A kind of color-fixing environment-friendly glassine paper and preparation method thereof

A technology of glassine paper and environmental protection, applied in the field of color-fixing and environmentally friendly glassine paper and its preparation, can solve the problems of increasing the amount of dye used, fading, and failing to meet customer expectations, achieving good color fixing effect and reducing the use of additives volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

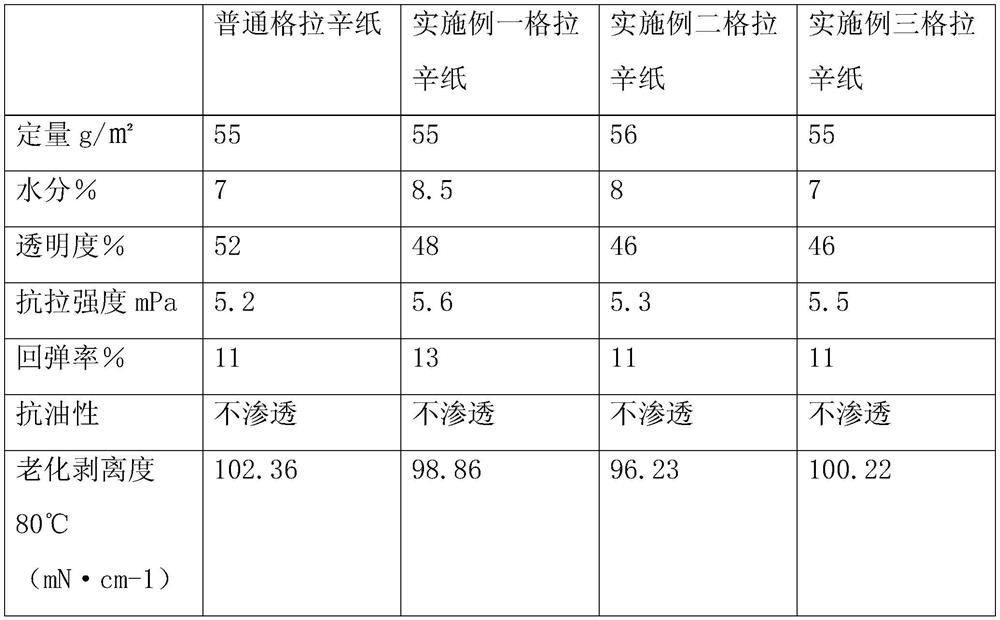

Examples

Embodiment 1

[0034] A solid colorful Glasnet paper comprising a Grash paper material and a coating layer, which is prepared by a raw paper slurry and a addending aid, and the add aid comprises a modified polyamide-ring. Oxychloropropane resin, cationic oxidation starch, aluminum sulfate, hydroxypropylmethylcellulose, cotton, hydroxyethyl cellulose, animal gel, the coating layer including a silicone oil layer and a coated gravary layer, the coating The cloth layer is coated on the original paper of Grash, and the silicone oil is sprayed onto the outer layer of the coated leakage layer, the coated leaf layer by a thermoplastic acrylic resin, a vinyl chloride resin, a salicylate Hiplaside, methoxycinic acid ethylhexylhexide, nano silica powder, water mixed, wherein the modified polyamide-epoxypropane resin comprises 3 parts of the total weight of the added auxiliarize the addition of a total of 3 parts of cationic oxidation starch. 7 parts of the total weight of the agent, 5 parts of the total we...

Embodiment 2

[0037]A solid colorful Glasnet paper comprising a Grash paper material and a coating layer, which is prepared by a raw paper slurry and a addending aid, and the add aid comprises a modified polyamide-ring. Oxychloropropane resin, cationic oxidation starch, aluminum sulfate, hydroxypropylmethylcellulose, cotton, hydroxyethyl cellulose, animal gel, the coating layer including a silicone oil layer and a coated gravary layer, the coating The cloth layer is coated on the original paper of Grash, and the silicone oil is sprayed onto the outer layer of the coated leakage layer, the coated leaf layer by a thermoplastic acrylic resin, a vinyl chloride resin, a salicylate Hexy esters, methoxycinic acid ethylhexyl, nano-silica powder, water mixed, wherein the modified polyamide-epoxypropane resin comprises a 2 partial cationic oxidation starch in addition to the total weight of the additive. 8 parts of the total weight of the agent, 5 parts of the total weight of the addition auxiliarin; hyd...

Embodiment 3

[0040] A solid colorful Glasnet paper comprising a Grash paper material and a coating layer, which is prepared by a raw paper slurry and a addending aid, and the add aid comprises a modified polyamide-ring. Oxychloropropane resin, cationic oxidation starch, aluminum sulfate, hydroxypropylmethylcellulose, cotton, hydroxyethyl cellulose, animal gel, the coating layer including a silicone oil layer and a coated gravary layer, the coating The cloth layer is coated on the original paper of Grash, and the silicone oil is sprayed onto the outer layer of the coated leakage layer, the coated leaf layer by a thermoplastic acrylic resin, a vinyl chloride resin, a salicylate Hexy esters, methoxycinic acid ethylhexyl, nano-silica powder, water mixed, wherein the modified polyamide-epoxypropane resin comprises a 2 partial cationic oxidation starch in addition to the total weight of the additive. 8 parts of the total weight of the agent, 3 copies of the total weight of the addition auxiliaries i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com