High-temperature-resistant and high-stability copper rod and preparation process thereof

A technology with strong stability and preparation process, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems affecting human body and environmental safety, high price, etc., to reduce safety and use hidden dangers, reduce bad phase transition, Good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

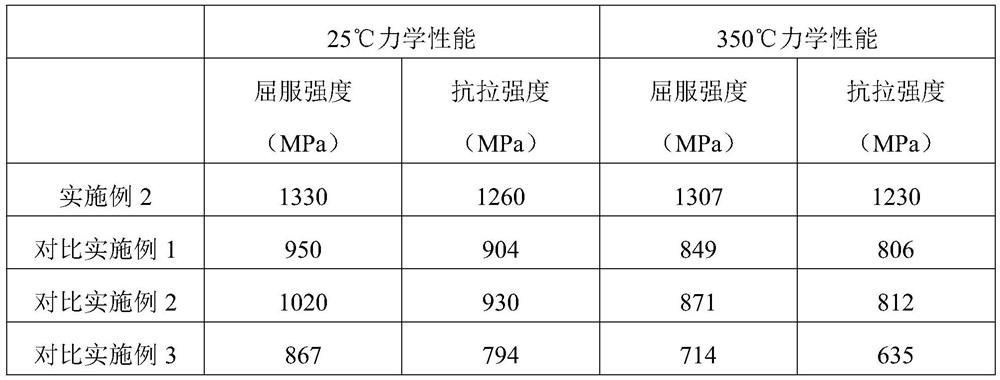

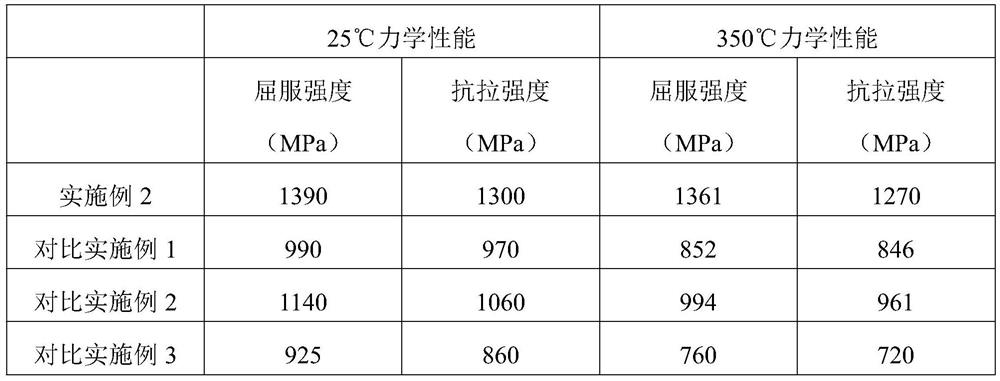

Examples

Embodiment 1

[0031] A copper rod with high temperature resistance and strong stability, comprising the following elements by weight percentage:

[0032] Beryllium: 0.1%, Silicon: 0.2%, Nickel: 1%, Cobalt: 0.2%, Zirconium: 0.1%, Titanium: 0.01%, Silver: 0.05%, Zinc: 0.01%, Rare Earth Elements: 0.2%, and the balance is copper and unavoidable impurities.

[0033] The rare earth element is a mixture of lanthanum, yttrium, and cerium; the mass ratio of the lanthanum, yttrium, and cerium is 3:0.3:1.

Embodiment 2

[0035] A copper rod with high temperature resistance and strong stability, comprising the following elements by weight percentage:

[0036] Beryllium: 0.2%, Silicon: 0.3%, Nickel: 1.3%, Cobalt: 0.4%, Zirconium: 0.11%, Titanium: 0.03%, Silver: 0.08%, Zinc: 0.02%, Rare Earth Elements: 0.4%, and the balance is copper and unavoidable impurities.

[0037] The rare earth element is a mixture of lanthanum, yttrium, and cerium; the mass ratio of the lanthanum, yttrium, and cerium is 4:0.5:1.3.

Embodiment 3

[0039] A copper rod with high temperature resistance and strong stability, comprising the following elements by weight percentage:

[0040] Beryllium: 0.3%, Silicon: 0.4%, Nickel: 1.5%, Cobalt: 0.5%, Zirconium: 0.12%, Titanium: 0.05%, Silver: 0.1%, Zinc: 0.03%, Rare Earth Elements: 0.5%, and the balance is copper and unavoidable impurities.

[0041] The rare earth element is a mixture of lanthanum, yttrium, and cerium; the mass ratio of the lanthanum, yttrium, and cerium is 5:0.6:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com