Electromagnetic drive dislocation micromechanical variable light attenuator

An electromagnetic drive, electromagnetic drive coil technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of increased driver travel and power consumption, practical difficulties, packaging and aligning optical fibers, etc., to achieve a large dynamic range, easy to array The effect of simplified packaging, structure and optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

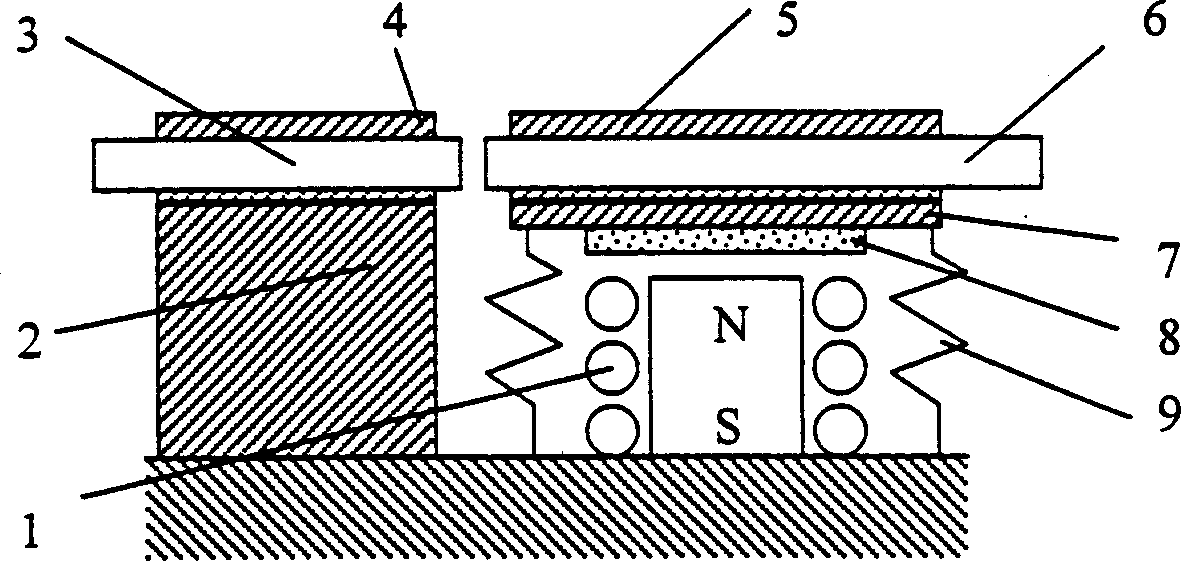

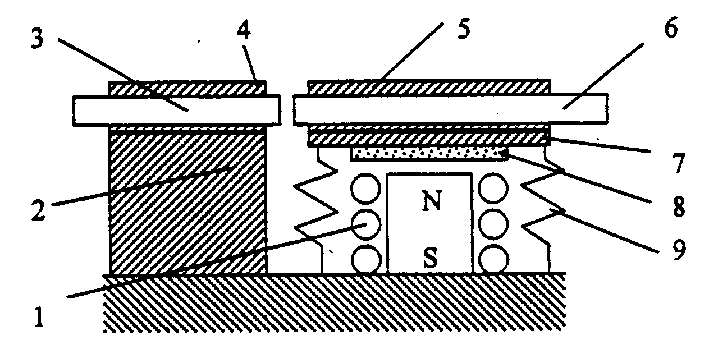

[0008] Such as figure 1 As shown, the present invention mainly includes: an electromagnetic drive coil 1, a base 2, optical fibers 3 and 6, positioning grooves 4 and 5, a movable platform 7, a magnetic body 8 and an elastic body 9, and the optical fibers 3 and 6 are respectively fixed on the base 2 and In the positioning grooves 4 and 5 on the movable platform 7, the movable platform 7 and the magnetic body 8 are fixed together, the base 2 and the movable platform 7 are connected by an elastic body 9, and the movable platform 7 moves up and down relative to the base 2 or / And rotate, the base 2 is fixed with the electromagnetic drive coil 1.

[0009] Through the deformation of the elastic body 9 under the action of the electromagnetic driving force, the upper and lower positions of the base 2 and the movable platform 7 are adjusted, the radial distance between the optical fibers 3 and 6 or / and the angle between the two axes are changed, and the optical properties of the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com