Oldham's coupling screw compressor with gap

A technology of coupling and clearance, used in couplings, elastic couplings, rotary piston machines, etc., can solve problems such as loud noise and overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

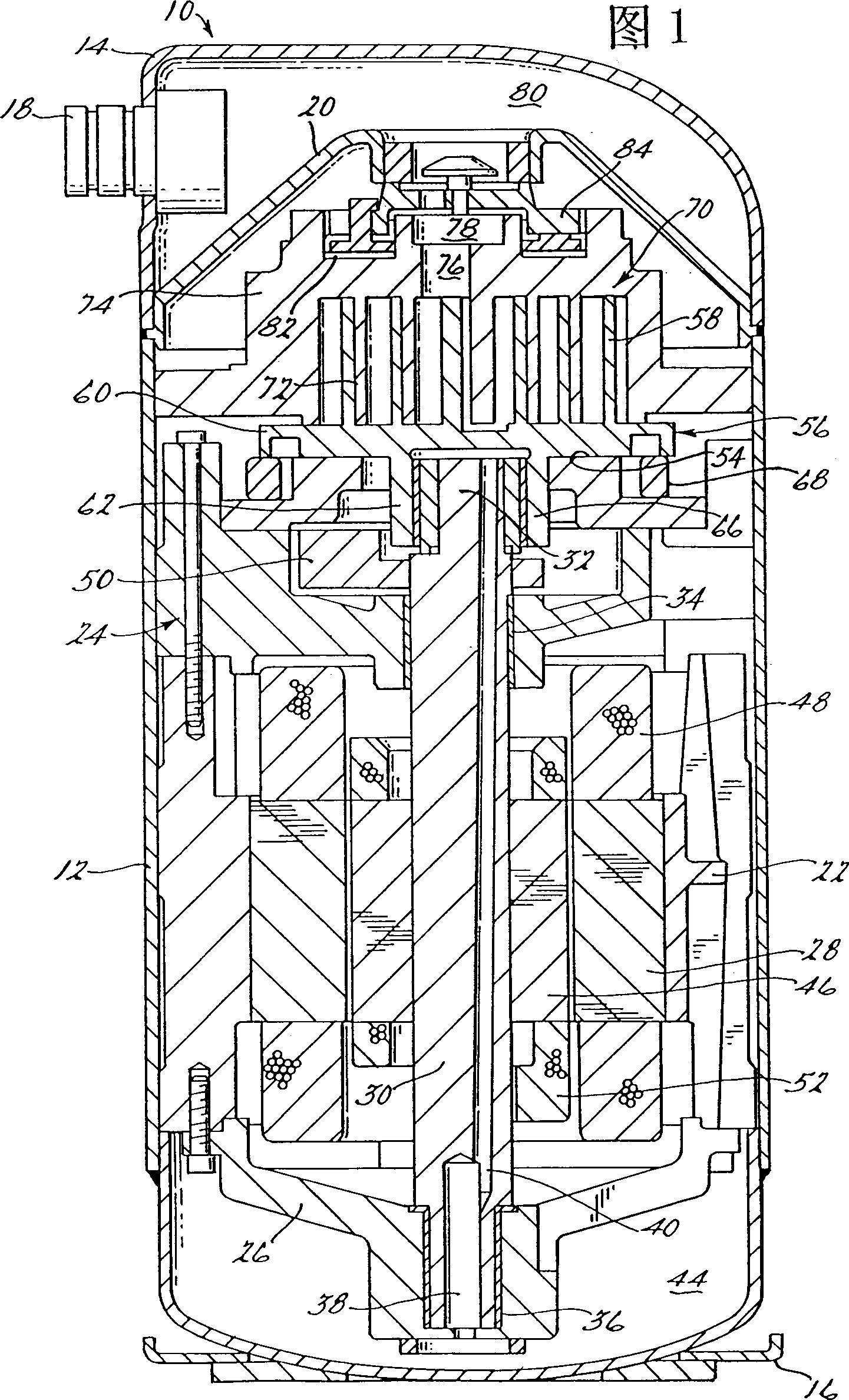

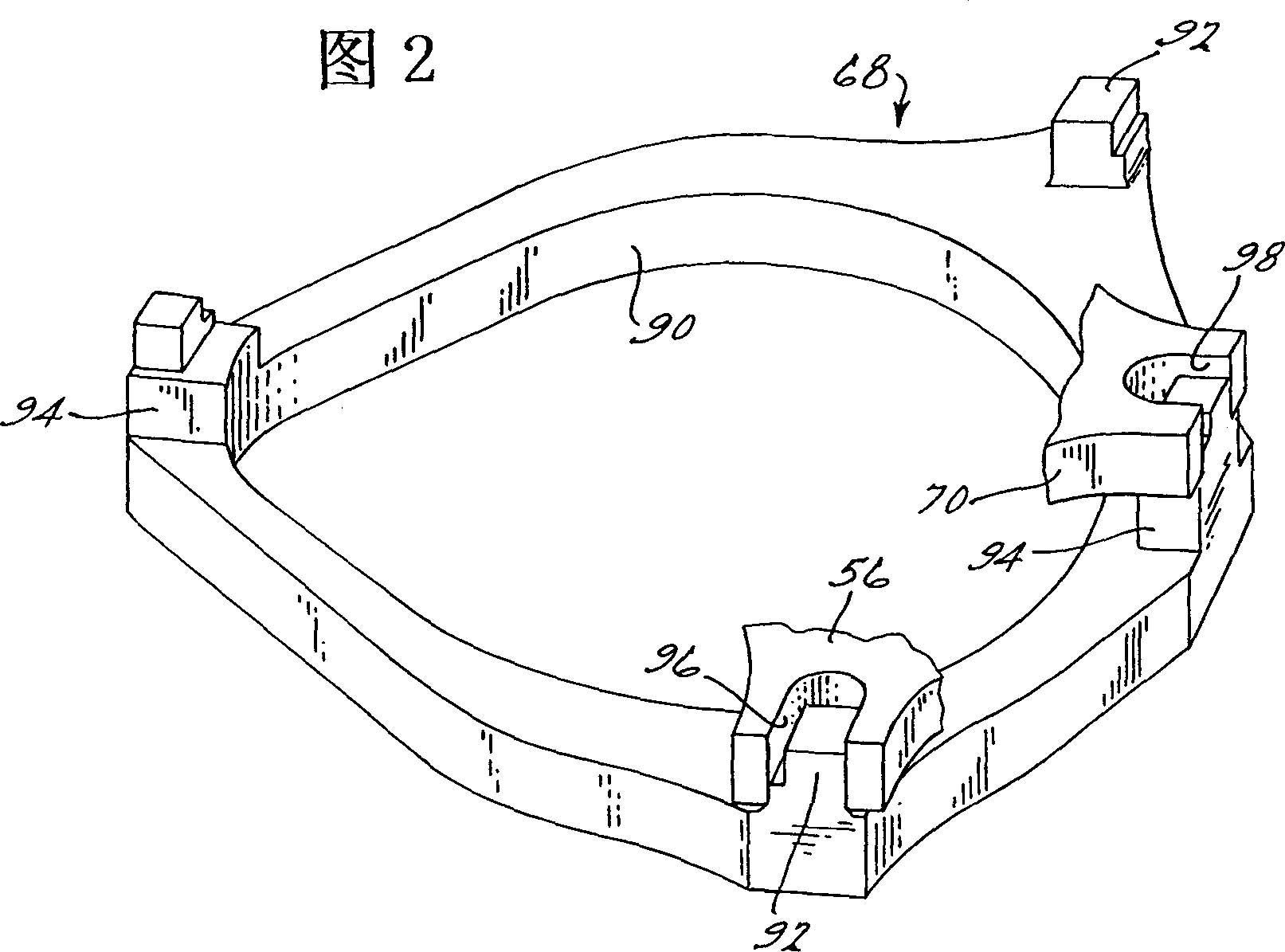

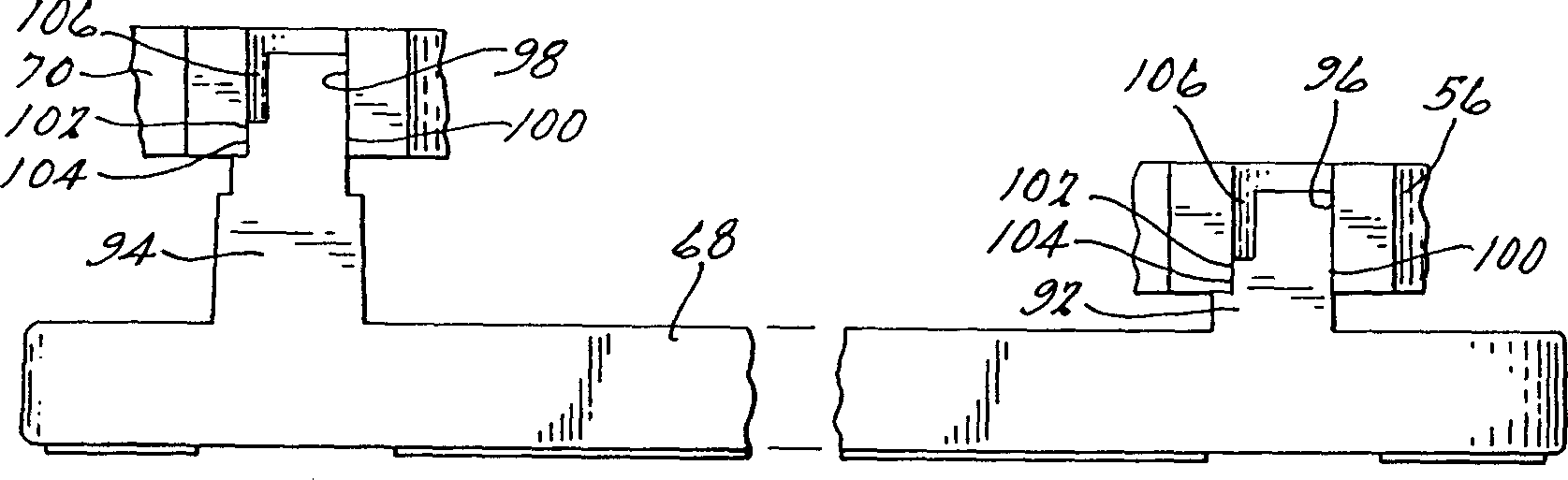

[0019] Referring now to the drawings, in which like numerals indicate like or corresponding parts throughout the several views, there is shown in FIGS. 1 and 2 a screw compressor including the unique The Oldham coupling, and generally indicated by the number 10. Screw compressor 10 includes a generally cylindrical hermetic casing 12 having a cover 14 welded at its upper end and a base 16 welded at its lower end having several Formed mounting feet (not shown). The cover 14 is equipped with a refrigerant discharge connection 18 which may have a customary discharge valve therein. A transversely extending bulkhead 20 is secured to the housing 12 by welding around the perimeter of the housing 12 at the same points as the cover 14 is welded to the housing 12, and a compressor mounting frame 22 is press fit inside the housing 12 and Supported by the end of the base 16 . The diameter of the base 16 is slightly smaller than the diameter of the housing 12 so that the base 16 is seate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com