Filling machine provided with flushing device

A packaging material and tubular technology, applied in the field of filling machines, can solve the problems of contamination of the cutting part of the packaging container, contamination, etc., and achieve the effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

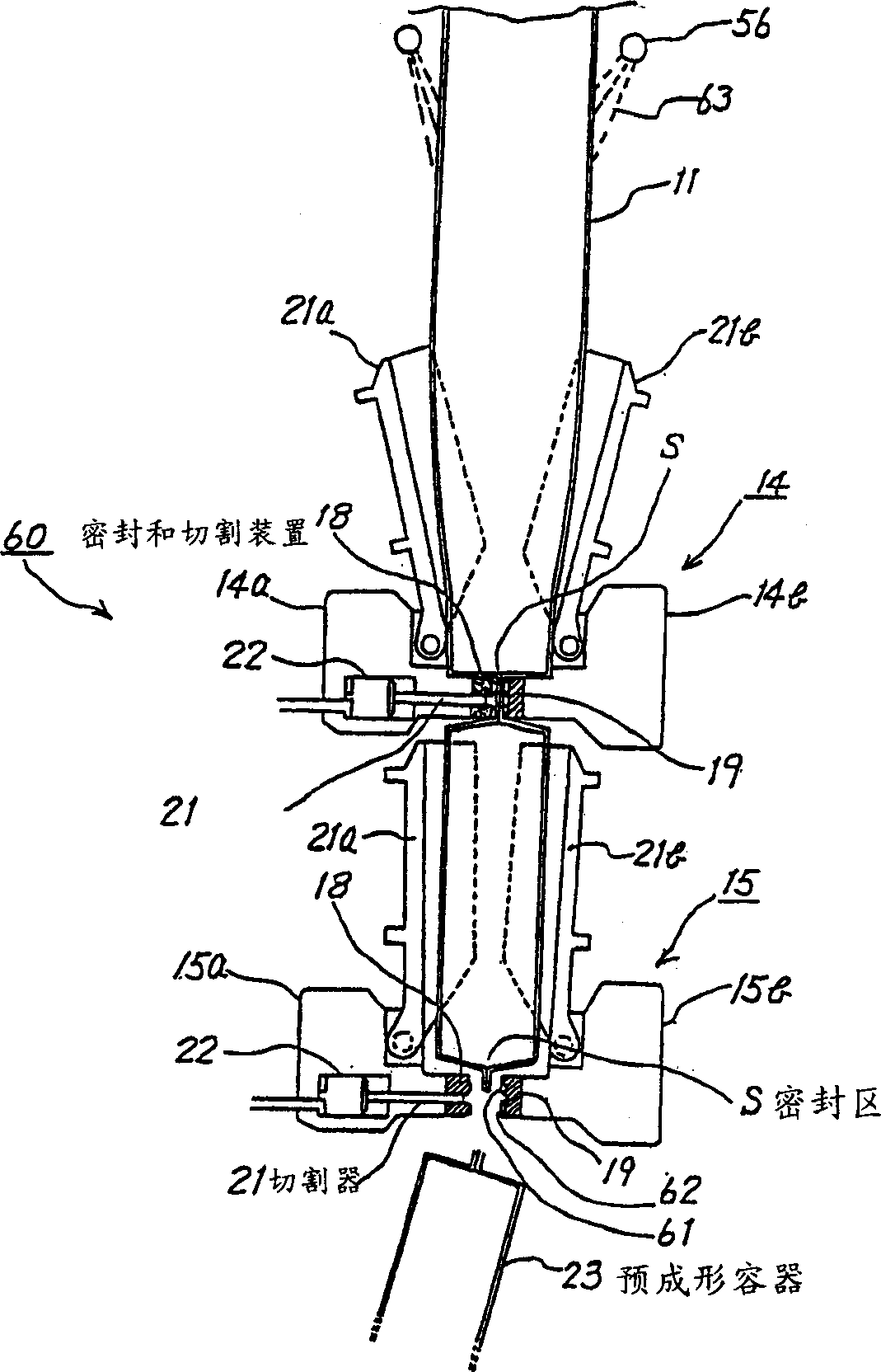

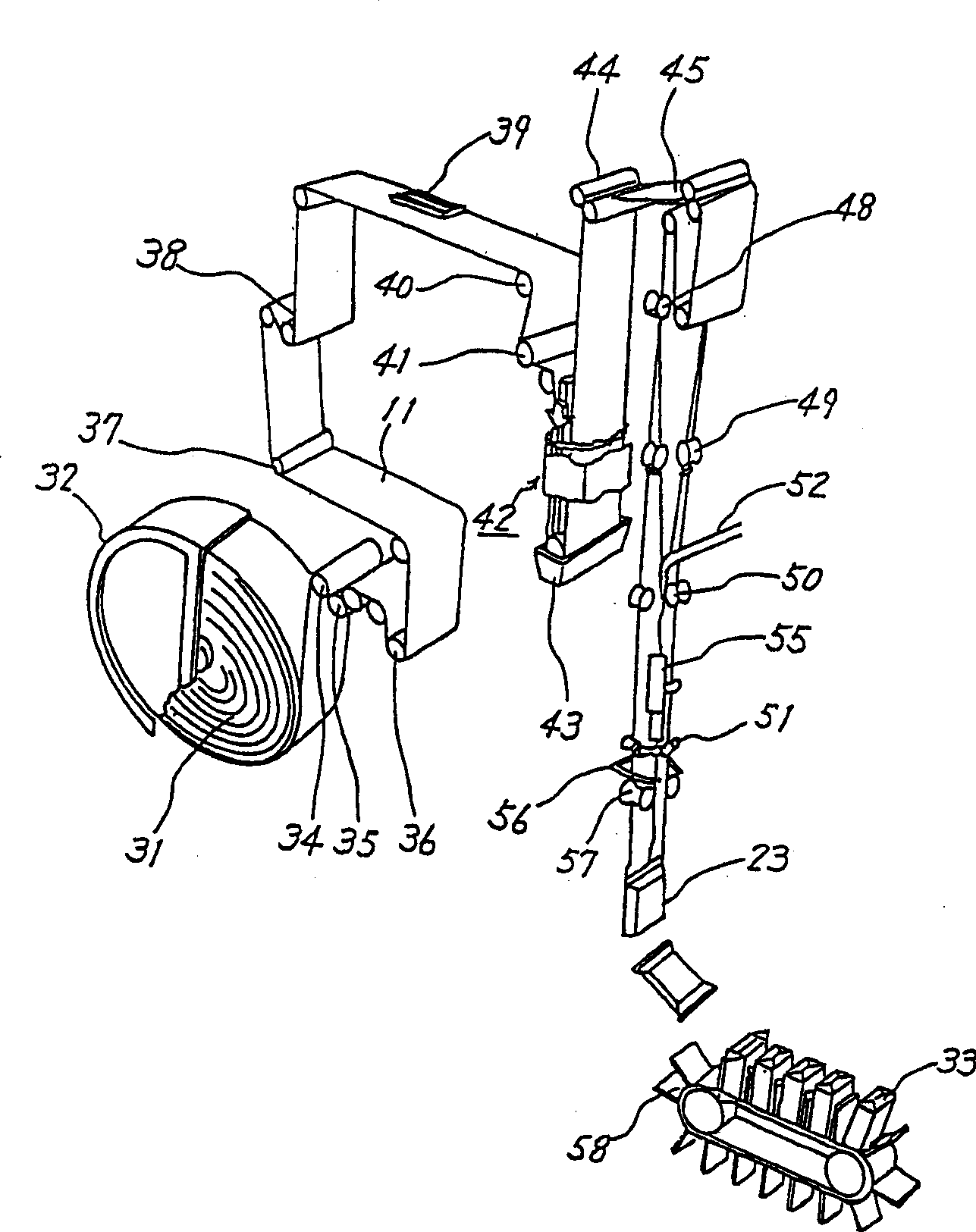

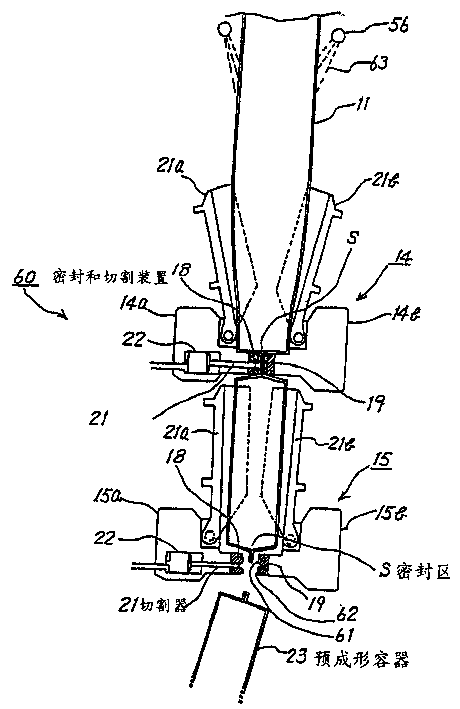

[0019] first reference figure 2 , one embodiment of the filling machine relating to the invention comprises the forming and filling of packages from flat web-like packaging material 11 . This web-like packaging material is contained in rolls 31 in boxes 32 and is loaded or conveyed via the boxes 32 to the loading station of the filling machine.

[0020] By way of example, the web of packaging material 11 may be in the form of a flexible paper laminate comprising a paper substrate and a heat-sealable / waterproof layer of polyethylene resin laminated on both sides of the paper substrate. If desired, a barrier layer in the form of aluminum foil or a resin having gas barrier properties is formed between the paper substrate and one or both heat-sealable / waterproof layers. In addition, an external design forming the appearance of the packaging container 33 may be printed on the outer surface of the material.

[0021] The packaging material 11 unwound from the reel to the loading s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com