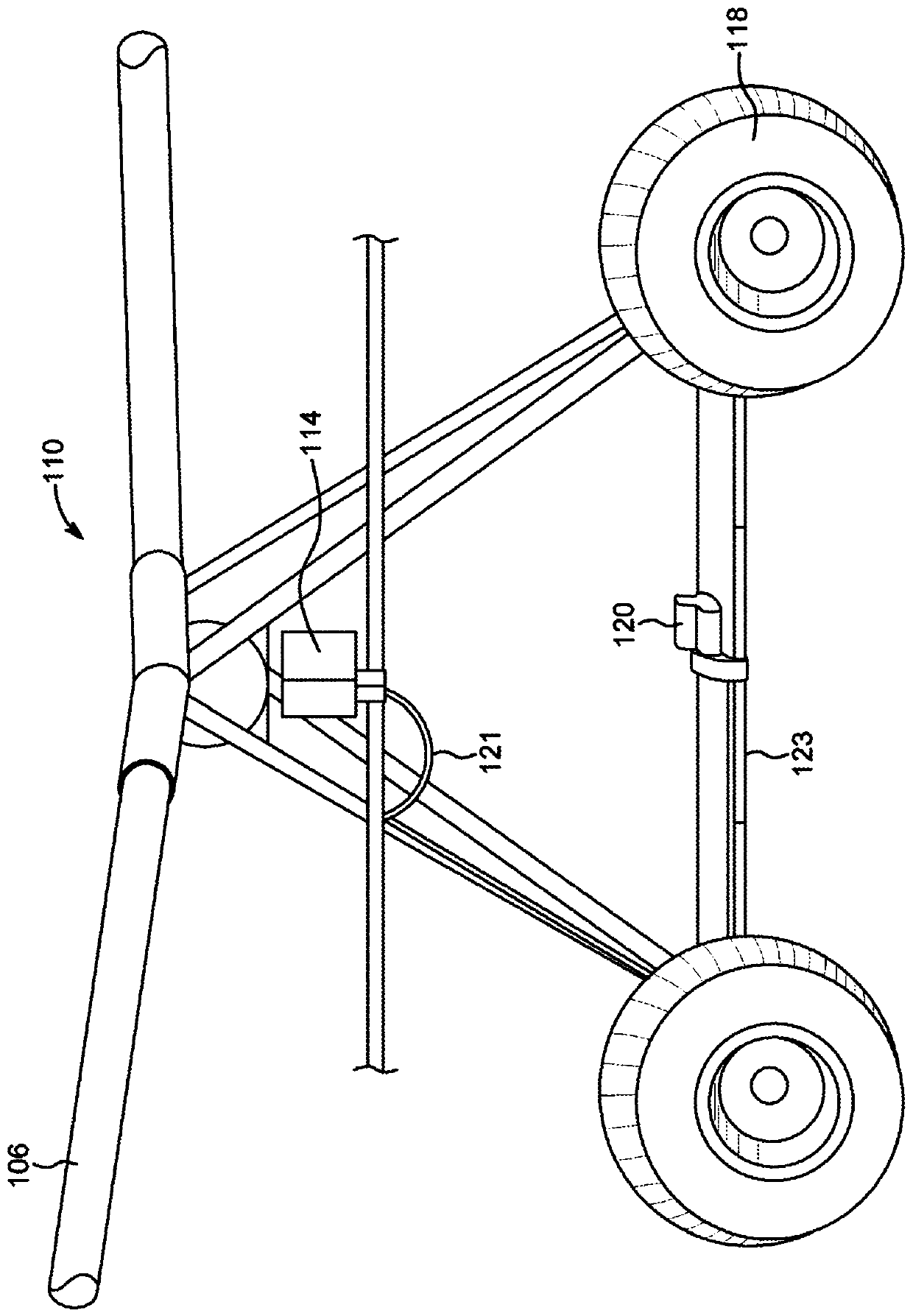

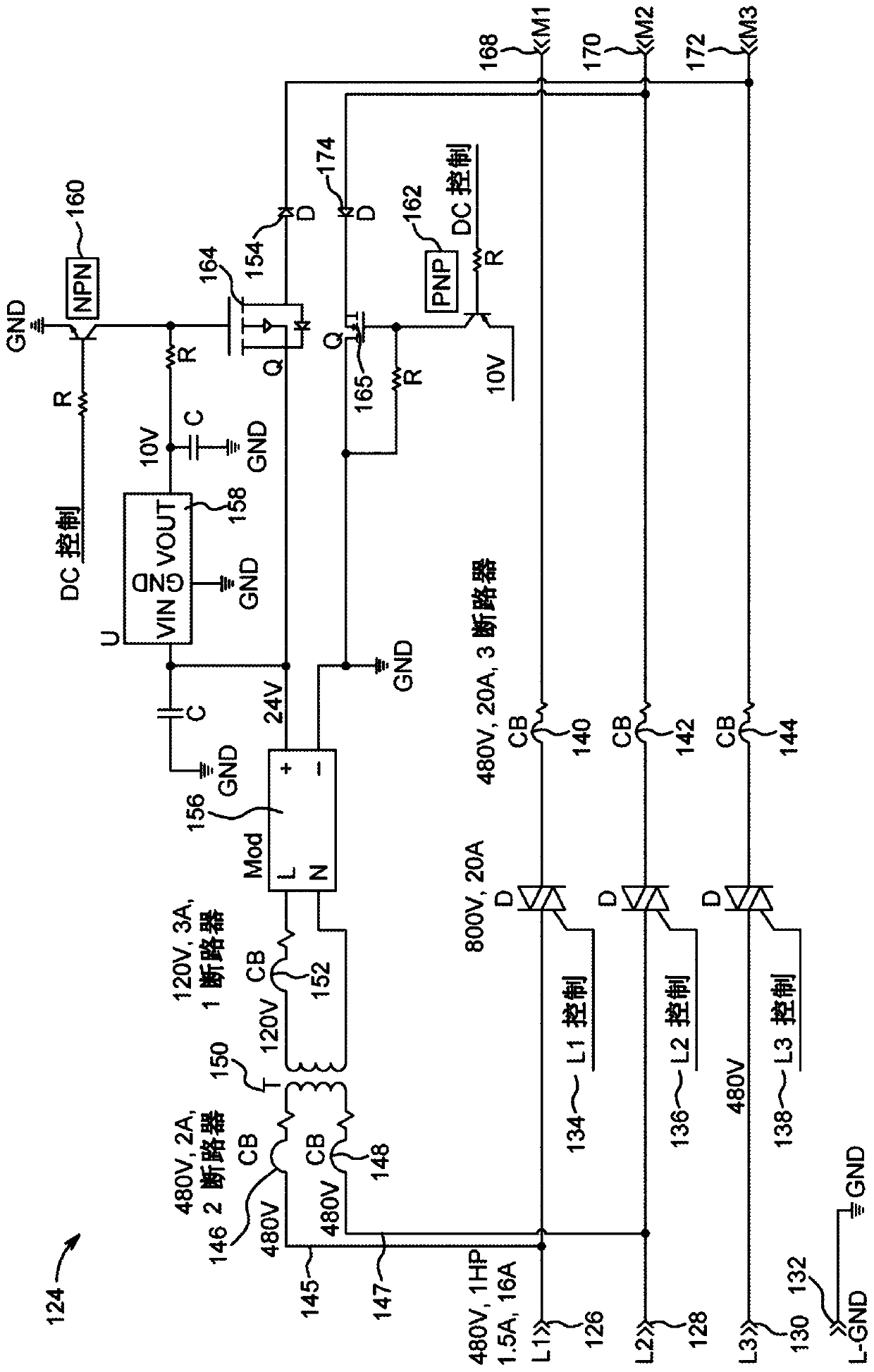

[0019] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts. The description, implementation and drawings should not be considered as limiting the scope of the claims. It should also be understood that throughout this disclosure, where a process or method is shown or described, the steps of the method may be performed in any order, repeatedly, iteratively or simultaneously, unless logically required otherwise. As used throughout this application, the word "may" is used in a permissive sense (ie, meaning "has the potential to") rather than a mandatory sense (ie, meaning "must").

[0020] Additionally, no example or illustration given herein should in any way be considered to restrict, limit or define an expression of any term or terms it uses. Instead, such e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com