Heater for preventing carburetor from icing up

A carburetor and heater technology, applied in carburetor, machine/engine, charging system, etc., can solve problems such as bad, hindering the freedom of engine load, and hindering the assembly of electric heater 13, to prevent The effect of freezing and suppressing fuel evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

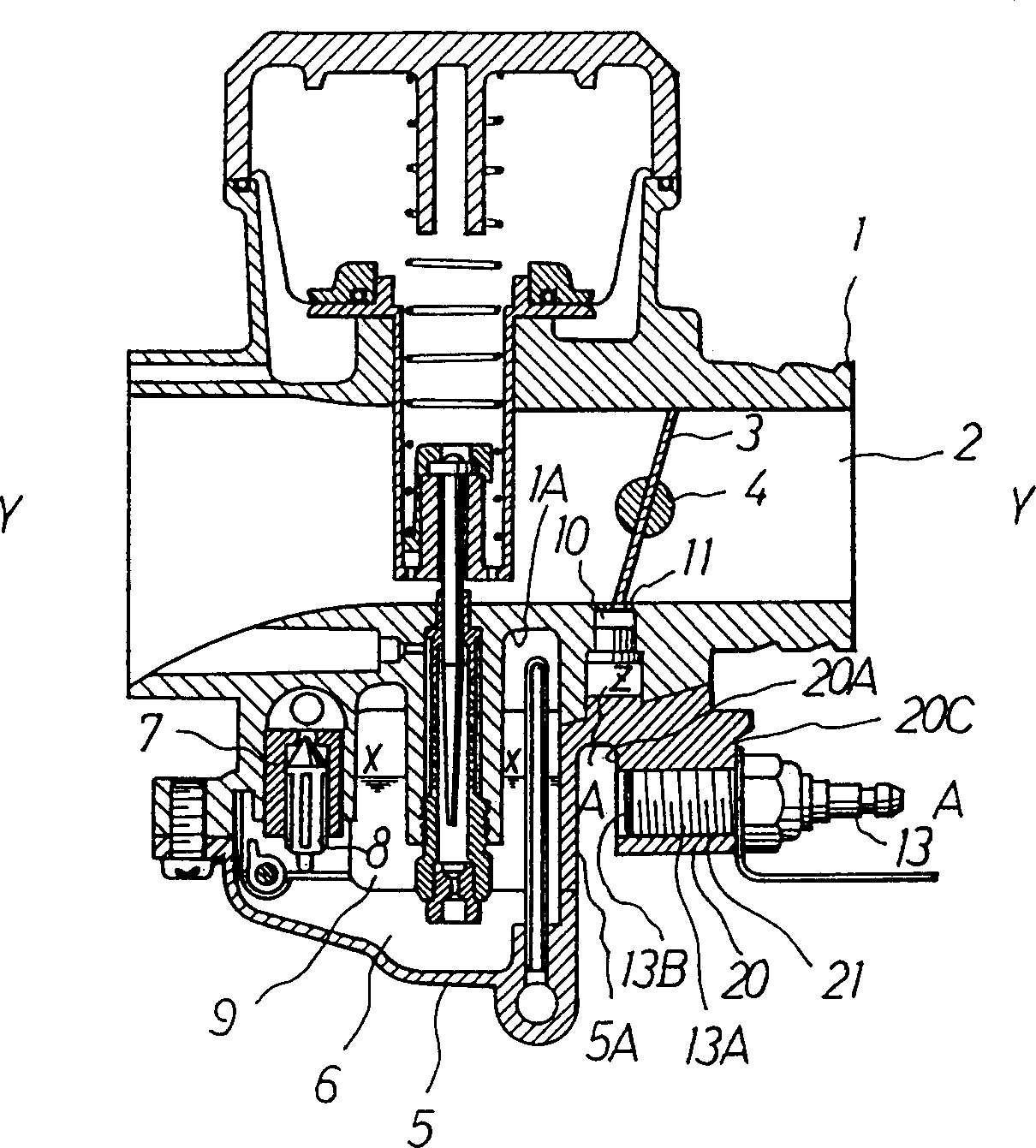

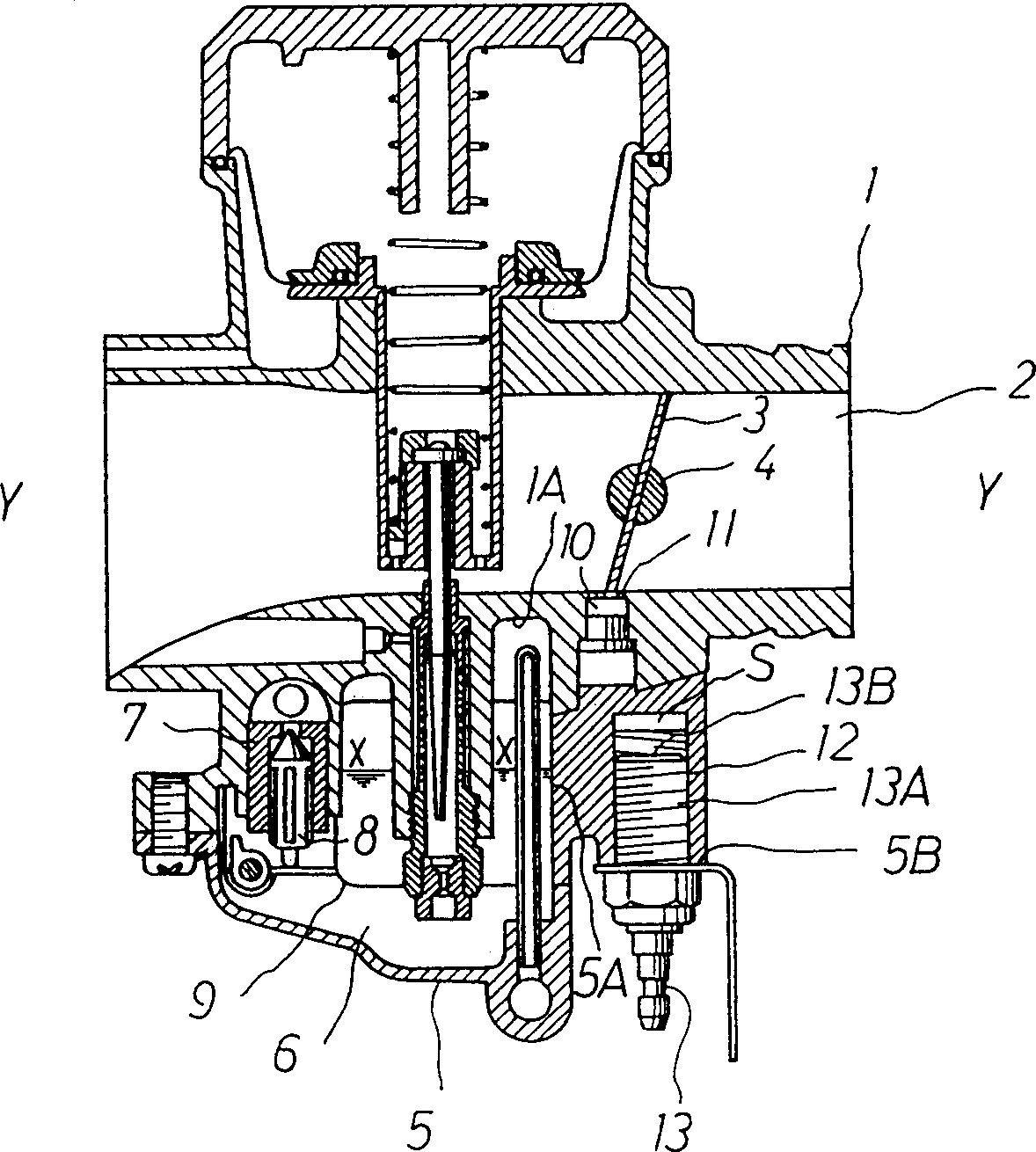

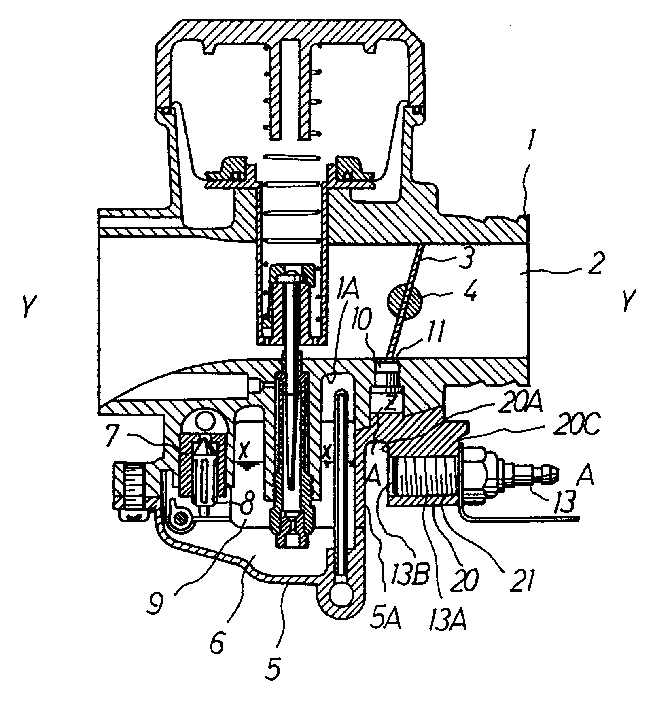

[0028] Below, according to figure 1 One of the anti-freezing heaters of the carburetor of the present invention is explained

[0029] Example.

[0030] For with figure 2 The same symbols are used for the same structural parts, and descriptions are omitted.

[0031] 20 is a heater mounting seat integrally formed with the float chamber main body 5, and the heater mounting seat 20 is formed approximately parallel to the long axis Y-Y of the air intake passage 2 and the fuel liquid level X-X in the float chamber.

[0032] Furthermore, a space Z is formed between the front end portion 20A of the heater mount 20 and the side wall 5A of the float chamber main body 5 .

[0033] Further, in this heater mounting base 20 , a heater mounting hole 21 is perforated from the rear end portion 20C toward the front end portion 20A, and a female thread is formed therein.

[0034] The heater mounting hole 21 is preferably formed as close to the bypass chamber 10 as possible.

[0035] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com