Microwave sulfur lamp shielding new cover and making method thereof

A manufacturing method and technology of shielding net, applied in the field of electric light source, can solve the problems of cost reduction and increase of microwave service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

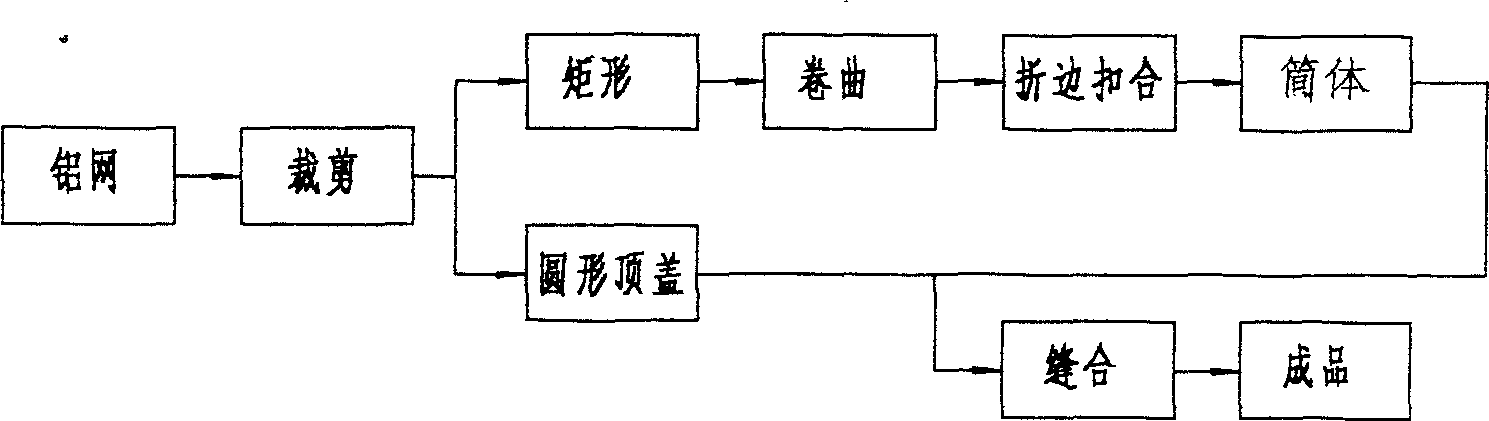

[0011] figure 1 , Figure 4 It is an embodiment of the present invention. Its specific production method:

[0012] Step 1: Select the required aluminum mesh and cut it into a rectangle according to the size, and reserve the side for folding and fastening.

[0013] Step 2: Fold the folded edge to the same direction to form an acute angle;

[0014] Step 3: Roll the folded aluminum mesh into a cylinder and fasten the folded sides together (such as Figure 4 shown);

[0015] Step 4: Put the cylindrical mold into the cylinder, press the folded edge with a smooth weight,

[0016] Take out the mould, and make the shielding net cover cylindrical body 1;

[0017] Step 5: Select the required aluminum mesh and cut out the circular top cover 2 according to the size;

[0018] Step 6: Sew the finished shielding grill cylinder body 1 and shielding grill top cover 2 with metal wire 3 to form a finished product.

Embodiment 2

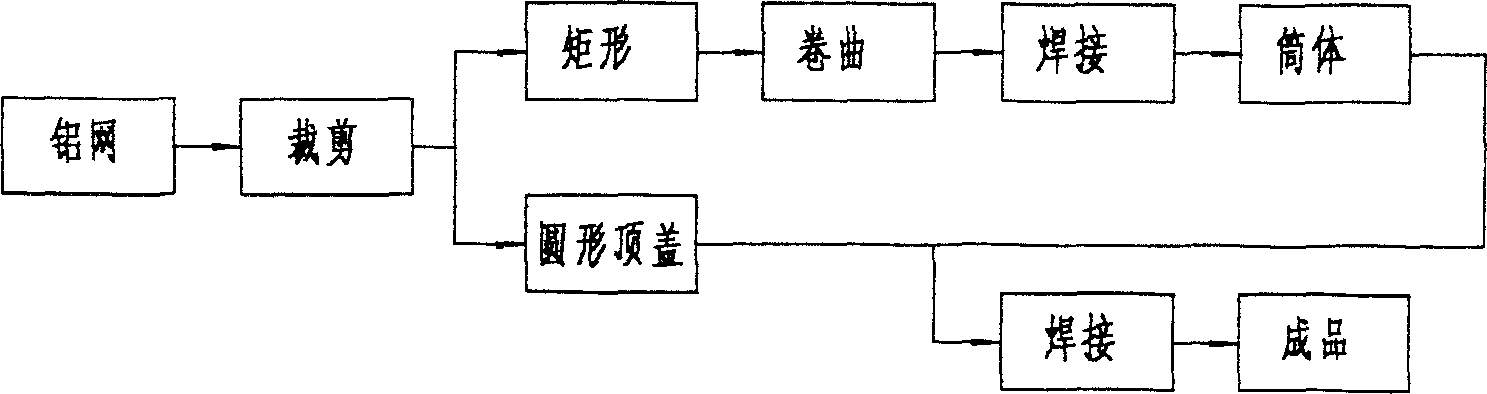

[0020] figure 2 , Figure 5 It is another embodiment of the present invention, and its specific production method is:

[0021] Step 1: Select the required aluminum mesh and cut it into a rectangle according to the size, and reserve the welding edge.

[0022] Step 2: Roll the aluminum mesh with welded edges into a cylinder, and weld the overlapping two edges to each other to form a cylinder 1 .

[0023] Step 3: Select the required aluminum mesh and cut out the circular top cover 2 according to the size. There are welding legs 4 on the circumference of the top cover 2 .

[0024] Step 4: Weld the cylinder body 1 and the welding legs 4 on the top cover 2 to form a finished product.

Embodiment 3

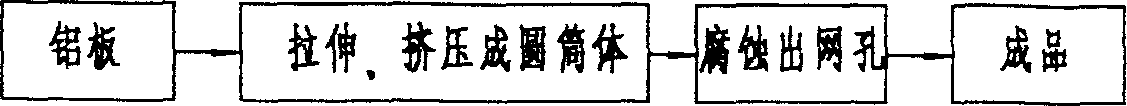

[0026] image 3 It is another embodiment of the present invention, and its specific production method is:

[0027] The first step: the selected aluminum material is stretched into a cylinder with a cover 1 at one time;

[0028] Step 2: Carry out photo-etching on the cylindrical body 1 to etch out the required mesh holes to make a finished product.

[0029] The microwave sulfur lamp shielding net cover made by the above embodiment is not easy to corrode at high temperature, and the conductivity and reliability are greatly improved, thereby ensuring the normal start-up of the microwave sulfur lamp and prolonging its service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com