Low-cost and pollution-less biomass liquefying process and equipment

A biomass and non-polluting technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of complex liquefier structure, environmental secondary pollution, unfavorable industrialization, etc., and achieve easy popularization and application without secondary pollution , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

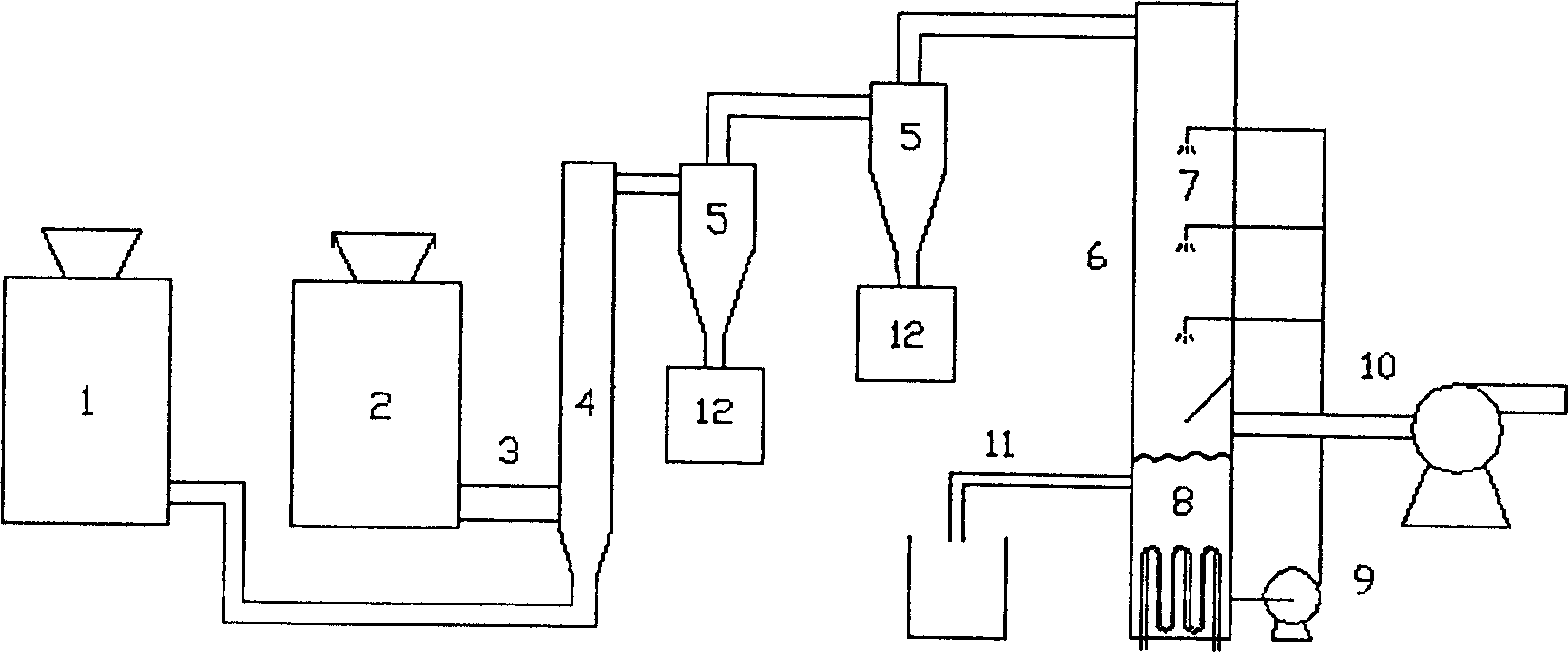

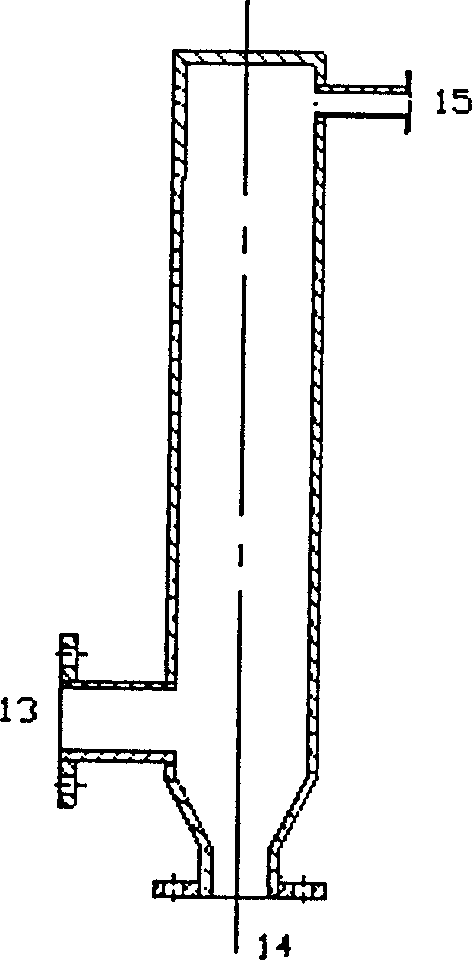

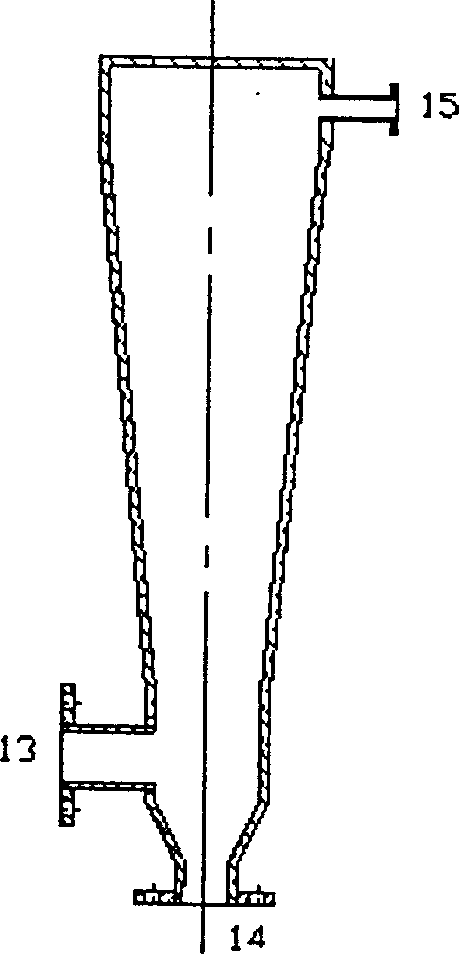

[0013] Further description will be made below in conjunction with the embodiments and accompanying drawings.

[0014] Gasifier 1 adopts the existing fixed bed downdraft type, with a rated gas production of 400m 3 / hr, the temperature of the outlet gas can be adjusted by changing the air volume of the most downstream fan (550°C in this example). The high-temperature anaerobic combustible biogas from the outlet of the gasifier is directly introduced into the bottom of the liquefier 4 (the feeding rate is about 400kg / hr according to the rated gas production), and at the same time, the crushed biomass in the raw material cylinder 2 (using 0.8mm or so sawdust) is also sent into the bottom of the liquefier via the screw material conveyor 3 (the feeding rate is 150kg / hr). According to the feeding rate of the aforementioned pulverized biomass and biogas, it can be seen that the mass mixing ratio of the two is about 1:2.7. The liquefier is made of stainless steel and is in the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com