Multi-layer magnetic engaged wheel and magnetic gearing device

A technology of magnetic transmission and meshing gear, which is applied in transmission devices, electromechanical devices, permanent magnet clutches/brakes, etc. It can solve the problems of inability to apply high-power transmission and small maximum meshing force, and achieve large meshing force and low noise , the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Preferred embodiments of the invention are described below with the aid of the drawings.

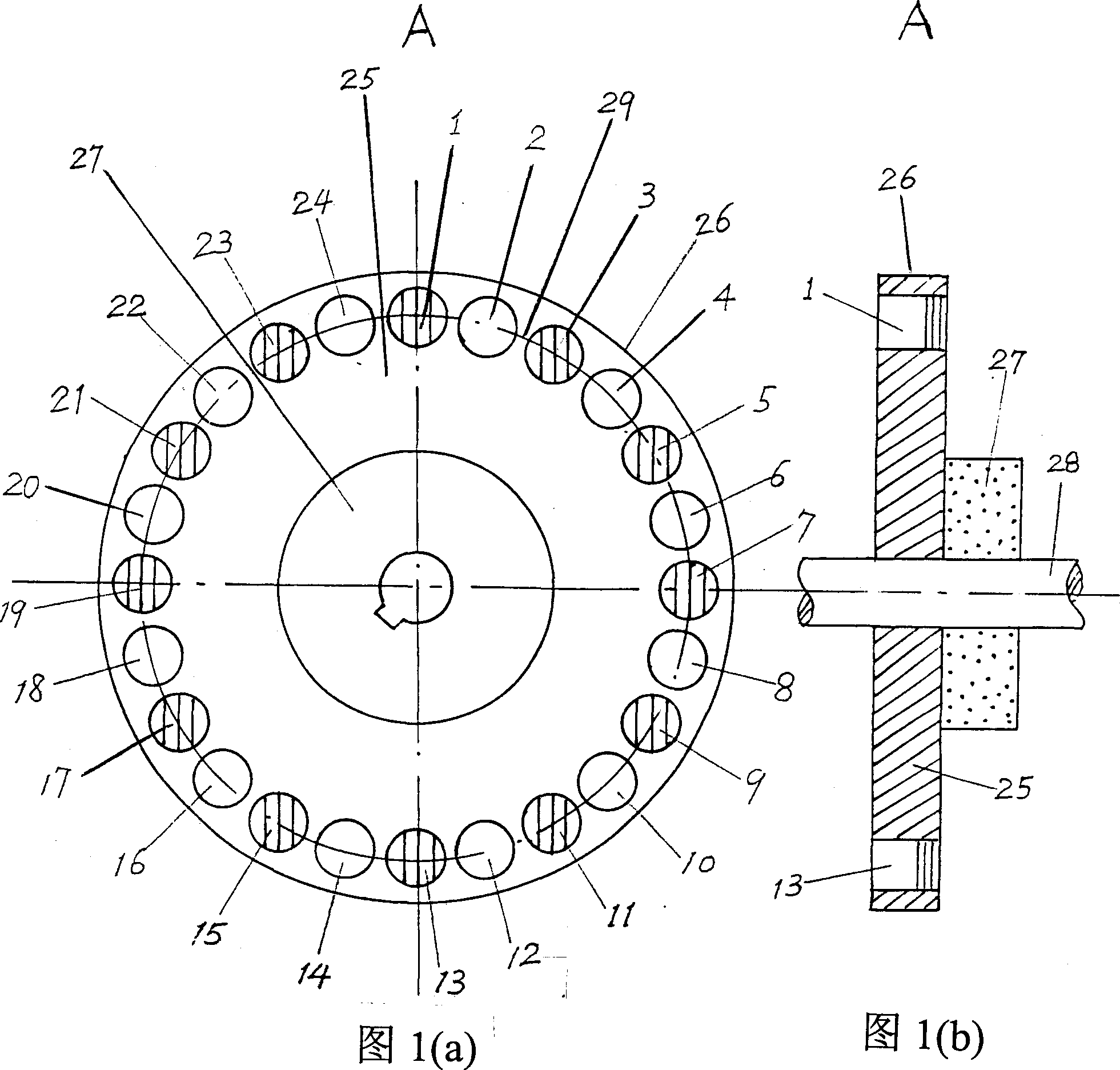

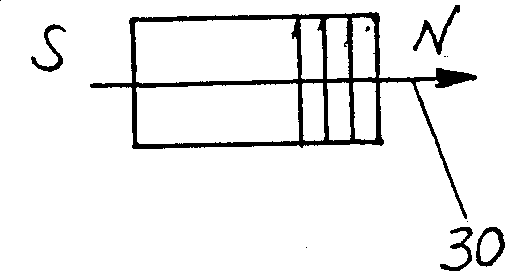

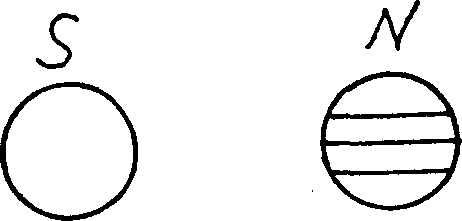

[0081] Fig. 1 (a) and 1 (b) are according to the structural diagram of multilayer planar magnetic gear A of preferred embodiment of the present invention, wherein Fig. 1 (a) is its front view, and Fig. 1 (b) is multilayer Axial sectional view of the plane magnetic mesh wheel, for the sake of simplification, only one layer is drawn in Fig. 1(b). As shown in Figure 1 (b), this layer of planar magnetic gears includes a magnetic wheel (magnetic wheels) 26, a spacer (Spacer) 27 and a shaft 28, and the shaft 28 runs through the center of the magnetic wheel 26 and through the spacer 27, and the magnetic disc wheel 26 and spacer 27 are fixed on the rotating shaft 28 and the planes of both are perpendicular to the rotating shaft 28. As shown in Fig. 1 (a), the disk wheel 26 is composed of a rotatable flat disc-shaped base 25 and magnets 1-24 arranged on the base 25, and the magnets 1-24 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com