Three-winding parallel single-phase induction motor

An induction motor, parallel-connected technology, applied in the field of motors, can solve the problems of single-phase motor air gap magnetic field asymmetry, single-phase induction motor large volume, high negative sequence magnetic field content, etc., to improve efficiency and power factor, reduce iron core The effect of simple size and wiring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

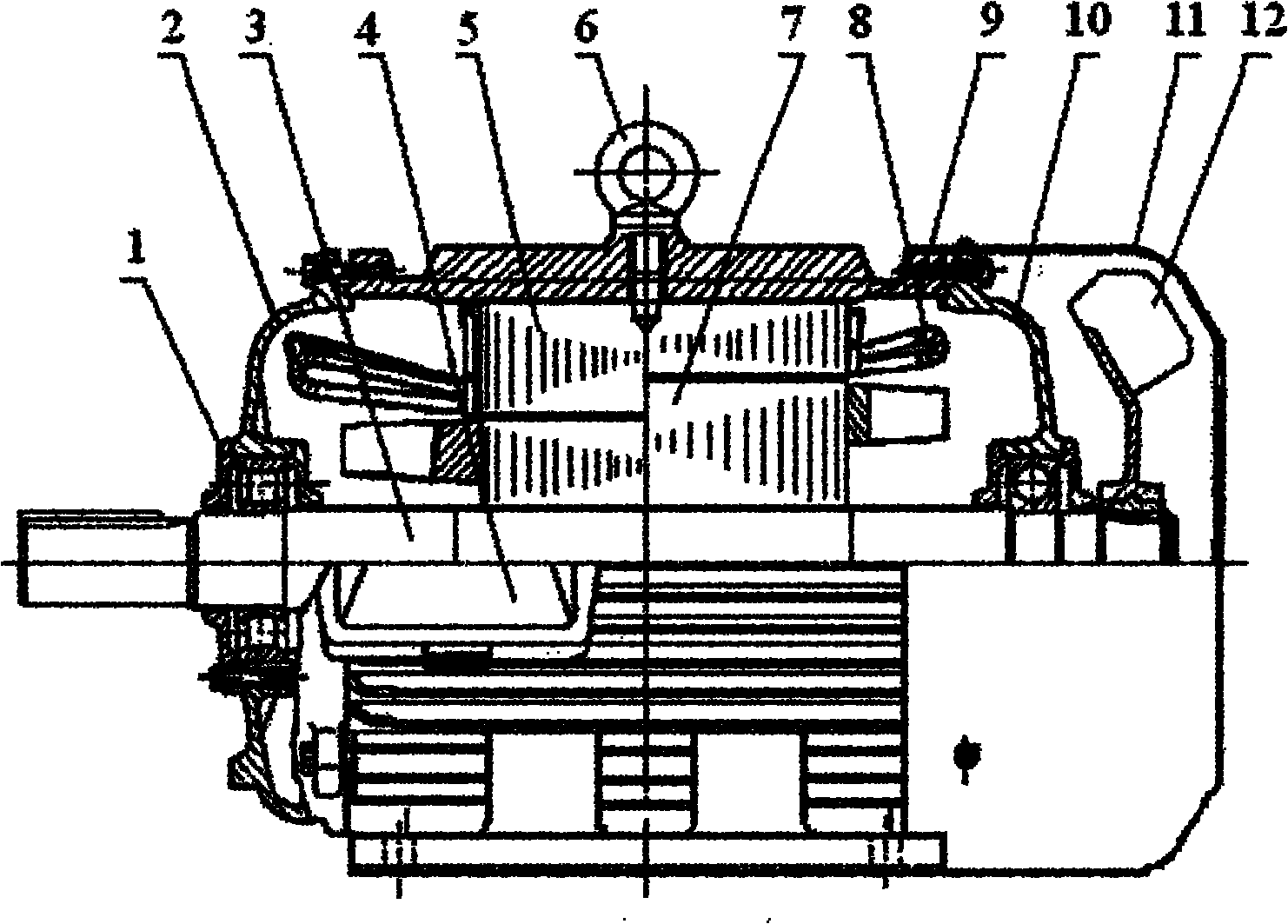

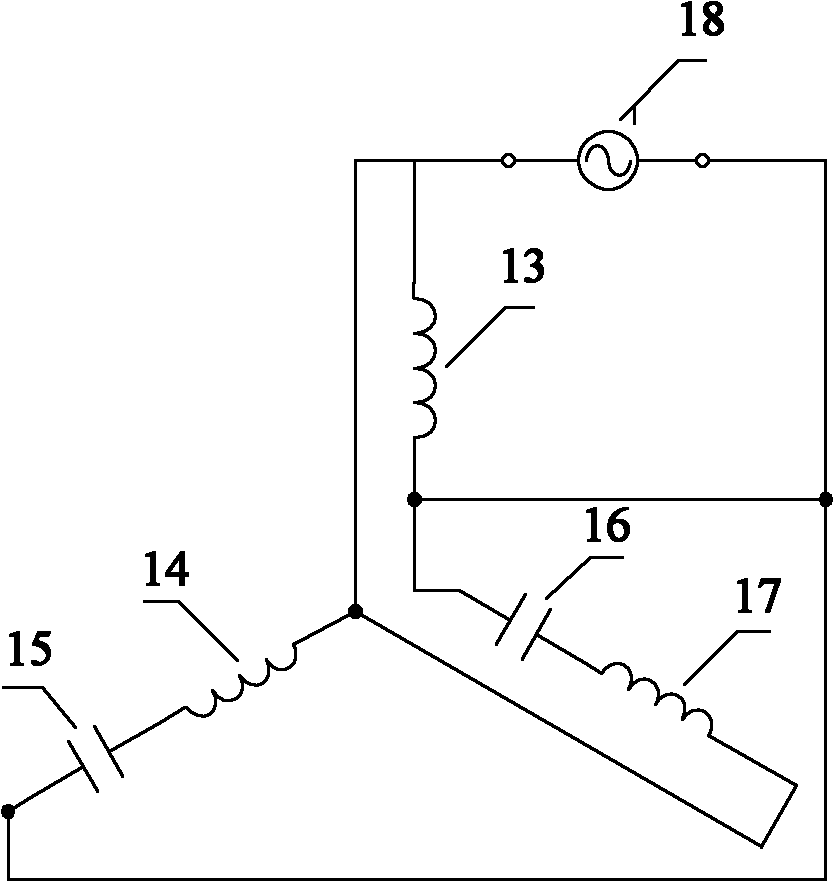

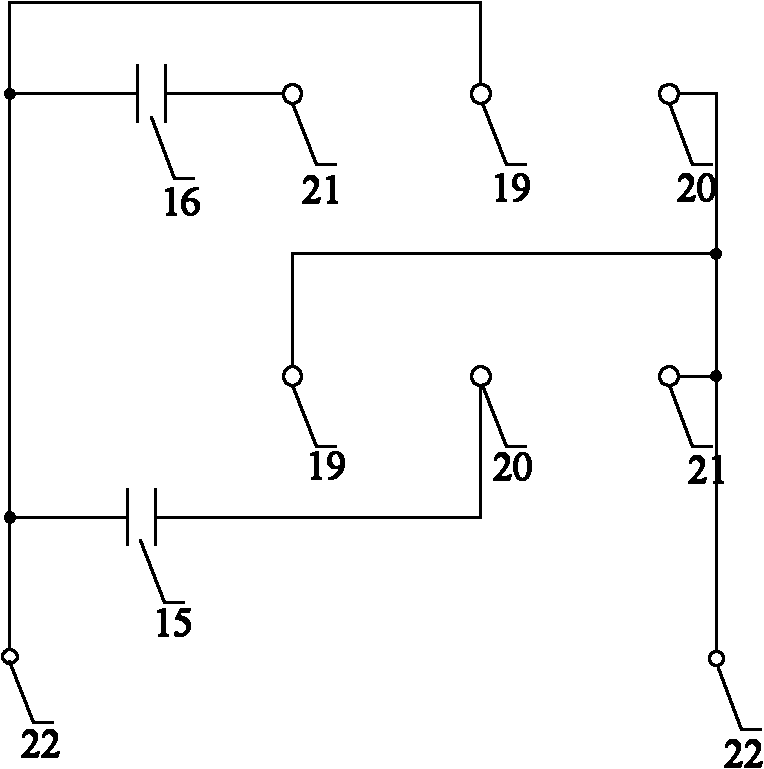

[0016] figure 1 , figure 2 , image 3 Among them, the three-winding parallel-connected single-phase induction motor includes a casing, a front end cover 10 and a rear end cover 2 are provided at both ends of the casing, and a wind cover 11 is provided at the front end cover 10, and a fan 12 is installed in the wind cover 11.

[0017] A bearing 1 is arranged on the rear end cover 2 and the front end cover 10 , and the rotating shaft 3 is mounted on the bearing 1 . The squirrel-cage rotor 7 is installed on the rotating shaft 3 and cooperates with the stator core 5 . Also be provided with on casing and hang and climb 6. A stator winding 8 is provided on the stator core 5 , and the stator winding 8 is connected to the outlet box 4 . A base 9 is provided between the front end cover 10 and the windshield 11 .

[0018] In the present invention, the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com