Mechanical-electrical integration separate production packer

A packer and electromechanical technology, applied in the field of electromechanical integrated separate production packer, can solve the problems of high cost, inability to wash wells, overhaul operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

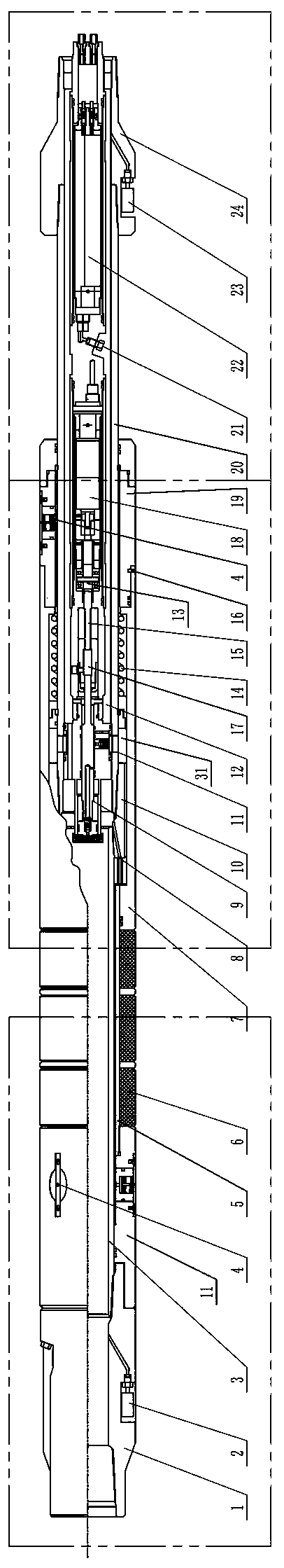

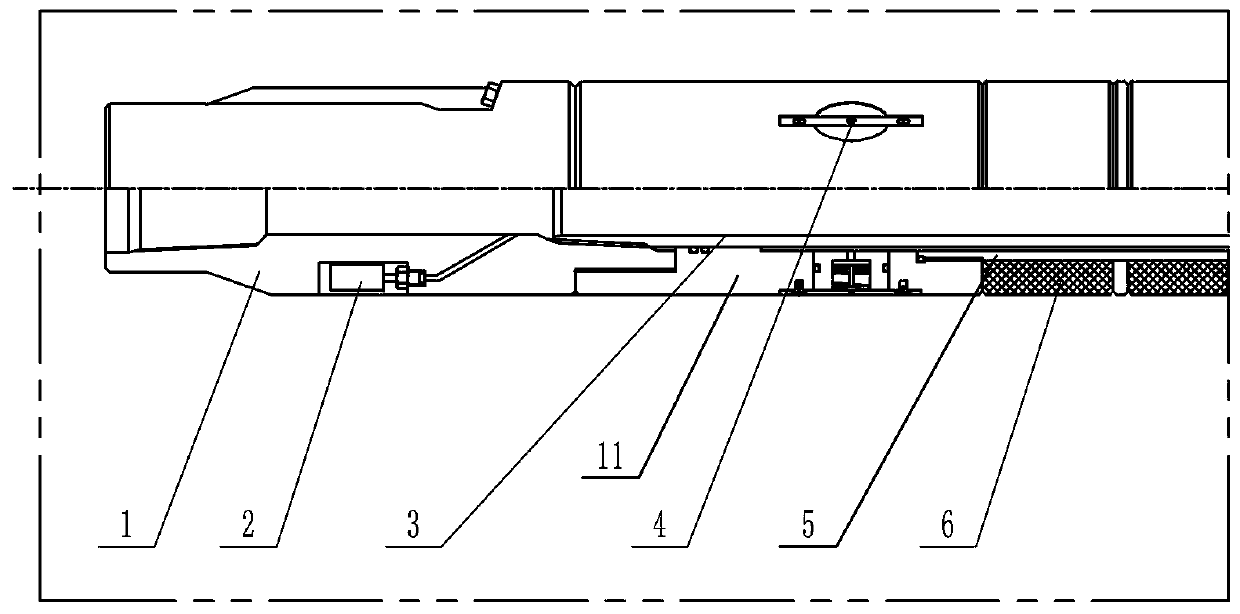

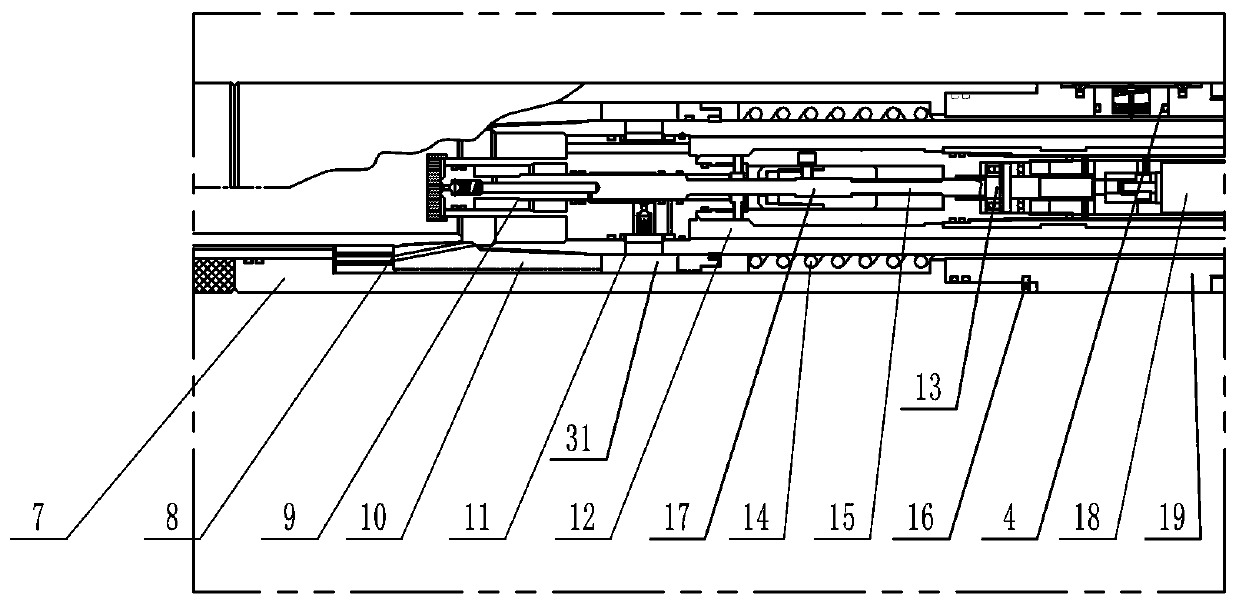

[0034] Such as Figure 1 to Figure 4 As shown, a mechatronic separate mining packer, the upper joint 1 is threaded to one end of the central pipe 3, and the outer circumference of the central pipe 3 is provided with a setting assembly; the other end of the central pipe 3 is threaded to the transfer joint 10, and the The transfer joint 10 is provided with a through hole 31, the inner circumference of the transfer joint 10 is connected to the outer steel sleeve 20, the inner circumference of the outer steel sleeve 20 is connected to the motor system through the outer member 12, and the front end of the motor system is connected to the pump at the front end through the transmission screw 15. The valve system 9, the communication between different pipelines in the pump valve system 9 and the through hole 31, realizes the setting and unsealing functions; the back end of the motor system is provided with a circuit system 22, and the circuit system 22 is connected to the motor system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com