Stage coloring and covering system

A technique for specimen slides and covers, used in conveyor objects, transportation and packaging, preparation of samples for testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

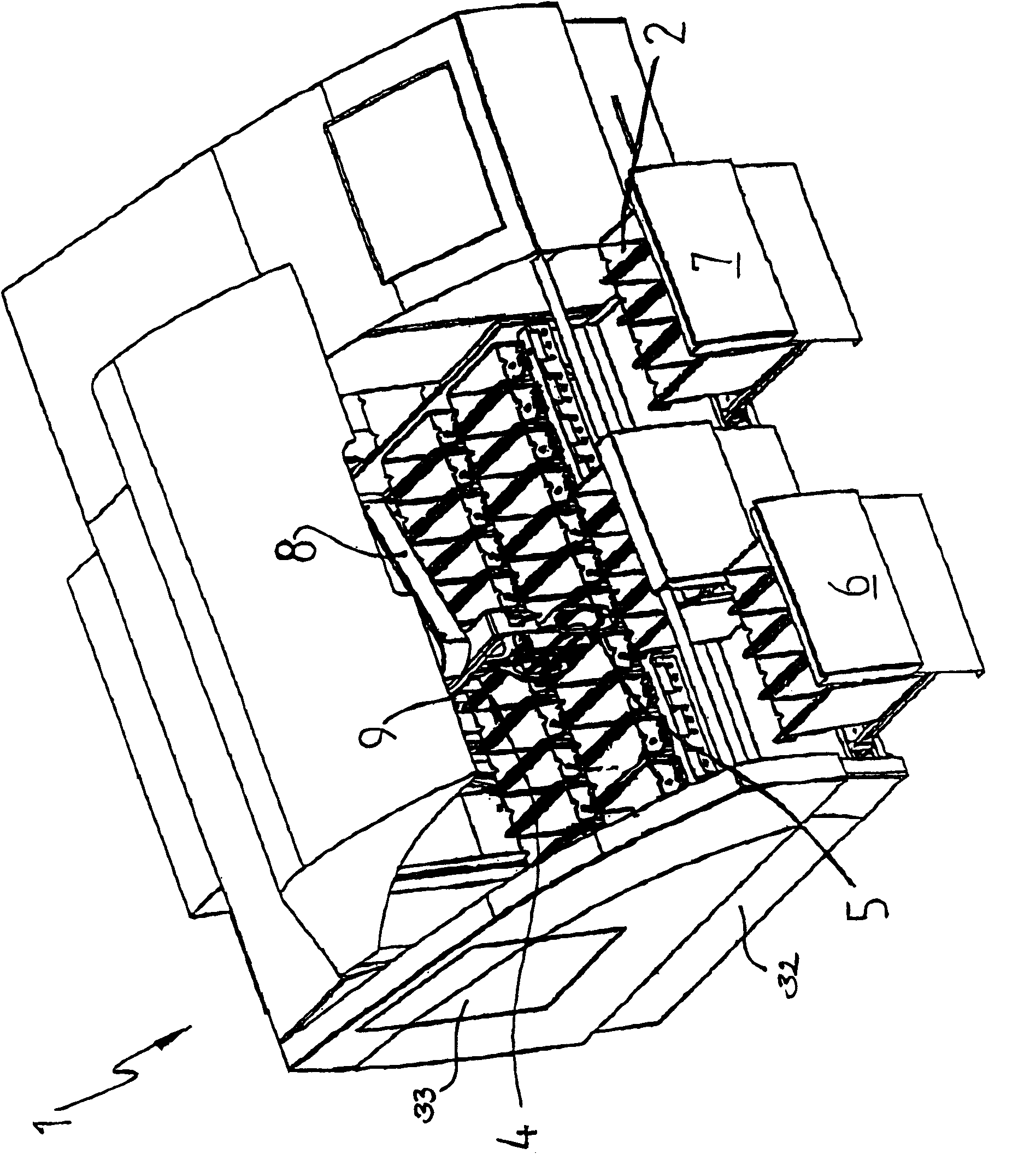

[0022] figure 1 It is shown that a transport device 4 is arranged on the staining robot 1 , which feeds the slides to the various processing stations 9 . Furthermore, a loading station 6 is provided for loading the objects to be processed or the racks 5 carrying the objects to be processed. In order to remove the grid 5 from the coloring robot, a removal station 7 is provided, from which the user can manually place the grid 5 into a downstream component.

[0023] Both the loading station 6 and the removal station 7 are loaded via the conveyor 4 . The specimen slides in the loading station 6 can thus be removed via the transport device 4 and sent to a dedicated processing station 9 . After the last processing station 9, the racks 5 are placed in the removal station 7, so that they can be removed together again there. However, this removal is realized automatically through the conveying device, or the specimen slide can be sent directly from a processing station 9 to the del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com