System and method for controlling indirect torque of single regulating loop of three-phase induction motor

A technology of induction motor and torque control, applied in motor generator control, electronic commutation motor control, control system, etc., can solve the problems of complex design and application, and achieve the effect of improving dynamic performance and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0058] 1. Existing system (double regulating loop)

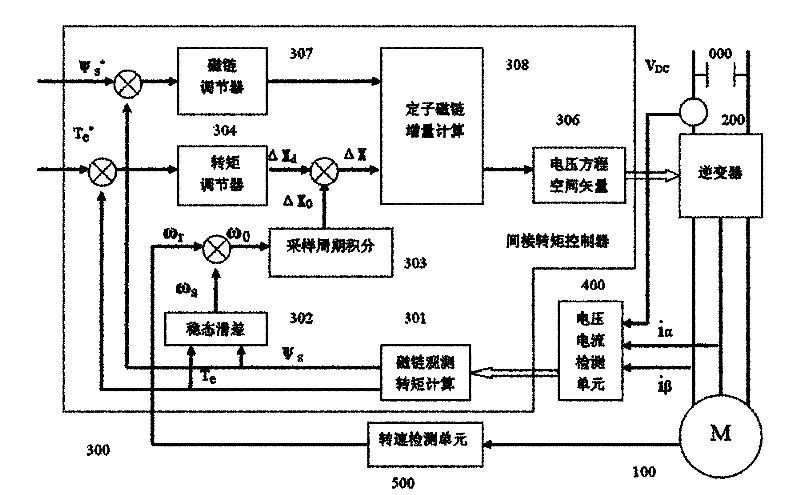

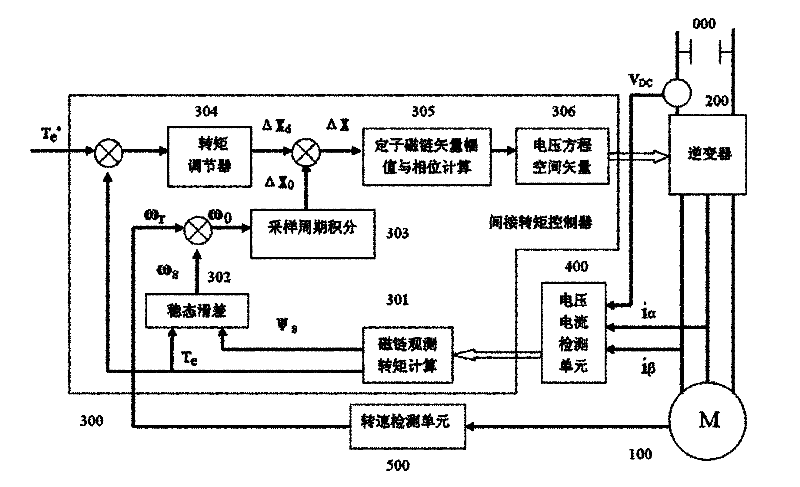

[0059] Such as figure 1 , the existing system includes a power supply 000, a three-phase induction motor 100, a power inverter 200, an indirect torque controller 300; a voltage and current detection unit 400, and a motor speed detection unit 500;

[0060] The software of the indirect torque controller 300 includes a flux linkage observation and torque calculation unit 301, a steady-state slip calculation unit 302, a rotational speed sampling period integration unit 303, a torque regulator unit 304, and a space voltage vector calculation output unit 306. Flux regulator 307 and stator flux increment calculation unit 308;

[0061] Its working principle is:

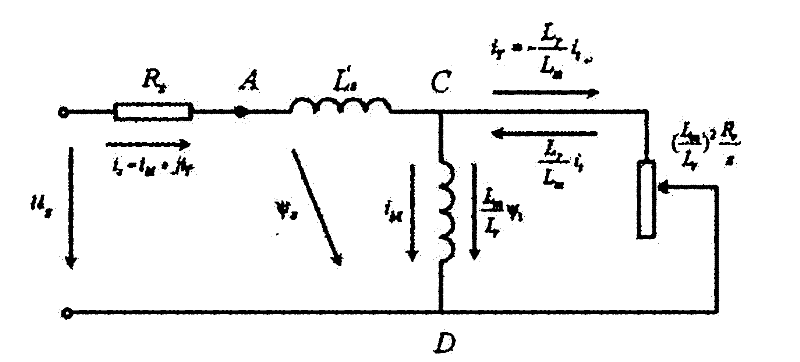

[0062] The stator flux vector of the three-phase induction motor is obtained by the stator voltage vector equation, the electromagnetic torque is obtained by the stator flux vector a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com