Countercurrent, copolymerizing and air-float process for purifying water and its equipment

A technology of copolymerization air flotation and countercurrent, which is applied in the direction of flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., which can solve the problems of long time, large floor area and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

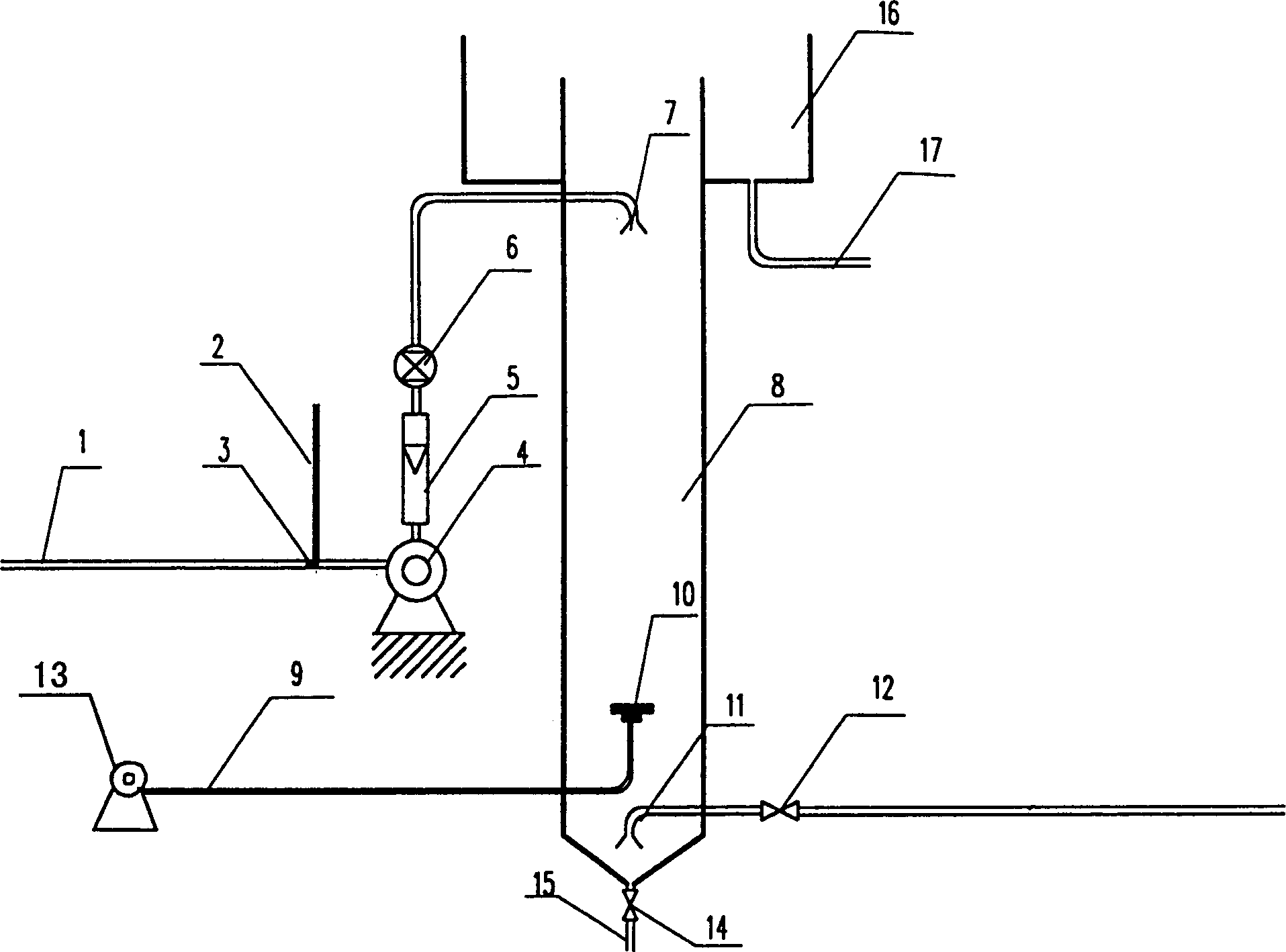

[0022] Please refer to figure 1 , the flocculant enters the water pipe 1 from the dosing port 3 of the dosing pipe 2, and forms a mixed liquid with the water to be treated, and is stirred and mixed by the impeller rotation of the water inlet pump 4, and the mixed water flows downward through the water inlet 7 to be treated and enters the reverse flow Copolymerization air flotation reactor 8, its flow rate is displayed and controlled by flow meter 5 and water pump valve 6. The pressure dissolved air tank 13 enters the countercurrent copolymerization air flotation reactor 8 upwardly through the dissolved air water inlet pipe 9 and the dissolved air release device 10, and releases microbubbles. During the downward flow of the mixed water, the micro-flocs contact and flocculate with the micro-bubbles in the upward-flowing dissolved air water, and the formed copolymer utilizes the buoyancy of the bubbles to rise to the slag collection tank 16 at the top of the reactor 8 and then di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com