Elastic eyeglass feet and its preparation method

A manufacturing method and technology of spectacle feet, which are applied in the field of glasses, can solve the problems of insufficient annealing elasticity, difficulty in guaranteeing the quality of spectacle feet, and affecting the appearance, and achieve the effects of good integrity, beautiful products, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

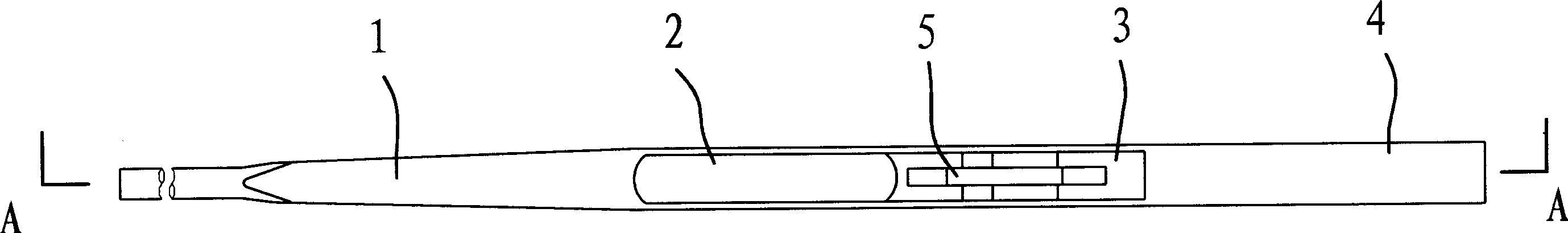

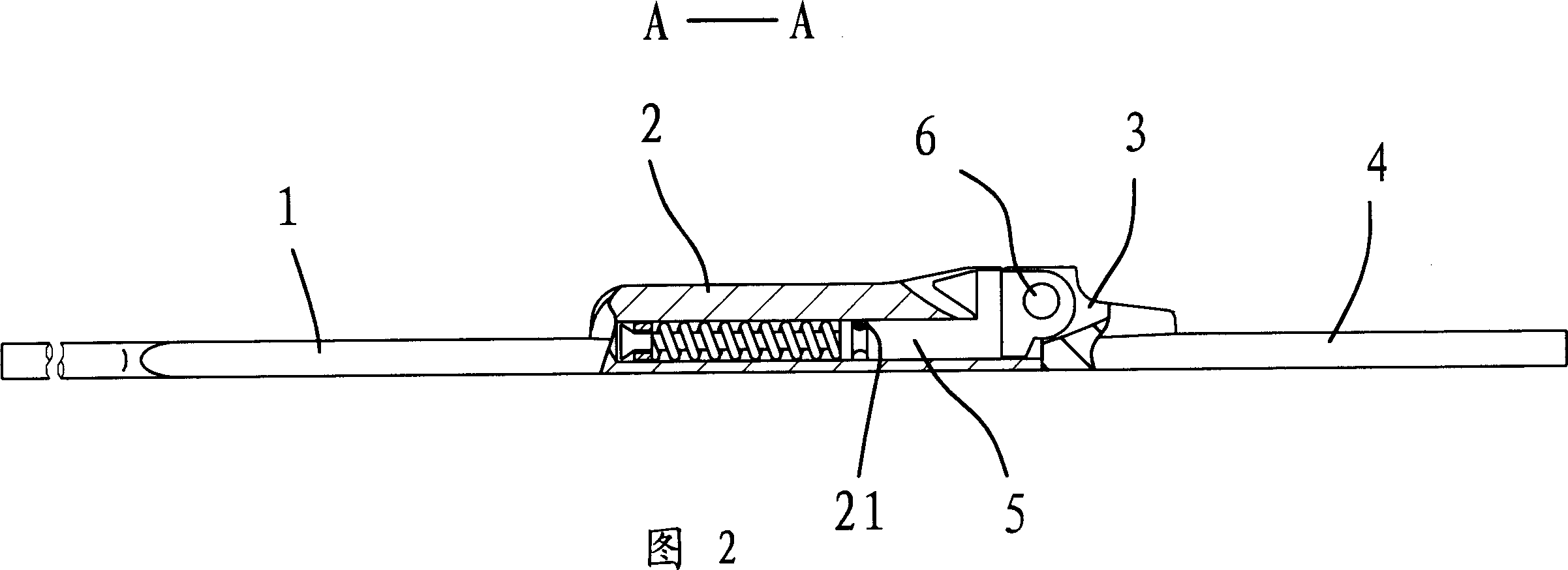

[0030] like figure 1 And shown in Fig. 2, this elastic spectacle foot comprises parts such as foot body 1, shell 2, spring core 5, hinge 3 and pile head 4. The shell 2 is located at the end of the foot body 1, and the shell 2 is connected with the foot body 1 as a whole. A part of the spring core 5 is housed in the housing 2 . The head of the spring core 5 is exposed from the shell 2 .

