High efficient valve assembly for compressor

A technology of valve components and compressors, applied in the direction of engine components, components of pumping devices for elastic fluids, control valves, etc., which can solve problems such as changes and deterioration of compressor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

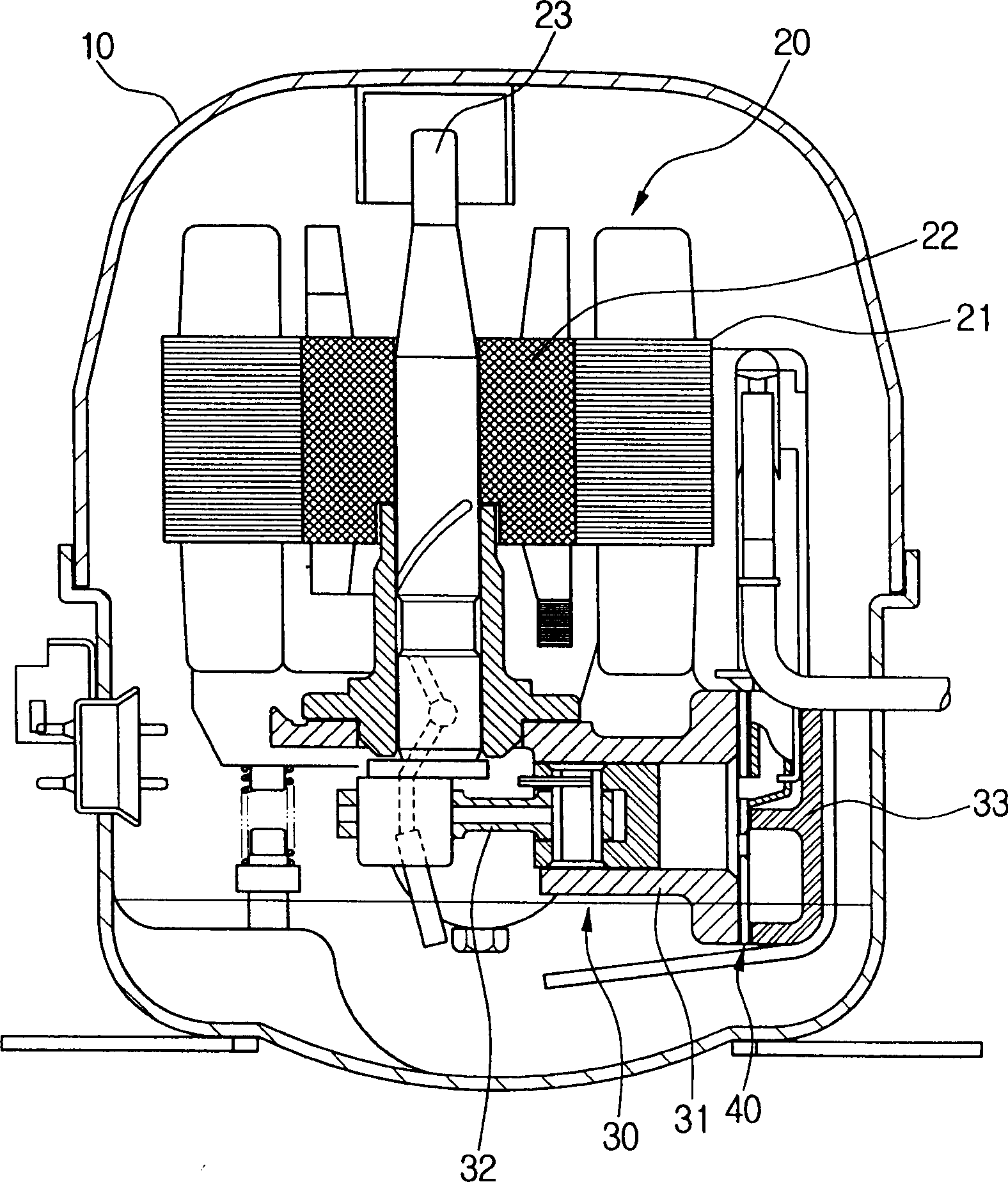

[0017] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. exist figure 1 In , the same related elements are denoted by the same reference numerals.

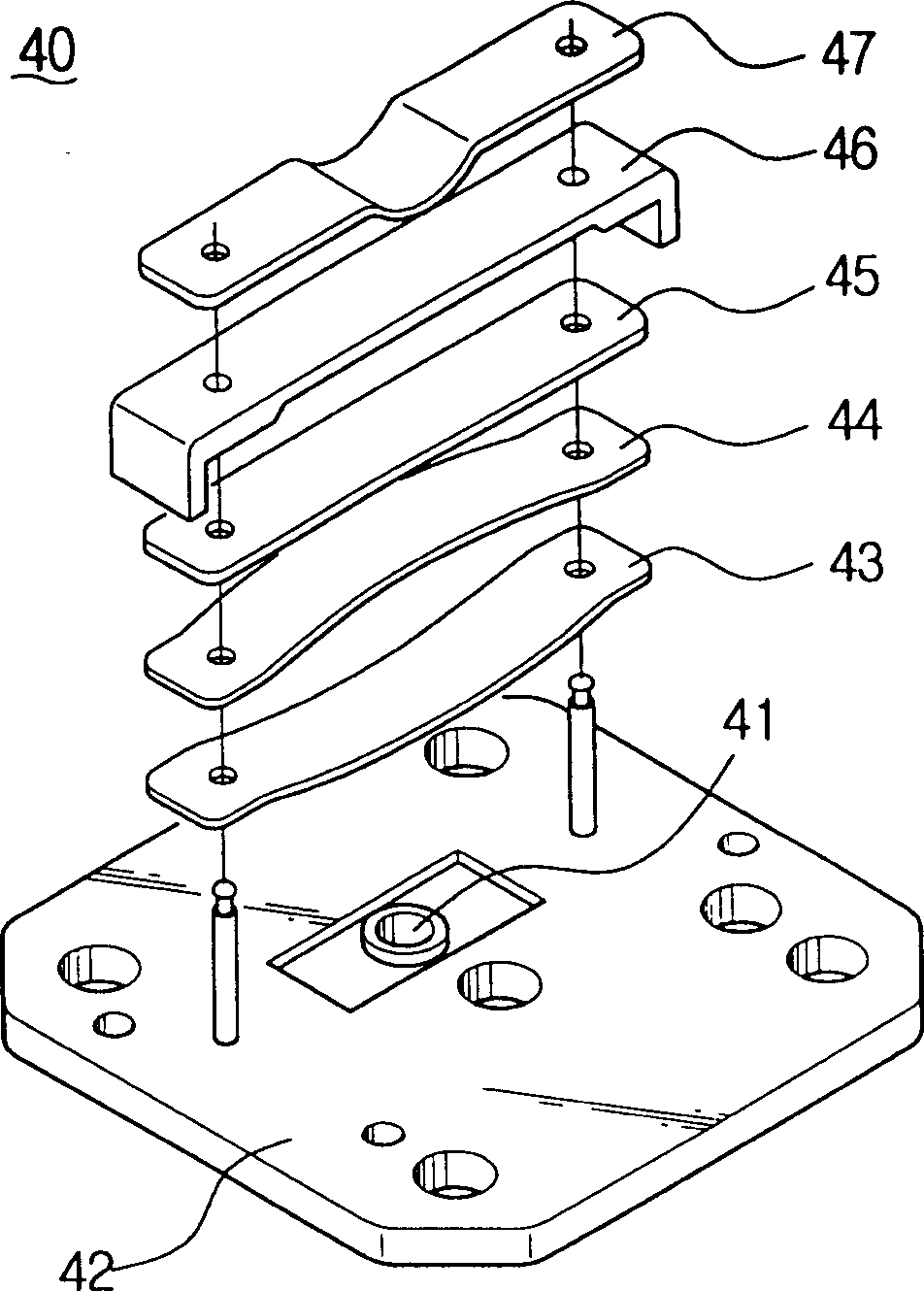

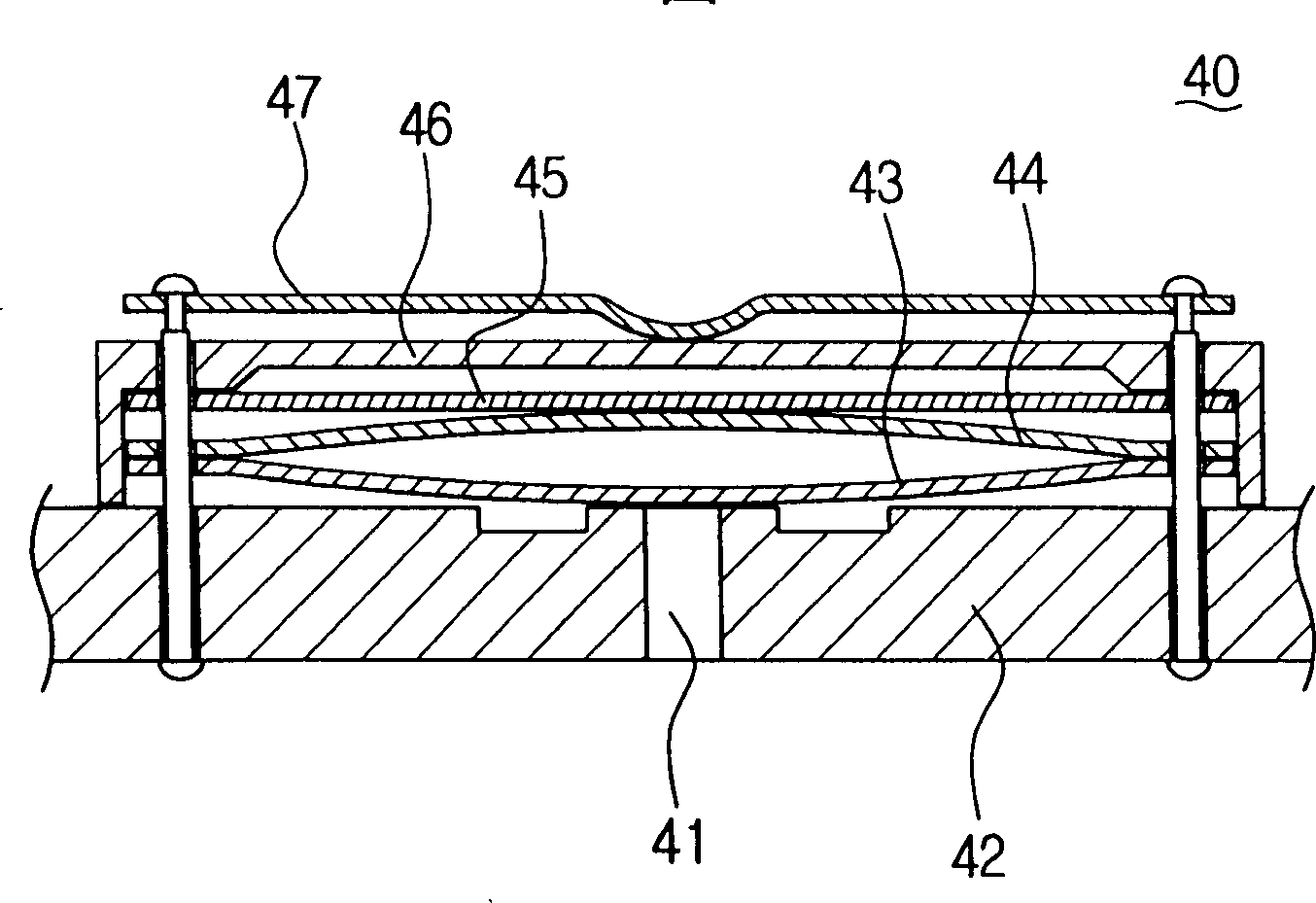

[0018] Referring to Fig. 4, the high-efficiency valve assembly 100 of the present invention comprises: a valve plate 110 with a refrigerant suction hole 111, and first and second discharge valves 112, 112'; figure 1 ) between the suction valve plate 120 of the suction valve 121 to open and close the refrigerant suction hole 111; a discharge valve 130 arranged between the valve plate 110 and the cylinder head 33 to open and close the discharge valve 112, 112' ; a brake valve 140, arranged on the top of the discharge valve 130, so as to control the opening degree of the discharge valve 130; correct position; a retainer 160 for flexibly supporting and setting the detent 150; and discharge valve setting members 132, 152 for positioning the discharge valve 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com