Semi-automatic film cutting/clamping device and its operating method

A technology for packaging film and clips, applied in one field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

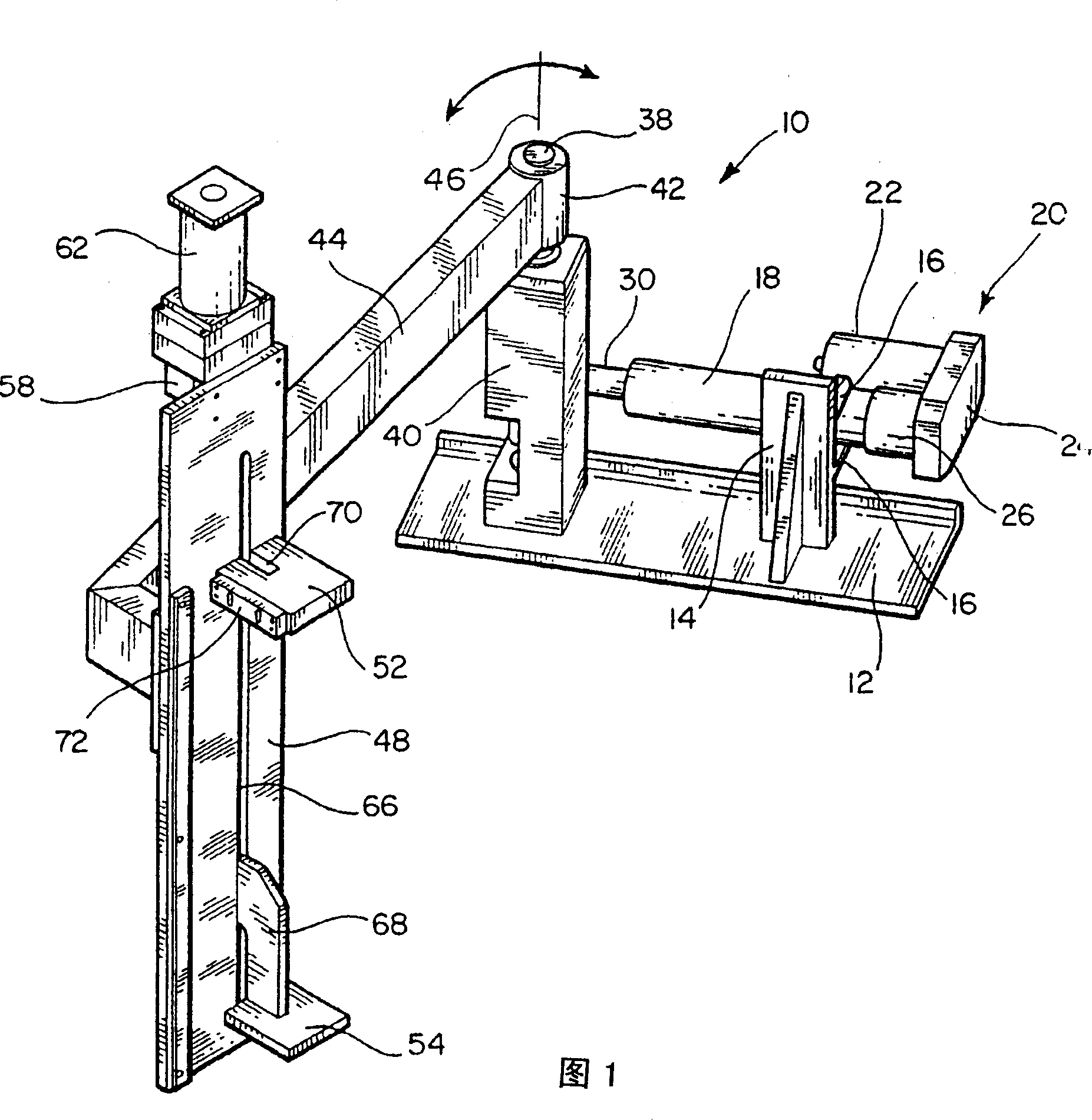

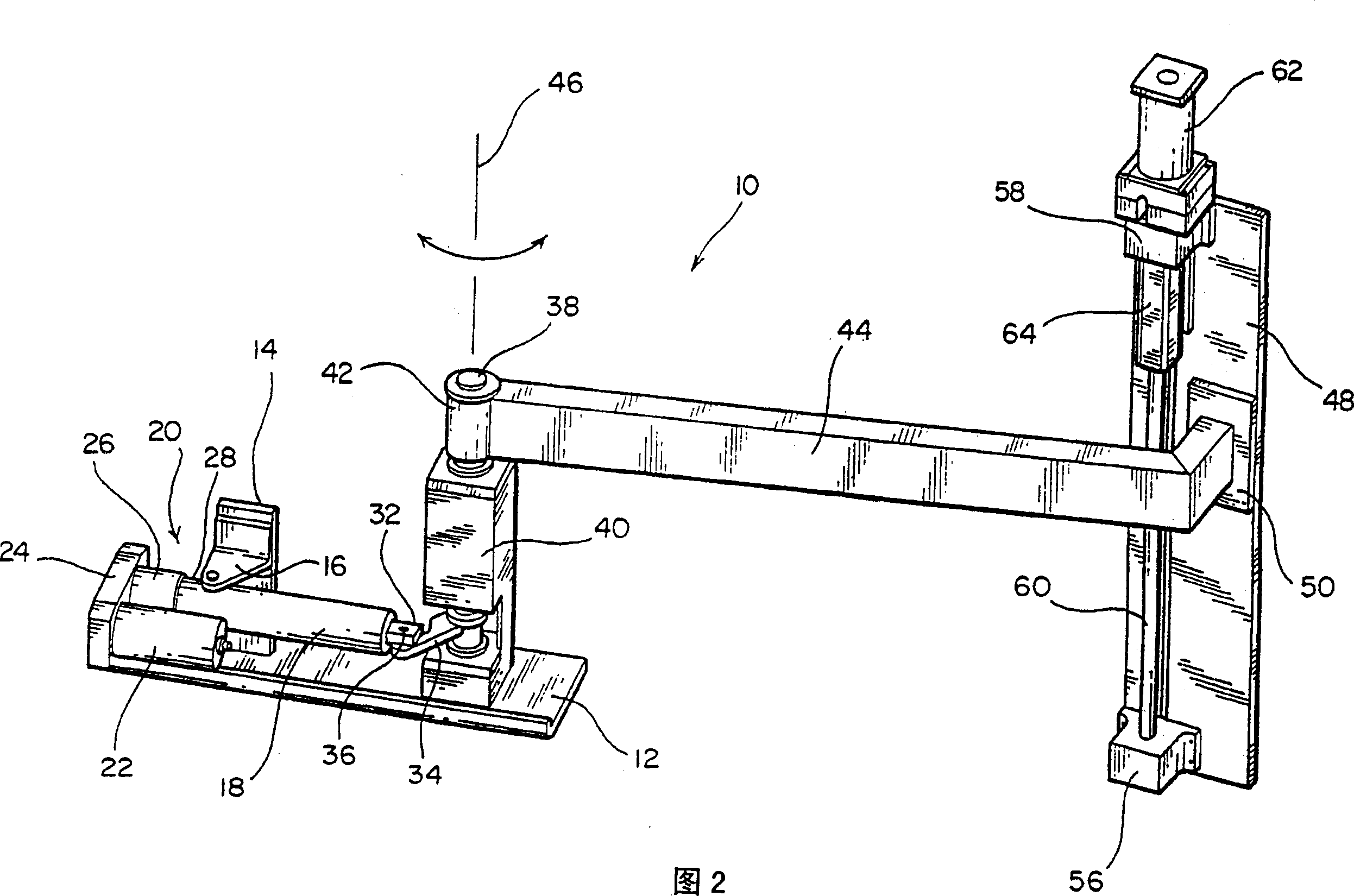

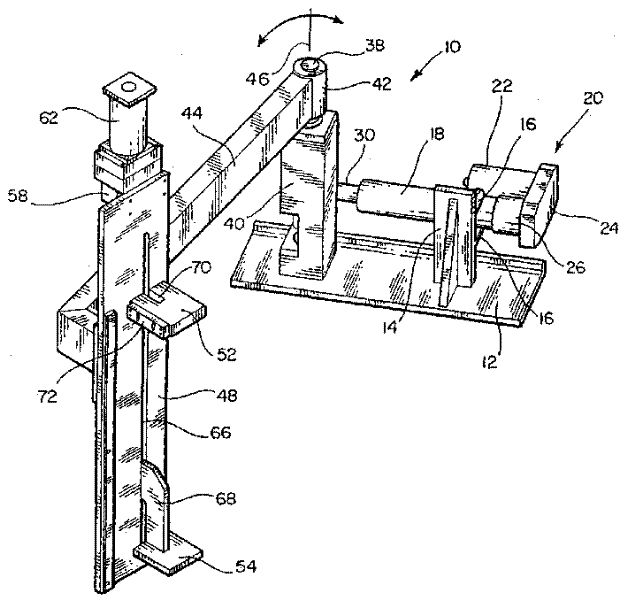

[0015]Referring now to the drawings, and more particularly, FIGS. 1 and 2 thereof, there is shown a new and improved mechanism or system, generally indicated by the reference numeral 10 . This new and improved mechanism or system is used in conjunction with a wrapping machine, device or system for parcels, goods or articles, to apply or secure in a semi-automatic manner the leading portion of the wrapping film to an article to be wrapped or packaged, goods or packages in preparation for commencing a wrapping or wrapping operation or wrapping cycle and separating the trailing edge portion of the wrapping or wrapping film from the package, goods or article once the wrapping or wrapping operation or cycle of the article, goods or package has been completed or Cutting, so as not to require the operator to manually attach or cut off the leading and trailing portions of the wrapping film to or from the object, cargo or package, respectively. In more detail, the new and improved mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com