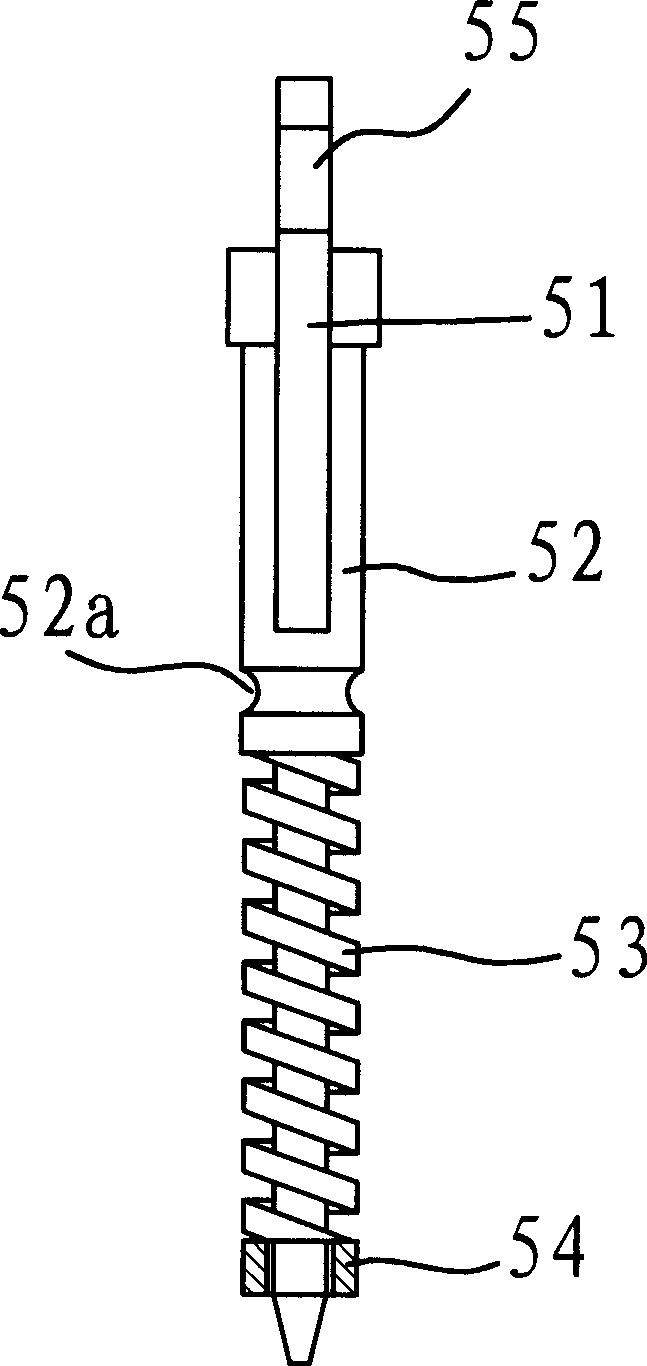

[0031] like image 3 and Figure 4 As shown, in the present embodiment, the spring core 5 is composed of a core body 51 , a spring 53 , a grooved small tube 52 and a sealed small tube 54 . The grooved small tube 52 , the spring 53 and the tail-sealed small tube 54 are sequentially sleeved on the body 51 . The tail end of the body 51 is flattened so that the various parts sleeved on the body 51 will not be separated. A groove 52 a is formed on the slotted tube 52 , and a pin 21 fixedly connected to the housing 2 is embedded in the groove 52 a for positioning the slotted tube 52 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com