Pipe joint for pipe-wall meter

A technology for pipe joints and pipe walls, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve problems such as high cost and difficult pipeline design, achieve small size, enhance market application value, and expand applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

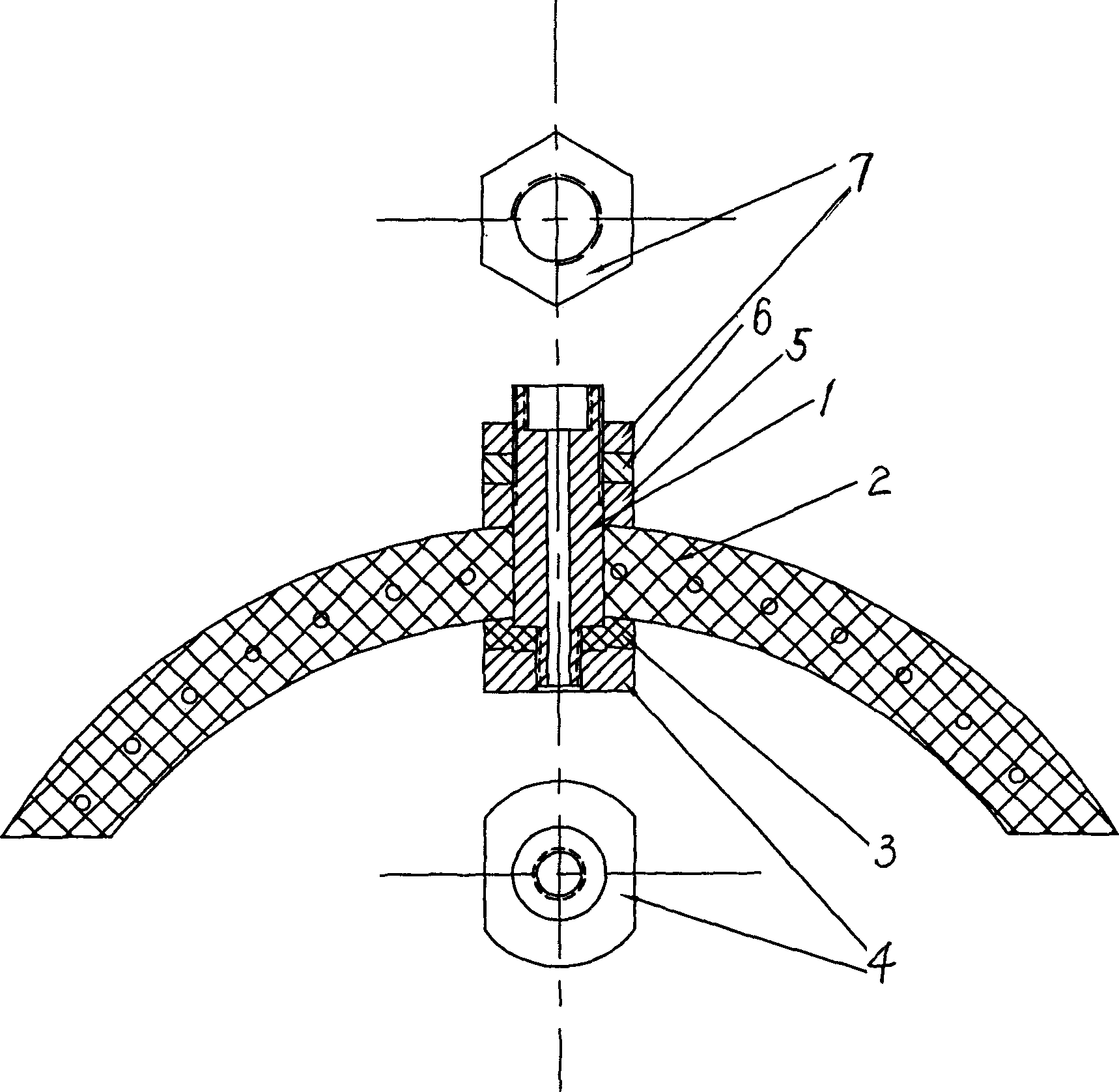

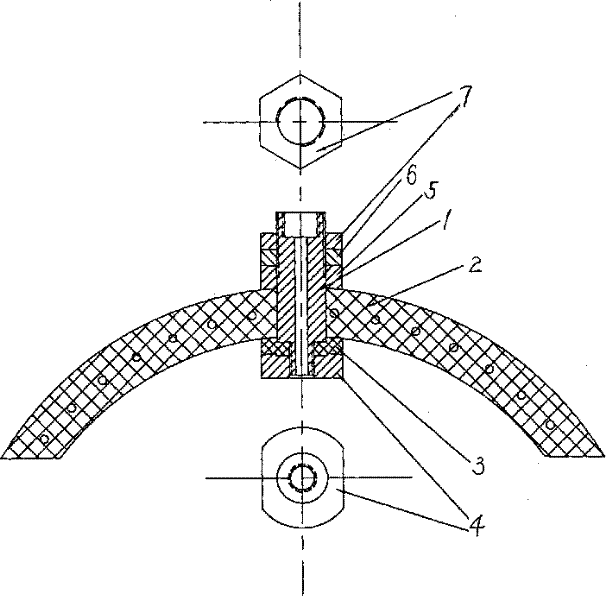

[0010] Referring to the accompanying drawings, a pipe joint for pipe wall instruments of the present invention is equipped with a joint body 1 , and the joint body 1 is provided with a central through hole 11 . The joint main body 1 is arranged in the pipe wall hole of the plastic pipe or the steel skeleton plastic composite pipe 2 .

[0011] The parts of the main body 1 of the joint protruding respectively from the inner surface of the pipe wall and the outer surface of the pipe wall are provided with external threads. The joint main body 1 located on the inner surface of the pipe wall is equipped with a sealing washer 3 and screwed with a compression nut 4. The sealing washer 3 is specially designed and customized. For different pressure levels and different media, the sealing washer 3 of different materials is selected. An upper pressure block 5 is mounted on the part of the joint main body 1 outside the pipe wall and is screwed with a stop pad 6 and a stop nut 7 .

[0012...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap