Mechanically glued veneer, its manufacture method and equipment

A kind of equipment, technology of sawdust, applied in the field of mechanical plywood of wood and its manufacture and equipment, can solve the problem of glue loss, etc., achieve the effect of short extrusion time, pollution problem and related cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

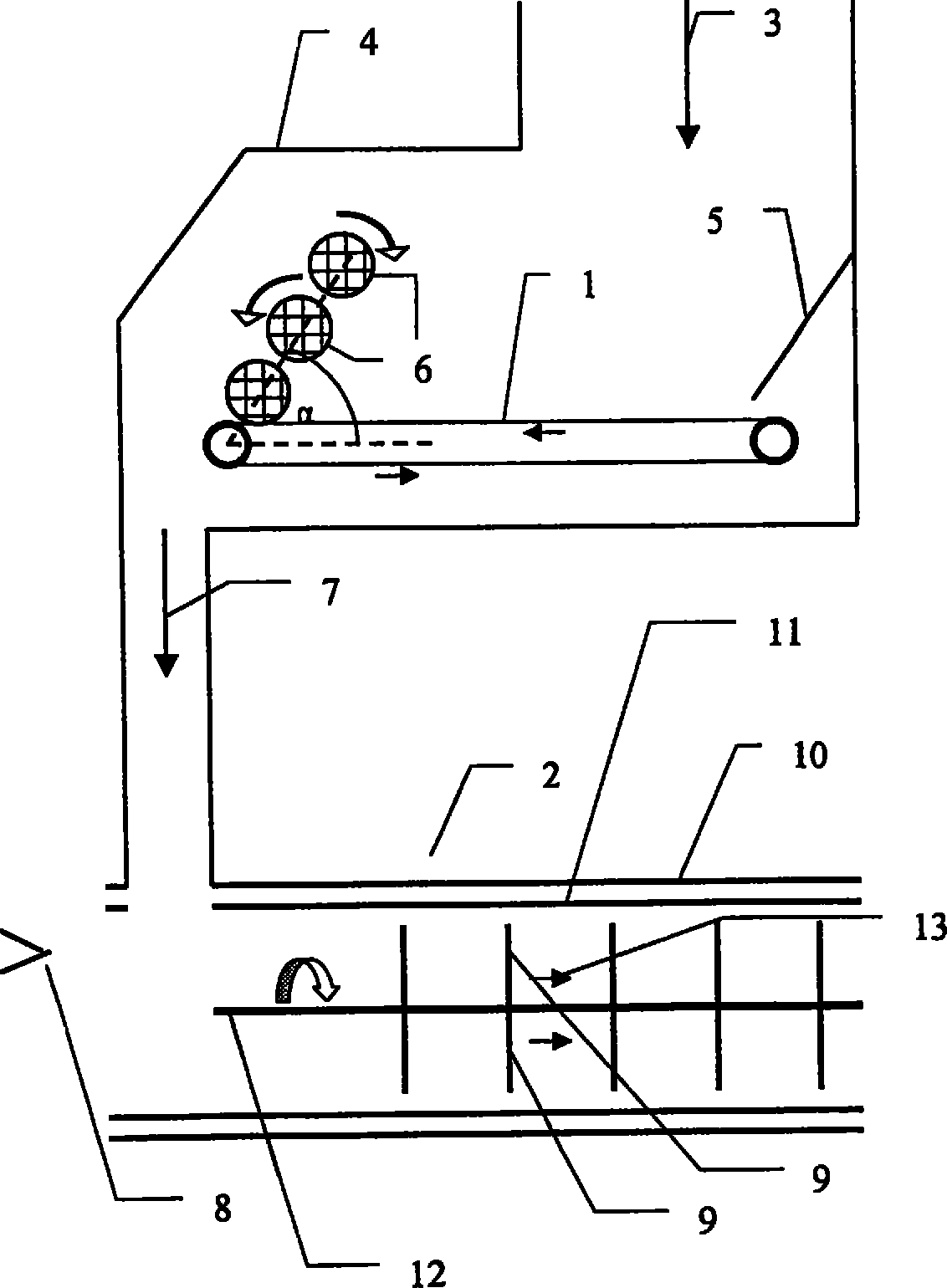

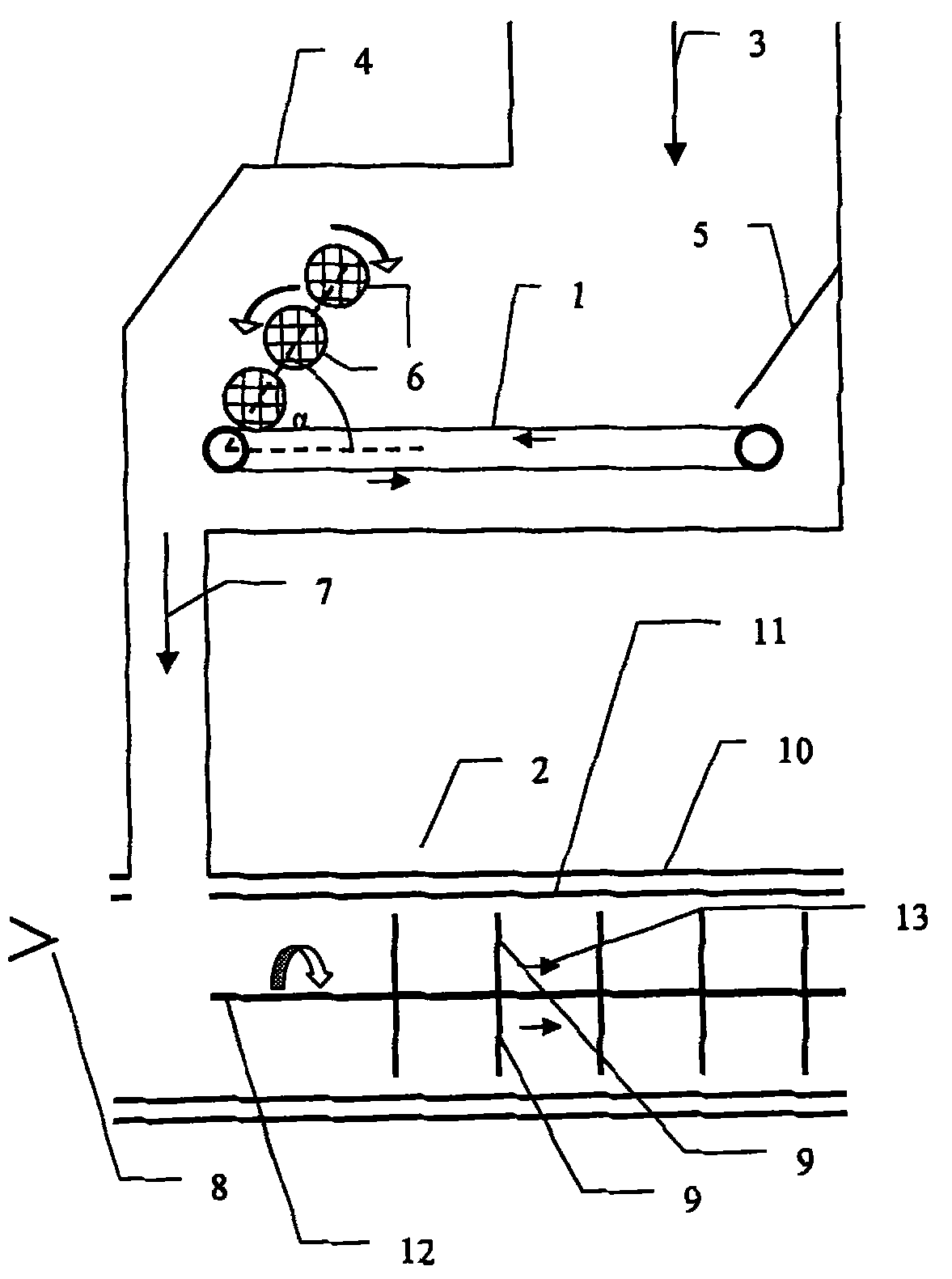

[0070] Such as figure 1 Shown by the arrow 3 in the shavings, the dry fibers made of shavings are conveyed to the weighing belt conveyor 1 through the opening of the housing 4 . The ramp 5 guides the arriving fibers onto the belt of the weighing belt conveyor. The weighing belt conveyor measures and controls the amount of material conveyed towards the three rollers 6 directions. Three rolls 6 are arranged up and down and alternately in turn, and they form an acute angle α with the weighing belt conveyor 1 . The fibers on the weighing belt conveyor 1 arrive within this acute angle. They pass through rotating rolls 6 . In the meantime, a thin layer is formed from the fibers, which is conveyed vertically further downwards in the direction of arrow 7 due to gravity. The thin layer thus enters the mixer 2 , in particular between the nozzles 8 and the tool 9 .

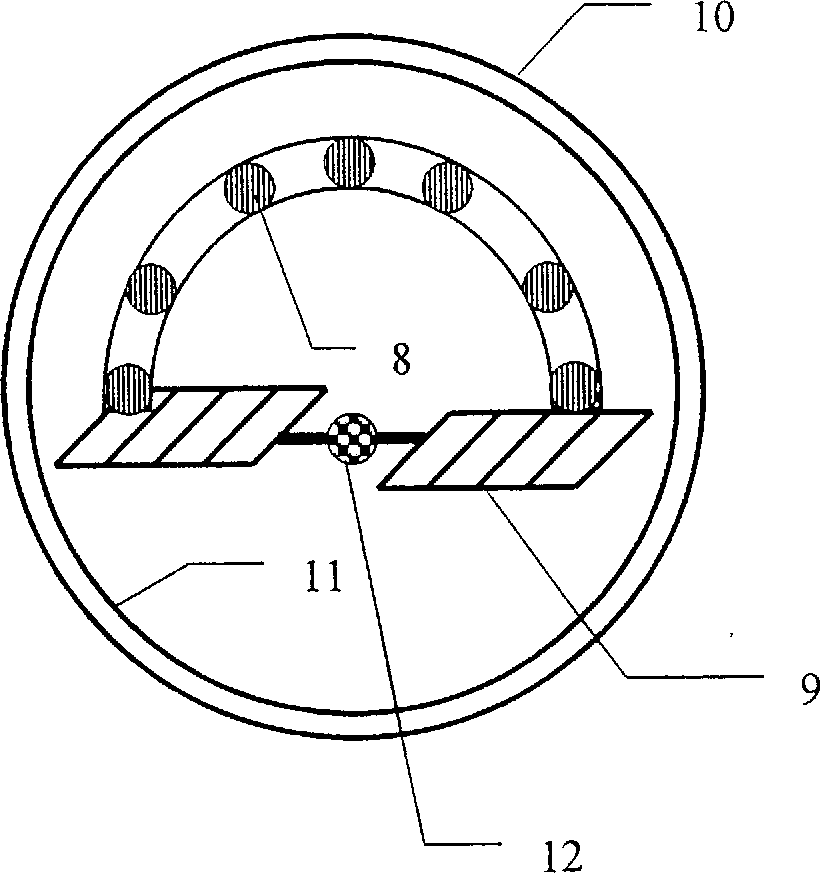

[0071] The mixer consists of a tubular housing. The housing consists of double walls 10 and 11 . A shaft 12 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com