Sheet glass manufacturing apparatus

A technology for producing equipment and glass, applied in glass manufacturing equipment, glass forming, glass forming, etc., can solve problems such as inability to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]

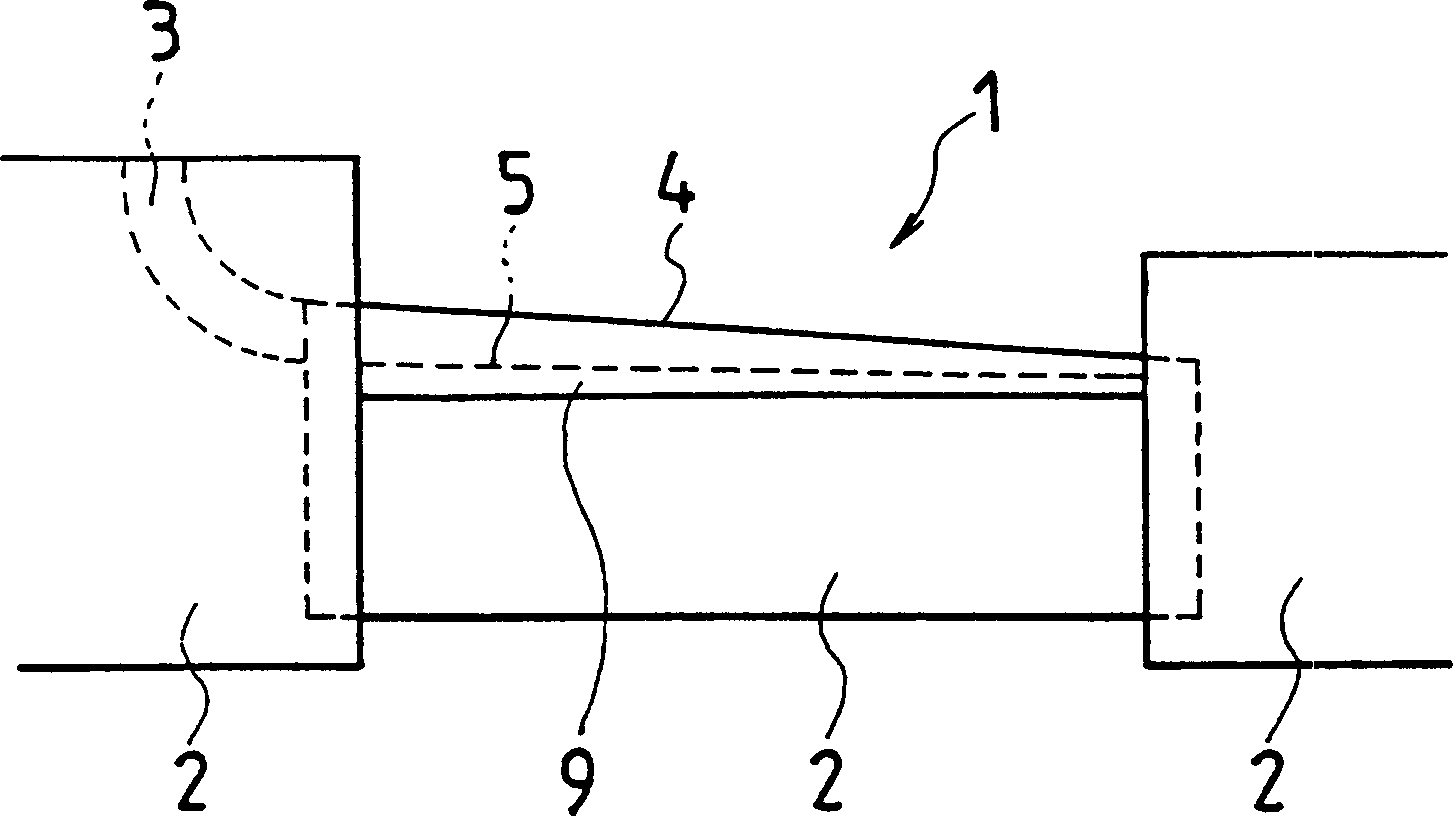

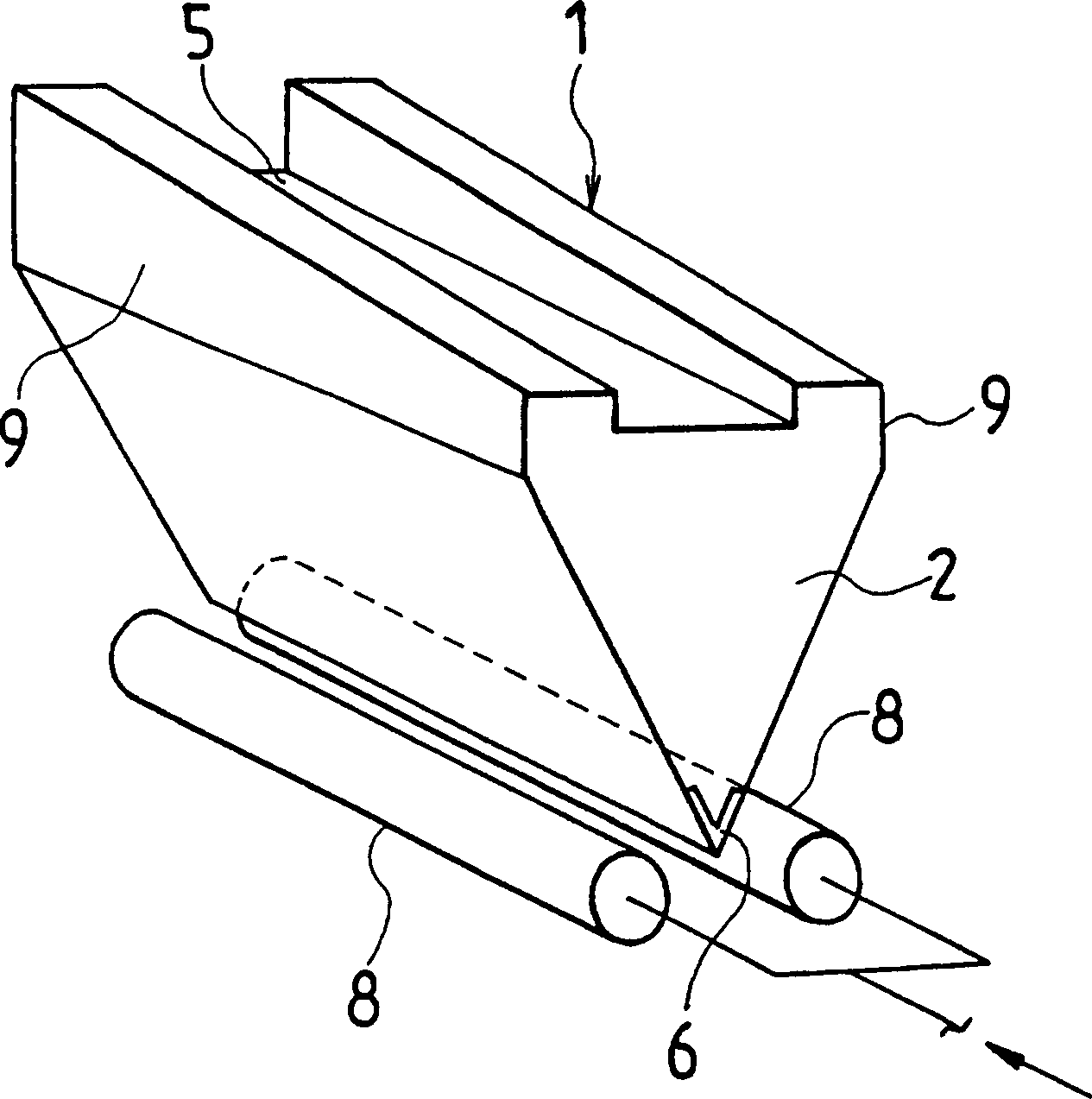

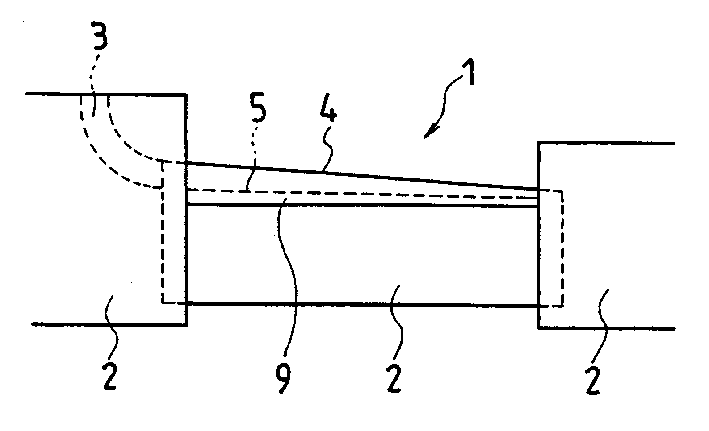

As shown in the figure, the forming body is composed of the following parts: a body 1 with a wedge-shaped cross-section and converging downward; side members 2 and 2 for adjusting the width of the glass plate are arranged on both sides of the body 1; Glass inlet 3. Although omitted in the drawing, the introduction port 3 is connected to a melting furnace containing clarified molten glass, and conveys the molten glass from the melting furnace into the groove portion 5 of the body 1 .

[0018]

exist figure 1 , the molten glass is conveyed to the groove portion 5 and flows from left to right along the groove portion 5 while overflowing from the upper edge 4 . The overflowing molten glass G flows down along the two surfaces 9 of the body 1, as figure 2 As shown, and integrated at the lower end edge to form a glass plate GR. The glass plate GR is pulled downward by a roller table (not shown) so that the glass plate GR moves downward, thereby achieving the purpose of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap